To date, the market of upholstered furniture in abundance is filled with various offers. But sometimes I want something special, made by your own hands. Choosing this path, you can make furniture you need and design, save finances.

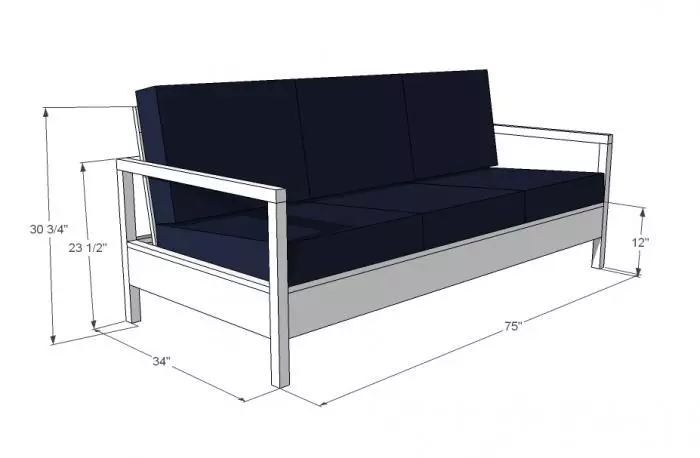

Sofa size scheme.

So how do you make a soft sofa with your own hands? Let's figure it out, after all, the sofa do it yourself - the case that is practically everyone.

First Stage - Preparatory

How to make a sofa with your own hands? This question interests many. The sofa design is quite complex for beginners in the creation of furniture, so before proceeding to its manufacture, it is necessary to carefully examine all the nuances and features relating to the production of such furniture.

First you need to make a drawing of the future sofa on paper. All its components must be drawn on paper with the exact dimensions and other characteristics. A qualitative and detailed draft of the future sofa is a pledge of simple and rapid work on its manufacture. The standard version of the sofa implies its length of 1.9 m, but the height of the back, counting from the floor, about 0.8 m. Please note that the height of specifically the seat (excluding the size of the sofa pillows) must correspond to the value of about 0.3 m.

Before answering the question: how to make a sofa, you need to figure out its component elements. What is the usual sofa? It:

Sofa sofa scheme.

- Frame design.

- Armrests or railing.

- Sofa legs.

- Spread sofa.

- And directly the seat.

Everyone is clear that the basis of any kind of furniture is a skeleton design. From how it is made, and will depend on the service life of your furniture, in our case of a soft sofa. That is why experts advise only those materials that have high quality for mounting the framework. And also, pay attention to the size of the frame structure, because during the operation, when applying even minor errors, problems may arise regarding the deformation and the deflection of the sofa you made.

What else to pay attention to the production of furniture? This is her legs. In the sofa, they are the main support, but sometimes the features of the design allow them to perform an exclusively decorative function. In this case, the entire load falls on the frame. Make the feet of a sofa from Balyasin. Usually choose oak. Such legs look great in almost any design. In addition to aesthetic appearance, this material has sufficiently high strength, which is also important.

Article on the topic: The best manufacturers of LED ribbons

How to make a sofa: Preparation required for work

So, to make a sofa with your own hands, you will need:

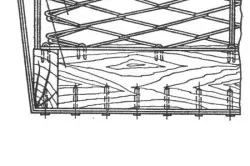

Sofa dragging scheme.

- Chipboard and fiberboard;

- Bar;

- plywood;

- foam, sintepon, etc.;

- Fabric for furniture upholstery;

- Furniture glue;

- nails, screws, etc.

This is due to materials. You need to choose them with quality and safety for human health. The optimal option for the purchase is a well-proven construction market of your city. And now a few words about the tools. All you need is:

- electric jigsaw;

- Drill and screwdriver;

- sewing machine;

- scissors and knife;

- stapler for furniture;

- a hammer.

Preparing all of the above, you can safely begin to make a frame design. This is one of the stages, allowing you to answer the question how to make a sofa yourself?

How to make a sofa: framework and councils of specialists

Soft sofa scheme in section.

Using prepared pre-drawings, you first need to make the base of the sofa. They drink it either from plywood or from wooden shields that remain from some old furniture. If you choose on the plywood, then you will need an electric jigsaw to work. With it, you can easily and quickly make the basis of the desired form and size.

