Ukufakelwa okushisa okuphezulu okushisa okushisa kusetshenziselwa ukuvikela nokufaka amapayipi ama-boiler kanye nemishini ye-Steam, ukuhlinzekwa kwamanzi okushisayo, amasistimu wokufudumeza. Ngenxa yokwakheka okukhethekile kwamakhemikhali kwezinto zokushisa eziphakeme zokushisa okuphezulu, ukufakwa okunjalo kungasetshenziswa ezintweni ezishisayo zokufakwa okushisayo, amapayipi okushisa, ezinhlelo zokushisa, kanye nokuhlanganiswa namapayipi akhethekile wokuhlukaniswa kwama-benzo-, amapayipi kawoyela negesi lapho Ukusebenza ukuxhumana nemidiya enolaka. Ukumelana kwamazinga okushisa okuphezulu kuyikhwalithi ebaluleke kakhulu yezinto zokwenziwa kokushisa kokushisa.

Isikimu sokushisa ipayipi ekufakweni kwePPU.

Ukufakwa okushisa okuphezulu kwamapayipi: izici nezakhiwo zezinto zokwakha

Emakethe yanamuhla, ukukhethwa okukhulu kwemikhiqizo esebenza kahle nezinto zokwakha kuvezwa, kusetshenziswa ukuthi yikuphi ukufakwa kwamazinga okushisa okuphezulu kwamapayipi angenziwa. Isibonelo, imikhiqizo eyenziwe ngemicu ye-refractory, ukuhlanganisa ikhwalithi ye-refliacties futhi ihlukaniswe, ibe nobuningi obuncane, balula ekucutshungweni nasekufakweni. Imikhiqizo enjalo yenziwa kubuchwepheshe bezikweletu ngefomethi yePlate, amakhadibhodi, amabhlokhi kanye nezingxenye ezahlukahlukene zokucushwa okuyinkimbinkimbi. Ukushisa okukhawulelwe lapho kusetshenziswa khona ukushisa okushisa okushisa okuphezulu kwe-fibrous high kungu-1200-1300 ° C.

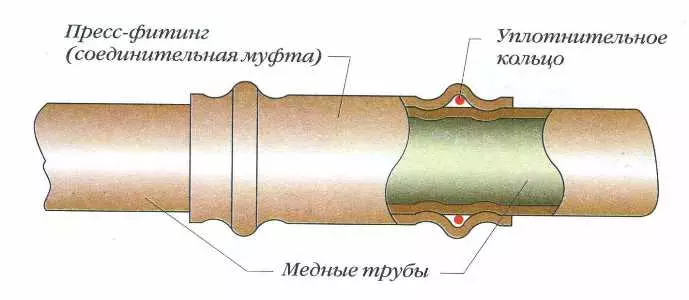

Umjikelezo wokuxhuma kwepayipi we-Copper.

Ngenxa yezimpawu zayo, ama-pibrous insulators of amazinga okushisa aphezulu angasetshenziselwa idivaysi yemiklamo ekhanyayo yama-apch aqoqeka. I-vault enjalo izokwenza ngasikhathi sinye imisebenzi ye-Heat Transfer Screen bese udlula. Ukufakwa kwamazinga okushisa okuphezulu kwalolu hlobo kufanelekile kuhhavini wesenzo sesikhathi, ngoba Obalangi be-fibrous bavame ukudlulisa imijikelezo yokushisa nokupholisa.

Ukufakwa okushisa okushisa okuphezulu kusetshenziswa ngempumelelo ebunjiniyela bemishini, i-metallurgy, ukwakhiwa (njengoba ama-flame retardant retardant ezindlini nasezakhiweni zezimboni), amandla nezindawo ezahlukahlukene lapho kunesidingo sokuvikelwa komlilo.

Ngaphezu kokusetshenziswa kwezimboni, izinhlelo zokusebenza emkhakheni wezomnotho kamasipala, kudivayisi yokufakwa kwezinsini okushisayo kwezinhlobo ezahlukahlukene zemishini namapayipi, ukwehlukaniswa kwamazinga okushisa okuphezulu nakho kusetshenziswa ngenkuthalo ekwakhiweni komhlaba okuphansi, kufaka phakathi ukuvikela umlilo wezakhiwo.

