Most of the materials for the soft roofing device are produced in rolls. They are intended for flat roofs or scanty, but with a small slope - up to 30 °. Mounted rolled roofing materials on the pitched roofs with a slope of more than 15 ° rarely - by their weight they slide from the skate. Have low cost, mounted simply, modern materials allow them to be operated without repair for 10-25 years. It is such a warranty period that manufacturers are given on materials. But how long the rolled roof will be operated, it depends in many respects how qualitatively it is made. With bad work, even the best materials will not save. Therefore, many dacha owners or private houses prefer to do everything on their own, with their own hands. On the main points of the device of the roll roofing with a mechanical fastening (on nails and self-tapping screw) or using mastic and talk on.

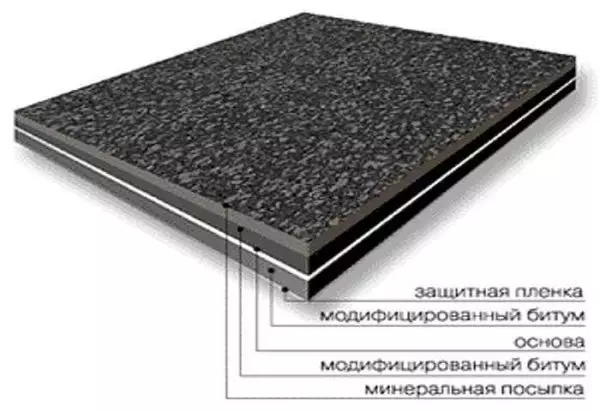

The structure of rolled roofing materials

The width of the rolled roofing materials is standard - 1 meter, the length of the roll can differ significantly - from 7 to 20 meters, the characteristics are changed in even wider ranges. So to choose a material for a roll roof, you need to understand the views.

Fundamental Classification

The choice of rolled material for a soft roof should be started with finding out its base. They are:

- Digesory. These are materials from recycled rubber (isol) or bitumen (bizol). There is a new butyl rubber-based material (highway). It turns out by rolling the crushed raw materials through the rolls that form a sheet. Most of the materials have a thickness of 2 mm. Used mainly in the lower layers of roofing cake for waterproofing base.

Domestic rolled materials are used mainly as waterproofing

- Based on the roofing cardboard impregnated with bitumen, sprinkled with mineral powder. The advantage of this material is its low price, disadvantage - a small life, poor tolerability of temperature drops. It crumbs at -15 ° C and drink + 50 ° C, which strongly narrows the scope of use like materials. Today, the rubberoid is mainly covered by the headquarters, and that is not always.

Ruberoid is based on construction cardboard

- Based on woven and nonwoven materials from fiberglass, polyester. The most expensive rolled roofing materials are made on the basis of polyester. They have excellent properties: have high tensile strength, can stretch by 30% without loss of integrity, can also be operated in a wide temperature range. Based on the fiberglass, it turns out durable, but non-ielastic material. In case of playing roof, it can break away from the base, but rushes in rare cases. Nonwoven glass coolers - the base is non-elastic and continuing, but the materials based on it make auxiliary, lining.

Based on fiberglass and polyamide there are many different materials

The best and durable materials for the rolled roof - based on polyester. The term of their operation is 15-25 years. They cost expensive, therefore are usually used as the top - roofing - coating, and the lower, lining layers, are made from the material cheaper, usually based on fiberglass or unduminarious materials (as a waterproofing coating).

The device of a soft roof from the installed materials is described here.

Types of binder

The base of the rolled roofing material is covered on both sides by a binding protective composition. It can be:

- bitumen (hydroizol based on asbestos paper, glasskerberoid);

- tar, bitumen-tar compositions;

- Rubber-bitumen composition (glazing)

- Rubber-polymer;

- polymeric.

The best features in rubber-bitumen and polymer-bitumen compositions. Some of them are intended for operation with severe frosts - up to -40 ° C, part well tolerates high temperatures - up to + 150 ° C.

Folgoisol - On the one hand, a bitumen-polymer binder is pasted foil

For regions with high temperatures there are rolled materials for a foil-based roof - foalisol. A bitumen-rubber or bitumen-polymer binder is applied on the foil on the bottom side. Due to foil reflective abilities, the temperature of the roof will be 20 ° C below. The facial surface can be painted by weather-resistant paints and varnishes. Foloisol is well bend, cuts, nailed with roofing nails. It happens roofing (FC) and waterproofing (FG).

Purpose

Roll roof rarely consists of one layer. Depending on the slope and complexity of the design, we latter from two to five layers. Bottoms are used for waterproofing, conservation of heat and improving sound insulation. They are called "lining", in marking they are denoted by the letter "P" (the letter reflecting the purpose of the material is in second place).

