Umkhakha hhayi kudala kangaka ukukhiqiza insimbi yensimbi. Amapayipi avela kulokhu okubonakalayo athandwa emkhakheni wokushisa kwezakhiwo zangasese nefulethini. Ukufakwa kohlelo lokushisa olunjalo kulula kakhulu futhi kungenziwa ngisho ne-non-professional.

Idivaysi yohlelo lokushisa kusuka kumapayipi epulasitiki alulalekile, kepha ukwazi yonke imiqondo ngalokhu kungaba ukubhekana ngaphandle kokuheha ochwepheshe ababizayo.

Ukukhetha uhlelo lokushisa

Kufanele kuphawulwe ngokushesha ukuthi uhlelo lokushisa lapho kusetshenziswa i-metalplastic kususelwa ezintweni ezahlukahlukene, njengendawo ye-boiler yokushisa, indawo yamakamelo nokunye okufanayo.

Enye indlela, ungazabela izimiso ezijwayelekile zokwakha izikimu zokushisa ezingahlukaniswa ngazo:

- Izikimu zeqoqo;

- ishubhu elilodwa noma amacebo amabili amapayipi;

- Amacebo aphezulu nangaphansi kwamapayipi.

Kunezinye izinhlobo zezikimu.

Kuyaqapheleka ukuthi ngezindlela eziningi uhlelo lokushisa luncike endaweni ye-boiler yegesi, uma kufika endlini yangasese enento eshisa.

Le nto ukuthi i-boiler yegesi ingafakwa kuphela ezimeni ezithile, okungukuthi, ngokuhambisana nazo zonke izidingo nokubamba wonke la mabanga ezintweni ezithile ngokuya ngemibhalo yezobuchwepheshe e-boiler.

Ngaphezu kwalokho, ngezindlela eziningi, uhlobo lohlelo lokushisa uhlelo lunquma ukuhlinzekwa kwamanzi kwamapayipi amanzi asendlini. Kukhona ezinye izinto.

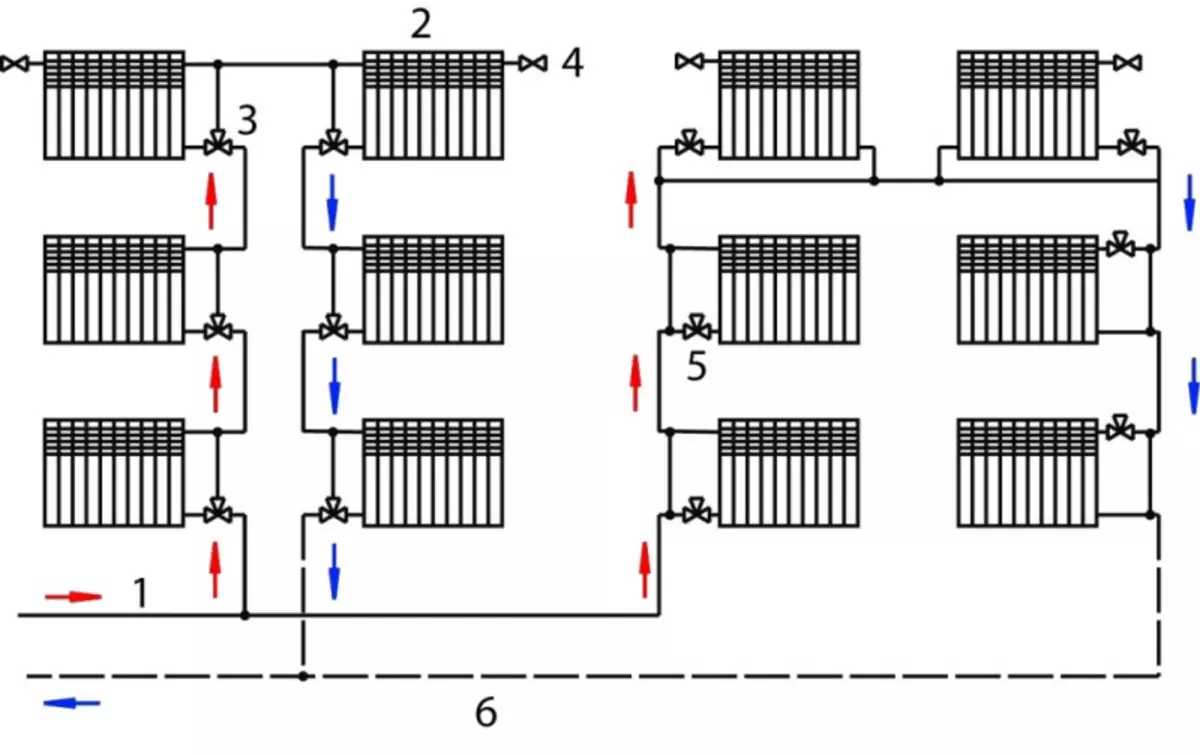

Isikimu sohlelo lokufudumeza lweshubhu esisodwa: 1 - Ukondla umugqa, 2 - Idivayisi yokufudumeza, 3 - I-Crane ye-Trane, 4 - Ukudla Komoya, 5 - Ukulawula isikulungisi,

Ngakho-ke, maqondana nohlobo oluthile lohlelo, ngamunye wabo angahlukaniswa zombili izikhathi ezinhle nokubi. Isibonelo, uhlelo lokufudumeza lweshubhu elilodwa kusuka ku-metalplastic luhle, kunalokho, ngoba indlu encane esetshenziswe njengokupha, lapho inani lama-radiator angeqi amayunithi ama-5.

