Muva nje, izitezi ezifudumele zithole ukuthandwa okukhulu. Ukushisa phansi kwenziwa ngezinhlobo ezintathu zokushisa kwesisekelo segumbi.

Lezi zinhlelo zamanzi ezifudumele zamanzi, ikhebula kagesi kanye nokuhlanganiswa kwamafilimu kwemisebe ye-infrared.

Amacebo anjalo ayakwazi ukudala izimo ezintofontofo zokuhlala komuntu egumbini nganoma yisiphi isikhathi sonyaka. Impahla ebalulekile yezinhlelo zokushisa yisikhathi sokushisa sokuhlanganiswa kwangaphandle. Abantu abaningi banentshisekelo embuzweni wokuthi kungakanani ukushisa okufudumele komhlaba. Cabanga ngezinto ezithinta isikhathi sokushisa phansi.

Izinhlobo zokufudumala phansi

Namuhla, izinhlobo ezintathu phansi ezifudumele zaziwa:- izitezi zamanzi afudumele;

- phansi kwekhebula;

- Ifilimu elifudumele.

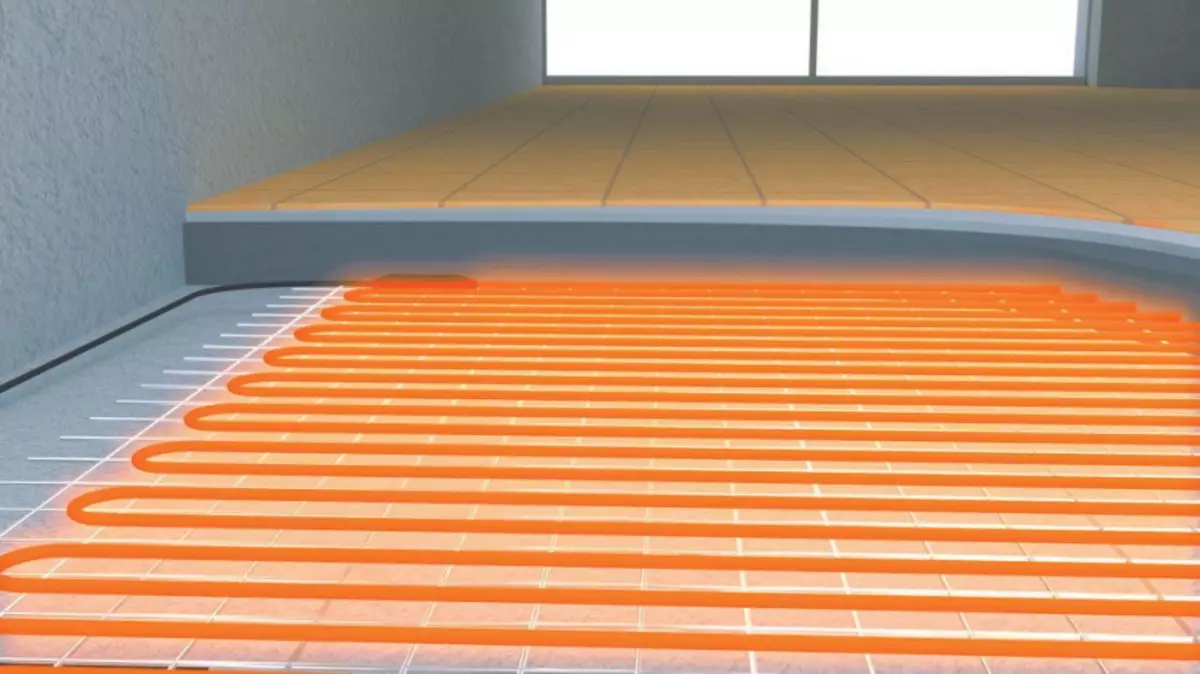

Amanzi afudumele amanzi

Izitezi zamanzi zimbozwe ngosimende screed futhi azifudumele

Izitezi zamanzi ziwuhlelo lwamapayipi axhunywe kwi-boiler yegesi ngokusebenzisa iyunithi leqoqo. I-boiler ngokusebenza kwamanzi ashisayo "yenza" phansi phansi kuyancela.

