The technology of making self-made vibrotol for paving slabs will be useful for those who are planning the paving path in the courtyard of an individual house. As well as private entrepreneurs, ready for the organization of mini-production tiles and pavers for sidewalks and tracks.

Paving tile. Survived material, both in communal services and private homeowners. Easy in stacking, resistant to abrasion, unpretentious in the care and other advantages of the tile led to an increase in its popularity.

Many, deciding to put tiles on the site of a large area, are independently accepted for its manufacture.

Vibrotol for paving slabs with their own hands

The main device to buy to start

The process of manufacturing the tile is vibrotol. It is intended for sealing

Form composition for tile and removal of air bubbles from it.

However, Master-craftsmen and here are independently

Preferring to make vibrationtol with your own hands, and not buy ready. Top

More than what to do it can be from the remedies at home.

We will try to consider in detail how to make vibrostol

do it yourself, in the form of step by step instructions.

What is vibrotole for tiles?

Vibrostol or vibropress - This is an equipment for productionPaving slabs. The working surface of the table can perform oscillatory

movements, such vibration is its main advantage and

purpose.

Vibrotol allows you to make not only paving slabs, but

and cast the concrete sections of the fence, monuments, decor elements, etc.

Vibrotole for tiles - types and types

To decide on the view of the future equipment, you need

Understand which vibrostoles there are and what appointment of each type:

1. In the direction of vibration:

Vibrotole with horizontal vibration; vibrotol with horizontal vibration

Vibrotol with vertical vibrationvibrostol with vertical vibration

The direction depends on how the rotor will be installed.

Horizontal vibration tables received the greatest distribution.

2. By installation method:

- Mobile (portable);

- stationary.

3. According to specialization:

- molding. Tables are designed to form a product;

- False (platform). Appointment - knock out

(Extract, Out) the product from the form using vibration.

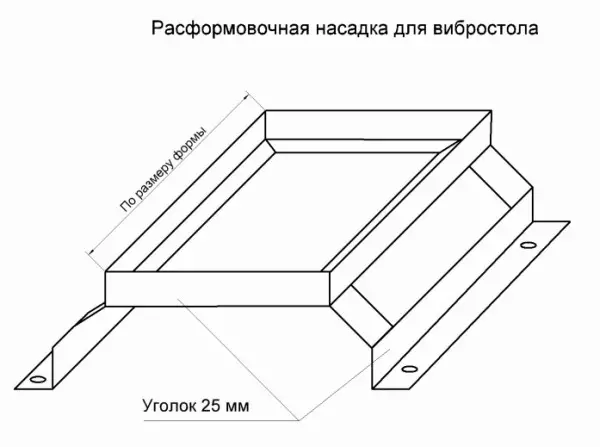

Vibrotol Destoforming Vibrotols have almost the same species. Distinguishes them only installed on the fastened table nozzle with holes.

At such a nozzle, a form with a product is installed and vibrated is removed from the form.

