Hoto

Allasterong ya dade da tsarin da ake ciki don gyara. Tare da taimakon sa, saman bangon yana daidaita, kuma ana yin suɓallan matakin farko na zamani.

A rufin da plasterboard ya shahara saboda sauƙin shigarwa da bayyanar kyau.

Plasterboard yana da wani "Sunan Batun" bushe. Cakuda na gypsum an gama da shi tsakanin yadudduka na kwali. Ya danganta da ingancin kayan, zanen gado sun kasu kashi ɗaya cikin subgrou:

- Takardar filasta na yau da kullun - GNL;

- danshi-hujja takardar - g cibiya;

- takardar sake fasalin - gklo;

- danshi-wuta-resistant takardar - Globo;

- Leafer na Swyan Fita - GVL.

Godiya ga irin wannan nau'in, ana iya amfani da wannan kayan don rabuwa, gina arches, jeri na bangon har ma a cikin gidan wanka. Amma mafi shaharar shahararrun shahararrun shahararrun kayan kwalliya a cikin kayan aiki na tushe. Azuzar daga GCLs ba su da aure da yawa, rauni da kuma fentin, tare da haskakawa da ba tare da ba tare da, tare da tsari madaidaiciya da kuma tsari madaidaiciya da kuma tsari madaidaiciya da kuma tsari madaidaiciya.

Kayan aiki da kayan don gyara rufin rufin filasji

Don aiwatar da gyaran rufin filasawa, kuna buƙatar irin kayan aikin da kayan:

A lokacin da gyara wani salon filasji don hade bayanan martaba, ana amfani da kwari.

Plasterboard. Tsarin adiresoshin zanen gado - 2500x1200 mm. Wajibi ne a lissafta yankin farfajiya da lissafin adadin kayan da ake so. Muhimmiyar fa'idodin bushewa shine yayin shigarwa akwai mafi ƙarancin sharar gida, kamar yadda za a iya linked ta kowace hanya.

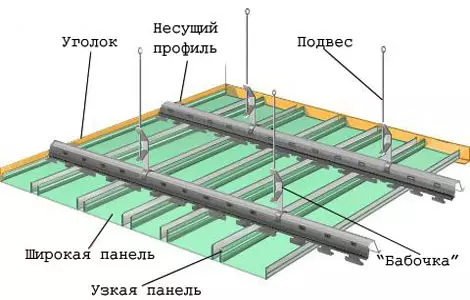

- Bayanan Jagora Jagora: Galayezar Jagora Mon 27x28 da bayanan bayanan PP 60x27.

- Dakatarwa don ɗaure bayanan bayanan rufin. Suna kai tsaye kuma an dakatar dasu da ta waya.

- Dowels ƙusoshi ne don hawa kan firam ɗin zuwa rufin kankare da bango, girman 6x40 mm. Idan rufi itace katako, to, ana ɗaukan dakatarwar da son kai.

- Saw-kwari. Ana amfani dasu don haɗa bayanan martaba.

- Tattarar al'ada na al'ada don bushewa bushewar bushewa.

- Kayan aiki don Aiki: Mai fasalin, rawar soja a kankare tare da diamita na 6 mm, siket, da sikeli na yankan martaba, almakashi na karfe, almakashi na ƙarfe.

Itace Sheet abu daban-daban kauri: daga 6 zuwa 12.5 mm. Ana amfani da bushewar siriri don tushe ana amfani da shi a cikin masana'anta na curvilinear, da kauri - don daidaita saman.

Don rufin filasawa yana da kyau zaɓi zaɓi abu tare da kauri 9.5 mm, ana kiranta rufin. Lokacin farin ciki plasterboard don tushe zai zama mai nauyi, wanda zai buƙaci ƙarin bayanan martaba da tsauraran wurare.

Monterage plaserboard tare da hannuwanku

Yin gyara na rufin filasannin platesboard tare da hannayensu suna da irin wannan jerin:

Azzage da ake buƙata don tsarin firam a ƙarƙashin filletirin fillet.

