At the cottage, the household site or in the courtyard of an honest house is arranged a separate construction for storing vegetables, conservation, winter blanks, spins and other things. The correct cellar device involves insulation to create an optimal microclimate in the repository. The cellar and the basement differ in a number of parameters, which means the approach to their insulation for the winter will differ in several points.

What is the difference between the cellar cellar

Basement - Room located under the residential house. Key characteristic - the presence of indirect heating. In this case, during the heating in the basement, much warmer than in the cellar. In addition, it has communications. In this connection, and the requirements for warming the basement is tougher. Among other things, the basement ceiling is a serious source of heat loss from heated rooms of the first floor.Cellar - an object located separately or under summer kitchen, a garage, household buildings. The temperature in it is more stable throughout the year, and therefore conservation, vegetables or wine are stored much better.

This is what leads to the fact that in the presence of free space on the site, the owners seek to build a cellar on the street. And already in the course of operation, the question arises, whether it is necessary to insulate the cellar. After all, from an excess heat, vegetables will begin to ride and rot, and from the lack of freeze.

Of course, work on thermal insulation is better carried out during the construction period. But, how to be the one who already has a cellar in the country. How to insulate the cellar from freezing without serious costs?

The choice of method of insulation provides for work on one of the directions:

- insulation cellar outside;

- insulation cellar from the inside;

- Combined insulation. Most effective way, because It is complex.

Types of cellars for a private house

By deciding how to insulate the cellar from the inside or outside, the type of cellar is first taken into account:

Ground cellar

Ground cellar

Separately standing room with shuffle in the soil up to 0.5 m. It happens separately or wallpapers (one of the walls of the cellar is the wall of the economic building or garage). From the point of view of insulation - this is the easiest option, because It is possible to insulate the walls and roof outside and inside.

Bulk cellar (semide-bed)

Outflowed cellar

The lower point of the building is located at a depth of no more than 1.5 m. From the surface of the soil. In this case, in addition to insulation, it is also necessary to think about the neutralization of the groundwater and frosty grounding of the soil.

Underground cellar (bulk)

Underground (bulk) cellar

Distinguishes the location of the floor at the level of 2-3 meters under the ground. With due waterproofing, this is the most winning in terms of operation, a cellar, which perfectly holds the plus temperature, roughly constant, throughout the year.Despite the differences in construction, the design of the cellar is not distinguished by a variety.

Standard cellar design:

- Walls - with dense soil - ground, with mobile - brick or stone;

- The floor is missing, or rather it is soil;

- The ceiling is reinforced or wooden.

Accordingly, the ceiling, walls, floor insulation. Those. All the surfaces of the cellar through which heat losses are possible.

Materials for insulation cellar

Despite the significant variety of thermal insulation materials, it should be taken into account that not everyone will suit them. Material for insulation of the cellar must have such properties as the ability to maintain geometry, to withstand water and soil pressure, have high insulating properties (table), absolute hygroscopicity.

Article on the topic: Installing platforms of interroom doors with their own hands: Fastening (video)

Due to these reasons, the thermal insulation is unsuitable mineral wool or eco-way.

If you place materials in descending order, such a sequence will appear:

- Insulation cellar foam . The most popular insulation. After all, in addition to thermal insulation characteristics, the foam is distinguished by low price and simplicity of installation. Polyfoam does not rot, not hygroscopic, biological inert, has a small weight, does not require the use of vapor insulating films and the arrangement of the crate. Mounted both outside and inside the room;

- Warming of cellar sawdust or peat ground which are well held warm and unattractive for rodents;

- Insulation cellar polyurethane foam . PPU refers to sprayed insulation. Having all the properties of their predecessors, it distinguishes the ingrediation and the ability to fill out all the space (gaps, cracks). PPU creates a shell, which is the most reliable way to warm the cellar both outside and from the inside. At the same time, the cost of polyurethane foam is high, and for applying requires special equipment and attracting specialists;

- Insulation cellar polystyrene foam . The polystyrene is inherent in all the characteristics of the foam. Only a higher price is distinguished, which is due to a greater density of the material, the integrity of the structure of the sheet (the ability not to crumble during the installation), the presence of a groove-cream installation system;

- Insulation cellar clamitis . Ceramizite, like any other bulk material, features a limited scope of application. As a rule, it is used for floor insulation. It can also be used for walls with external insulation of underground (covered) cellar.

- Insulation cellar chernozem . Used for outdoor insulation. In this case, the Earth is poured on the roof of the cellar. However, with the current level of technology development, there are many more efficient methods of insulation while maintaining the absolute environmental purity of the site.

Warming technology depending on the type of cellar

Approach to thermal insulation taking into account the construction of the structure.Insulation of ground cellar

With this design, the main emphasis is on the insulation of the walls and the roof. So it is best to perform outdoor work and use foam or polystyrene foam. Warming work is carried out on the street, according to the installation technology of these materials. The insulation of the roof is performed from the inside. For these works, a soft or rigid insulation can be used.