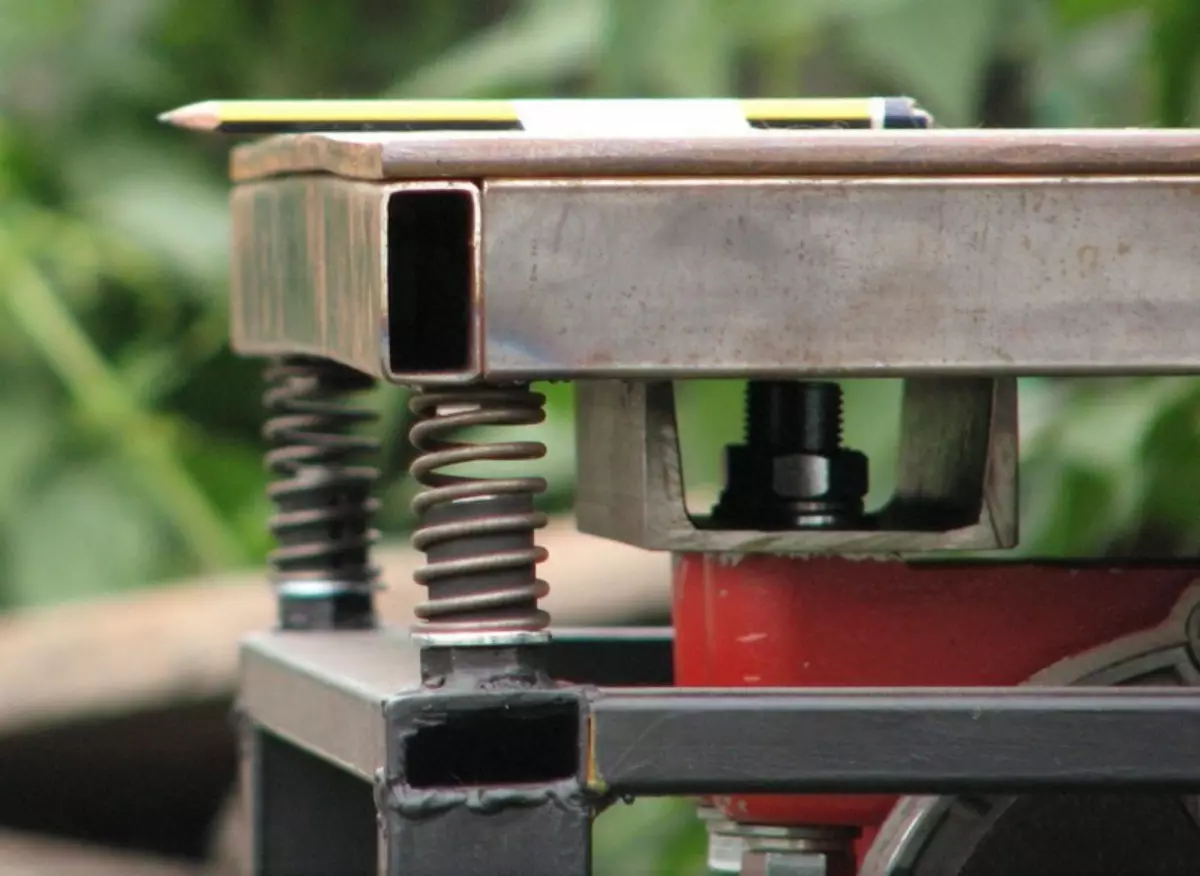

The appearance of the table is shown in the photo.

A drawing of a fastening nozzle for vibrotolate of individual construction is enough to make one vibrationtol with horizontal vibration. And removing the tile from the forms is not

Labor, since in private production, flexible forms are usually used. Top

More, you can install a reforming nozzle at any time.

Article on the topic: How to make slips from drywall: three ways

The drawing diagram of the fastening nozzle is shown in the picture.

Material prepared for site www.moydomik.net

In practice, vibrotol manufactured for production

paving slabs at home, most often used as a base

For a cutting machine or as a platform for installing a circular saw.

Principle of Vibrotol Action for Tile

To understand what details / structural elementswill be needed for work and why each of them, briefly describe the principle of work

Vibrostol.