Very often, in the production of furniture of a complex shape, its base is cut from several parts, which are subsequently connected to each other.

After completing the work on making the foundation of the future sofa, you can move to the assembly of the frame structure. It will consist of racks and partitions. Racks will be vertical, horizontal partitions. Do not forget that the height of your sofa should be designed in advance. You should choose this indicator, focusing on the purpose of furniture and the place in which it will be located. If this is a sofa for the kitchen, then its height will be slightly higher than usual, as it is linked, sitting on low furniture, very uncomfortable. But the sofa for the living room either the bedroom implies a smaller height, since his destination is rest.

Article on the topic: Why convector cracks

Sofa upholstery scheme.

At the next stage, the frame construction is covered with plywood. Its installation is carried out with the help of adhesive composition, the screws are used in addition. The space formed inside the space is very well suited for storage of bed linen.

So, the frame is assembled, now it's time to proceed to the manufacture of the back of the sofa. If your sofa is usual and is not a folding or other mobile design, the mounting work on the backing fastening is performed similar to the method described above. It is clear that the back should correspond to the size of the sofa base. The bar in the upper and lower parts of the back should correspond to the size of 9 cm. But the length of the vertical parts is usually about 45 cm, while the width of each part is about 6 cm. In order to combine the back with the base with a qualitatively, metallic corners are used.

As for the angle of inclination, here you can choose a convenient option for you.

Make a sofa comfortable very simple, you just need to choose a convenient position for yourself.

Transition to the sofa design

Now everything is ready for us, all parts of the sofa are assembled, it means that the time of making soft details of furniture has come. Do not forget to pre-process the framework using sandpaper, then paint it into the color you need or apply a layer of colorless lacquer coating.

Using the fabric for furniture and foam rubber, you need to make two bases, the thickness of which will be approximately 20 cm. As for other sizes, for example, the widths and lengths of these parts, then you need to proceed from the parameters of your frame. More precisely, you need to take the sofa backrest parameters and base. In order for the foam rubber to you for a long time, it should be wrapped in a synthepion, so it will be much less subjected to wear. You can connect two soft parts with each other using the stapler or sewing with lightning between them (better detachable).

After that, on the base of the sofa, it is necessary to fix the prepared pillows. For these purposes, the so-called velcro tape is used. If you have excess fabric, foam rubber and other materials, you can in addition to sew beautiful sofa pads. They look beautiful in the interior, creating comfort, and very functional during the rest.

Article on the topic: Wallpaper colors

SIVAL Formation Scheme on spring block.

Performing work on the courtyard of the sofa, it is necessary to listen to some advice of professionals, then in the process of work you will not have any problems and do not have to start all over again. So:

- Before you begin to cut, you need to carefully measure all design details. Do not forget that you need to add a couple of centimeters to the parameters received to perform seams.

- In order to determine the amount of fabric more accurately (to save money), you can pre-make the layout of the piece of cuttings on paper. Do not forget that at the same time you need to take into account the pattern, and the direction of the pile, if any. If these are details of the seat, the direction of the pile should be from the back, and on the contamination of the backrest. If you have chosen a cloth with a large pattern, for example, striped, then, most likely, you will have to customize the drawing, and it will take a significant amount of material. Therefore, do not forget to purchase an additional tissue.

- Do not immediately cut down all parts, as some nuances can be revealed during the work. Collect and sew first one of the details, and after that, by estimating the result and making the necessary amendments, you can continue to work. For example, some furniture fabrics have the property in one direction or in both, some, on the contrary, are absolutely not subject to it. All of these moments need to be taken into account both at strollers and when the sofa is directly upholstered.

Summing up the outdated

Now you know how to make a soft sofa with your own hands. Agree, despite the complex design, work on its manufacture is available for self-execution. And the result of the work done will certainly be able to please not only you and members of your family, but also guests who can appreciate your work by spending the evening in your home.

Do not be afraid to do something wrong, because the experience brings only benefits, and, gaining it, you become a real professional master, who can be done by doing anyone, even the most difficult, tasks.