Amapayipi wohlelo lwamanzi asetshenziswa kusuka ku-polyethylene eqinile, i-polyurethane, i-metalplatic nethusi. Amapayipi enziwe nge-polyethylene eqinile esebenzisa ukuthandwa okukhulu kakhulu. Imikhiqizo yePolyurethane idinga ukufakwa kwemishini ekhethekile yokufaka i-welding.

Amapayipi e-COPPER amahle kakhulu wezimpawu ezisezingeni. Ngasikhathi sinye, lawo ngamapayipi abiza kakhulu.

Izitezi zamanzi ezifudumele zifihliwe ngosimende. Isikhathi esingakanani sembozo esisemuva sizofudumeza, ikakhulukazi kuncike ekuqineni kwesikhundla sikasimende. Amapayipi amaphakethe afudumele avame ukusetshenziswa nobubanzi be-16 mm. Usayizi onjalo oqinisekiswa isipiliyoni sokusebenza esinqwabelene kunqunywa ngesisekelo sokubala ubunjiniyela bokushisa.

Ngokushesha yonke imfudumalo iqala ukunikeza ipayipi lethusi

Ngokusebenzisa i-Node Collector Mede yamanzi ashisayo, inani elithile lemibuthano yokushisa etholakala emakamelweni amaningana afudumele.

Isihloko ngesihloko: umehluko wamawindi epulasitiki

Onjiniyela bokushisa bancoma ukwenza ubude be-1st contour ecishe ibe ngu-70 m ngewayimitha yamapayipi ayi-16 mm. Ukuphakama kwe-screen kwelulekwe ukuthi kwenziwe kungabi ngaphezu kwe-50 mm. Kulokhu, ukushuba kwesikrini phezu kwamapayipi abunjiwe kuzoba ngu-30 mm.

Izinga lokushisa elidingekayo ngeke likhuphuke ngaphambi kwengxenye yosuku

Kushisa kangakanani kufudumele okufudumele ekufakweni kokuqala ngaphansi kwezimo ezinjalo?

Ukuzilolonga kukhombisa ukuthi isikhathi sokushisa sesitezi esifudumele ngokujika kokuqala singagcina kusuka emahoreni ayi-12 kuye kwezinsuku eziyi-12.

Kulokhu, amanzi avela ku-boiler ashintshelwa amazinga okushisa angama-90 ° C.

Ngemuva kokuthi phansi kufudunyezwa, izinga lokushisa lokuqala le-coolant lincishiswa libe ngu-70 ° C.

Uma isitezi sifudumele isikhathi eside, khona-ke isizathu kufanele sifunwe ekufakweni okungalungile futhi sixhuma amasekethe okushisa noma imishini ifakiwe ne-screen "eluhlaza".

Phansi kwekhebula

Amakamelo ekhebula afudumele ngokushesha futhi apholile kancane kancane

Ukubekwa kwamakhebula kwenziwa ngendlela yokuvunguza nenyoka. Ukwakheka kwe-helix kusetshenziswa ezindaweni ezincane (kufika ku-20 m2). Ezisekelweni ezinkulu, ikhebula lihlelwe ngesimo senyoka.

Into yokushisa kagesi ishisa ngokushesha futhi iqale ukunika ukushisa emzimbeni wephansi. Ubukhulu be-screece 70 mm futhi buzokhulisa kakhulu ukugcwala kokhonkolo. UPawulu kuleli cala, kuzoshisa isikhathi esingakanani, kupholile kancane. Ngasikhathi sinye, ukusetshenziswa kukagesi kuzokhuphuka kakhulu.

Ngokushisa kokuqala, kuyadingeka kusuka emahoreni ayi-6 kuye kwayi-8

Mangaki phansi okufudumele okufudumele lapho ikhebula livulwa kuqala, ikakhulukazi lincike emandleni ocingo.

Ngokufakwa okulungile kokushisa kukagesi nokuhambisana namazinga wokwakha lapho ubeka isiketi, isikhathi sokufudumala kokuqala kwesisekelo segumbi singasukela emahoreni ayi-6 kuye kwayi-8.

Lapho ikhebula libekwa limbozwe nge-bitumen coating mastic mastic, ngaphansi kwesendlalelo se-cellarics, isikhathi sokushisa sendawo yaphansi sincishiswa kakhulu.

