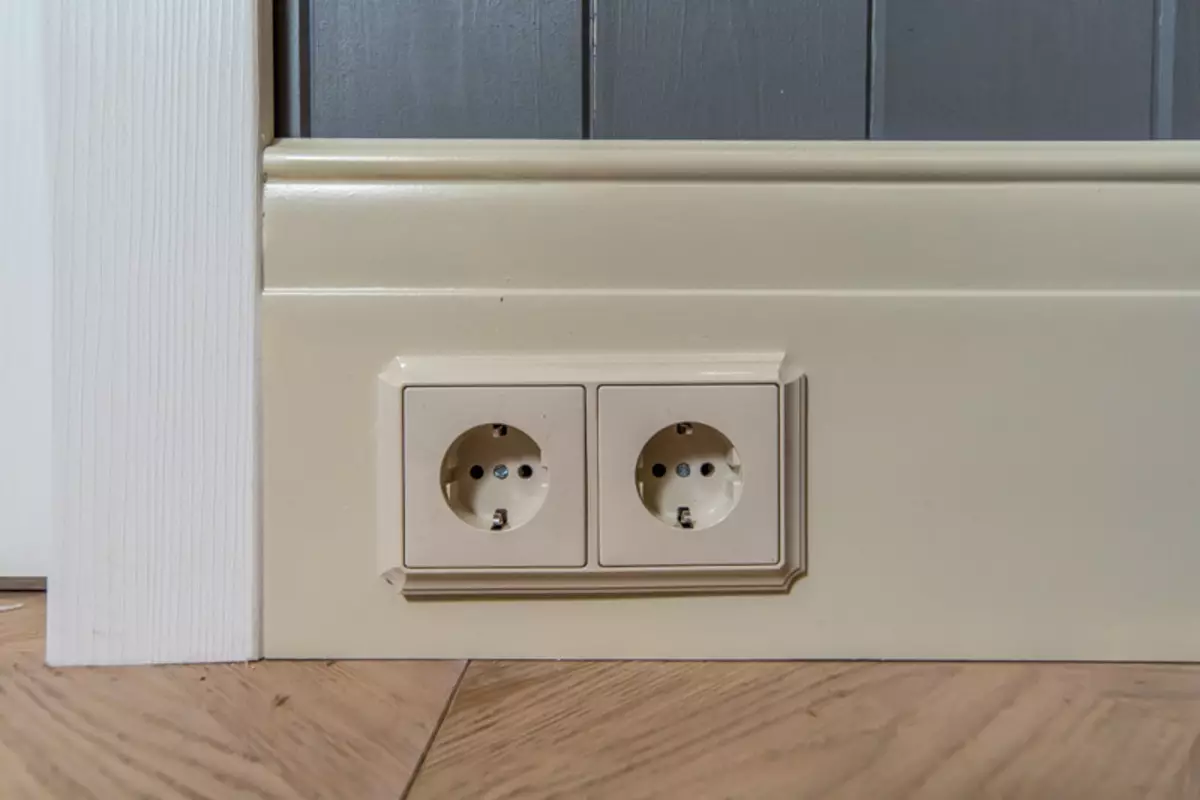

A cikin ginin gidaje na zamani, sabbin zane-zane na plastal sun bayyana tare da soket ɗin ginannun. Don sadarwa yanzu baya buƙatar gyara tsayayyen - rawar rami kuma yin gasket a bango.

A cikin ɗakuna tare da yawan kayan lantarki na lantarki, ya isa ya sanya filayen USB wanda aka ɗora don akwatina na musamman don kwasfa na musamman don kwasfa.