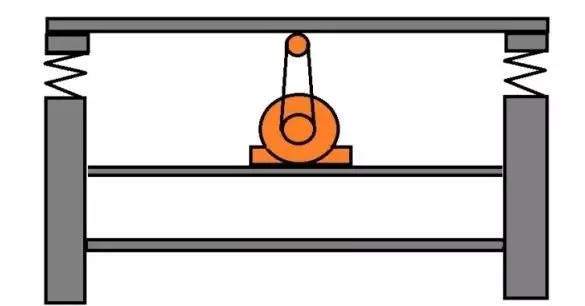

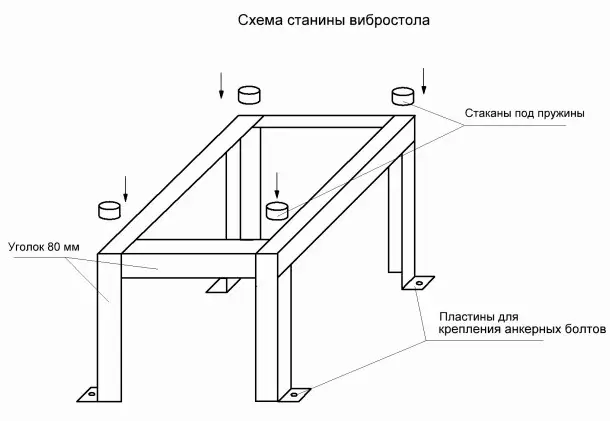

Vibropress Design for Paving Tile (Device)

The working surface is fixed on the bed through

use of the springs system (for horizontal vibration) or suspensions (for

vertical). The countertop is driven by an electric motor, calculated

Power with eccentric on the shaft. Eccentric task shift the center of gravity

Engine to provide the desired vibration.

Vibrostol sketch is shown in the figure.

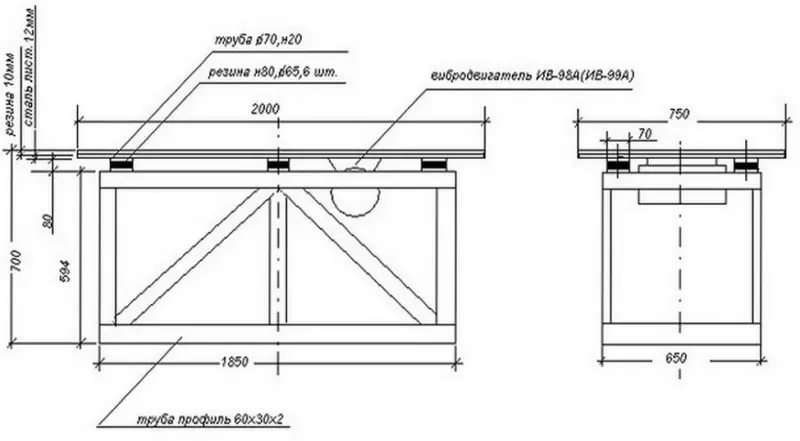

Drawing of vibrotol for tile

Despite the fact that the sketch gives a general idea of

Principle of the functioning of vibrationtola in order to make vibropress

With my own hands sketch, do not do, you need a full drawing.

1. For novice . Simple design of vibropresse

Perform the molding of the product, it is more simple in manufacturing and maintenance.

Treatment of simple vibrotol for tile

Construction of simple vibrostol for tile

In principle, you can add any functions to this vibrotol,

The main thing is to correctly calculate the engine power and design parameters.

For example, you can combine it with sifter for sand.

