Ku-Welding kagesi yokushisa insimbi, kusetshenziswa i-arc kagesi. Kwenzeka phakathi kwemininingwane kanye ne-electrode - umnyombo kusuka kwinsimbi esebenzayo (kwesinye isikhathi kusuka ku-non-ngensimbi). I-Metal ifakwe emazingeni okushisa we-arc. I-Zone of Fusion endaweni yezingxenye ibizwa nge-welded (welding) seam. Ngezinsimbi ezahlukahlukene nezinhlobo ezahlukene zezinhlanganisela, inqubo ye-welding, isikhundla se-electrode, ijubane lokuhamba kwalo, amplitude lingashintshwa. Ungawupheka kanjani umthungo, ukuze ukuxhumana kungathembeki kuphela, kodwa futhi kube kuhle, ake sixoxe.

Izinhlobo zama-welds nokuxhumeka

Umthungo unokuhlukaniswa okubanzi kahle. Okokuqala, ahlukaniswe ngohlobo lokwenza. Ngokuya ngezidingo zokwethenjwa, umthungo ungaqoqwa ngenhlangothi eyodwa noma zombili. Ngokushiswa kwezinhlangothi ezimbili, ukwakheka kutholakala okuthembekile futhi kungcono kugcina ifomu. Uma umthungo owodwa uvame ukuvela ukuthi umkhiqizo uphonswe ngu: suture "Dons." Uma kukhona ezimbili zazo, la mabutho ayanxeshezelwa.

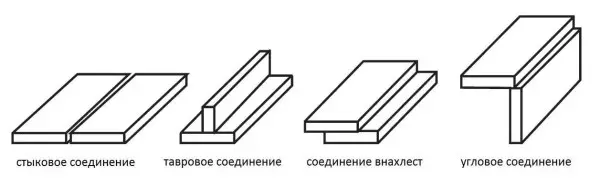

I-Welded Seams kuya ngohlobo lokuxhumanisa kukhona i-butt (online), uhlobo lomkhiqizo, ukubhidliza kanye ne-angular (ukusondeza ngosayizi, chofoza ku-IT REAM MOUM)

Kuyaphazamiseka ukuqaphela ukuthi ukuthola i-welvel esezingeni eliphakeme, insimbi akufanele ibe rusty. Ngoba izindawo ze-welding ziyi-pre-soda noma ziphathwe ngefayela - kuze kube yilapho ukugqwala kunyamalala ngokuphelele. Okulandelayo, ngokuya ngezidingo, okungahleliwe noma hhayi onqenqemeni.

I-Butt Compound (seam-jack)

Umthungo ku-welding usetshenziswa lapho uxhuma insimbi yensimbi noma amashubhu. Lezi zingxenye zibekwe ukuze phakathi kwazo kwakuyigebe le-1-2 mm, uma kungenzeka, zilungiswe kanzima ngama-clamps. Enqubweni yokufudumala, igebe ligcwele insimbi encibilikisiwe.

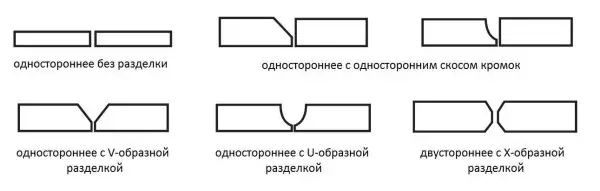

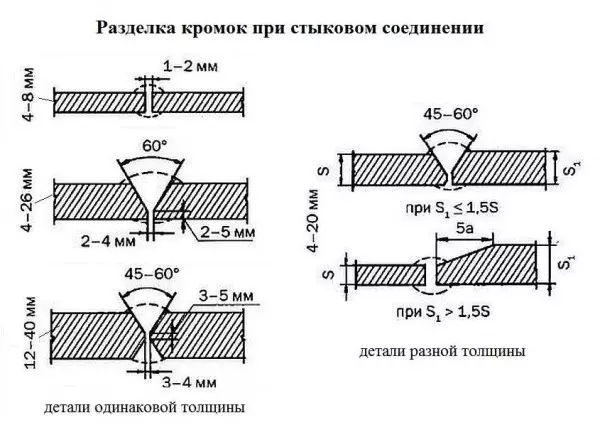

Insimbi eshidi elincanyana - kuze kufike ku-4 mm ubukhulu ngaphandle kokulungiselela kwangaphambilini (ukujikijela okuhlunga akubaliwe, kuphoqelekile). Kulokhu, ubilise kuphela ngakolunye uhlangothi. Ngobukhulu bezingxenye ezivela ku-4 mm, umthungo ungashabalala noma uphindwe kabili, kepha uphawu lonqenqema ludingwa yinye yezindlela ezethulwe esithombeni.