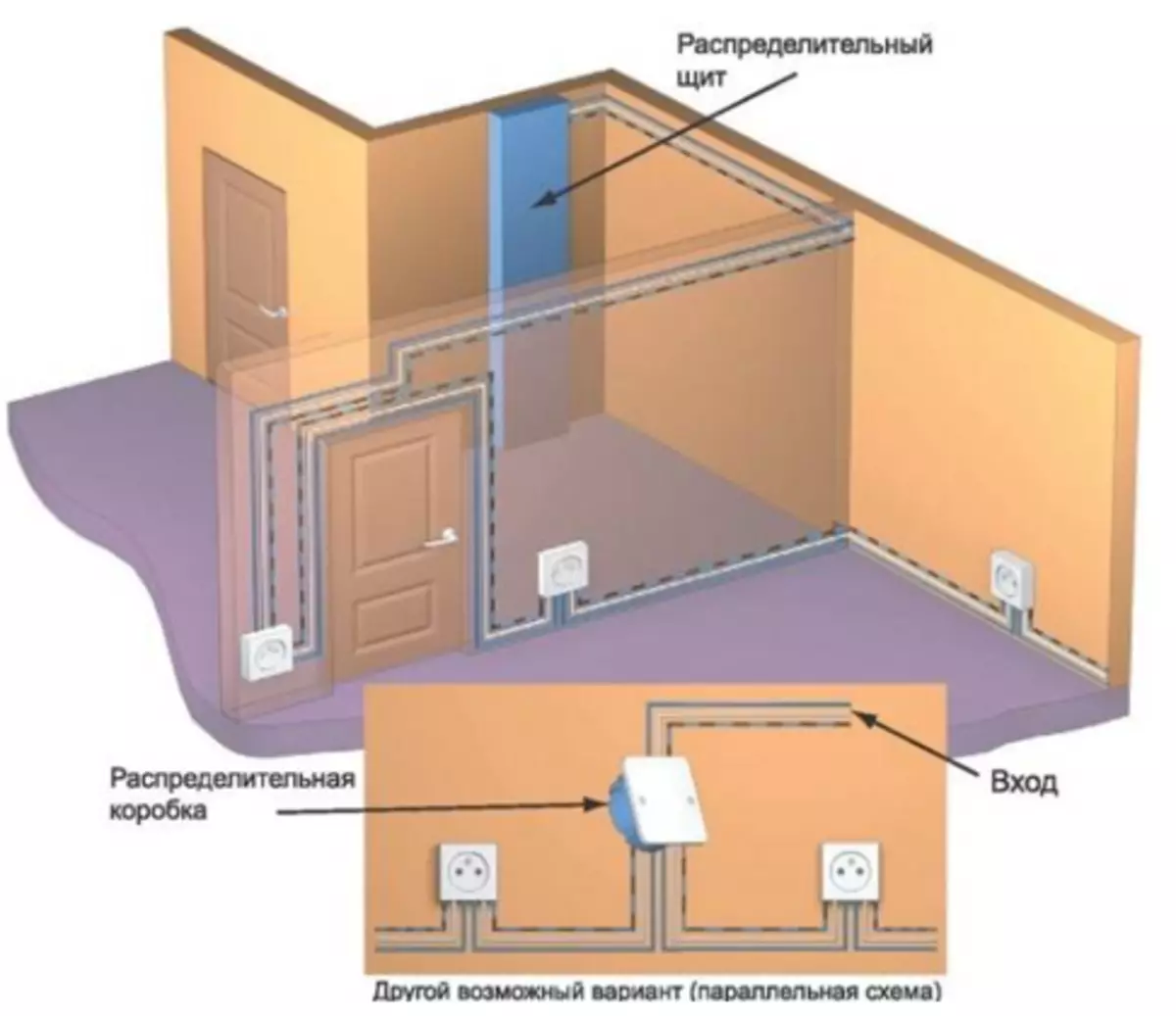

Akwatin shigarwa a cikin yanayin da ake yi yawanci ana yin shi ne kawai lokacin da kebul dole ne ya shimfida ta fuskar gaba ɗaya ko kuna buƙatar faɗaɗa hanyar sadarwa ta lantarki. Gurfar da Jiki ta Plinint zai iya saukaka tarar, igiyoyi na Intanet da wayoyi masu ƙarfin lantarki. Don hanyar sadarwa da wayoyi na waya, ginannun ginannun sune zaɓi mafi dacewa.

Bugu da kari, shigarwa na kwasfa na plinth shine mafi inganci lokacin da ke sanya wiring wiring. A wannan yanayin, yana yiwuwa a gano hanyoyin wutar lantarki a ko'ina.

Abvantbuwan amfãni da rashin amfanin sutturar sphett

- Ikon ɓoye kwasfa ta hanyar sanya su ɓangare na ciki;

- ba mu damar amfani da kayan aikin lantarki da kullum, tunda tare da wannan wurin da aka kwaso, kayan aikin ba ya rufe lambobin sadarwa;

- Taimakawa ajiye sarari kuma rage farashin rufi na wiring;

- Sanya sabulu a waɗancan sassan dakin, inda ba a baya ba;

- Matsayin tsaro yana ƙaruwa, tun da wayoyi ba sa ɓoye tare da irin wannan haɗin;

- Yana kare kebul daga lalacewar dabbobi.

Rashin irin wannan wuri shine kawai idan ruwan ya fadi a cikin ƙirar, zai kai ga ɗan gajeren da'ira. Don guje wa irin wannan yanayin, sandan sandan sanannun labulen na musamman waɗanda ke kare lambobin sadarwa daga danshi.

Halayen akwatin shigarwa

- Don hawa akwatin shigarwa yana buƙatar masu submersors (kwalaye) da kuma socks kansu. Tasuwar Canjin ya ƙunshi kwalin tare da adaftar a kasan.

- An sanya ɗakunan lantarki na polyvinyl chloride, fim mai ɗorewa, wanda zai iya kwaikwayon kowane irin rubutu (dutse, itace, da dai sauransu). Abubuwan kayan gyada da na peavercraft yana da tsauri mafi girma fiye da na Plinth, kamar yadda ya zama dole don tsayayyen gyara yayin shigarwa.

- Ana samar da nau'ikan manya-raga - a waje, a hankali kusa da bene da filaye da bango, wanda aka haɗe zuwa bango da plinth, ba ya taɓa bene.

- Tsarin akwatin shigarwa an sanya duniya duka don saukar da bututun lantarki da kuma haɗin wayar, kebul na cibiyar sadarwa ko eriya, da dai sauransu, da sauransu, da dai sauransu.