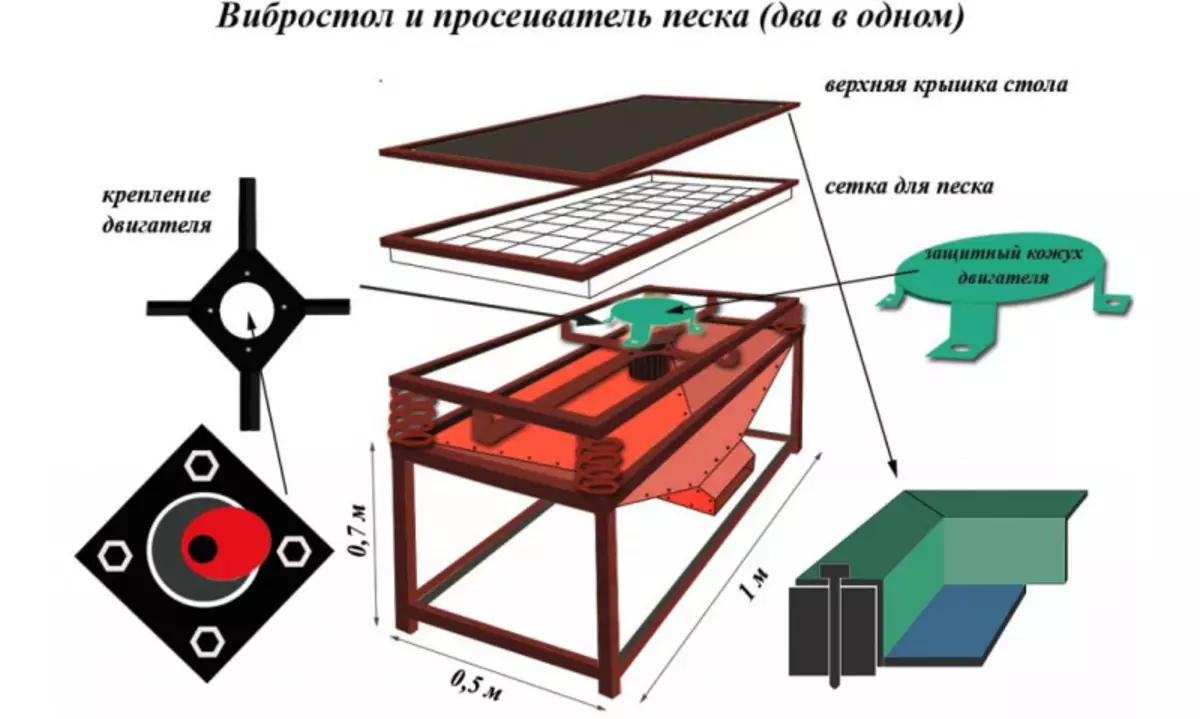

2. For masters - Design two in one - vibropress and

Sifter for sand. It is convenient to get the components of the desired

fractions.

Diagram of vibrostol and sand sifter

Design of vibrationtol and sand sifter

How to make vibrotole with your own hands with horizontal vibration

Dimensions of vibrotol for tile

- Sizes countertops It is advisable to make 600x600 orlengthen one or both sides. Make them already - it is inexpedient, because for

Vibrating shapes have the property to move and they need to constantly "catch"

Or install less and place strictly in the center. Too narrow table

reduces vibrotol performance and is quite unstable

design.

Note. The dimensions of vibrationtola affect the planned

Production volume than it is more, the more must be the sizes of the table top. IN

turn, the increase in the dimensions of the countertops put forward increased requirements for

The material of its manufacture, to the stable stability and engine power.

- Height of vibrationtola. . Calculated on the basis of physiological

The parameters of the person who will work at the table. With average, Growth

A convenient high is 900-1000 mm.

Note. Determining with the table height, consider the way it

Installations. If the feet of the table will be dock and cemented them to do

Long. If the design is mobile - such a height is enough.

Article on the topic: Interior wall decoration: Materials and options (PHOTO)

Tool:

- welding machine;

- drill;

- Bulgarian.

Table manufacturing materials:

- Material for table top . As such, you can

Use Fane or Metal. Plywood countertop (14 mm) due to low weight

allows you to transfer greater vibration from the vibration engine, besides significant

The noise level is reduced when working. But most users give

Preference for metal, a steel sheet with a thickness of 5-10 mm, in mind more

The resource of its use.

Tabletop for vibrationtola from chipboard

Tabletop for vibrostol from sheet steel

Cost of plywood grade FC 15 mm from birch veneer

(sheet dimensions 1,525 x 1 525) - 650 rubles.

The cost of metal hot rolled thickness 5 mm

(sheet dimensions 1,500 x 6,000) - 10 870 rubles.

Note. Thinner sheet should be increased metallic

Pipe or corner, welding them around the perimeter and in the center.

- Metal corner 50x50 mm (136 rub / mp). For edging

Countertops. Such a side will not allow the molding capacities to shift with

surfaces during vibration;

Vibrostol Frame from Corner

Vibrostol edge limiter from corner

- Motor Fastening Schwerler (from 211 rubles / mp).