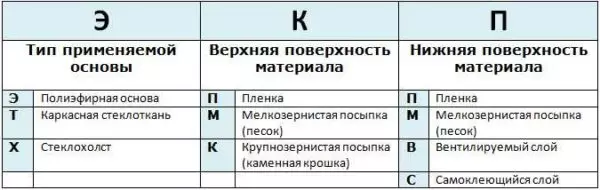

What denotes letters in marking

The upper layer should be more durable, it accounts for the main mechanical load, the climatic and natural factors affect. For this layer, the most expensive materials are used. They are called "roofing" and denoted by the letter "K".

The order of installation of soft bitumen tiles is described here.

Types of protective coating

The binders that are used in the production of rolled roofing materials require protection against weather factors. As a protective layer, the sprinkle of different degrees of grinding is used:

- coarse-grained (k);

- fine-grained (m);

- dust-shaped (P);

- scaly (h);

- Special resistant alkalis or acids.

Coarse-grained sprinkle not only protects, but also gives a decorative look.

In the marking of the letter, which displays the type of sprinkling, is faith. Rolled materials used for lining are sprinkled with both sides of a fine-grained or dust-like sprinkler. Her task is not to glow in a roll.

On the back side of the roofing roll material is also applied fine-grained or dusty crumb, and on the front - coarse or scaly, which not only protects the coating, but also gives it more attractive appearance. To give an even more aesthetic species, the sprinkle paint into different colors. It is usually red, gray, burgundy, brown, green and blue.

Method of installation

Most of the materials for the roll roof will be filmed on the base. This uses special burners connected to cylinders with liquefied gas. With their help, the lower layer of the binder is melted, adopting with the base or already laid material. This technology is applied on flat roofs, overlapped with reinforced concrete plates (for example, on garages).

Method of installation of the rolled roofing on mastic

In private house-building, flat roofs are found very rare in our country. On small houses, it is usually a bartal roof, less common - single one. The rafting system and the lamp these roofs are wooden, the use of open fire on them is the big risk and owners of cottages or small houses are looking for a rolled roof that does not need to be contacted. There are such materials. Some of them are attached with the help of mastic, part - nails nails (about them slightly lower). There are materials with self-adhesive layer. All that is needed is to remove the protective film, roll out the material and press it tightly.

Roll roofing of material with self-adhesive layer

Foundation for rolled roof

Claimed rolled materials are usually fitted on flat concrete roofs. In some cases (when repairing roofs of garages), they can be laid on a metal base. In this case, the roof material itself is the basis. All that is necessary is the pre-treatment of liquid waterproofing. There are two options:

- Bituminous primer. Suitable for concrete and metal. There is in the finished form - in buckets, you can do yourself yourself - mix bitumen with diesel.

- Penetrating waterproofing based on cement. It contains polymers whose chains block pores for which moisture seeps. Such processing at times reduces the water absorption of concrete. Her minus is a high price. And the second is to apply the roofing material on top, it will be on top of it all the same to wash the roof by bitumen mastic. Expensive pleasure. But after such a processing, even if the upper layers will skip the water, the roof simply cannot flow. If there is at least a small bias toward the runoff (prerequisite, by the way), water will leave, almost without leaking down.

On the pitched roofs under rolled roofs make a solid foundation

On the pitched roofs with a rapid system for rolled roofing materials, a solid base is necessary. Both of all make a continuous crate of plywood, an OSB, edged or tipped board. But these bases are combustible and to remove rolled roofs on them with the help of a burner. Then use materials for a rolled roof with a mechanical installation method (slate nails) or glued on mastic.

There are several other variants of non-combustible materials from which it is possible to make the base under the rolled roof - this is a flat slate, CSP, GVL and a professional sheet (galvanized). On these bases, special linings and long peasants with plastic sleeves are used for fasteners.

Example of fasteners for rolled roofing firms TechnoNIKOL

Any national bases make a sheet material with a thickness of at least 8 mm, laid into two layers. The second layer is put so that the seams of the first layer overlap the second sheets (with the displacement of the seams).

Materials for rolled roofing without stuffing

They are not very much, but they are. The method of fastening - roofing nails (galvanized with a wide flat hat), for special mastic (usually on mastic for flexible tile). Some have self-adhesive base protected by a polymer film. This film is removed during installation, rolling the laid part with a heavy metal roller, seeking to avoid the occurrence of air bubbles.

So, materials that are attached to mastic, nails, have self-adhesive base:

- Glassizol. Based on fiberglass or glass cholester, covered by bitumen. Located on bitumen mastic. The warranty period is 5 years.

- Ruberoid. Based on the construction cardboard impregnated with a low-melting bitumen. Mounted on bitumen mastic. Warranty - up to 5 years.