- rufin sutura;

- Mamita;

- Hawa bushe bushe zuwa firam;

- Putty, zanen, manna wallpaper.

Da farko kuna buƙatar yanke shawara wacce aka saukar da rufi ta daga babban aiki. Yawanci, wannan nisan shine 100-200 mm. Rayawa da aka dakatar yana da kyau cewa a cikin rata a tsakanin kankare da plasterboard surface, zaku iya ɓoye wayoyi don aya da kuma babban luminaires.

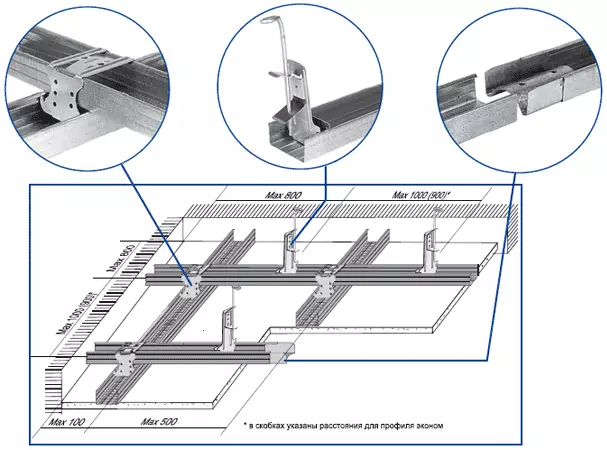

Tare da taimakon matakin ko lers, muna alamar layin rufin da aka dakatar daga busassun da sanya alama a bango. Dangane da waɗannan layin, ana gyara bayanan jagora. Mataki tsakanin matakan ya kamata kusan 400 mm. Idan an shirya ƙarin abubuwa a cikin nau'i na kwalaye a kan rufi, to, ana haɗe da ƙarin bayanan martaba a haɗe da wannan.

Bayan haka, ya kamata ka sanya hannu don shigar da shawarwarin: A duk faɗin ɗakin an zana layi ɗaya tare da rami na 450 mm. A layin farko da aka yi alama tare da fensir tare da mataki na 500 mm. A layin tressvere na biyu, an yi alamar farko a cikin 250 mm daga bango, da alamun alamun zasu zama karbuwa na 500 mm.

Hanyoyi na uku da sauran m an sanya haka daidai zuwa layin farko, da na huɗu da kuma duk ma - yi kama da layin transelse na biyu. Don haka, ana yin aikin gona ne a cikin tsari na Checker. Wannan zai tabbatar da rijiyar madaidaiciyar dutse.

Kuna iya gina firam ɗin ta hanyar dakatarwa ko bayanan jagora a cikin hanyar harafin "G".

Zane daga cikin tsarin firam a ƙarƙashin rufin filastik.

Ya kamata a gyara shawarwarin da aka tsara a cikin wuraren da aka yiwa rufin ta amfani da slanka ta amfani da kai ko dowels. Na gaba, ci gaba don tabbatar da bayanan masu kula da ɗaukar nauyi. Tsawon su ya dace da farkon firam ɗin da ke kewaye da gefen ɗakin. Don yin wannan, auna nisa da ɗakin da kuma rage 10 mm daga wannan darajar shine tsawon bayanan talabijin.

An saka bayanan martaba na rairayin da ke cikin rairayin da aka dakatar da su tare da kusancin kai. A cikin wannan tsari, yana da mahimmanci don lura da bayanin martaba a kwance. Don daidaita wurin bayanin martaba, kuna buƙatar canza matsayin haɗe-haɗe. Don sarrafa kwance, ya fi kyau a yi amfani da matakin laser.

Don haka tsarin aikin yana da dorewa, bayanan juyawa ba kadan bane - yakamata a inganta shi da abubuwan da ke cikin gidaje. A saboda wannan, an yanke kayan Jagora cikin guda 400 mm. An kafa su da galatar da su da karuwa na 500 mm na musamman na Mod na musamman - "Crabs".

