I-Welding yensimbi Emnandi iyinkinga ngisho nakwamanye ama-welders anesipiliyoni. Wabasaqalayo kuma-welds ngokuvamile banzima. Ayikho yonke leyo mithetho ebekhona lapho imikhiqizo ebunjiwe ye-welding: kunezici eziningi nobunzima ngoba kunzima ukukhetha izindlela nama-electrodes. Kulula ukwenza lokhu nge-welding semi-othomathikhi, kepha ekufeni kwansuku zonke - into engavamile, ama-inverters ajwayelekile kakhulu. Lokho kumayelana nokushiswa kwe-inverter yensimbi emincane futhi kuzoxoxwa ngakho.

Futhi ubulukhuni bokuqala e-welding yensimbi yobukhulu obuncane ukuthi akunakwenzeka ukuyishisa futhi akunakwenzeka: kuvutha, kuvutha izimbobo. Ngakho-ke, basebenza ngokwesisekelo "okusheshayo, okungcono" nanoma yikuphi lokho okwenziwa yi-traveverories of the electrodes akwenzile jikelele. Insimbi yensimbi emincane ibilisiwe ngokuqhuba i-electrode endaweni eyodwa - eceleni komthungo ngaphandle kokuphambuka.

Lapho amashidi we-welding metal metal eseqile futhi agobe

Ubunzima besibili ukuthi kuyadingeka ukusebenza ngemisinga emincane, futhi lokhu kuholela eqinisweni lokuthi i-arc kufanele yenze amafushane. Ngokuwohloka okungasho lutho, uyaphuma nje. Izinkinga zingavela futhi nge-arc yokulahla, ngoba sebenzisa amadivaysi ane-Volt-Ampere acingweni (i-Idling Voltage ngenhla kwama-70 v) nokulungiswa okubushelelezi kwe-10 a.

Enye inkathazo: Ngokushisa okuqinile, ushintsho ejometry yamashidi amancanyana lushintshiwe: abiwe ngamagagasi. Kusukela kulokhu kuntuleka kuqeda kanzima. Okuwukuphela kwendlela ukuzama ukungakushisi noma kuthathe ukushisa (mayelana nendlela enama-gaskets okushisa okushisa afundwa ngezansi).

Lapho ufudumala i-jack yamashidi amancanyana ensimbi, imiphetho yawo iphathwa ngokucophelela futhi ihlanzwe. Ukuba khona kokungcola nokugqwala kuzokwenza ukushibilika kube yinkinga ngokwengeziwe. Ngakho-ke, hlangana ngokuphelele futhi uyihlanze. Banamashidi asondele kakhulu komunye komunye - ngaphandle kwegebe. Imininingwane ilungiswe ngama-clamp, ama-clamp namanye amadivayisi. Ngemuva kwalokho imininingwane ibanjwe njalo ama-seams amafushane we-7-10 cm - ama-patches. Ngeke bavumele imininingwane ukuthi ishise futhi amathuba abo amancane azosebenza.

Isihloko ngesihloko: Ungayenza kanjani insimbi yokuthengisa ngezandla zakho

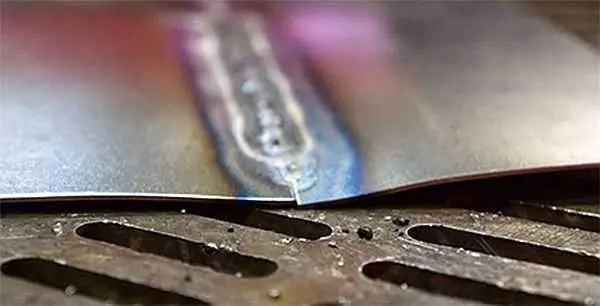

Uma ihlanza kahle imiphetho, kungahle kube nomthungo omuhle

Ungayipheka kanjani i-inverter yensimbi emincane

Imishini ye-Welding, ivelele evelele yamanje yokuthi singapheka ebukhosini obuhle. Ukuze wenze lokhu, xhuma ikhebula nomnikazi we-electrode, futhi "-" unamathela engxenyeni. Ngokuxhumana okunjalo, i-electrode inamafutha, futhi insimbi ifudumala kancane.

Ungayikhetha kanjani i-inverter ye-welding ekhaya noma amakhethini afunde lapha.

Ukupheka kuyadingeka kusetshenziswa ama-electrodes amancane: kusuka ku-1.5 mm kuya ku-2 mm. Ngasikhathi sinye, udinga ukukhetha ngokuncibilika okuphezulu: Bese ngisho nesibhamu esincane, kuzoba sekhwalithi ephezulu. Okwamanje kusethwe okuncane. Okwe-elektrodi ngosayizi ongu-1.5 mm, kufanele kube cishe ama-30-45 amps, for "TwoS" - 40-60 Amps. Beka ngempela kwesinye isikhathi ngezansi: Kubalulekile ukuthi ukwazi ukusebenza.

