Isitezi esifudumele samanzi namuhla kungenye yezinhlelo ezithandwa kakhulu zokushisa.

Into yokushisa kulolu hlobo lokushisa yipayipi epulasitiki, yensimbi noma yethusi, embozwe ngosakhiwo sokwehla kwesihlahlandlela, etholakala ngaphansi kokuqeda phansi (ithayela, i-parquet noma i-laminate). Kepha iyunithi enkulu yokusabalalisa yokuhlinzekwa kwamanzi futhi indawo yamapayipi okushisa yiqembu leqoqiwe phansi efudumele.

Umqoqi, inhloso yawo, izinhlobo nezinto zokuklama

Umqoqi - inhliziyo kaPawulu ofudumele

Umqoqi we-Flate Floor angabizwa nangokunye ukuzethemba ngenhliziyo yomuntu wonke. Kunzima ukubukela phansi ukubaluleka kwalo emsebenzini wohlelo lokushisa oluphelele.

Njengoba wazi, izinto zokushisa (amapayipi) alolu hlelo lokushisa kufanele abe nokushisa kwe-35-450c. Le pharamitha ifakwa ngenxa yokuhamba kwamanzi afudumele ngaphakathi kwamapayipi (kuze kufike ku-500 ° C).

Umqoqi usabalalisa amapayipi amanzi ashisayo

Uketshezi wohlelo lokushisa kanye nepayipi elishisayo elishisayo linamazinga okushisa amakhulu, ngakho-ke ukunikeza okupholile esifundeni samanani afunekayo, kusetshenziswa umqoqi.

Eminye yemisebenzi yayo ukusatshalaliswa komthwali wokushisa we-contours eqeda amandla. Isifunda ngasinye sinokufaka okukodwa kanye nemiphumela eminingana. Ukuze amanzi epayipini anamazinga okushisa afanayo phezu kwayo yonke indawo, kukhona ukusakazwa okuqhubekayo (okucushiwe yipampu ye-coolant nge-collector comb.

Kuyafaneleka ukwazi, ukuxabana kubizwa ngokuthi amapayipi okushisa athile akhiwe ngaphansi komhlaba.

Inani le-contours on for floor lincike endaweni engaphezulu kanye nesitayela sento yokushisa (i-Spiral noma iZigzag).

Uma amapayipi okushisa abekwa emakamelweni amaningana efulethini noma endlini, inani lezinyuso zenyuka. Mayelana maqondana nokuthi amapayipi afudumele angakanani axhunyiwe kumqokeleli, uhlobo lwayo nosayizi kuyakhethwa.

Isihloko ngesihloko: Ungasivala kanjani igebe phakathi kwephansi nodonga ngaphansi kwe-plinth

