To create a high-quality and durable base for any finishing flooring, it is necessary to find out the carrying ability of the entire structure.

The weight of the screed is large enough, and therefore it has a large pressure on the basis of the structure.

In cases where, not a ready-made mixture acquired in construction stores is used to perform work, but the composition prepared independently, accurate calculations should be made taking into account the features of the materials used.

Selection of materials and preparation of the mixture

The CPS or the cement-sand screed is a necessary and fairly simple way to level surfaces. It requires sand, cement and water to create it. The amount of each of the components depends on their features.

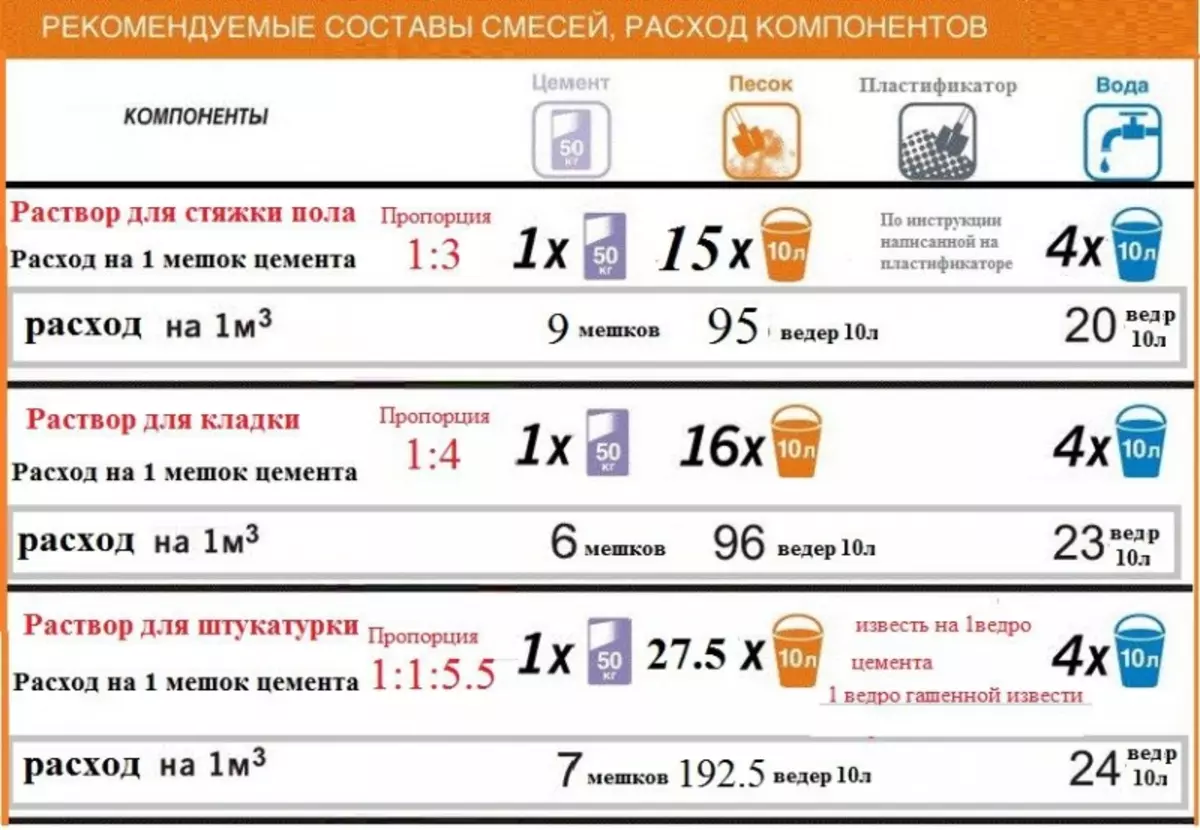

For example, if the cement brand M150 is taken, then the sand will be needed three times more. If the M500 brand cement is used to prepare the mixture, then the sand is taken in accordance with the proportion of 1: 5.

For a bag of 50 kg Take 150 kg of sand

The use of the brand M 150 cement is optimal, because for this material weighing 50 kg will need 150 kg of sand. As for the amount of water, it depends on the humidity of the sand.

