Ukulungiswa efulethini noma endlini yezwe kuqala ngokususa umsebenzi kanye nokulungiselela indawo yokuqeda ukuqeda. Enye yemisebenzi enzima kakhulu ukufaka esikhundleni saphansi. Isisekelo kunoma yiliphi igumbi kufanele sihlale isikhathi eside futhi sibushelelezi.

Ukushintsha phansi ngendlela efanelekile, kuyadingeka ukuba ube nomqondo wenqubo yomsebenzi kanye nezinto zokwakha ezingaba wusizo. Izitezi ezinhle nezithembekile ziyisisekelo esiphakeme sanoma iyiphi ifulethi noma indlu yangasese.

Izinhlobo zezitezi ezindlini nasezindlini

Izitezi zihlukaniswe ngezinhlobo zokugcwala nokuqeda phansi. I-Overlaps iyizinhlobo ezimbili zokhuni nokhonkolo, kepha indawo yokuqeda kungaba isethi enkulu.

Izinto eziphambili zokuqedela zangaphandle zifaka amathayili, i-laminate, i-linoleum, i-parquet, i-parquet, ekhaphethi, ukuphatha imikhiqizo eyenziwe ngokhuni lwemvelo nobuningi bezemvelo.

Okweqiwe ngokhuni kuvame kakhulu ezindlini zezwe

Izitezi zokhuni zisetshenziswa ikakhulukazi ekwakhiweni kwezindlu zezwe. Futhi, izinhlaka ezinjalo zingatholakala ezakhiweni zasefulethini zesakhiwo esidala sekhulu leminyaka elidlule.

Izitezi zokhonkolo zeMonolithic noma amapuleti ukhonkolo aqinisiwe asetshenziswa ekwakheni kwesimanjemanje kanye nokwakhiwa kwezindlu zangasese ezinezitezi ezimbili. Inqubo yokufaka esikhundleni sangaphansi esigabeni esisha esisezingeni eliphakeme kuncike kuhlobo lokugqagqana.

Enye into yezitezi ukusetshenziswa kokushisa okufakelwa, okubizwa ngokuthi yi-Flate Floor. Izinhlelo ezinjalo eziguqukayo zifakwe ngesikhathi sokulungiswa kwe-coating.

Ngaphambi kokuthi phansi kuguqulwe kube okusha, uhlelo lokufudumala oluguqukayo lukhethwe ukusebenza kahle kwamandla.

Ngokufakwa kwayo, izimo ezithile zenziwa. Ngemuva kokulungiswa, izitezi ezifudumele zingasetshenziswa njengomthombo oyinhloko wokushisa. Kwezinye izimo, akunakwenzeka ukukwenza ngaphandle kokusebenzisa ukufudumeza nama-radiator. Ezindaweni ezinjalo, izitezi ezifudumele nokufudumeza kungasebenza ndawonye noma ngokuhlukile.

Uhlobo ngalunye lokuqeda phansi kufanele lubekwe esitezi esibhalwe phansi esihambisanayo. Izinga lesisekelo esiyinhloko linqunywa kakhulu ngenxa yalokho.

Umsebenzi wokulungiselela

Uma ama-lags asevele eseqalile ukumodela, kungcono ukuwasusa kanye nenhlanganisela yakudala

Ekuqaleni, ukususwa kwesembozo esidala sekwenziwe. Ingaphezulu lihlanzwa ngokuphelele kwezinto zokuqeda ezenziwayo. Wonke udoti uphonswa kude.

Isihloko ngesihloko: Ungasithunga kanjani i-Phriza Curtain ngezandla zabo?

Uma isisekelo esivulekile esivulekile sisesimweni esihle, khona-ke singasindiswa noma silungiswe ngokwengxenye uma kungenjalo, kuyadingeka ukuyifaka esikhundleni.

Lapho amabhodi ezakhiwo zokhuni esesimweni esingafanele noma esikhishini sikasimende esekwe phezu kokhonkolo oqhekekile, khona-ke kuyasuswa izisekelo ezifanayo ezifanayo.

Ukubekwa kwamandla okufaka amanzi nokungena kwamanzi - izinyathelo ezibalulekile zokulungiswa phansi

Ukususa ukuhlanganiswa okusalungiswa emiklamo yokugqagqana, kufanele kuhlolwe ngokucophelela futhi kunqunywe isimo samanje. Ukulungiswa kokugqagqana - ukuguqulwa ngokweqile, okwenziwa ngokwephrojekthi yomuntu ngamunye othuthukisiwe. Ngemikhiqizo yokhuni, ukuhlanganiswa kufanele kuphathwe ngezingoma ezikhethekile ezivimbela ukubola, kanye nokhonkolo - ukuqeda ukungabi nalutho kanye nemifantu.