Warming of a swallowed cellar

The walls of such a cellab are half arranged in the ground. Consequently, there is a risk of flooding. To level it, it is necessary to release (open) the covered part of the outer wall from the soil, to process it with any waterproofing solution (mastic) or to overtake the rubberoid. Then put a hard insulation or PPU, re-wrap the rubroeroid (it will save the sheet from deformation) and pour into the soil. To minimize the effect of water better to equip the drainage system.Insulation of bulk cellar (underground)

It is performed both outside and from the inside. Below are detailed recommendations and advice of phased thermal insulation facilities for the storage of agricultural products in the country.

How to insulate the cellar do it yourself

Different insulation technologies in the form of step-by-step instructions.

Outdoor insulation of bulk cellar

The most time-consuming part of the work, the implementation provides for the implementation of a number of actions:- It is removed soil surrounding the roof and the walls of the cellar.

Note. Further recess is sometimes not possible. For example, when the cellar is dug in the ground, and the resulting slopes are decorated with bricks. Such walls can collapse. In this case, users advise to remove the ground at a distance of 100-150 mm. From the wall, and then gradually remove the rest.

Additional protection against moisture will give arrangement of a chump-sanded pillow at a depth of 200-300 mm. From the base of the wall.

- Mounted slabs of a hard insulation or polyurethane foam;

- All defects are eliminated from the surface of the walls;

- For further work, it is necessary that the roof and walls are absolutely dry. Therefore, work is stopped until the walls are completely drying. As you can see, work is better to perform in warm dry season;

- The insulation of the roof is, in fact, overlapping the cellar with insulation. The technology provides for the installation of the rubberoid over the overlap, the roof backing on top of the clay-straw mixture. The height of the filling on the roof is 0.4-0.5 m. The mixture is thoroughly tram and covered with a dense film. The edges of the film wrapped onto the wall with a fattest 150-200 mm.

- Wall insulation is performed. The processing of the primer will help in this case. It is better to use a bitumen solution with diesel salon (1: 3), mastic, rubberoid or special film;

- The joints between the sheets are bleed by mounting foam;

Some masters advise to tighten the insulation with a polymer grid, to ensure the integrity of the sheet. With this task, Ruberoid will cope with this task. But often the distance between the wall and the soil is simply falling asleep with a clay, soil with a high clay content or a mixture of soil, sawdust / straw and clay.

In the absence of ventilation in the cellar, it will be advisable to take care of this stage.

- The resulting hill is covered with a layer of fertile soil with a height of 100-150 mm. With the subsequent landing of grassy plants that will protect the cellar from sunlight, and the soil will strengthen their roots.

Article on the topic: How to choose the right paint for wallpaper

Internal insulation of the cellar

From the insulation of thermal insulation are subject to walls, ceiling, floor and doors. Several photos in the form of an example of a finished result.

Finishing of a warmed ceiling in the cellar of plastic clapboard

Warming floor facing in cellar tiles

Thermometer in the cellar (temperature sensor)

Steel in the cellar, insulated walls are covered with plasterboard and painted

Insulation of the wall of the cellar from the inside

Execution technology:- Walls are inspected for defects;

- The cellar is released from the contents, shelves and drawers for a while are dismantled;

- Detected defects are eliminated (the protrusions are knocked down, the cracks are messed with foam or sealant);

The quality of the surface is highlighted by increased attention, because Significant irregularities prevent the high-quality installation of foam;

- Wall waterproofing is performed (mastic or liquid rubber);

- Fixed plates of hard insulation.

This uses dowels-umbrellas or glue. Fastening foam begins from the bottom row and moves up. In this case, each subsequent row is shifted by half of the sheet;

- A polymer mesh is fixed on a warmed surface;

- Places of adjoining sheets are blown by foam. If the slit is largely placed in the trimming of foam;

- Apply stucco.

Note. To eliminate the foci of mold formation, the walls are appropriately treated with a solution of lime and copper sulfate.

{Banner_advert_2}

Insulation gender cellar

There are several ways of insulation that have proven themselves in practice. Consider the insulation of the floor by clamzite as the most optimal option, in terms of price / quality ratio.

Procedure for performing work:

- After soaring the concrete, on which the lighthouses are exhibited and fixed, the claymzite gravel is falling asleep with a fraction of 5-20 mm. At the same time, the thickness of the gravel layer depends on the load that will be on the floor;

- The film of the Parobarker is stacked on its surface with access to the wall. The height of the adolescence is equal to the height of frustration;

- The floor is deepened to the depth of the future heat insulating layer (200-300 mm) and aligns;

- Lighthouses are installed on the film. The first of them at a distance of 300-400 mm from the wall. The rest at a distance equal to the length of the rules that will be equal to the screed;

- The reinforced screed is poured. The thickness of the screed also depends on the load.