- Technoelast solo. A bitumen-polymer binder was applied to the polymer base, it has an increased thickness (at least 5 mm), can be used without additional lining layers, has increased fire characteristics. It is placed on mastic with an additional fastening on nails or self-tapping screws, it is necessary to fusion of seams. Lifecycle - 25-30 years.

Technoelast solo - for the device of the roll roof from one layer

- Technoelast Titan. Bituminous polymer binder on a polymer basis. There are three modifications of this material. Titan Top and Base - for two-layer roofing, Titan Solo - for one-layer. Fastening - mechanical, with seams, the service life is 25-30 years.

- Technoelast-s. A bitumen-polymeric binder is applied to the polyester base, on the underside - self-adhesive coating. Used to create a two-layer roofing coating, laying technology - immersion. The adhesive layer is applied to the lower side, protected by a polymer film. Before laying, the film is removed, the material is spread, roll roller. The laying temperature is higher + 15 ° C, at lower temperatures, we need to warm the material with a construction hairdryer. Possible laying on a fuel base (expanded polystyrene, wooden base). Lifecycle - 25-30 years.

Rolled roofing material on adhesive basis - TechnoElast with

- Technoelast Prime. Material for a two-layer rolled roofing, glued on the Mastica "Vishera". The base is a polyester cloth, the binding - bituminous polymeric. Lifecycle - 25-30 years.

- Technoelast Fix. Material for the lower layer of two-layer systems with mechanical mounting (nails). Bituminous-polymer binder is applied to the base of the reinforced polyester. The reinforced base gives increased strength, which allows you to use this rolled material on the pitched roofs with a large slope. As the top layer, the technoelast ECP (applied) is used.

As you can see, there is a choice. True, only two categories are very cheap and expensive materials, but you can choose from plans for the near future. If a temporary option is required - to cover the roof, for several years - you can use cheap materials. If the roof roof roof is arranged for a long time, it makes sense to use expensive.

Roll roofing device without stuffing

Regardless of what the roof base is, it should be smooth, dry and clean. No garbage and dust. Only clean material.

It is possible to make a roll roof on the scope roof, but you have to use certain materials that are for this purpose and comply with the rules and recommendations. The thing is that rolled materials for the roof have a sufficiently solid mass. Without adequate fixation, they slide down their own weight. To this not happen, special measures are needed. Here are the rules of the device of a roll roof with a mechanical fastening:

- When the slope slope, less than 15% of the canvas roll parallel to the skate. Stacking starts from below, move up.

When the roof bias up to 15% rolled roof racks parallel to the skate

- With a bias, more than 15% of the canvas are slipped from above-down. In order to under the action of gravity, they did not slip, they are usually put with overweight through the horse. If it turns out, you can roll both skate with one roll. But in this case, the vent hole is overlapped in the area of the skate. Then for ventilation, the attic is required to make individual ventilation pipes.

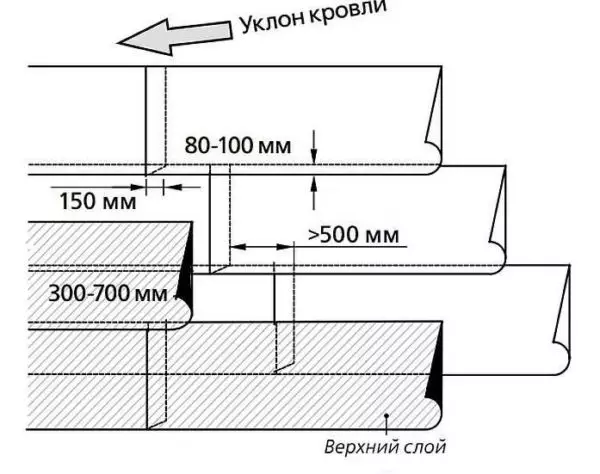

- Note: When using modern materials for two-layer roofing pie, perpendicular location of the layers is not allowed. Laying occurs only in one direction. At the same time, the seams of different layers should be shifted relative to each other. The minimum shift in the horizontal plane is 300 mm, the vertical joints must be separated by at least 500 mm. To shift the seams, one of the layers start with a roll, cut in half.

Displacement of the cloth when the device of the roll roof

- When laying the panels, it is necessary to roll out with the opening of the adhesive. The side base should be at least 120 mm, the end is at least 150 mm.

Outlines with a soft rolled roofing device with mechanical fastening

- In those places where there are any structural elements on the roof (the outlet of the heating and ventilation pipes, hearing windows, adjacent to the wall, etc.), the roofing carpet is enhanced by an additional layer. EPP uniflexes or technolast EPP are recommended.

- When entering vertical surfaces (on the pipe, parapet, adjacent wall, etc.), the material is glued to mastic throughout the area, and if possible, they will be filled.