Ngasikhathi sinye, sebenza ku-hydro kanye nokufakwa okushisayo, kanye nokuvikela igumbi kusuka ku-Noise, okungenziwa lapho isitezi esimnyama siphezulu kophahla.

Umsebenzi wokulungiselela awuphothuli ngemuva kokususa phansi phansi. Isigaba esibalulekile sokulungiselela ukudala uhlelo lwamanje lomsebenzi nohlu lwezinto ezidingekayo.

Ukuhlela ukulungiswa phansi phansi

Ngaphambi kokulungisa, ukubala inani lezinto zokwakha ezidingekayo, lungiselela amathuluzi

Ukubalwa okulungile kwemisebenzi nezinto zokwakha kuyadingeka ukwenza izenzo ezilandelayo.

- Ukuchaza wonke amasayizi. Ngemuva kokususa impahla yakudala, ukugcwala kuzovulwa, ungabeka uphawu oluphansi olungaphezulu bese unquma ukuphakama lapho izitezi kuzofanele ziphakamise khona.

- Okulandelayo, ukwakheka okumile kwenziwa. Kwenziwa kusuka phezulu kuya phansi. Ukuze wenze lokhu, kuyadingeka ukunquma iphuzu eliphakeme kakhulu ekubhekeni, maqondana nokuthi izitezi ezintsha zizophakanyiswa zibe yimikhawulo ephansi, lapho udinga khona ungqimba lokuqeda phansi phansi. Ibanga elisele kuzoba ukuphakama kwesitezi esidingekayo esidingekayo. Ukwazi ukuphakama kwesitezi esisalungiswa, ungakhetha izingqimba ezifaka ukufakwa noma ucabangele ukuthi kungenzeka ukufaka uhlelo olufudumele lwaphansi. Njengomphumela wesakhiwo mpo, zonke izingqimba zesitezi esizayo kufanele zichazwe. Indima ebaluleke kakhulu kulesi sigaba sokuhlela izodlala ukuqokwa kwale ndawo, indawo yayo endlini kanye nezici ezengeziwe zesici.

- Ukunquma inani lezinto zokwakha kanye nemisebenzi. Kulesi sigaba, zonke izinto ezidingekayo zichazwa, kanye nezindleko zokulethwa kwazo endaweni yokukhiqiza. Ngokukhetha zonke izingqimba zesitezi esizayo, inani lezinto zokwakha kanye nezindleko zazo, ungaya lapho ufuna usonkontileka ukwenza umsebenzi noma usebenzise izinsizakalo zonjiniyela we-Intertar, ohlelweni olukhethekile onganquma izindleko zephansi Amadivayisi wesifunda isikhathi samanje sesikhathi.

- Ukudweba ubukhulu bokulethwa kwezinto zokwakha kanye nokwenza umsebenzi. Lolu hlelo kufanele lusize ngesikhathi sokulawula esichithwa nokuthengwa, futhi kulungiswa phansi.

Isihloko ngesihloko: Izindawo ezikhanyisiwe, ukubukeka okusha nokukhanya

Chitha ukuhlanza phansi ngokuphelele

Abaningi abanaki ukuhlela ukuhlela isigaba. Lokhu kuholela ekuqineni okubili. Kokunye, ukulungisa kufakwe inani elanele lezinto zokwakha, okuholela ekuwohlokeni kwekhwalithi yomsebenzi, noma izindleko ezingezekile zokuthengwa okungahlosiwe kwezinto.

Kwesinye isigameko, inani elibi lokuqukethwe noma ukuthengwa kwemikhiqizo eqinile futhi ebizayo kutholakala, ukusetshenziswa kwawo okungalungisisiwe. Izenzo ezinjalo ziholela nezindleko ezingalindelekile. Mayelana nokuthi ungahlela kanjani ukulungisa kahle, bheka le vidiyo:

Ukuntuleka kokuhlela kuholela ekwandeni kwezindleko zokulungiswa nesikhathi sokwenza umsebenzi wokulungisa uqobo.

Idivayisi kaChernob

Phakathi kwama-lags abeka ungqimba wokufakelwa

Ngokuya ngesakhiwo esikhethiwe esikhethiwe, ukwenziwa komsebenzi okwenziwe ngezigaba, okuqala ngokulungiswa ngokweqile.

Okulandelayo, ezakhiweni zokhuni, ukufakwa kwama-lag amade, ambozwe ngezinto zeshidi ezenziwe. Emakhonsi ukhonkolo athululela isisu. Uma umehluko wokuphakama ukhulu, khona-ke uma kunesidingo, kwenziwa i-screen ye-Welveling Cresed.