Izinhlobo zokulungiswa kwezingxenye lapho i-welding

- Ngobukhulu bengxenye kusuka ku-4 mm kuya ku-12 mm, umthungo ungashadile. Lapho-ke imiphetho ihlanjululwa nganoma iyiphi yezindlela. Kuyinto elula kakhulu ngobukhulu obufinyelela ku-10 mm ukwenza ukulungiswa okunecala elilodwa, futhi izingxenye ezinkulu zihlanzwe kaningi ngendlela yencwadi v. I-Stripper iyinkimbinkimbi ngokwengeziwe ekubulaweni, ngakho-ke ayijwayelekile. Uma izidingo zekhwalithi ziphakanyiswe, zinobukhulu obungaphezu kuka-6 mm, kuyadingeka ukugqagqana zombili izinhlangothi kanye nomthungo ophindwe kabili ngenye nangako.

- Lapho insimbi ye-welding enobukhulu obungu-12 mm, umthungo ophindwe kabili uyadingeka ngokunembile, akunakwenzeka ukufudumeza ungqimba olunjalo ohlangothini olulodwa. Ukuqothuka imiphetho kuhlaselwe kabili, ngesimo sencwadi X. Sebenzisa i-v noma imiphetho ebunjiwe ka-v noma imiphetho yemiphetho akusizi ngalutho: ukuze ugcwalise kuthatha ama-Metal amaningi. Ngenxa yokuthi ukusetshenziswa kwe-electrodes kwanda futhi ijubane le-welding lincishiswa kakhulu.

Ukusika imiphetho yensimbi lapho kuxhuma imininingwane yesethi ye-inthanethi (ukusondeza ngosayizi wesithombe, chofoza kuyo igundane elibalulekile)

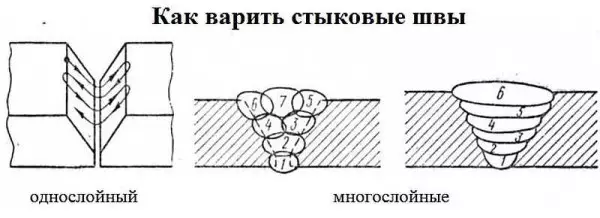

Uma ngabe usaxazululwa insimbi yobukhulu obukhulu ukupheka ngokusika okuhlangene, ukugcwalisa umthungo kuzodingeka kube kumavesi amaningana. Ama-seds anjalo abizwa ngokuthi abekwe kabusha. Njengoba kulokhu, ukulungiswa komthungo kuboniswa esikrinini esingezansi (izinombolo zikhonjiswa ngokubeka izingqimba zensimbi nge-welding).

Mayelana nokushiswa komshini omncane wensimbi we-walter inverter lapha.

Ungapheka kanjani i-butt seam: ungqimba olulodwa kanye ne-multi-ungqimba (ukusondeza ngosayizi wesithombe, chofoza ku-Right Key Mouse)

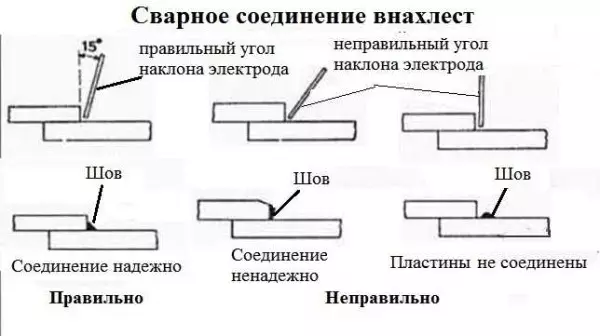

Ukuxhumana kwe-Vangest

Lolu hlobo lweCompund lusetshenziswa lapho ishidi le-welding shidi lensimbi elinobukhulu obufinyelela ku-8 mm. Ubilise nhlangothi zombili, ukuze kungabikho umswakama phakathi kwamashidi futhi kwakungekho ukuthuthuka.