Lokhu kungenxa yokuthi ngohlelo lweshubhu elilodwa, iredithi ngalinye elilandelayo lizoba namazinga amancane kunalolo langaphambili. Ngamanani amancane, izinga lokushisa lizobe licishe lifane, eline-radiator yokugcina alisoze lafudumala nhlobo.

Isihloko esihlokweni: Ukubalwa kwesikhuthazo seKhabhinethi kwenze ngokwakho - Uhlaka neminyango

Iphuzu elihle lohlelo olunjalo ukuthi inani lezinto ezibonakalayo ezichithwa lincane kakhulu kunanoma iziphi izikimu.

Ngokuqondene nohlelo lomqoqi, ludinga inani elikhulu kakhulu lezinto ezibonakalayo ezivela kuzo zonke izikimu ezikhona. Kodwa-ke, ukulungisa izinga lokushisa lokushisa lento ngayinye kulula kangangokuba kunxephezele kalula zonke izindleko. Ngaphezu kwalokho, ukusatshalaliswa kokushisa phakathi kwazo zonke izinto cishe kuphelele.

Okuthile okujwayelekile phakathi kwalezi zinhlelo ezimbili ezichazwe ngenhla uhlelo olufudumele lwamapayipi. Kudinga izindleko eziphakeme eziphakeme uma kuqhathaniswa ne-tube eyodwa, kepha ezincane - kuqhathaniswa nomqoqi.

Ukushisa ngokuya ngesikimu esinjalo kungaba ngesakhiwo esiphansi samapayipi nangaphezulu.

Ukufakwa kwama-radiator, ama-boiler egesi nezinye izinto zohlelo lokushisa

Ukufakwa kohlelo lokushisa, lapho kusetshenziswa khona insimbi ye-metalplastic, iqala ngokufakwa kwe-boiler, ama-radiator kanye nezinye izinto zohlobo oluthile lohlelo lokushisa.

Kuyaqapheleka ukuthi ukufakwa kwemishini yegesi kufanele kwenziwe kuphela ngabasebenzi abaqeqeshiwe abavela kwinkonzo efanele. Ukufakwa okuzimele kwe-boiler yegesi kungahle kube nomthwalo wemfanelo omkhulu.

Ama-radiator wensimbi-epulasitiki ahlala isikhathi eside futhi aqinile. Zihlukaniswa ngokudluliswa okukhulu kokushisa kanye nobungane bezemvelo.

Ngokuqondene nama-radiator okushisa avela epulasitiki yensimbi, angafakwa ngokuzimela. Ekuqaleni, izindawo zokuqinisa ama-radiator zikhethiwe. Zinamathiselwe ezindongeni zisebenzisa amabakaki akhethekile. Amabakaki, nawo anamathele ngqo ezindongeni usebenzisa ama-anchor bolts. Izimbobo ezindongeni zimiswe ngaphansi kwazo, bese i-BOLT ngokwayo iphuthunyiswe engxenyeni yangaphandle, ilungisa kahle ubakaki.

Uma sikhuluma ngemisebe yensimbi ye-cast-iron, khona-ke ngaso sonke isikhathi izigaba ezi-3 kubakaki kucatshangwa, kepha kungaphansi kwamabakaki amabili kuwo wonke ama-radiator akufanele abe.

Ngemuva kokufaka zonke izinhlobo zemishini, ngokwesibonelo, igeji yengcindezi, uma i-boiler yegesi ingafakwanga, noma yikuphi ukuqiniswa kokukhiya kungaqhutshwa ngokuqondile ngamapayipi.

Sebenza nge-metalplastic

Ipulasitiki yensimbi iyinto eqinile. Ngakho-ke, umsebenzi ungaqhutshwa ngaphandle kwemikhawulo ekhethekile nezidingo. Kodwa-ke, eminye imithetho isenayo:- Ukufakwa kwamapayipi kufanele kwenziwe emazingeni okushisa aqondile kuphela ngaphezu kwama-degree ayi-10;

- Uma i-metalplastic igcinwe okungenani isikhashana emazingeni okushisa aphansi, ngaphambi kokuqala umsebenzi, kufanele anikezwe kancane ukuzivumelanisa nokushisa;

- Wonke umsebenzi onjalo kufanele wenziwe lapho usuqedile ukuqeda ezindongeni zendlu;

- ukusika insimbi ngosizo lwethuluzi elikhethekile - isikele;

- Esezinhlelweni zokufakwa, akunakwenzeka ukushintsha ukugoba kwepulasitiki yensimbi kuhluke, kufanele kusetshenziswe ama-ry ama-ry;

- Onke amapayipi ahlelwe ngokuphoqelelwa ezindongeni usebenzisa ama-clampis noma iziqeshana.