Floor insulation in sand cellar

The method of thermal insulation using sand and rubble. This method can be used only for bulk gender.Sequence of work:

- If the insulation is not used, the floor is flooded with hot bitumen. It will perform the function of waterproofing;

- Sand-chumbs pillow thoroughly tram;

- The layer of rubble (100 mm) is poured;

- The floor is deepened to the depth of the future heat-insulating layer and aligns;

- on top of the sand layer (50 mm);

- It is possible to lay the hard heat insulating material on the surface (for example, penplex, polystyrene plates);

- The prepared floor is flooded with a concrete reinforced tie.

Floor insulation in sand cellar

Hearth ceiling cellar

In the case of a swallowed or ground cellar in insulation, the roof of the structure needs. Roof warming work provide for the use of a soft or rigid insulation, which is mounted in accordance with the manufacturer's instruction.Article on the topic: The ceiling of laminate with their own hands - laying technology (video)

As for the underground (covered, bulk) cellar, the ceiling of the room needs in additional insulation.

Procedure for performing work:

- Stucco is applied.

- The layer of hard insulation is mounted;

- Concrete slab overlap or wooden beams are treated with penetrating waterproofing primer. The composition fills the capillaries and prevents water seeping. Wood is additionally processed by an antiseptic;

- The heat insulation material is closed by mounting mesh;

- Cleakers are performed with a copper cune.

Note. The ceiling in the cellar is the most vulnerable place in terms of temperature. Therefore, it is better to warm in two layers (100 mm).

Warming overlap between the cellar and the first floor of the house

Insulation of the entrance group: doors or hatch in the cellar

If the entrance to the cellar is in the house or in the garage to its insulation does not put forward special requirements.But if the entrance is located on the street, then you need to warp the lazium into the cellar.

Procedure for performing work:

- Warming Door in the cellar Previously, they were performed using felt and other soft materials. However, now justified is the use of hard insulation, which are glued on the doors. Then the insulation is closed with a sheet of plywood, plastic or natural wood. Be sure to eliminate the slits in the place of the door joining the box. In this place the door seal is installed;

- Insulation Luke cellar Performed in the same way. Only more attention is paid to the reliable fixation of the insulation on the surface of the lid. Otherwise, he can disappear.

An important point to pay attention to, insulation the door or hatch is to exclude the possibility of their arbitrary opening. Otherwise, all work on the heat insulation of the cellar will be useless.

Cable insulation for cellar

The insulation of the concrete cellar or brick is not labor due to the optimality of their forms and resistance to mechanical damage (brick, concrete walls can be drilled by fixing a dowel-umbrella or process with hot mastic to ensure waterproofing).

Cable insulation for cellar

But with modern caissons for cellars the situation is somewhat different, because Events on thermal insulation may damage the tank tightness.

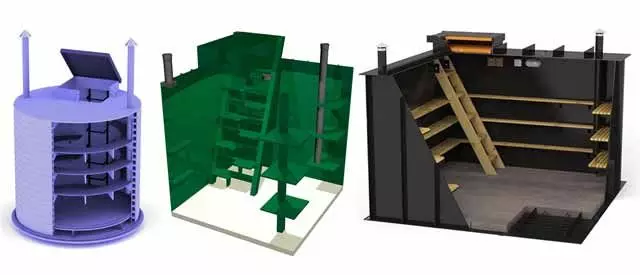

Nevertheless, the insulation is also important, because the walls are easily skipped both warm and cold. Since the caisson is a one-piece design, it does not need waterproofing. From the point of view of the material used, caissons for the cellar may be (views):

- plastic (from polymeric materials);

- reinforced concrete (made of concrete rings);

- Metal (steel).

It should be borne in mind that the materials have a different heat loss indicator.

At the same time, the cellar caisson may have the shape of a cube or cylinder, which imposes a print on the selection of the heat insulator. To insulate the caisson for the cellab you can use bulk, hard and sprayed insulation. Consider how their use in descending order of popularity:

- Hard insulation. Used in cases where the caisson has the shape of a cube, a square, a rectangle with a smooth wall. The insulation is glued to the caisson surface. Kesson is placed in the ground, the distance between it and the soil falls asleep;

- A bulk insulation: soil, ceramzit, sand, peat ground. In this case, the caisson is placed in the ground, and the distance between its walls and soil falls asleep;

- Sprayed insulation - polyurethane foam. Provide the most efficient heat insulation. But the lack of PPU isolation at a high price and the need to attract masters with special equipment.

The designated types of thermal insulation materials are suitable for the insulation of the metal cellar, as well as the insulation of the cellar from the plastic. The construction market presents a plastic cellar with insulation, which eliminates the need to perform work on warming with their own hands, the installation is fairly correct.

Conclusion

The insulated cellar in the country or in the courtyard of a private house is the key to the fact that the workpiece for the winter will be safe and preservation, despite the cold or heat "overboard".