It is possible to prepare a high-quality solution by taking:

- 1 bag (50 kg) cement;

- 15 declined buckets (150 kg) of dry sand;

- 27 liters of water.

Introduction to the composition of wet sand will reduce water volume to 25 liters.

From the weight of the cement-sand tie depends on the pressure that it will have on the base of the structure. Accordingly, before proceeding with the performance of work, it is necessary to clarify the thickness of the layer of the layer.

Screed must be a thickness of at least 30 mm

The minimum screed thickness is 0.3 cm. Otherwise, after pouring the solution, the surface covers cracks. Excess maximum thickness equal to 0.5-1 cm leads to exceeding the permissible load on the base.

If this value reaches 8-10 cm, the weight of the cement screed on each square meter will be about 150 kg. It is unacceptable and therefore experts recommend not exceeding the set parameters.

Article on the topic: How can you get rid of small ants in the kitchen?

Density of the mixture depends on the quality of the material

When creating a cement-sand screed with a thickness of 1 cm, the flow rate will be at least 20 kg per square meter. At the same time, it will be from 15 to 20 kg by 1 cm².

It must be taken into account during the creation of a cement-sand screed density of the composition, which depends on which materials will be selected by masters.

For this parameter, the compositions are divided into:

- Light, the density of which does not exceed 1400 kg / m³.

- Heavy ties indicated by the indicator of which are significantly higher than 1400 kg / m³.

With accurate technology compliance with the proportion of a sand-cement screed, depending on this sand characteristic, will not exceed the permissible limits.

In accordance with GOST 8736-77, one cubic meter of sand must contain no more than 1600 kg, and its proportion should be 1550 to 1700 kg / m³. For details on how to make a solution, see this video:

Calculate the consumption of materials by using the existing formula and reference data. When working with cement brand M 400 for the construction of a string of a thickness of 3 cm in the room, the area of which is 50 m², it will take such a number of cement and sand, to find out which will help a simple calculation:

- Calculate the volume of the screed. 50 × 0.03 = 15 m³.

- The volume of each component. Under the proportion of 4: 1, 15: 4 = 3.75 m³.

- The volume of sand will be 3.75 × 4 = 15 m³, the volume of cement is 3.75 × 1 = 3.75 m³.

- Using reference data, calculate the specific weight of the sand - 15 × 1600 = 24000 kg, and the proportion of cement - 3.75 × 1300 = 4875kg.

The volume of water is determined at the rate of 0.5 liters per 1 kg of cement. Accordingly, 4875 × 0.5 = 2437.5 liters will be required.

Compliance with all these norms will allow you to perform work to qualitatively and create a solid and reliable base for the finish coating.

Procedure for performing work

Start actions are necessary with the preparation of the base.

Article on the topic: Original composition of 3-samp in the form of cats or lamps do it yourself

For this, the floors are cleaned from the former flooring, freeing the room from the construction trash and expose construction lights, determining the horizon with a level.

The arrangement of a sand-cement screed is possible in any room, the temperature of the base in which does not fall below +5 ͦcellia.

Having installed beacons, proceed to the fill of the screed from the far corner

Lighthouses are installed on a preceded layer of waterproofing, which can be used polyethylene film. The edges of the canvas are at the wall so that they performed on the screed level.

Fill the screed starts with the most hard-to-reach places of the room, but if the door is provided in it, it is important to do so that it is not blocked by the doorway.

After the solution is hardening, to which the beacons are installed, the prepared mixture is poured onto the base, filling it with one strip. Using the rule, the solution is aligned, and only after the first strip will be ready, proceed to the pouring of the solution into the second. After 12 hours, lighthouses are removed, the resulting space is filled with a solution that will take about 15 hours for complete pouring.

Now they prepare a grout mixture and perform manipulations associated with the grout surface. It will take a dry or wet mixture consisting of equal parts of sand and cement. Slip surface with special equipment or manually, using a field or grater. All the details of the process of fill breeds on beacons, see this video:

After completion of all the work, a flat charming surface is obtained, which must be laid with a wet roller and cover with a plastic film. Moisturize the screed of at least seven days, after which the film is removed.