Umehluko kanye nokucushwa kwabaqoqi

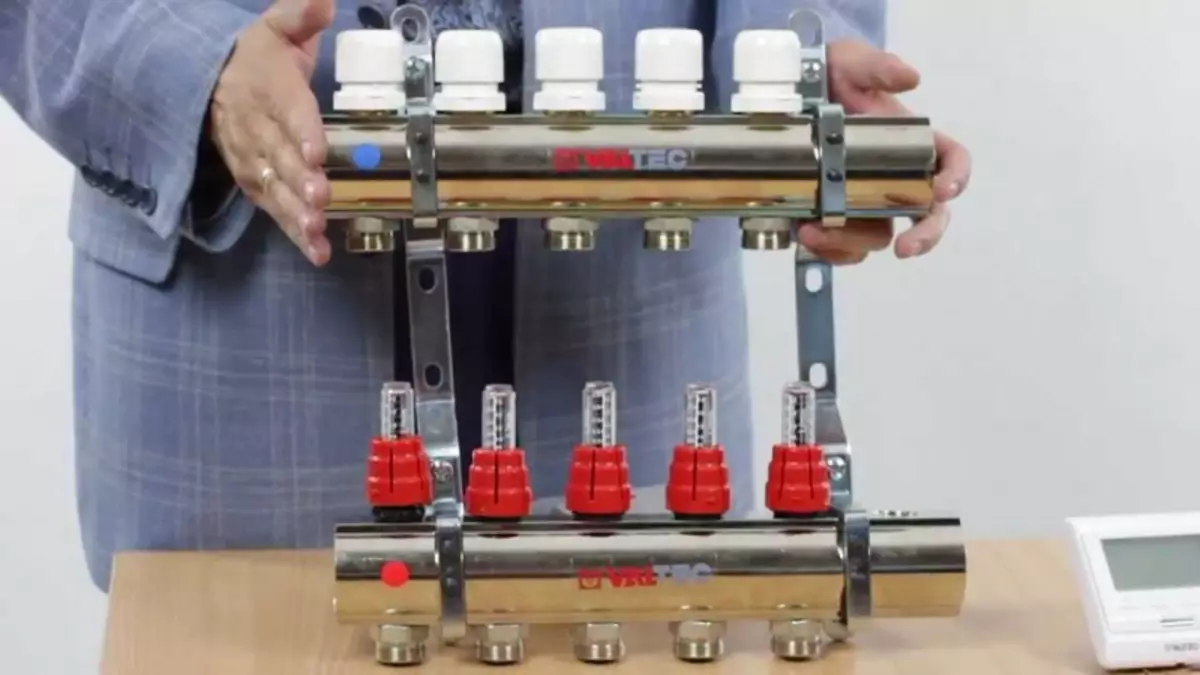

Imiphumela eminingi, ikhudlwana i-Collector usayizi

Ikhwalithi eyinhloko yokuhlukanisa iqembu leqembu lomqoqi ukuze phansi okufudumele kubhekwa njengenombolo yemithi exhunyiwe nohlobo lokushintshana kwama-Izinkomba zokushisa.

Usayizi womqoqi uhlobene ngqo nenombolo yemidwebo exhunyiwe. Uma ufaka amanzi angaphansi komhlaba egumbini elilodwa, ngokwesibonelo, egumbini lokugezela, kwanele ukubeka lo usayizi 2 wesifunda samapayipi wamanzi. Imvamisa, ngenombolo encane yeziyingi, ama-Flowmeters afakiwe ku-Feed Cold, futhi kufakwa ama-valve aguqukayo.

Imitha yokugeleza iyithuluzi lokulinganisa, okuyinto, ngenxa yesidumbu sepulasitiki esisetshenziselwa yona, isikali esifakwe esigabeni kanye nokuntanta okufakwe ngaphakathi, kukala isilinganiso sokudla okupholile ohlelweni lokushisa.

Lapho kukhudlwana inani lamanzi, likhudlwana uketshezi olukhudlwana ku-contour, okusho ukuthi izinga lokushisa laphansi lizoba ngaphezulu.

Ukunciphisa amapharamitha okushisa ento yokushisa, kuyadingeka ukunciphisa inani lamanzi anikezwe. Ukwenza lesi senzo udinga ukuguqula i-valve etholakala kwi-refper com, ehambelana nalesi sasemjikelezo.