Isihloko ngesihloko: Ungalisebenzisa Kanjani ukhonkolo we-Foam - Ubuchwepheshe bokusebenzisa udaka ezindongeni zikakhonkolo we-foam

Lapho wenza umthungo wamadevu, udinga ukukhetha i-electrode inclenge engela kahle. Kumele kube ngu-15-45 °. Ngemuva kwalokho kuvela ukuxhumana okuthembekile. Ngokuphambuka endaweni eyodwa noma ngakolunye uhlangothi, inqwaba yensimbi ebilisiwe ayikho emhlanganweni, kodwa ohlangothini, amandla okuxhuma ancishiswa kakhulu noma izingxenye zihlala zixhunyiwe kakhulu.

Ungayigcina kanjani i-electrode lapho i-welding idevu (ukukhulisa usayizi wesithombe, chofoza ku-Right Key Mouse)

I-Taurus ne-angular uxhumano

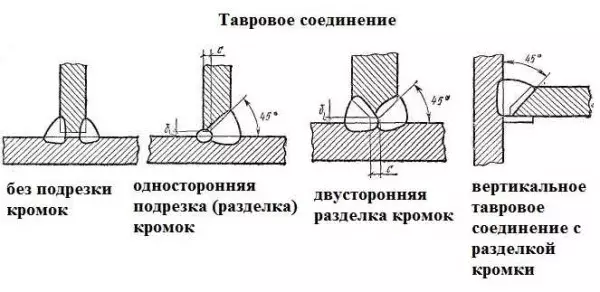

Ukuxhumeka komkhiqizo ku-welding yincwadi "T", ekhoneni - incwadi "g". I-brand compound ingaba nomthungo owodwa noma amabili. Imiphetho nayo ingahlukaniswa noma cha. Isidingo sokusika umphetho kuncike ekukhulumeni kwezingxenye ze-welded nenombolo yemisipha:

- ubukhulu bensimbi bufika ku-4 mm, umthungo nglokho - ngaphandle kokwelashwa;

- Ukushuba kusuka ku-4 mm kuya ku-8 mm - ngaphandle kokucubungula imiphetho ye-seam kabili;

- kusuka ku-4 mm kuya ku-12 mm - umthungo owodwa ngokusika ohlangothini olulodwa;

- Kusuka ku-12 mm onqenqemeni lokuchitheka ezinhlangothini zombili, nomthungo wenza amabili nawo.

Izinhlobo zama-welds: I-Taurope Compound nge-Cutting (Trimming) Emaphethelweni futhi ngaphandle

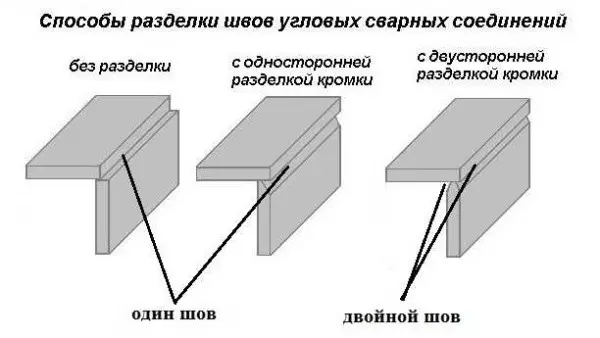

I-Corner Seams ingabukwa njengengxenye yomkhiqizo. Izincomo lapha ziyefana ncamashi: insimbi emincane ingahle ifakwe ngaphandle kokusika imiphetho, ngobukhulu obukhulu kufanele ubambe iqhaza kwinhlangothi eyodwa noma ezimbili.