Ukufakelwa okushisa okuphezulu okushisa okuphezulu kuyinto enhle ebaluleke kuphela ukuvikela kuphela amapayipi ahlukahlukene, kepha futhi nokufakwa kwezindonga, ngaphezulu, ama-facades nophahla.

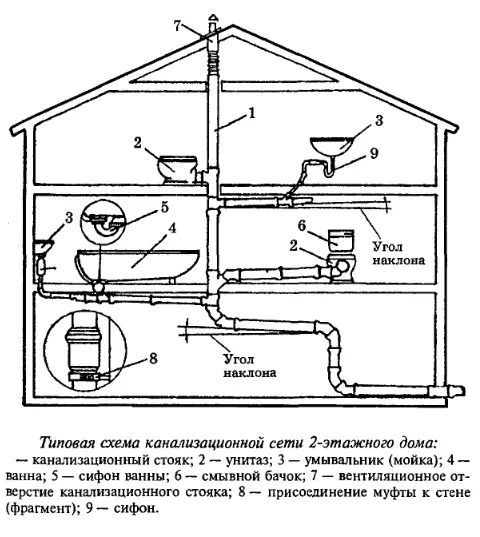

Isikimu senethiwekhi yendle,

Isihloko ngesihloko: Amakhethini ezindabeni zenze ngokwakho: Imithetho yokuthunga

Isixazululo esisebenza kahle kakhulu sokufakwa kwe-thermal kwezakhiwo "ezishisayo": ukomisa, amabhati, i-saunas - kuzoba nokufakwa okushisa okushisa okushisa, i-foil ngenhlanganisela ebonakalayo.

Ukudalwa kokusebenza kahle kakhulu futhi, kanye nalokhu, izinto zokuvikela izivikelo zemvelo zingenye yemisebenzi ebaluleke kakhulu embonini yezokwakha. AKUKHONA, okungalungile nokungafanele ukufakwa kwe-thermal kwezakhiwo zezimboni nezokuhlala kuholela ekulahlekelweni okufika ku-40-45% wemithombo yamandla ngonyaka. Ngaphezu kwalokho, imililo, njengoba imibukiso yokuzijwayeza, kuholela emiphumeleni emibi kakhulu. Ngakho-ke, kungokwemvelo ukuthi intuthuko entsha kule ndawo iyathakazelisa kusuka kochwepheshe nakuBAKAZI.

Ngokufakelwa, i-polyurethane Foam, i-basalt, i-polyethylene esetshenzisiwe. Indwangu ngayinye ingaba ngobukhulu obuhlukile, ama-diameter ahlukile. Endabeni yokubeka amapayipi emoyeni ukuze kufinyelelwe umphumela omkhulu wokufakelwa okushisayo, kungcono ukusebenzisa impahla ngenhlanganisela ye-aluminium, ngokwesibonelo, i-polyurethane Foam.

Amapayipi aphezulu okushisa okushisa okushisa okushisa okushisa okushisa okushisayo kwe-polyurethane Foam

I-Polyurethane Foam ibonakala ngezimfanelo ezingenakuqhathaniswa, futhi ukufakwa okushisayo kwamapayipi ahlukahlukene nokusetshenziswa kwayo kubonakaliswa ukumelana nokushisa okukhuphukayo. Ngenxa yezimpawu eziphakeme, ithokozela ithandwa kakhulu. Lokhu okuqukethwe kungavunyelwe, kunokuphamba okuphansi okushisayo, kuhlala isikhathi eside, kumelana nezinqubo zokubopha futhi akusekeli ukuhlanganiswa.Izinzuzo zalokhu okuqukethwe kokufakwa kwamapayipi okushisayo kusobala:

- Ngenxa yesakhiwo esihle, isebenza kahle kakhulu kunezinye izifaniso;

- ubuchwepheshe, ngoba Ukufakwa nokufakwa akudingi isikhathi esiningi, amathuluzi angeziwe akhethekile namakhono ochwepheshe;

- isimo semvelo sihlanzekile;

- Ingaphezulu le-Outer lokuqukethwe limbozwe nge-aluminium foil, ukwenza ukubukeka okuhle nokukhangayo.