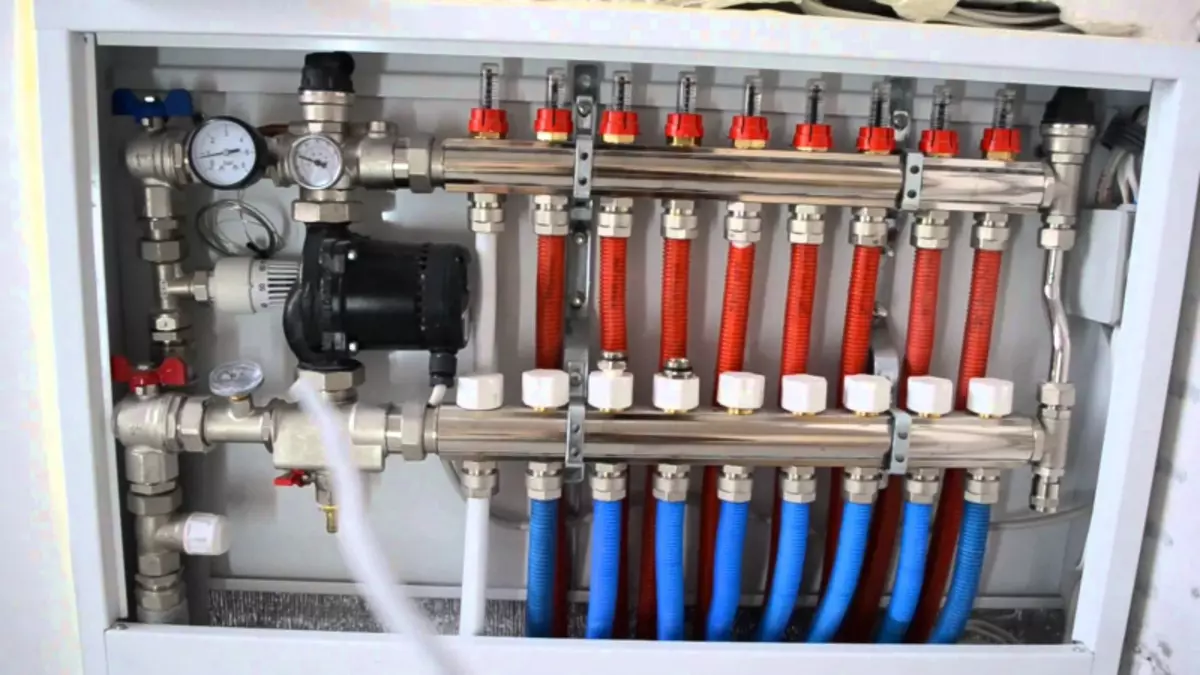

Lolu hlobo lweqembu lomqoqi luyindlela elula kakhulu futhi lwenzelwe izakhiwo ngenani elincane lemigodi efakwe ukushisa. Uma ufaka lolu hlelo lokushisa kubo bonke ekhaya futhi ungafuni ukulungisa izinga lokushisa kwezinto zokushisa nge-mathupha, khona-ke umqoqi kufanele afakwe ngokulungiswa okuzenzakalelayo kwamapharamitha.