Ungayilungiselela kanjani insimbi yokuxhuma kwe-angular (ngesibambiso esisodwa noma ezimbili)

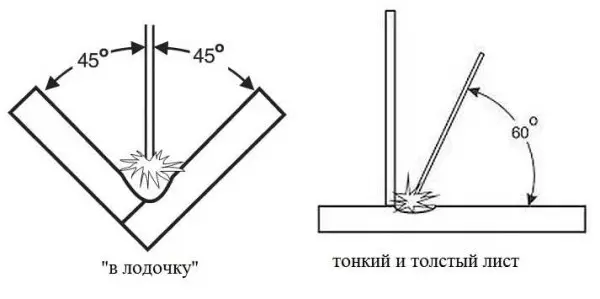

I-Corner and Brass Joints kwesinye isikhathi kufanele ubilise nhlangothi zombili (ama-seams amabili). Ukuze upheke kahle umthungo onjalo, izingxenye zijikeleza ukuze izindiza zensimbi zise-angle efanayo. Esithombeni, le ndlela isayiniwe "esikebheni". Kulula ukubala ukunyakaza kwe-electrode, ikakhulukazi okusha nge-welding.

Ungawupheka kanjani umthungo: "Ngesikebhe" nalapho uxhuma izinsimbi zobukhulu obuhlukile

Lapho uxhuma insimbi emincane nenhle, i-angle yokuthambekela kwe-electrode kumele yehlukile - cishe i-60 ° kuya engxenyeni enkulu. Ngalesi sikhundla, iningi lokufudumeza kuzofanela libe phezu kwalo, insimbi emincane ayishisi, okungenzeka uma i-angle yokuthambekela ingu-45 °.

Ukushiswa kwama-seams ekhoneni

Lapho i-welding angular angular, kuyadingeka ukuqapha isikhundla nokunyakaza kwe-electrode. Kufanele ube nomthungo ngokugcwaliswa komfaniswano. Kulula ukukusebenzisa lokhu uma ubeka izinto zokufudumala "esikebheni", kepha lokhu akutholakali njalo.

Uma indiza engezansi inokuvundlile, imvamisa itholakale ukuthi endizeni ebheke mpo, kanye nasekoneni lensimbi, akwanele: liphansi. Lokhu kwenzeka uma phezulu kwe-engela i-electrode ingaphansi kwesikhathi sezindawo zayo eziseceleni. Ukuhamba kwesihloko se-electrode kumele kube umfaniswano. Isizathu sesibili sikhulu kakhulu ububanzi be-electrode, engavumeli ukuwela ngezansi bese ufudumeza indawo yokuhlangana.

Ukugwema ukubonakala kwalesi sici se-arc esivundlile (ephuzwini elithi "a"), ukuhambisa i-electrode endaweni ebheke phezulu, khona-ke ukunyakaza okuyindilinga kubuyisele endaweni. Lapho i-electrode ingaphezulu komngcele, ine-45 °, njengoba iqhubekela phambili, i-angle kancane iyancipha (isithombe esithombeni ngakwesobunxele), lapho kuqhubekela endaweni evundlile, kukhuphuka. Ngale ndlela, umthungo uzogcwala ngokulinganayo.

I-Corner Welding - Isikhundla nokunyakaza kwe-electrode

Lapho ukuxhumeka kwe-welding angular, ubuye ubheke nesikhathi sokuthola i-electrode kuwo wonke amaphuzu amathathu (ezinhlangothini nasenkabeni) okufanayo.

Mayelana nokukhetha ama-electrodes we-Inverter Welding Machines, funda lapha.