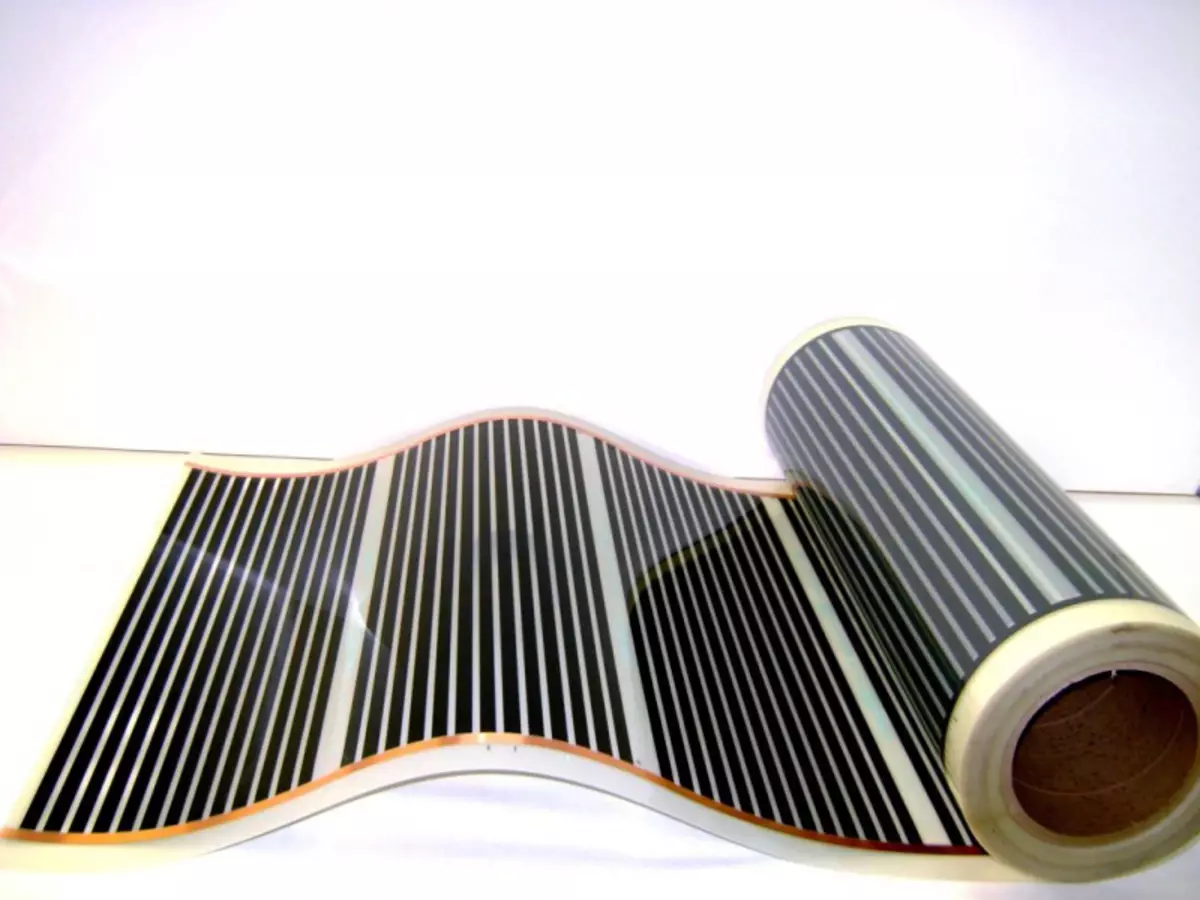

Ifilimu Effared Heating

Ukushisa Ngemuva kokufakwa kokuqala kwenzeka ngemuva kwamahora ama-2 - 3

Isigaba: Izici zabameli be-chip

Ukunakwa okuningi kwabathengi kwaheha izitezi ezithambile zefilimu. Ku-polymer ungqimba lwefilimu, i-electrode mesh, okuyinto, ngaphansi kwethonya lamanje kagesi, imisebe yokushisa ehlelweni olungenhla.