- Don saita akwatin shigarwa gaba daya ya dace da plulth, ya fi kyau siyan su daga masana'anta ɗaya.

Mataki na a kan batun: Aljan kaset ɗin ƙasa: Hanyar na'ura, Wurin Riga, Semi-Groric Drindical nika

Hawa soket

Shigarwa na juyawa ba na babban wahala bane, don haka za'a iya yi da kansa.

Ana buƙatar kayan aikin da ke gaba: masu sihiri, sikirin (dunƙule da aka saita), ga filastik mai kaifi, nassi tare da kayan aiki mai kaifi.

Hakanan muna buƙatar ƙwayoyin hannu na kai (daga 6 mm), inforing tef, da sauransu. Hanyar adanawa da manne ko teku ba abin dogaro bane, tunda akwatin a wannan yanayin ba zai zama tabbaci ba.

Kafin aiwatar da kebul yana sauya zuwa mashigar, yana da mahimmanci don sa a kan filayen na USB wanda ke da jagorar mai ɗaukar wutar lantarki wanda zai wuce.

Don yin wannan, ƙwayoyin ta cire bangarori masu kariya, to, jarumawar hawa suna tare da taimakon filastik downals a baya alama. Ana saita sasanninta da adaftan da ke tsaye a cikin asusun ajiyar wires.

A cikin wuraren shigowar saitin an riga an riga an riga an yi alama alama. Na gaba, masu girman girman sigar da suka dace ana yanke su, kuma ajiyar ne 4-5 mm a garesu.

Don shigar da juyawa na waje a cikin plah, ya zama dole a bar rata (60-70 mm) tsakanin madaukai daban na mold ko sanya wani a wurin shigarwa. Don juyawa, wanda aka haɗe zuwa bango, incision a kan filastik an yi shi ne daga sama. Ana sarrafa ramuka a gefen gefen tare da fayil don guje wa lalacewar ware.

Daga kebul na tashar jirgin ruwa na Tsakiya, an cire waya, wanda aka yi niyya don haɗin, an yanke shi kuma an tsabtace shi. Plinth rufe da kariya ta kariya

Ana amfani da akwatin zuwa bango kuma ta hanyar ramuka alama da ɗaukar fansa. Alamar rawar soja don masu ɗaukar hoto da kuma rufe filastik dowels. Don tabbatar da ƙarin yawan dace na downel da aka yi amfani da shi ba tare da bangarori ba.

Akwatin shigarwa an daidaita shi zuwa bango ta amfani da sukurori masu ɗamara kai. Ramin yana nuna wayoyi ba tare da juyawa da lalacewa ba.

Ana shigar da soket ɗin a cikin yanayin da aka shigar azaman. Pre-kan mashigai, Uncrewalls tashar amfani da sikirin mai siket, sannan a haɗa da wayoyi masu ƙarfi. Tighting da sukurori, kuna buƙatar tabbatar da cewa ba ku lalata masu gudanarwa saboda matsin lamba da yawa. Don a cikin dambe, da bends suna kara kara ja na USB.

Mataki na kan batun: Sauya shafin gas

A ƙarshen shigarwa, an haɗa ƙarfin lantarki, duba aikin soket ta mulkerima da kayan aikin lantarki kuma amintaccen kwamitin ado na ado.

Bidiyon Bidiyo na gani Yadda ake yin wannan AlgorithM:

Shawara mai amfani

Outdoor Paaind, samun ƙasa, ya fi dacewa a cikin shigarwa, kamar yadda ya dace da nau'ikan kwasfa iri daban-daban. Irin waɗannan samfurori suna da akwati tare da zurfin zurfin, don haka lokacin da aka shigar baya fuskantar matsaloli.

Don wasu nau'ikan submersors, sun zaɓi wani soket tare da filaye.

Koyaya, aikin samfurin kusa da ƙasa yana haifar da wasu damuwa. A yayin aikin da ke kusa da akwatin, ƙura da datti yana tara a kusa da akwatin, kuma yayin tsabtatawa yana iya samun ruwa, wanda zai haifar da gajeren da'ira. Sanya kayan daki kusa da bango ba zai yi aiki ba. Don haka, peavering, gyarawa zuwa bango ya fi dacewa a rayuwar yau da kullun.

Lokacin sa shigarwa, ya zama dole a lura da wuta da amincin lantarki. Dole ne a aiwatar da duk aikin kawai bayan cire wutar lantarki. Wutar lantarki bai kamata ya sami lalacewa ba, kuma wuraren da ba za su iya ware bangarorin ba.

Kwalaye na lantarki tare da wurin da aka yi amfani da ɗumbin igiyoyi masu yawa a masana'antu. Yanzu irin wannan injiniya da mafita na fasaha an yalwaci cikin sassa daban-daban na ƙirar ciki.

A yau, ta amfani da ginanniyar da aka gindaya, zaka iya sanya soket a kowane bangare na gidan, wanda zai iya adana lokaci da kuma nazarin gyare-gyare. Kwalaye na Plinth suna da tsari mafi banbanci da ƙira, ba ku damar zaɓar zaɓi mafi dacewa kuma sanya su ɓangare na gida.