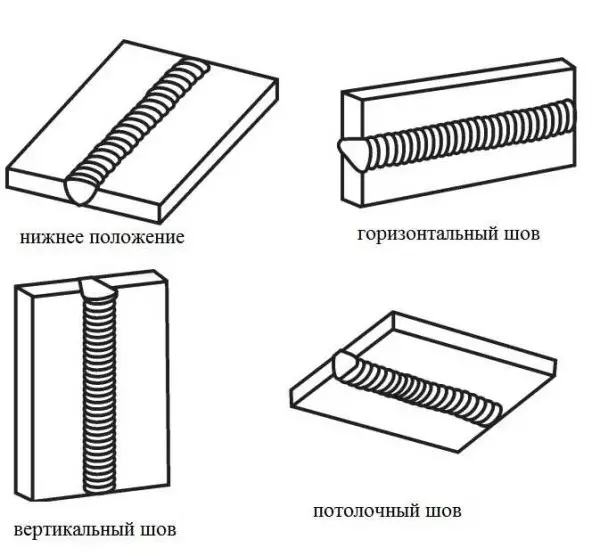

Isikhundla esikhaleni

Ngaphezu kwezinhlobo ezahlukene zezinhlanganisela, umthungo ungatholakala ngokuhlukile emkhathini. Zisesimweni esingezansi. Ngoba i-welder iyinto ekhululekile kunazo zonke. Kulula kakhulu ukulawula ukugeza okuhlaselwe. Zonke izikhundla zingezo izikhundla ezivundlile, zimile futhi zidinga ulwazi oluthile lwamasu we-welding (mayelana nokuthi ungapheka kanjani umthungo onjalo ngezansi).

Isihloko ngesihloko: Ungawaza kanjani izimpumputhe ze-aluminium

Izinhlobo zama-welds ezikhundleni esikhaleni: mpo ezivundlile, uphahla

Ungapheka kanjani ukuhlwanyela

Lapho u-welding esimweni esingezansi, abukho ubunzima benzeka ngisho naku-novice welder. Kepha zonke ezinye izinto zidinga ulwazi lobuchwepheshe. Ngesikhathi ngasinye kukhona izincomo. Inqubo yokwenza imishayo ye-weld yohlobo ngalunye ibhekwa ngezansi.Imisipha ye-Welding Vertical

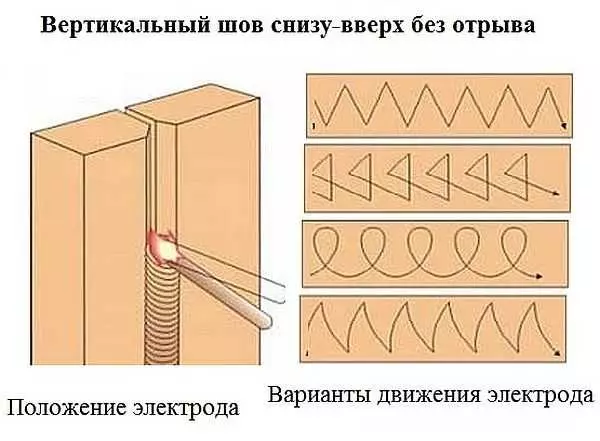

Ngesikhathi se-welding yezingxenye ezisesimweni esithe mpo, insimbi encibilikisiwe ngaphansi kwesenzo samandla adonsela phansi ihlele phansi. Ukuze ungaphuli, sebenzisa i-arc emfushane (ithiphu le-electrode liseduze nokugeza okuhlaselwe). Abanye abathakathi, uma ama-electrodes evumela (unganamatheli), ngokujwayelekile asuselwa entweni.

Ukulungiselela insimbi (ukusika okunqenqemeni) kwenziwa ngokuhambisana nohlobo lokuxhuma kanye nobukhulu bezingxenye ezifakwe izinsimbi. Ngemuva kwalokho bahlelwe endaweni ebekwe kusengaphambili, exhunywe ekukhuphukeni kwamasentimitha amaningana anama-seams amafushane aguqukayo - "iziqeshana". Lawa ma-seams awanikezi imininingwane yokususwa.

Imishini emile mpo ingaphekwa kusuka phezulu-phansi noma phansi-up. Kuyinto elula kakhulu ukusebenza kusuka phansi-up: ngakho-ke i-arc iphoqelela ukugeza okuhlanjululwe, ukuyivimbela phansi phansi. Kulula ukwenza umthungo osezingeni eliphakeme.

Ungapheka kanjani umthungo mpo kusuka ngezansi: Isikhundla se-electrode kanye nokunyakaza okungenzeka

Kule vidiyo, kukhonjiswa ukuthi ungapheka kanjani kahle umthungo mpo wokufudumala kagesi ngokuhamba kwe-electrode kusuka phansi-up ngaphandle kokuhlukana ngaphandle kokwehlukana ngaphandle kokwehlukana ngaphandle kokwehlukanisa. Indlela efushane ye-roller nayo ikhonjisiwe. Kulokhu, ukunyakaza kwe-electrode kwenzeka kuphela phezulu, ngaphandle kokufuduka okuvundlile, umthungo utholakale cishe eyisicaba.