Umqoqi Wezingxenye Ezihlanganisiwe

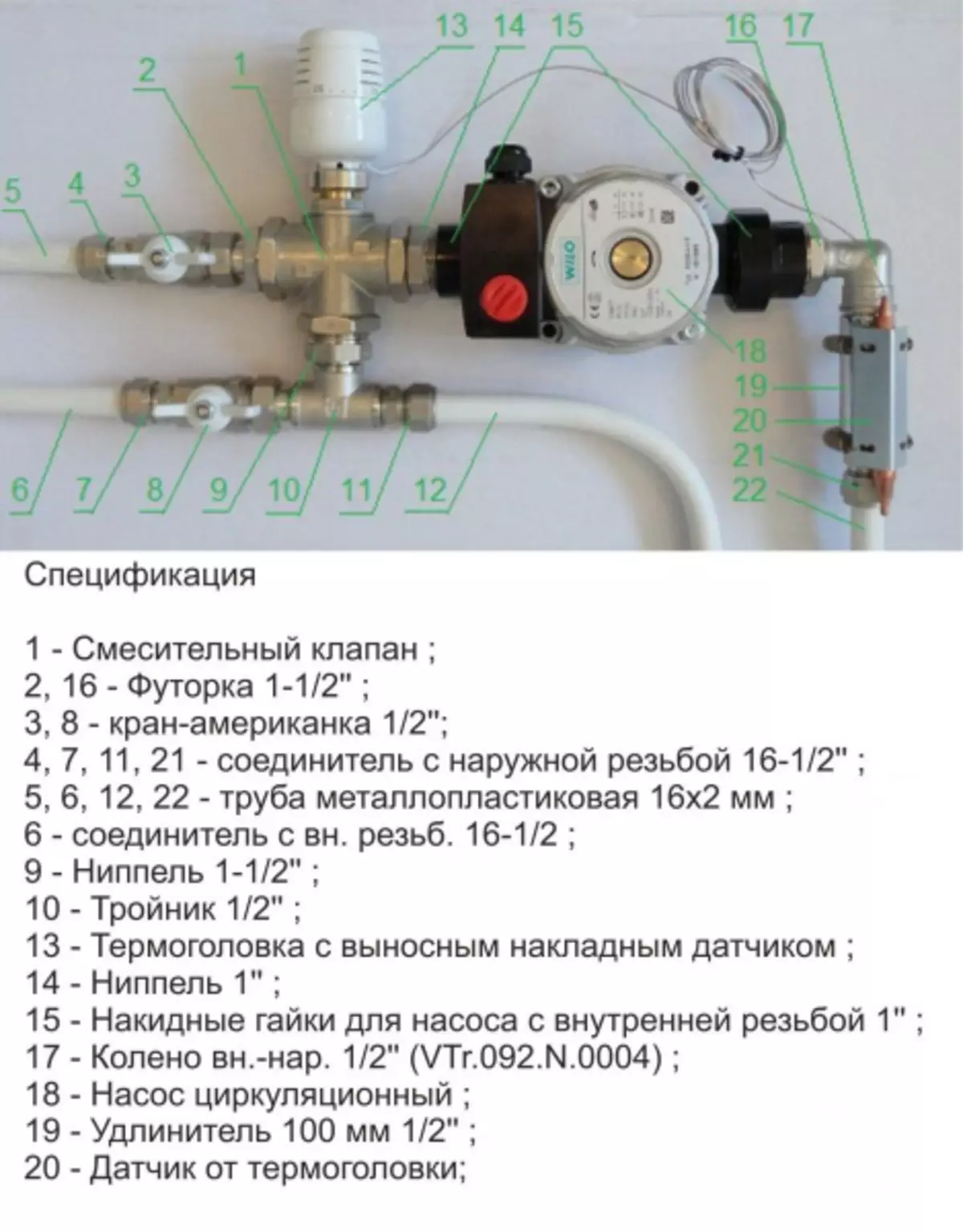

Le divayisi ifakwe nge-thermostat ene-thermostar ne-sensor eshisayo, ephendula ushintsho ekushiseni kwesifunda. I-thermostat ibhekwa njengento esebenzayo, futhi amandla okushayela angu-servo.

I-thermostat uma kwenzeka ushintsho lokushisa lusebenza kumyalo we-servo, okungu-2 noma 3, ichopho le-elektroniki le-elektroniki elinciphisa noma lenyuse ukugeleza kokupholile ku-contour.

Kufanele kukhunjulwe ukuthi uhlelo oluzenzakalelayo lokuguqula nokulawula amapharamitha okushisa aphansi, okumele i- "thermostat-servo" eyinkimbinkimbi, esikhundleni ngokuphelele i-valve ngokulungiswa okwenziwa ngesandla.

Izinto zokwenziwa Kwezinto Ezibonakalayo

Umqoqi wethusi

Isihloko ngesihloko: Ungayikhetha kanjani i-Cornice ye-Metal Ceiling efanelekile egumbini lokuhlala

Umqoqi uyisitho esibaluleke kakhulu sohlelo lokushisa lwamanzi afudumele amanzi. Kusukela lapho kusizwa, ukuhlinzekwa kwamanzi kanye namapharamitha okushisa alawulwa, idivaysi kufanele ibekezelele ukucindezelwa okukhulu nokushisa okushisa.

Ngokuvumelana nalokhu, idivaysi kumele yenziwe kusuka ezintweni ezinokwethenjelwa ezikwazi ukuphendula izidingo.

I-Polypropylene - Inguqulo Yezezimali Ezenzelwe Kakhulu

Kuze kube manje, abaqoqi bezingubo zangaphansi kwamanzi benziwe ngezinto ezi-3:

- zethusi;

- yensimbi engenasici;

- I-Polypropylene.

I-Brass iyinto ethandwa kakhulu yokwenziwa kwezinhlelo zomqoqi. Inentengo ephakathi nokuthembela okuhle kanye nezinkomba zokusebenza.

Insimbi engenasici - impahla ehlala isikhathi eside, ebizayo futhi ebizayo, ukusetshenziswa kwayo kuholela ekwandeni okukhulu kwezindleko zedivayisi. Ngemininingwane engaphezulu ngezinhlobo zabaqoqi, bheka le vidiyo:

Abaqoqi be-polypropylene basetshenziselwa amakamelo amancane futhi basebenze nge-coolant ephansi yokushisa, intengo yaso izojabulisa umnikazi ngamunye.