Welded in the center under the tabletop. It drilled holes under the bolts

for mounting the motor;

Vibromotor fastening channel

Fastening for vibromotor

- Metal Pipes for Foot Support - 40x40 with a thickness of 2 mm (107 rubles / mp);

- Pipes for the formation of upper crossbars - 40x20

Thickness in 2 mm. (84 rubles / mp) and lower crossbars - 20x20 with a thickness of 2 mm.

(53 rubles / mp). If the same size of the blanks is used, you need to take more

Massive, because they must withstand the weight of the table top and placed on it

forms;

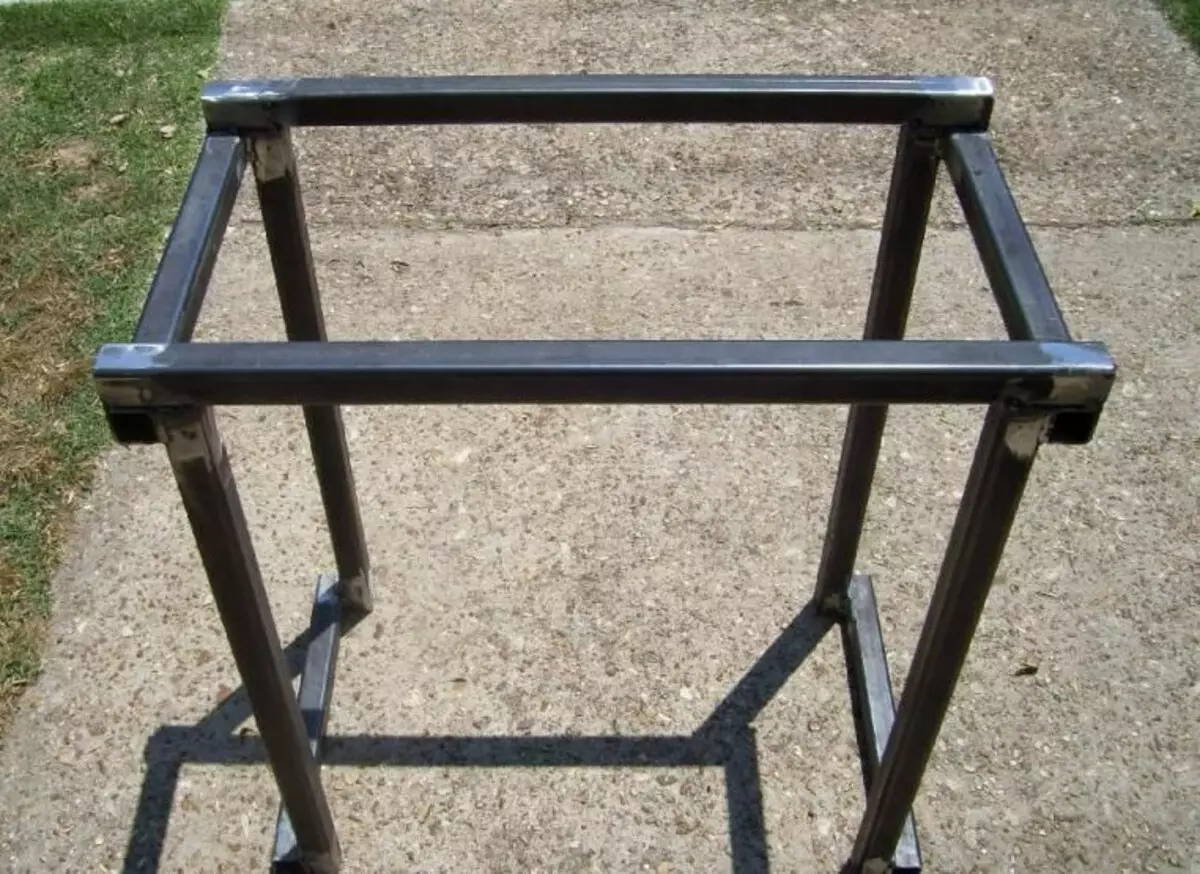

Vibrotol frame design for tile

Frame with supports for vibrationtol

- Metal plates for forming the soles of the foot support.