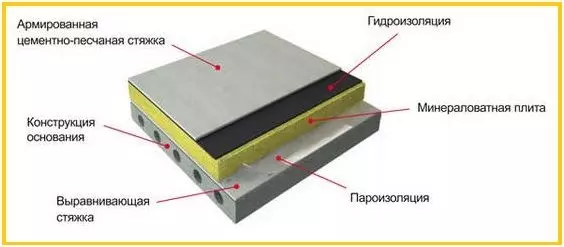

Phansi kokhonkolo ngeke kube yi-hydroling

Lapho kuqala ukusalungiswa kwenziwe ngokhuni oluvela phezulu, kubhekwa ungqimba lwamanzi. Ukufakwa okushisayo kulezi zinhlaka ezinjalo kwenziwa phakathi kwama-lags.

Imvamisa yenziwa ngoboya bezimbiwa phansi noma besebenzisa izinto eziningi ze-bulk. Isendlalelo esingezansi samanzi esishisayo siyadingeka ngokuya ngohlobo lwegumbi futhi lungafakwa ngaphambi kokubeka ama-lags lokhuni.

Ukwenza i-screed ekuqedeni kokhonkolo, ungakwenza ngaphandle kwesendlalelo esingenzi manzi. Uma ihlinzekelwe yiphrojekthi, ibekwa ngqo ngesisekelo uqobo ngaphambi kokuthululwa kwesitezi esisalungiswa.

Uboya obukhulu bamaminerali obukhulu noma ukufakwa okuqinile okusekelwe ku-polystyrene kusetshenziswa njengokufakelwa okushisayo. Ukuvimbela amanzi kwenziwa ngaphezulu koboya bezimbiwa, izinto ze-polystyrene zingabekwa ngaphandle kwesendlalelo esengeziwe sokuvikela.

Enye yezibonelo zothayela wesitezi ingabukwa emjondolo.

Isihloko ngesihloko: Ungayisebenzisa Kanjani I-Primer Plasterboard nokuthi Kungani Kudingeka

Uma uhlela idivaysi efudumele yaphansi, shiya kule ndawo.

Lapho isitezi esisalungiswa, ungashiya indawo ngaphansi kohlelo lokushisa lokufakelwa. Kulokhu, isisekelo sokuqala senziwa ngaphandle kokufakwa okwengeziwe. Umsebenzi oyinhloko wesisekelo esinjalo ukuphakamisa phansi phansi ekuphakameni okudingekayo.

Zonke izenzo ze-hydro nezokushisa zenziwa ngokwenziwa ngokwezidingo ezidinga ukwenziwa lapho zifaka uhlelo olufudumele lwaphansi. Ekupheleni kokufakwa kohlelo, kufanele kwenziwe ukuhlanganiswa okusalungiswa okuphezulu, kufanelekile ngokubeka impahla yaphansi yokuqeda. Funda kabanzi mayelana nokukhuphuka komhlaba okumnyama, bheka le vidiyo:

Ezinye izinhlelo zokufudumala okuguqukayo zikuvumela ukuthi wenze ngokushesha isendlalelo sokuqeda ngesimo se-laminate noma ama-bulk phansi.

Idivaysi ephelele ye-coating yangaphandle

Isibambiso esimnyama esimnyama - isibambiso sokushesha okusheshayo kokuqediwe ukunamathela

Ngemuva kokulungiselela, ukuhlela nedivaysi ye-Draft coating, imisebenzi yokuqeda kuzothatha isikhathi esincane. Ukubeka izinto zokuqeda endaweni ephansi kwenziwa ngokushesha futhi ngeke kube nzima kwi-wizard enhle.

Ama-Coatings anjalo njenge-laminate noma i-linoleum kungenziwa kungakapheli izinsuku eyodwa noma ezimbili. Izitezi ezizikhazimulayo zizophinde zihlanganyele ngasikhathi sinye, kodwa ukuhambahamba kuzofanela zilinde kuze kube yilapho zithola amandla. Amathayili we-Ceramic kanye ne-parquet kungathatha isikhathi eside ukufaka.

Izinhlobo ezintsha zezinto zokuqeda zikhishwa ngemiyalo kudivayisi yabo.

Kungenzeka ukuthi ngokuzimele yenza ukufakwa kwesembozo esiphansi sokuqeda ngokutadisha kahle inqubo yokufaka.

Izinto ezinjalo zifaka phansi kakhulu phansi.

Ukuze kukhiqizwe umsebenzi, imishini ebizayo ngeke idinge, futhi inqubo ngokwayo ilula.

Sebenza ngokuya ngemiyalo yokufaka kanye nendawo ebushelelezi efanelekile kufanele inikeze izimo ezifanele zokwakha indawo ephezulu yokuqeda.

Ukubuyisela indawo yakudala ye-New One kuzodinga hhayi ukutshalwa kwezimali kanye nezindleko zesikhathi. Lokhu kungumsebenzi osindayo owenele odinga ulwazi oluthile.

Kungenziwa ngokuzimela ngezandla zakho, kepha kungcono ukusebenzisa usizo olukhethekile. Uma kunecebo lesenzo elicacile, izindleko zingancishiswa.