Izakhi zedivayisi yedivayisi

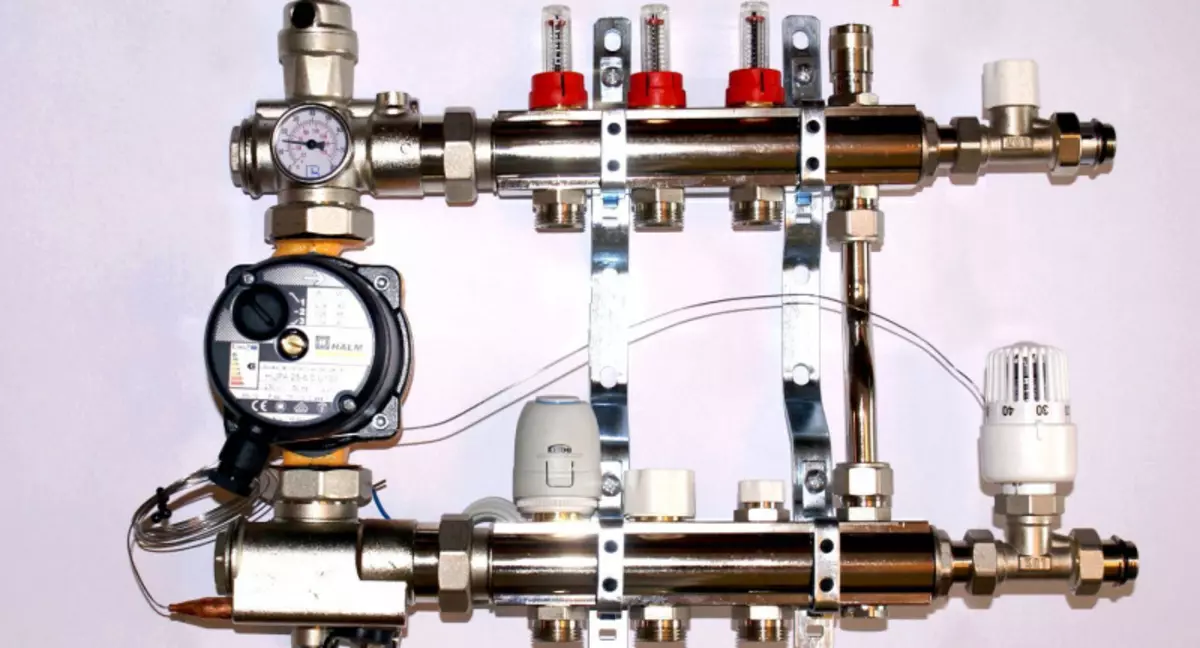

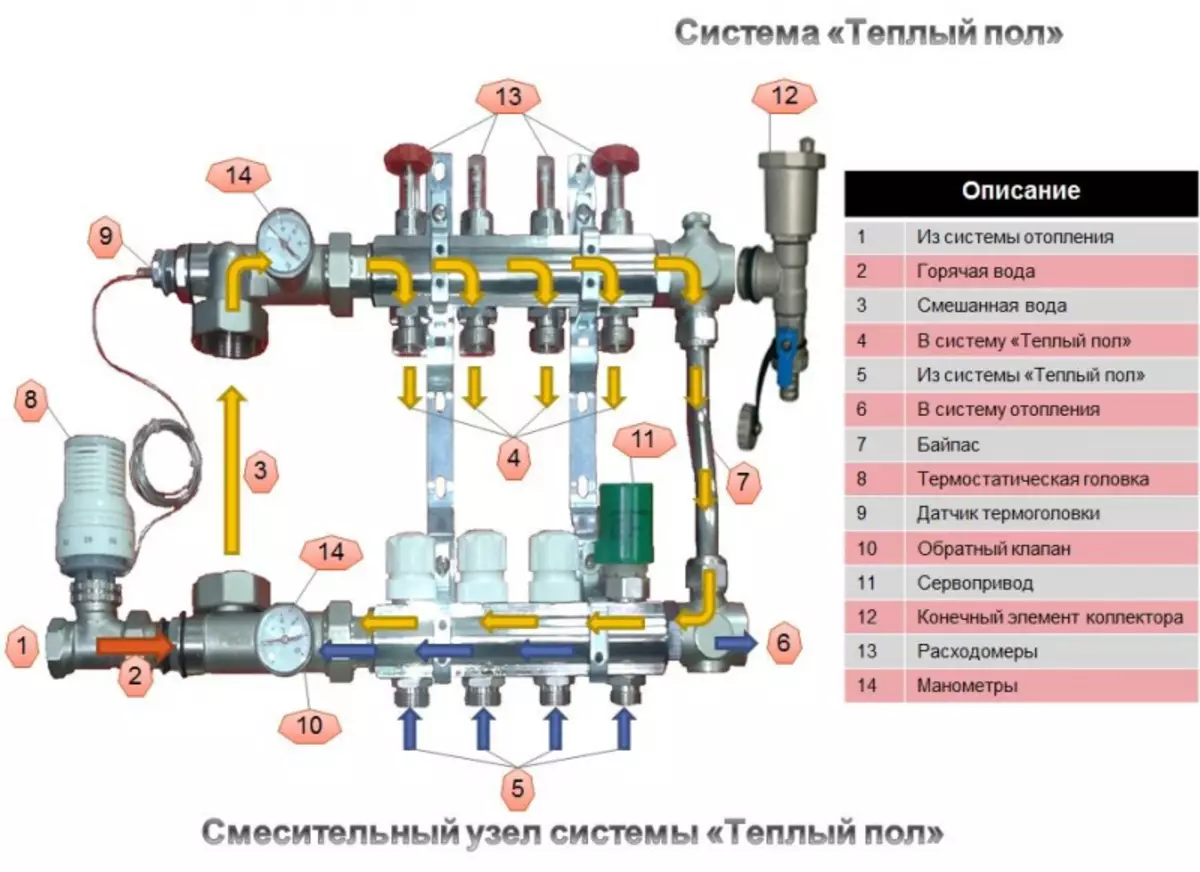

I-subrurbs node idla i-contour yamanzi ashisayo

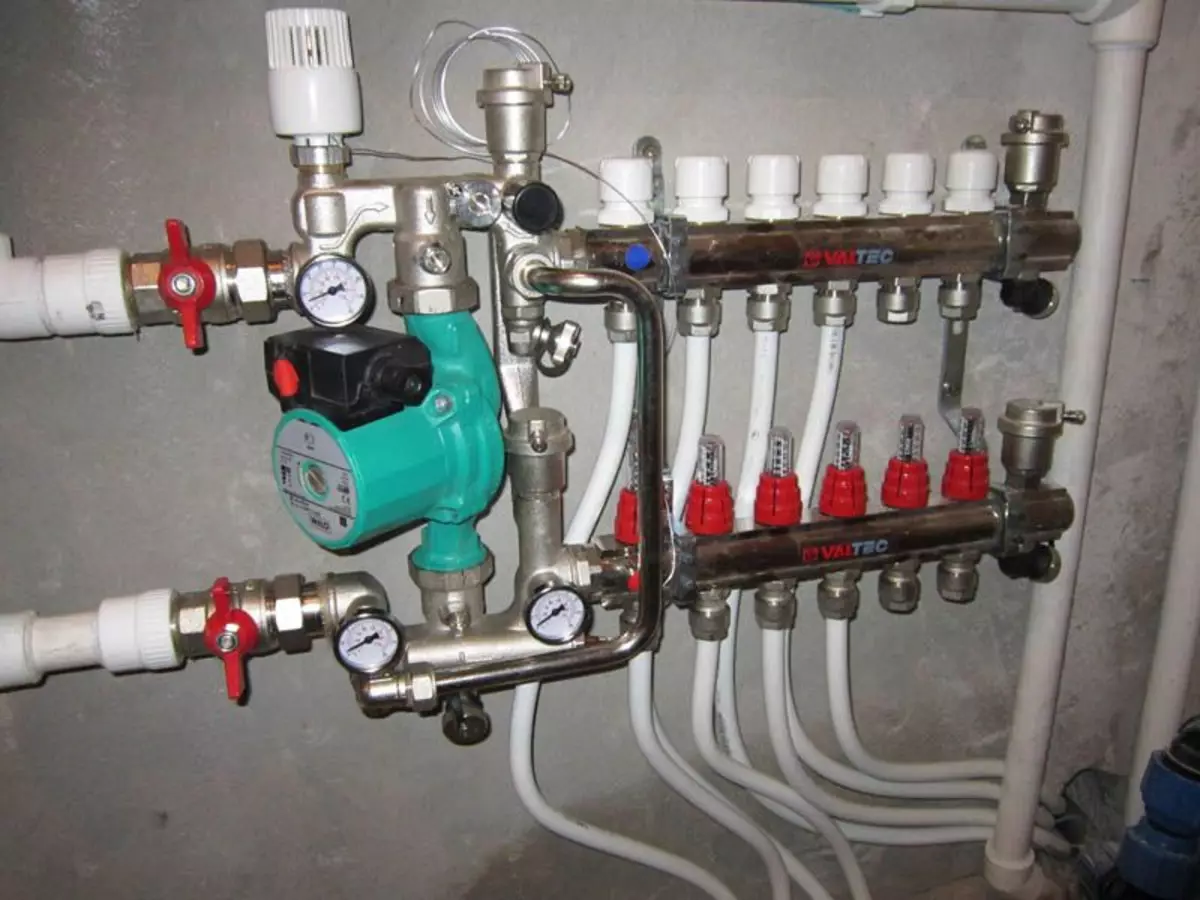

Umqoqi idivaysi ebanzi efaka phakathi izakhi ezibaluleke kakhulu:

- Indawo yokukhosela ye-NOde. Lesi yi-valve ethomathikhi lapho isitezi esifudumele esihlasela khona kufanelekile. Ukulawulwa kwe-valve kwenzeka ngosizo lwe-servo umyalo oluvela kuwo ku-thermostat ngemuva kokuthi inzwa ibangelwa. Lapho nje amazinga okushisa okupholile esifundeni efinyelela inani elijwayelekile, i-valve iyavalwa.

- Ukujikeleza kwegazi. Umqoqi ngePump uhlinzeka ngokwakha ingcindezi oyifunayo ohlelweni. Okuvumela, lapho uqhuba ukujikeleza kwegazi, isikhathi eside gcina izinga lokushisa