| Ubukhulu bensimbi, mm | 0.5 mm | 1.0 mm | 1.5 mm | 2.0 mm | 2,5 mm |

|---|---|---|---|---|---|

| Ububanzi bama-elekthroni, mm | 1.0 mm | 1.6 mm - 2 mm | 2 mm | 2.0 mm - 2.5 mm | 3 mm |

| Amandla akhona | 10-20 Ampipes | 30-35 ama-ampers | 35-45 mm | 50-65 mm | 65-100 mm |

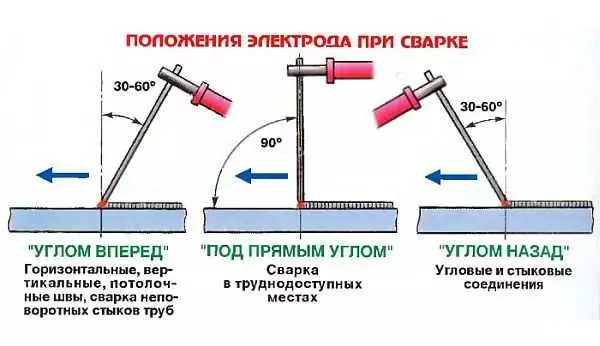

Ukuze i-Metal yensimbi ingafutheki kancane, imininingwane ifakwa mpo noma okungenani isiqondiso esithambekele. Bese ubilise ngaphezulu, uhambisa ithiphu le-electrode ngokuqinile kulokhu okuqondiwe (ngaphandle kokuphindisela futhi ungabuyi). I-angle yokuthambekela i-angle phambili, ngenkathi inani laso lingu-30-40 °. Ngakho-ke ukufudumala kwensimbi kuzoba mncane, futhi lokhu kungokwezinsimbi ezithambile ze-welding - enye yemisebenzi ebaluleke kakhulu.

Izikhundla ze-electrode ngesikhathi se-welding kanye nokusebenzisa kwazo

Ukuncoma okujwayelekile kokukhethwa kwama-electrodes ngezinsimbi ezithambile ze-welding: Thenga ama-electrodes asezingeni eliphakeme ngomsebenzi onjalo. Kuzoba nezinkinga ezingaphansi kwesinye isikhathi.

Mayelana nokwenziwa kwesigaxa ngohlaka lwensimbi Funda lapha.

Amasu nezindlela zokufudumala kwamashidi amancanyana ezinsimbi

Kwesinye isikhathi amashidi amancanyana adinga ukufakwa e-angle. Kulokhu, kulula kakhulu ukusebenzisa indlela yokugoqa: Imiphetho yeshidi yenqatshelwa ku-angle efiselekayo, qinisa ngama-seam amafushane aguqukayo njalo nge-5-10 cm. Ngemuva kokushiswa phezulu: umthungo oqhubekayo phezulu.

Ividiyo ikhombisa ukuthi ungapheka kanjani insimbi eshidi elincanyana nge-electrode ene-inverter ye-welding. Indlela yokushabalala isetshenziswa: Imiphetho yezingxenye iyanqatshwa, bese unamathela kuma-seam amafushane ezindaweni eziningana. Ngemuva kokuthi kukhona i-welding nge-electrode emincane enobukhulu be-2 mm.

Isihloko ngesihloko: amakhethini ohlangothini olulodwa ekhishini namakamelo okulala - ikhambi elifanele

Akukenzeki ngaso sonke isikhathi lapho ufudumele ngaphandle kokuhlukaniswa ukugwema umthwalo. Lapho-ke ungazama ukudiliza i-arc imizuzu embalwa, bese uphinda ushiye i-electrode endaweni efanayo futhi uyithuthukise amamilimitha ambalwa. Ngakho-ke, ancike futhi abuyise i-arc, apheke. Ngale ndlela, kuvela ukuthi insimbi ngesikhathi sokuhlukaniswa kwe-arc inesikhathi sokuphola. Kuvidiyo uzobona ukuthi umbala we-welding wendawo ushintsha kanjani ngemuva kokuthi i-electrode isusiwe. Into esemqoka akufanele inikeze insimbi ukuze iphole kakhulu.

I-welding yensimbi encanyana ehlukaniswe nge-arc ehlukanisayo i-arc ikhonjiswa engxenyeni yokuqala yevidiyo. Indlela ye-Docking iyinhlangano yamadevu (ingxenye eyodwa inqoba umzuzwana nge-1-3 cm), i-electrode ene-coatile coatinte (yensimbi yensimbi yesakhiwo nephansi) iyasetshenziswa. Lapho-ke i-welding yensimbi engenasici iboniswa nge-electrode engenasici ngenhlanganisela enkulu, nasekupheleni kwe-electrode efanayo kusuka ngensimbi engenasici, ukuhlanganiswa kwensimbi enobunzima. Umthungo, ngendlela, kwavela kangcono kunalapho usebenzisa ama-electrodes anconyiwe.

Ekukhetheni ama-electrodes wokufaka ama-inverter affatus, funda lapha.

