Warm floors are currently new, but a fairly popular way of heating residential premises.

When installing the floor heating system, special attention should be paid to accurate compliance with the installation technology.

Only in this case it can be guaranteed long and trouble-free operation. One of the main stages of work is the screed under the warm floor. The screed for a warm floor simultaneously plays the role of a solid base and provides protection against external influences. Consider how to make concreting under the warm floor with your own hands.

Functions outdoor screed

The chatting of a warm floor makes it possible to simultaneously align the draft floors and create a protective coating of heating elements.

Concrete is well transmitted heat from the heating element

In addition, the concrete serves as a mediator of heat transfer from the heating construction of the indoor volume.

Concreting floor heating systems should be performed if an electrical cable or metal pipes are used as the heating element.

When installing infrared heating systems, the floor screed is allowed only as an aligning base.

Alignment of the base

It often happens that inter-storey floors or draft floors have some slopes in the horizontal plane. The reasons for this can be the most different - from the negligence of builders to the preservation of the foundation of the house.

The concrete screed for a warm floor is necessary if the base has a drop of more than 1 cm vertically by 1 meter of length. The leveling screed for warm water floors is particularly relevant, since the height difference can adversely affect the circulation of the coolant on the system pipes.

For electrical warm floors, a smooth base, although not so critical, but still preferably. Otherwise, when pouring the upper layer, located directly under the finish finish, the depth of the heating elements may be different, and this will not be better enough to the uniformity of the room warming.

Protection of heating elements

Concrete protects the heating contour from mechanical damage

The concrete layer, filled top of the heating elements, performs a protective function for them. Particularly vulnerable places in this case are the insulating gear of electrical cables and plastic pipes for which the coolant circulates.

Under the weight of furniture, household appliances and people moving around the room, the insulation of the wires is gradually engaged, and the cable themselves can be interrupted by an inadvertent blow through a soft floor covering (linoleum, carpet).

Polymer pipes of water systems of heating are even more exposed to external influence.

Under external pressure, the pipe can be easily shifted, which will create problems for circulating the coolant, and, consequently, to warm the room. Concrete for a warm floor in this case is a kind of protective armor.

Article on the topic: How not to view the floor to eliminate the creaking of the wooden floor in the apartment

Heat transfer function

A concrete screed for a warm floor also plays the role of "mediator", heat conductor from heating elements to the entire volume of the room.

The wiring or pipes mounted in a tie of concrete work on heating much more efficiently than if they were under a militant or polymer flooring.

This is associated with a high coefficient of thermal conductivity of concrete, much higher than the indicators of all other materials for flooring.

For this reason, it is not recommended to fit the heat insulating materials on top of concrete floors: insulated linoleum, carpeted coatings, substrate for laminate, etc. This can minimize the efficiency of outdoor heating systems. The best option of the finish coating on top of the concrete layer is a tile, porcelain stoneware, clinker.

That is, such materials, the heat transfer coefficient of which is comparable to a similar coefficient for concrete.

Material selection

When choosing a material for filling, there are two options:

- Use an already ready-made dry mixture for a raised floor screed selling in building stores.

- Prepare a concrete mix for a warm floor alone.

Both these options are equally popular, and, like all other construction technologies, have their advantages and their disadvantages.

Ready mixes

In the modern market for finishing materials, a wide range of all sorts of finished concrete mixtures is presented, including those specially intended for filling the cement screed.

The advantage of this option is the composition ready for "use", the proportions of which are already calculated.

As a rule, the composition of the solution already includes large-phrase sand, portland cement and various additives that improve the quality of concrete. For the preparation of concrete you just need to add water to a dry mixture in the amount specified in the instructions for use.

When describing ready-made dry compositions, it particularly wants to mention such a high-tech material like bulk floors. The mixture data contains in its composition a large number of special polymer additives plasticizers that give the finished solution of the enhanced flow.

Ready mixes are usually more expensive

When pouring the base, this mixture is aligned independently, distributed throughout the field of floors. Typically, the bulk floors are used to create a perfectly smooth surface and are poured with a small layer of 0.5 - 1 cm.

Among the minuses of this option, you can call a higher cost of concrete prepared from the finished mixtures compared to self-cooked concrete.

Alone prepared concrete

Preparation of a concrete mix for warm sex with their own hands is a budget alternative to the finished dry formulations. The fill of the warm floor under the concrete screed in this case can do it at times cheaper than when using factory dry compositions. For details on how to make a tie of a warm floor, see this video:

Especially financial benefits will be noticeable with large fill volumes, as well as if you have the opportunity to get fillers for concrete for free - sand and crushed stone.

The last factor is decisive in the choice of one or another option: if residents of rural areas or small cities are pretty simply to reach the fillers, then in large megalopolises to purchase 300 - 400 kg of sand or rubble will be very difficult.

First, the delivery of such materials is usually carried out much large volumes; Secondly, problems can arise with the storage of purchased sand or rubble at the local area.