I-Basalt High Temperature Irmal Insulaction

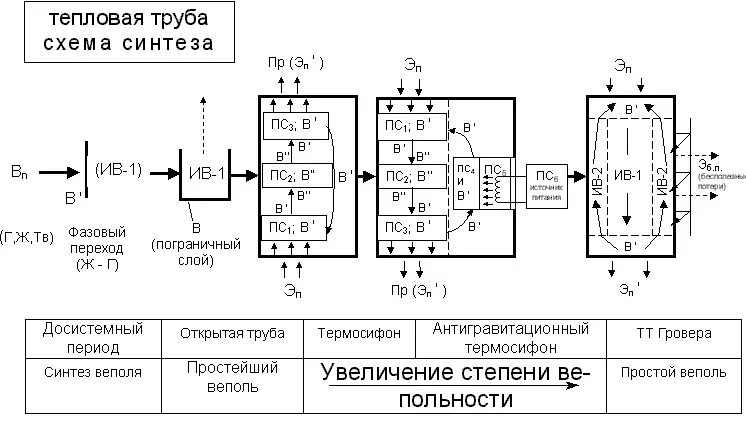

Synthesis wepayipi elishisayo.

Izinto zokufakwa kwe-basalt theralt thertal, izindleko ezincanyana, kungenye yezinto ezivame ukusetshenziswa kakhulu ekwakhiweni kwama-insulatorof angu-Fireproof.

Ama-Intertals we-Basalt Thermal asuselwa kuma-minvates angenye yezinto ezinobungane kakhulu zemvelo "ezihlanzekile" ezethulwe emakethe yanamuhla. Kunobubanzi obuhlukahlukene bemikhiqizo ehlukahlukene yokufakelwa kwe-basalt ngezimpawu ezahlukahlukene zobuchwepheshe ezinquma ukusetshenziswa kwalokhu okuqukethwe.

Isihloko ngesihloko: Ungabala kanjani amandla we-boiler ohlelweni lokushisa lwamanzi

Ngenxa yokusetshenziswa kwe-basalt njengesisekelo, lokhu kufakwa okushisa okushisa okuphezulu kunemininingwane efana nezakhiwo zezinto zomthombo. Okokuqala, lezi yizinkomba ezinhle kakhulu zokufakelwa kanye nokufakelwa komsindo. Okwesibili, kungamandla aphezulu, ngenxa yokuthi iminyaka eminingi yokusebenza, impahla yokufaka okushisayo ngesisekelo sama-basaltal agcina izimfanelo zayo zoqobo, ayifakwanga ukubekwa uphawu kanye nezinye izinhlobo zokukhanya.