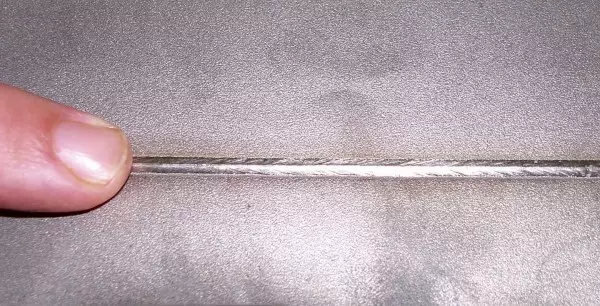

Uma ngesikhathi sokushiswa kwensimbi enhle akudingi ukwakhiwa komthungo oqhubekayo, sebenzisa ama-point seams. Ngale ndlela yokufudumala usayizi omncane weteyipu usekude nebanga elilodwa eduze kolunye. Le ndlela ibizwa ngokuthi umthungo we-Intermittent.

Kubukeka njengomthungo we-intermittent kwinsimbi emnene

Ngokuvamile, ubilise insimbi emincane ye-welding inzima. I-Vangest ilula: Imininingwane ayikabiywa futhi ayinawo amathuba amancane lapho konke kuzolunga. "

Funda ngezinhlobo zama-welds nokuxhumeka ukuze ufunde lapha.

Lapho i-welding kagesi yensimbi encanyana, i-jack ingenziwa phakathi kwamashidi ocingo oluncane onobubanzi obungu-2,5-3,5 mm (ungagibela ukumboza ama-electrodes alimele bese uwasebenzisa). Itholakala ukuze isebusweni baso ukuze idonswe ngaphandle kwensimbi, futhi ngokungavumeli kwenziwe cishe isigamu sobubanzi. Lapho i-welding i-arc ihola ngalolucingo. Kuthatha umthwalo oyinhloko we-thermal, futhi amashidi wensimbi we-weld afudunyezwa yimisinga ephelele. Ngasikhathi sinye, abangenzi ngokweqile, abavuni, umthungo uyisicaba, ngaphandle kwezimpawu zokushisa ngokweqile. Ngemuva kokususa ucingo, kunzima ukubheka iminonjana yalokho ayekhona.

Isihloko ngesihloko: Ukufakwa kweplastiki yeplastiki ophahleni ngezandla zakho

Ngakho-ke kubukeka njengomthungo lapho i-welding i-jack metal jack eboshwe ngocingo olushisayo

Enye indlela ukubeka amapuleti ethusi ngaphansi komngcele. I-Copper inokuphamba okuphezulu kakhulu okushisayo - izikhathi ezingama-7-8 eziphakeme kunaleso sensimbi. Ibekwe ngaphansi kwe-welding. Kuthatha ingxenye ebalulekile yokushisa, ukungavumeli ukugcwala ngokweqile kwensimbi. Le ndlela yezinsimbi ezithambile ze-welding ibizwa ngokuthi "ngama-linlings echibi lokushisa."

Ungayipheka kanjani i-gazebo kusuka ku-Metal. Funda lapha. Mhlawumbe uzoba nesifiso sokufunda ukuthi ungawenza kanjani umkhiqizo kusuka kusilinda segesi noma ngensimbi? Into iyadingeka futhi ukuthuthukiswa kwe-welding kufanelekile.

I-Welding Galvanovka

I-Steel ye-Galvanized yishidi elincanyana elifanayo, embozwe kuphela ngesendlalelo se-zinc. Uma udinga ukupheka, kuzodingeka ususe lokhu kuhlanganiswa emiphethweni yokufudumala, ukuze uhlanze insimbi. Kunezindlela eziningana. Owokuqala ukususa ngomshini: umbuthano oshubile kwi-grinder noma ukugaya, i-sandpaper kanye nensimbi egcwele. Kusenendlela - eshisa i-welding. Kulokhu, phinda udlule i-electrode edlula emthungo. Ngasikhathi sinye kukhona ukuhwamuka kwe-zinc (kuvele ku-900 ° C), futhi ngababili babuthi anobuthi kakhulu. Ngakho-ke ungasebenzisa le misebenzi kungaba emgwaqweni, noma uma kune-hood emsebenzini. Ngemuva kokudlula ngakunye, udinga ukudubula uFlux.

I-Welding Galvanized ingcono ukufeza ngaphandle: Ukufafaza uZinc kuyingozi kakhulu

Ngemuva kokususwa okuphelele kwe-zinc, i-welding ngokwayo iyaqala. Lapho amapayipi we-welding galvaning egayisele ukuthola umthungo omuhle, kuzoba nezindima ezimbili ezinama-electrodes ahlukile. Umthungo wokuqala ubilisiwe ngo-electrodes we-rutile coating, ngokwesibonelo, i-MP-3, ANO-4, OGSC-4. Ngasikhathi sinye, ama-oscillations ane-amplitude encane kakhulu. I-TOP Seam - ebheke ekwakhekeni. Icishe ilingane namadayimitha amathathu e-electrode. Kubalulekile ukuthi ungagijimeli futhi uzame ukuphendula kahle. Le ndima isetshenziswa yi-electrodes ngenhlanganisela enkulu (isibonelo, i-wiwi-13/55, i-wiwi-13/45, DSC-50).

Funda kabanzi ngokukhetha ama-electrodes we-inverter welding lapha.