Yenza ukuxhumana kwezingxenye endaweni ebheke phezulu ngokuhlukaniswa kwe-arc. Wabasaqalayo be-welders, kungaba lula ngokwengeziwe: Ngesikhathi sokwehlukana, i-Metal inesikhathi sokuphola. Ngale ndlela, ungachaza i-electrode eshalofini leWeldvic. Kulula. Uhlelo lokunyakaza lucishe lufane nangokuthi ngaphandle kokuhlukana: kusuka ngapha nangapha, izihibe noma "i-roller emfushane" - phezulu.

Ungawupheka kanjani umthungo mpo nge-margin, bheka ividiyo elandelayo. Esikhathini esifanayo sevidiyo, umphumela wamandla wamanje ngesimo somthungo uyakhonjiswa. Ngokuvamile, okwamanje kufanele kube ngu-5-10 ngaphansi okunconyelwe lolu hlobo lwe-electrode nobukhulu bensimbi. Kepha, njengoba kukhonjisiwe kuvidiyo, akuhlali kulungile futhi kunqunyelwe.

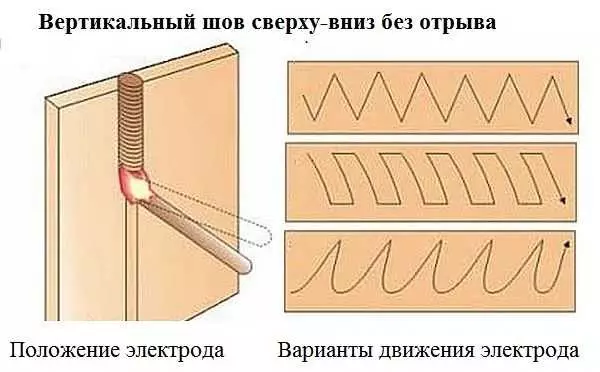

Kwesinye isikhathi umthungo mpo ubilisiwe phansi. Kulokhu, lapho i-arc ikhishwa, bamba i-electrode perpendicular ezinhlamvu zalo. Ngemuva kokulahla kulesi sikhundla, kufudule insimbi, bese wehlisa i-electrode bese ubilisa kakade kulesi sikhundla. I-Welding of the veam toam ephezulu-phansi ayilungele kakhulu, idinga ukulawula okuhle kokugeza okufakwe, kepha ngale ndlela ungathola imiphumela emihle.

Ungapheka kanjani i-vertical seam ugesi welding welding top-phansi: isikhundla se-electrode nokuhamba kwethiphu yakhe

Ungawupheka kanjani umthungo ovundlile

Umthungo ovundlile endizeni ethe mpo angaqhutshwa ngakwesokunxele nakwesobunxele nangakwesobunxele. Akukho mehluko, ukuthi kungcono kuye, upheka kangaka. Njengalapho beshelela umthungo mpo, ukugeza kuzokwela phansi. Ngoba i-angle yokuthambekela kwe-electrode inkulu ngokwanele. Kukhethwe ngokuya ngejubane lokunyakaza kanye namapharamitha akhona. Into esemqoka ukuthi ukugeza kuhlala endaweni.

I-Welding evundlile seams: isikhundla se-electrode nokunyakaza

Uma insimbi igeleza phansi, yandisa ijubane lokunyakaza, insimbi efudumeza kancane. Enye indlela ukwenza ukwahlukana kwe-arc. Ngalezi zikhala ezimfushane, i-wetal epholile kancane futhi ayigezi. Unganciphisa futhi amandla akhona. Zonke lezi zinyathelo kuphela ezisebenzisa izigaba, hhayi zonke ngasikhathi sinye.

Kuvidiyo, kuboniswa ngezansi ukuthi ungayivula kahle kanjani insimbi esesimweni esivundlile. Ingxenye yesibili ye-roller mayelana nemithungo emile mpo.