Ayyukan ƙarshe na gyara na filasji na filasji

An kammala babban wani ɓangare na aikin: firam ɗin yana shirye da kayan kwance ya dace da ka'idodin da aka karɓa gabaɗaya. Yanzu zaku iya shuka shi. Don hawa rufin filasawa, zaku buƙaci aƙalla mutane biyu: ɗayan hawa ɗaya, ɗayan kuma yana riƙe da takardar. Idan rufin ya kunshi sassa da dama, to, GLC an riga an gina GLC da kuma yanke.

An sanya zanen gado kusa da bangon da jack ga juna, a fadin bayanan martaba na tsaye. Plasterboard yana haɗe zuwa gawa tare da zanen kai a mataki na 200 mm. A lokaci guda, ƙirar kayan kayan aiki bai kamata a sake dawowa cikin abu ba, tunda tsaftataccen firam ɗin ya ɓace.

An kamata wurin zama na zanen gado na plastogboard ya kamata a karyata.

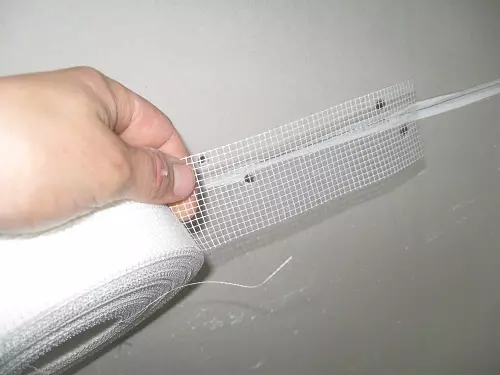

Yakamata a karɓi wurin zanen gado na filasannin filasje. Wannan dabarar za ta tabbatar da santsi mai santsi bayan putty. Wuraren da aka goge sukurori, kuma, ya kamata a sarrafa shi.

Yanzu saman ya shirya don putty. Rufin a cikin yadudduka biyu na cakuda "Kasarawa", da bayan an yi amfani da Layer. Ya kamata a yi amfani da yadudduka na Putty tare da tazara na kwanaki 1-2 domin kowane Layer ya bushe sosai.

Bayan rufin bushewar bushewa ya bushe sosai, ana iya fentin ta ko hugged da fuskar bangon waya.

Don zanen wannan farfajiya, fenti acrylic a kan tushen ruwa-emulsion ya dace. Irin wannan shafi ya faɗi a zahiri, ta bushe da sauri kuma ba shi da ƙanshi mai kaifi. Za'a iya zabar launi mai launi daga tabarau daban-daban. Ana amfani da fenalu a kan rufi da aka yi amfani da gajeren tari mai ɗan gajeren lokaci ko mai sikila idan har yanzu ba a sarrafa bango ba tukuna.

Akwai tukwici da yawa don yin rufin filastik tare da hannayensu:

- Dowels ya kamata ya zaɓi ƙarfe, ba filastik ba.

- Al'umcin daidaitattun abubuwan da ake amfani da shi lokacin da aka saukar da rufi ta hanyar 20 cm. Idan nisan daga daidaitaccen dakatarwar ya fi girma, sannan a maimakon haka nesa daga babban abin da aka gudanar za ka iya isasshen bayanin martaba na PP 60. bayanai sukan isa zuwa tanƙwara ƙarƙashin 90º da ɗan gajeren gefe don haɗe zuwa kankare.

- Bututun lantarki da aka ɓoye gwargwadon tsarin da aka riga aka zana. Dole ne a ware su a cikin gawawwakin.

- Kafin sanya tsarin firam, duba madaidaicin aikin masu lantarki. Don yin wannan, haɗa fitilun da kwasfa kuma duba aikinsu.

Gyawar plaserboil ɗin yana kallon kusancin zamani a ƙarshen wuraren zamawar amfani da mafi ƙarancin kayan aiki, gogewa da lokaci.

Mataki na a kan batun: Ribobi da Cons na Sabon Gidaje