le-coolant ohlelweni lokushisa malta lukumaki oyifunayo. Ngosizo lwephampu eyindilinga, amapayipi amanzi asatshalaliswa, adala izinga lokushisa elifanayo laphansi endaweni yalo yonke.

- Ikamu lokusabalalisa. Idivaysi yomqoqi ebhekele ukusatshalaliswa kwamanzi okuvela ohlelweni lokushisa kanye nemibuthano yesitezi esifudumele. Kubandakanya amamitha okugeleza nama-valve alungiswa ngesandla.

- Umoya womoya. Kuyi-valve enomugqa evumela ukuthi wena ususe uhlelo lokuphoqelela, ngaleyo ndlela uthuthukise ukusakazwa kwamanzi ngemikhuba.

- Meteertachik. Le yidivaysi eyengeziwe, njengoba i-thermostat echazwe ngenhla, evumela ukuthi uphendule ekushintsheni kwezimo zezulu, ukhulisa noma wehlise izinga lokushisa elifudumele (i-actuator, futhi i-servo). Ngemininingwane ekwakhiweni kwefindo lokuxuba, bheka le vidiyo:

Isihloko ngesihloko: I-Chandelier Yemicu: Ukufundiswa okulula nge-Master Class nesithombe

Ibonisa amadivaysi esistimu umqoqi angabonakala ohlelweni.

Kufanele kukhunjulwe ukuthi indlela umqoqi ebengeke aqedwe ngayo, isabelo sawo ngeke siguquke kulokhu.

Lokhu kufaka phakathi ukusatshalaliswa okufanayo komthwali wokushisa ohlelweni lwezinqwaba, ukugcina izinkomba zokushisa ezidingekayo nokulawula inani lamanzi ahlinzekwe.

Imininingwane enikeziwe izokusiza ekutholeni impendulo emibuzweni: "Yini i-node yokuqoqa edingekayo ngokunembile phansi yayo efudumele, ingabe kufanelekile ukusetha idivaysi yayo efudumele, i-thermostat?", Nento esemqoka ukuqonda ukuthi umqoqi uyi Idivaysi ebaluleke kakhulu yohlelo lokushisa lokushisa kwamanzi.