Uphahla lomthungo

Lolu hlobo lokuxhumeka kwe-welded luyinkimbinkimbi kakhulu. Dinga i-mastery ephezulu nokulawulwa okuhle kokugeza okuhlaselwe. Ukwenza lo mthungo, i-electrode ibamba ama-engeli angakwesokudla ophahleni. I-arc imfushane, ijubane lihlala njalo. Yenza ikakhulukazi ukunyakaza okujikelezayo, ukunwebisa umthungo.Ukuhlanza imicu ye-welded

Ngemuva kokufudumala ebusweni bensimbi, ama-splashes esikalini, amaconsi ensimbi kanye ne-slag kusala. Umthungo ngokwawo uvame ukukhipha, uvimbela ngaphezulu. Konke lokhu kungaqedwa lokhu: Hlanza.

Isihloko ngesihloko: Izici zokulungisa izingodo

Ukuhlunga imishini ngemuva kokushiswa kwe-welding yenza izigaba. Esigabeni sokuqala, ngosizo lwe-chisel kanye nesando kukhishwe esikalini kanye noSlag kusuka ebusweni. Ngokwesibili, uma kunesidingo, qhathanisa umthungo. Lapha udinga ithuluzi: IsiBulgaria sihlome ngediski yokugaya yensimbi. Kuya ngokuthi ingaphezulu kahle kangakanani ingabe kusetshenziswa okusanhlamvu okuhlukile.

Kwesinye isikhathi, lapho ama-welding epulasitiki izinsimbi zepulasitiki, kudingeka udaka - ukuhlanganiswa kwe-weld ngesendlalelo esincanyana se-tin molton.

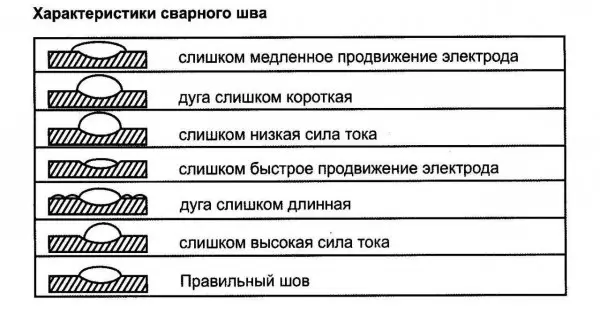

Iziphambeko ze-welded seams

Abaqalayo uWelders bavame ukwenzeka lapho benza umthungo kunamaphutha aholela ekubukekeni kweziphambeko. Ezinye zazo zibalulekile, ezinye - cha. Kunoma ikuphi, kubalulekile ukukwazi ukuthola iphutha ukuze ulilungise. Izinkinga ezivame kakhulu phakathi kwabasaqalayo ziwububanzi obungalingani bomthungo nokugcwaliswa kwaso okungafanele. Lokhu kungenxa yokunyakaza okungalingani kwethiphu ye-electrode, eshintsha ijubane nokuphakama kokunyakaza. Njengoba isipiliyoni siqongelela, lokhu ukushiyeka sekuba ngaphansi futhi kubonakale kancane, ngemuva kwesikhashana kuyanyamalala.

Amanye amaphutha - lapho ukhetha okwamanje nosayizi we-arc - kunganqunywa ngendlela yomthungo. Ngamazwi, kunzima ukuzichaza, kulula ukubonisa. Lesi sithombe esingezansi sibonisa iziphambeko eziphambili zesimo - isigatshana kanye nokugcwaliswa okungalingani, izizathu ezibangele zibekiwe.

Amaphutha angenzeka lapho kufakwa i-welding

Ukucwilisa

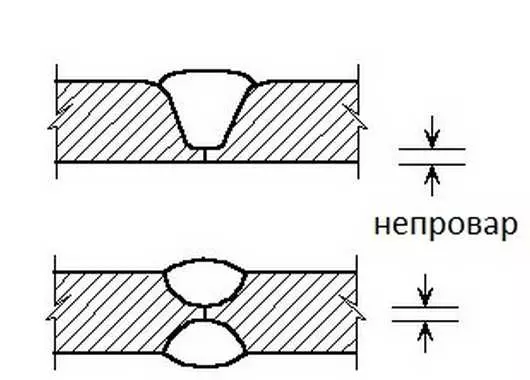

Elinye lamaphutha aqala ekuqaleni ama-welders: never

Lesi sici siqukethe ekugcwaliseni okungaphelele ukuhlanganiswa kwemininingwane. Lokhu kudonswa kwemali kufanele kulungiswe, njengoba kuthinta amandla okuxhuma. Izizathu eziphambili:

- I-Welding enganele yamanje;

- ijubane eliphezulu;

- Ukulungiselela onqenqemeni olunganele (lapho ama-welding izinsimbi ezinkulu).