A sheet of metal is suitable with a thickness of 2 mm with dimensions of at least 50x50;

Device frame vibrationtola

- Plate for installing electrical equipment;

- Springs . Their appointment to ensure vibration. Springs can be

Purchase on the caring. According to user reviews, springs are excellent.

mopeds. Springs are installed in the corners of the table. With a significant area

The working surface is installed an additional spring in the center. Wherein

The support configuration and engine installation location changes;

Springs for vibrationtola

Springs for vibropress

For your information. Spring cost with a diameter of 53 mm, height 113

mm. For the scooter is 500 rubles.

- Bolts for installing springs on them . Or pipe blanks

50-70 mm long and a diameter greater than the diameter of the springs by 5-10 mm, which

will perform a glass of a glass for a spring;

Glasses for vibrostol springs

Place of fastening of glasses for springs of vibrationtol

Note. With a diameter of a glass significantly exceeding

The spring diameter will occur uneven vibration and springs wear. BUT

The tabletop will swing, not vibrate.

- Bolts and washers (4 pieces). Designed for mounting the engine;

- electrical cable sufficient cross section, socket,

switch, circuit breaker;

- Electromotor (Vibrotole Vibrotol).

Electric motor mount for vibrationtol

Electric motor for vibrationtol

What engine is better for homemade vibrostol?

Users advise to use for private productionPaving tile Vibrating engine:

- YB 99 E (7650 rubles): Power 0.5 kW, power supply - 220

B, weight 14.5 kg, generating force up to 5 kN, vibration frequency 3000 rpm.

- YB 98 E (8540 rubles): Power 0,9 kW, power supply - 220

In, weight 22.5 kg, generating force up to 11 kN, vibration frequency 3000 rpm. This

The vibromotor is distinguished by the presence of debaissions mounted on the rotor. Rotating S.

Rotor shaft, they create forgoing power.

For production on an industrial scale, the vibrator will fit

YB 104 B: Power 0.53 kW, power supply - 380 V, weight 25 kg, forcing

Strength up to 6.3 kN, vibration frequency 1500 rpm.

Note. It is important to ensure uniform vibration. Otherwise

High probability of boiling cement mixture in molding tanks. Those.,

Instead of compacting the composition of the vibration form will allow you to saturate it

Air, which will lead to fragility of paving slabs.

The easiest and most economical way - use the old

drives from the washing machine, pumping station, etc., which will cost much

Cheaper than 1 thousand rubles. + Tokary (shaft (axis), eccentric, clip under bearings).

Homemade Vibrotol for Paving Tile - Video

How to collect vibrationtol

- Before assembly, metal parts are desirable to handleAnticorrosion solution that proactive the appearance of rust. For example,

primer GF-021 Lacra (125 rubles / kg) or enamel-paint "Special Forces Soil Emale

Rzavchin "(383 rubles / 0.8 kg). For metal, which is already touched by corrosion, you need

Use special primers, such as EP-0180 primer (188 rubles / kg).

- The components of the vibrotol parts are connected by the weld.

The choice of rigid fastening is due to the fact that the bolts for vibration can

Share and reduce the rigidity of the support. If you need to make a collapsible design

Bolts are used to periodically pull up.

- Motor, driven by vibrationtol, should not touch

Earth. After installing it, it is advisable to make a trial launch

Equipment in order to check the amplitude of oscillations, stability

Designs and rigidity springs.

- The length of the legs of the support should be the same. In addition, place

The settings of the table must be smooth, so as not to create a skew when installing

Vibrostol. The table is intelligent to fix motionless on the ground. Or with help

Concrete solution or with anchors.

Conclusion

Vibrotol device is a relatively difficult task;

less, it can be made with your own hands, practically from the remedies or with

minimal costs (if not take into account the purchase of an electric motor, although,

You can also buy used). Such an approach is advisable in the conditions of the Big Front

work or if desired to organize a small business for the production of paving

Tiles or blocks.

Article on the topic: Corner of plasterboard - do smooth and beautiful