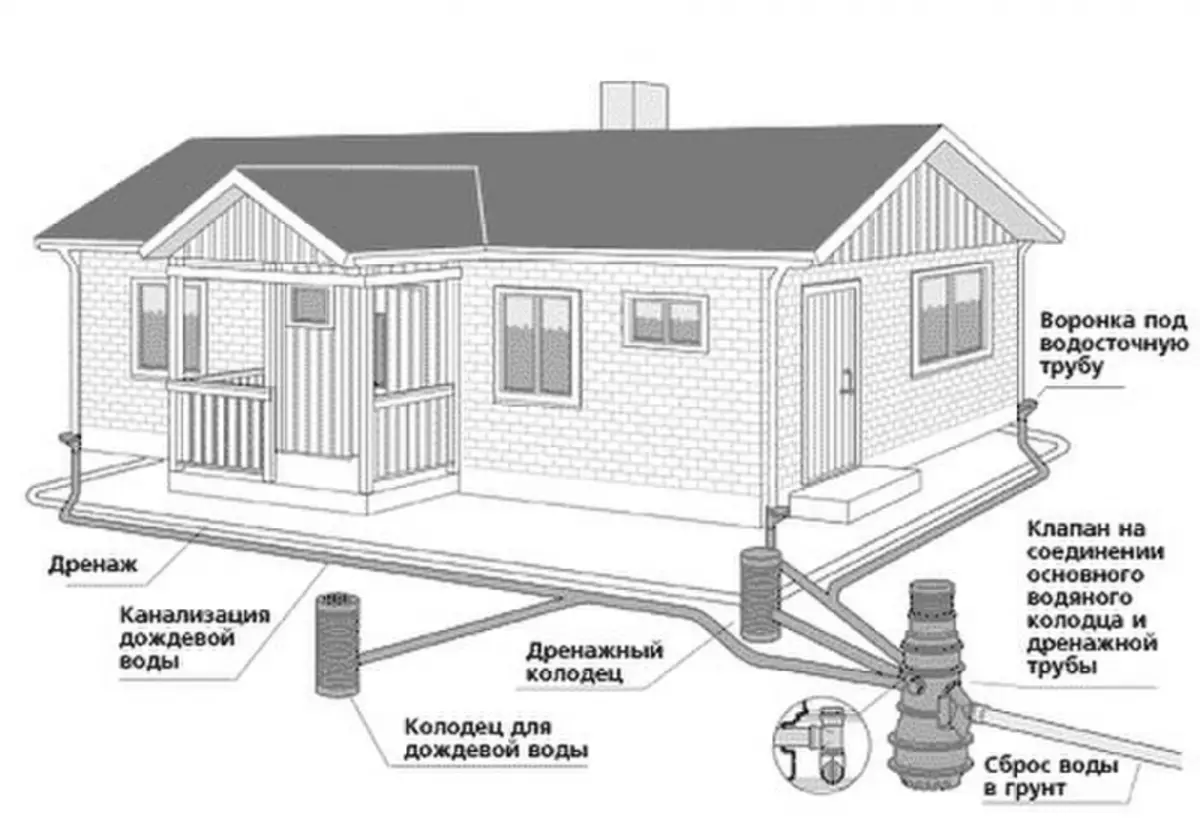

Uhlelo lwendlu yangaphandle yendle.

Enye, asikho isici esibaluleke kakhulu sezinto ezibonakalayo ukumelana nokushisa kwayo okuphezulu. Ukufakwa okunjalo okushisayo kubona umlilo ovulekile futhi kungasetshenziswa emazingeni okushisa afinyelela kuma-degree ayi-1000. Lapho ipayipi lidlula umthwali onamazinga okushisa aphezulu, futhi ukufakwa kwamapayipi okushisayo kuyadingeka, amapuleti e-basalt eba yisixazululo esifanelekile. Ukumelana nomlilo kwalezo zinto zokufakelwa kokufakwa okushisayo kuphakeme kangangokuba kusetshenziswa ngokusemthethweni njengokuvikelwa komlilo.

Enye yezimpawu ezibaluleke kakhulu ze-basalt thermal yokufakelwa kwezinto zokufaka i-hydrophobic. Amarekhodi aphezulu okubhekiswa kwe-vapor kwalokhu kufakwa kunikeza i-microclimate ethokomele nenempilo ekwakheni.

Okunye ukusebenziseka okungathandeki kwalokhu okuqukethwe amandla alo aphezulu. Ukwakheka kwemicu, etholakala ku-oda elinesiphithiphithi, kuvumela ukufakwa okufudumele okusekwe kokushisa kokumelana nemithwalo ngaphezulu kwesilinganiso esingenhla.

Ukufakwa kokushisa okushisa okuphezulu okushisayo kumapayipi

Ama-insulators amazinga okushisa aphezulu avele afakwe kumapayipi. Lungiselela amathuluzi nezinto zokwakha ezilandelayo:

- I-Foil Scotch;

- ukufakwa;

- Ukuhlanzeka okuhlanzekile;

- ummese.

Ngaphambi kokufaka amapayipi okushisa, udinga ukunamathela ethephani. Beka i-scotch eSpiral. Songa ukufakwa kwamazinga okushisa aphezulu azungeze ipayipi. Qiniseka ukuthi ama-seams axhumanisa ahlangana futhi alungiswe kahle.

Ngaphezu kwalokho, ngosizo lwetheyiphu ekhethekile (ungasebenzisa futhi nokuhlanzeka) Vikela impahla ekhethiwe yokufakelwa okushisayo kumapayipi. Sula kanzima ngangokunokwenzeka.

Into yokugcina ibaluleke kakhulu, ngoba uma kungenjalo amanzi aphansi angawela ezigabeni ezingenzeka, ezizoba nomthelela ongemuhle ekusebenzeni kwepayipi.

Isihloko ngesihloko: Iminyango yokufudumeza ene-canvas evuthayo futhi engahlosiwe ngezandla (ividiyo)