Production of cement mortar with their own hands

For thin screeds suitable as a sand filler

Article on the topic: Penage door do it yourself: Installation Recommendations

In the manufacture of concrete for floors of floors, special attention should be paid to the composition and the ratio of its ingredients. If the thickness of the concreting layer does not exceed 4 - 5 cm, you can do the use of a large fraction of 3 - 5 mm, the so-called sandbetone as a filler for concrete.

With a thicker layer of concreting, it is necessary to add crushed stone to the solution. It serves as an additional binder, increasing concrete strength. In addition, additional plasticizer additives can be used as an additional component.

With a large layer of fill in order to avoid excessive pressure on the supporting structures and overlaps, it is recommended to add porous fillers to the solution - perlite or clamzite that reduces its density.

For the best bundle of the components among themselves, you can use micronmating fiber fiber, which reduces the probability of cracking the screed when drying it.

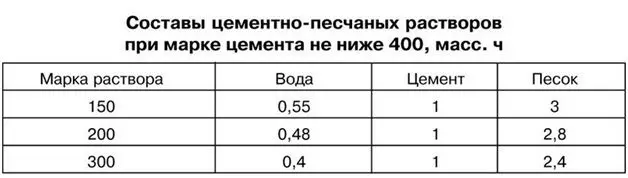

To obtain the highest quality cement mortar, it is necessary to strictly observe the proportions of components recommended by construction standards.

An exemplary ratio of components in the manufacture of various types of cement solutions is given in the table presented.

Work on the device screed

For high-quality arrangement of concrete fill, it is recommended to produce all work in a clear compliance with construction technologies. Consider gradually how the screed for a warm sex is done with your own hands.Preparation of the foundation

Old cracks can be sealing with putty or special compositions.

The first stage of work consists of preparing the bearing base for the pouring of concrete. Preparation consists of the following works:

- shplanie crack;

- waterproofing arrangement;

- reinforcement.

First of all, it is necessary to clean the base from the old coating up to the slabs of the ceiling. Then you need to examine the entire surface for the presence of cracks in the concrete fill. Most often they are located in the joints of the slabs of floors, as well as along the walls.

For their embelling, depending on the size of the gap, use either the shp can, or plaster solutions.

Shplanke

After the sealing of all cracks it will be necessary to produce waterproofing draft floors. The arrangement of waterproofing the base is necessary, firstly to protect their home from the possible penetration of dampness from the basement or the ground floor.If you live in an apartment building, the water-repellent layer will prevent flooding of neighbors from the bottom during the accident of water heating systems or water supply.

Waterproofing

Waterproofing can be carried out with the help of rolled (rubberoid and its analogues), or coating materials (bituminous or polymer mastic). In the first case, the waterproofing is laid on the floor and is mounted on glue solutions produced based on bitumen.

For greater reliability, laying of moisture protection material is produced in 2-3 layers, while the joints of the lower layers should not coincide with the joints of the upper.

Water-repellent mastic are applied to the concrete surface like paint - with the help of brushes or painting rollers.

Article on the topic: Gate do it yourself: Wooden, metal

Reinforcement

Concrete reinforcement is necessary to prevent its cracking and destruction during operation.

In this case, a masonry mesh can be used as a reinforcing material, or make a frame of metal wire or rods of fiberglass reinforcement.

Marking of floors

Applying markup, place the beaches along the room

The next step should be made horizontal markup. To do this, we need the usual construction, laser or water level.

With it, we find the highest point of our premises, and we produce the installation of beacons - metal or wooden guides that mark the level of the horizon.

Beachts should be located parallel rows, ranging from far wall. The width between the beacons should not exceed 1 - 1.2 m: so it will be possible to achieve a more accurate surface equalization. To set the beacons at the required level, wedges or substrates from any durable materials - pieces of ceramic tiles, small stones, etc.

Fill first layer screed

Start the fill of the screed from the far wall

The chatting of a warm floor is made on a solid base - concrete overlap or gravel cushion of an earthen base. Concrete fill on wooden floors is not recommended due to its large mass, dramatically increasing the load on wooden structures.

The fill should be started with the farthest from the door of the wall. Fill over the prepared cement mortar, the first strip running along the wall. Further, with the help of the rule, align the fill in the level of beacons, adding or removing the concrete in the right places. Thus, we produce filling with a solution of all compartments and leave the screed to dry.

After a while, when the screed snacks, remove the beacons. After 2-3 days, the concrete layer hardens enough so that it was possible to start laying warm floors.

Mounting outdoor heating should be made in a clear accordance with the instructions attached to them. On how to upload a screed for lighthouses, see this video:

After installing heating elements and check their work, fill the top layer of the screed. The fill of concrete on the warm floor is produced by the same technology as concreting bases for them.

The reinforcing mesh is stacked over the cables or pipes and horizontal beacons are installed. If self-leveling bulk floors are used as a filling material, it will be possible to do without installing beacons.

After full fill and align the floors, the concrete leaves to stick. The time of the complete pouring of the concrete screed to the maximum set of fortress is about 4 weeks. But for faster drying, you can, starting from the 2nd week, to include at low power system outdoor heating, enhance the temperature of several degrees every day.

After the screed is completely free from the excess moisture, it will be possible to start the installation on a warm floor of the decorative finish coating.