Kuqedwe ngokulungisa amanje nokunciphisa ubude be-arc. Kufakwe kahle wonke amapharamitha, hlukana nento enjalo.

Mayelana nokukhetha umshini we-inverter welding wekhaya namakamelo afundwa lapha.

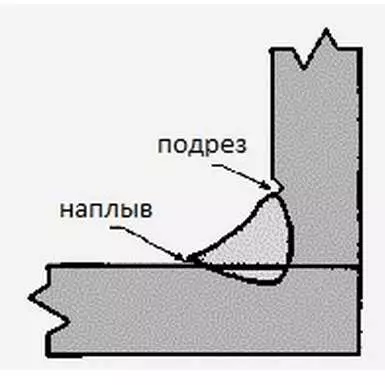

Subica

Lesi sici siyi-groove eceleni komthungo kwinsimbi. Kuvame ukuvela nge-arc ende. Umthungo ubanzi, izinga lokushisa le-arc lokufudumala akwanele. I-Metal ezungeze imiphetho iqhwa ngokushesha, yakha le grooves. "Iphathwe" nge-arc emfushane noma ukulungiswa kwamanje kwabaningi.

Ekhoneni ekhoneni

Ngekhompiyutha ye-angular noma yomkhiqizo, ukuguqulwa okungaphansi kwakhiwa ngenxa yokuthi i-electrode iqondiswe endizeni ebheke phezulu. Lapho-ke insimbi igeleza phansi, i-groove yakhiwa futhi, kepha ngesinye isizathu: ukufudumeza okuqinile kakhulu kwengxenye ebheke mpo yomthungo. Kuqedwe ukwehla kokuncipha kwamanje kanye / noma kwe-arc.

Ushikumba

Lokhu kudlula umgodi eWeld. Izizathu eziphambili:

- Alloy i-welding ephakeme yamanje;

- Ijubane elinganele;

- Igebe elikhulu kakhulu phakathi kwemiphetho.

Lokhu kubukeka njengomthungo womlilo lapho i-welding

Izindlela zokulungiswa zicacile - sizama ukukhetha imodi ye-Weld efanelekile nejubane le-electrode.

Pores kanye nokungena

Ama-pores abukeka njengezimbobo ezincane ezingahlelwa zibe yiqoqo noma zihlakazeke phezu kwazo wonke umthungo. Ziyisici esingamukeleki, sinciphisa kakhulu amandla endawo.

Kuvela ama-pores:

- Ngokuvikelwa okunganele kokugeza okufakwe ngenani elinenani elikhulu kakhulu lamagesi avikelayo (ama-electrodes asezingeni eliphansi);

- Okusalungiswa endaweni ye-welding, evimbela amagesi avikelayo nomoya-mpilo ekwehleni kwensimbi ebilisiwe;

- phambi kokungcoliswa nokugqwala kwensimbi;

- Imiphetho enganele yokusika.

Izilango zivela lapho i-welding inezintambo ezisontekile ngezindlela ezikhethiwe ngokungalungile namapharamitha we-welding. Ziyinsimbi ebabazekayo engaxhunyiwe engxenyeni eyinhloko.

Iziphambeko eziyisisekelo ze-welded Swiss

Imifantu ebandayo neshisayo

Imifantu eshisayo ivela kwinqubo yensimbi epholile. Ingaqondiswa kanye noma ngaphesheya komthungo. Kuvele kubanda sekuvele kumthungo obandayo ezimweni lapho umthwalo walolu hlobo lomthungo uphezulu kakhulu. Ukuqhekeka okubandayo kuholela ekubhujisweni kokuhlanganiswa kwe-welded. Lokhu kushiyeka kuphathwa kuphela nge-re-welding. Uma kukhona amaphutha amaningi kakhulu, umthungo usikiwe futhi ugoqe.

Ukuqhekeka okubandayo kuholela ekubhujisweni komkhiqizo

Inqubo ye-welding inverter ichazwa lapha.