Abantu abaningi banentshisekelo yokuthi isembozo saphansi sisuka e-IR Film sishisa ngokushesha. Akunakwenzeka ukuphendula lo mbuzo. Konke kuncike endaweni yokuhlanganiswa, izinkomba zobuchwepheshe zefilimu ye-IR, indlela yokubeka uhlelo lokuxhuma kwinethiwekhi kagesi. Kepha umuntu angaphikisana nokuthi lapho, lapho kwafuthelwa khona phansi ngaphansi kwe-IR Coating, isikhathi sokushisa sokuqala kwakungu-2 - 3 amahora.

Ngenxa yezici zayo ezakhayo, izimbobo ze-IR zifakwa kalula futhi zishesha ngaphansi kwanoma isiphi isimbozo sangaphansi, ngaphezu kwamathayili e-ceramic. I-Express iyithuluzi lokufudumeza le-IR ngaphansi kwethayela. Ngemininingwane engaphezulu ngokuxhuma nokushisa, bheka le vidiyo:

Isibonelo sedivayisi yokufudumala kwe-IR ngaphansi kwe-laminate Parquet

Idivaysi yesitezi esifudumele yalolu hlobo iqukethe izigaba eziningana:

- Esisekelweni esiqediwe phansi, isithiyo sensimbi yensimbi emfisweni obukhulu be-polyethylene.

- Ngemuva kwalokho faka ukufakwa okushisayo okuvela kumapuleti we-polyurethane, amagwebu noma kwezinye izinto ezifanayo.

- Kwezinye izimo, ukufakwa kwe-thermal kumbozwe ngesendlalelo se-mastic ye-bituminous coatic mastic.

- Ngaphezulu kwesendlalelo sokufakwa kwe-mastic noma okushisayo, i-foil substrate yi-foil substrate, ebekwe indawo ebonakalayo ekhomba phezulu.

- Rolls IR amafilimu agoqwa phezu kobuso be-substrate. Izingcezwana zezimbali ze-IR zihlanganiswe neziqeshana zokuxhumana.

- Faka inzwa ye-Thermal.

- Xhuma i-IR Feting kugridi yamandla ngokusebenzisa iyunithi yokulawula efakwe isibonisi.

- Izivivinyo. Ukutholwa okutholakele kuqeda. Ukuhlola ukuphinda.

- Kusuka phezulu, izimbobo ze-IR zisakaza i-substrate ethambile.

- I-Parquet kusuka ku-laminate ibekwe kwi-substrate. Ukufakwa okuningiliziwe kwefilimu phansi kungabukwa kule vidiyo:

Sizobonisa amatafula etafuleni. Isikhathi sidinga ukufudumeza okugcwele phansi okufudumele ngesikhathi sokuvula kuqala:

| № | Uhlelo lokushisa lweGala | Isikhathi sokushisa okugcwele |

|---|---|---|

| okukodwa | Amanzi afudumele amanzi | Amahora ayi-12 nokuningi |

| 2. | Ukushisa Cable | 6 - 8 amahora |

| 3. | I-IR Combongs yefilimu | 2 - 3 amahora |

Isihloko ngesihloko: Imishini yokuwasha uswidi nokungasebenzi kahle

Izici zokushisa phansi lapho uqala ukuvula

Lapho izinga lokushisa elidingekayo lifinyelelwa, izitezi ezifudumele zisekela ukushisa okuncane okudingekayo ukuze uzilondoloze.

Kungani ukugcizelelwa kwenkulumo ethi "Ukuqala Kokuqala"? Impendulo yalo mbuzo ilula. Lapho uhlelo olufudumele lwaphansi lufudunyezwa ezingeni lokushisa elifunekayo, isisekelo sesisekelo asicishiwe ngokuphelele, futhi sisekele izinga eliphansi lokushisa.

Lokhu kwenziwa ukuze kufinyelelwe ezingeni eliphezulu lokufudumala phansi nganoma yisiphi isikhathi ngesikhathi esifushane.

Ukujika kokuqala kokufudumele kudinga izindleko eziningi zamandla ukwedlula ukusebenza. Ngenxa yalokho, kuzothatha isikhathi esiningi. Amandla okwengeziwe nesikhathi adingekayo ukunqoba ukugcwala kwesihlahla.

Kufanele kuqashelwe ukuthi ngokushisa kwe-IR, inkinga yokunqoba ukugcwala kwesakhiwo sendawo ayikho.