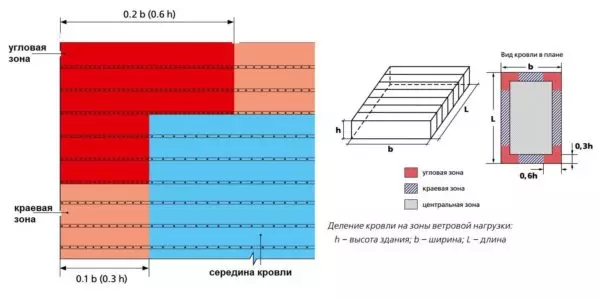

- The fastener installation pattern depends on the corner of the roofing corner, the height of the building, wind loads in the region. The most frequent installation is in the corners of the roof (step 25 cm). There are the biggest wind loads. A little less often put fasteners in the edge zone (up to 35 cm) - the load is medium. Sometimes fasteners are installed in the central region of the roof (up to 50 cm).

Fastener installation scheme

- Nails are clogged backing at least 10 mm from the edge.

- Each strip is fixed around the edges, and sometimes in the middle.

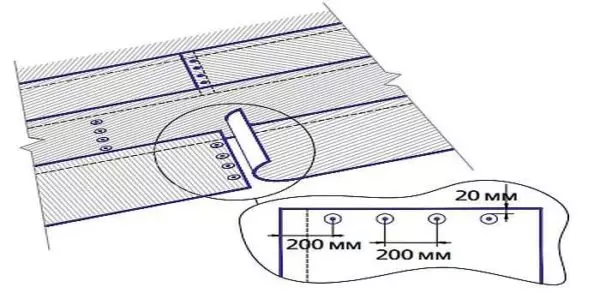

- The horizontal cunning joints are fixed with galvanized steel plats, which screw the screws, the second option - nails or screws with a washer with a diameter of at least 50 mm.

How to fix the cloth on horizontal joints

- The perimeter of the roof, along the sinks, around all the structural elements, along the rtands, clog extra fasteners with a step of no more than 25 cm.

- There are not less than 4 nails around the pipes of small diameter.

Sealing pipe output

In places where tubes or antennas are out of roofing pie, an additional layer is laid. It is glued on mastic directly to the base. To seal the passage of a round tube through a roll, non-splashing roof occurs with the help of a special rubber shaped element. This is an elastic cap with a rubber skirt. It happens for pipes from 110 mm to 250 mm in diameter.

Shaped element for the passage of pipe through rolled roof

The rubber cap is stretched onto the pipe, it falls so that the skirt freely lay on the base. The bottom of the skirt is missing by mastic, pressed well. Rates from the edge of a 10 mm skirt, installed fasteners with a step no more than 200 mm. The butcher of the rubber cap and the pipes are filled with the appropriate sealant (for chimneys, the sealant should be heat-resistant).

Next, the roofing material is spread from above, which is additionally fixed around the pipe with nails or screws with washers. Fastening installation step - no more than 250 mm, but there should be at least 4 fastening elements around the pipe.

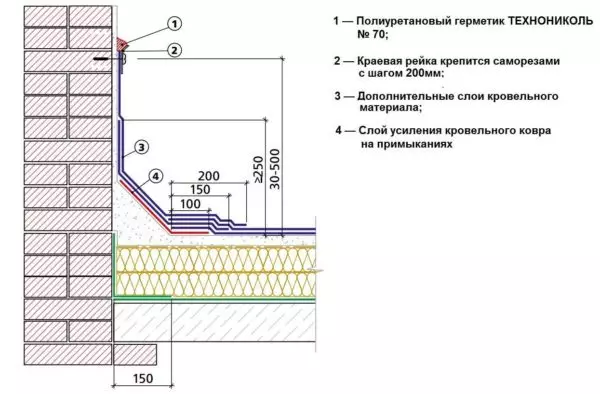

Bog with vertical structures (adjoining wall, brick tube)

In place of the joint of the roof with a vertical wall, an additional layer of underlying material is placed. It should go to the vertical surface at least 250 mm, on the skate should lie at least 200 mm. The entire surface of the extra layer is labeled with mastic, well pressed. After that, the upper part is still attached to the metal edge rail. It is attached to the vertical surface with screws with washers at least 50 mm in diameter. The link of the rails with a wall is poured by polyurethane sealant.

An example of an organization of adjustment to the vertical wall

If the roof is warmed, to ensure a high degree of tightness, you can make several additional layers (drawing above). Each of them per 100 mm goes on the previous one. Each is missing with bitumen mastic, but the bar is nailed only to the highest top, although the intermediate can be fixed with screws with washers with a pitch of 200 mm.

These are all the main points that are needed during the device of the rolled roof without flashing.

Article on the topic: Specifications and GOST on PVC doors