Isihloko ngesihloko: Ingaphakathi le-Hallway endlini yangasese: Ungawenza kanjani uswidi ovela ku-Corridor (Izithombe ezingama-39)

Kuyafaneleka amagama ambalwa okusho ngokusika amapayipi anjalo. Ukusika insimbi-ipulasitiki, njengoba sekushiwo, okungcono kakhulu ngesikhafu esikhethekile noma abasiki bepayipi. Yebo, ungasebenzisa futhi uHacksaw wensimbi. Kungemva nje kokusika umphetho wepayipi kufanele kusulwe nge-sandpaper ukuvumelanisa nakho. Ungasebenzisa ummese obukhali olula ngale nhloso.

Izindlela Zokuxhumeka

Kunezindlela eziningana zokuxhuma amapayipi anjalo ohlelweni lokushisa amabili main:

- ngosizo lokufakwa kwezingcindezi;

- Ngosizo lokufakelwa kwabezindaba.

Indlela yokuqala yinhle ngokuthi ukusetshenziswa kwezifo zokucindezela kube lula kakhulu wonke umsebenzi. Ukufakelwa okunjalo akudingi amathuluzi akhethekile, ngaphandle kwesikhafu esishiwo ngenhla.

Ngaphandle kwazo, mhlawumbe ungadinga:

- iqoqo okhiye baphondo noma ukhiye oguqukayo;

- Fum rti;

- Calibrator.

I-FUM Retacta ingathathelwa indawo ngama-palauls ajwayelekile nge-sealant ekhethekile.

Ngokuqondene nokufakelwa, kungaba ngezimo ezahlukahlukene:

- amakhona;

- Tees;

- Adaptha nokunye.

Konke ukufakwa kufinyeleleka ekugcineni kwayo, okuqukethe izindandatho eyodwa noma eziningi zokubekwa uphawu. Ngaphezu kwalokho, kukhona indandatho ehlanganayo kanye ne-nati enqunu, ecindezela ipayipi futhi lifanelana.

Ngaphambi kokuxhuma ipayipi futhi kufanelekile ngepayipi, indandatho ne-nati kusuka kulokhu kufanelekile. Manje udinga i-calibrator. Kusebenza ukuze kwakhiwe ukwakheka okubushelelezi okuzungezile ekugcineni kweshubhu. Uma lelifomu lingenjalo, khona-ke enqubweni yokulungisa okufanelekile kanye namapayipi, izindandatho zokubopha uphawu kulokhu kufanele zilimaze, ezizoholela ekuvuzeni.

Ngemuva kokulinganisa, ipayipi lifakwa ekufanele. Kuphinde kuqiniswe ukubeka indandatho yokubhomba kanye ne-cape nati, okuphokophela ngaphezulu kwentambo kuye esitobhini. Iphaneli noma i-fum-tape iyilonda ngaphambi kwendandatho.

I-Nut iyabambezeleka ngokungazenzi kakhulu. Uma unamathisela amandla amaningi, i-nati iqhuma nje noma isuse intambo. Ukuqiniswa kufanele kuqhubeke kuze kufike isikrini sensimbi esicacile.

Isihloko ngesihloko: I-Nizhny Novgorod, isifunda sokwakhiwa kwesimo sezulu

Ngokuqondene nokusetshenziswa kokufakelwa kwabezindaba, ukufakwa kungahlukaniswa ngezinhlobo ezimbili, yize ukwahlukana kufanele kubhekwe njengemibandela:

- ngokusetshenziswa kokuqothuka kokuqothuka;

- usebenzisa ukufakwa kwezindaba.

Le ndlela idinga ithuluzi elikhethekile, ngokwesibonelo, imikhaza cindezela. Leli thuluzi lingaba ngumshini noma nge-hydraulically. Kuyaqapheleka ukuthi uhlobo ngalunye lokufakelwa kwezindaba ludinga ukusetshenziswa kohlobo lwethuluzi layo, oluhlukile ekuklameni kanye nomgomo wokusebenza. Isibonelo, ukufakwa kwezindaba ze-granur fress kudinga umkhawulo okhethekile.

Ngaphezu kwaleli thuluzi, lena elichazwe ngenhla lizodingeka.

Indlela yokugoba amapayipi epulasitiki wensimbi

Enqubweni yokufaka, kuvame ukudingekile ukushintsha ukuqondiswa kwepayipi, okungukuthi, kugoba i-metalplastic, futhi kwesinye isikhathi ngisho nama-degree angama-90 noma asondele kakhulu kuleli nani. Kulokhu, kuyadingeka ukuthi usebenzise, njengoba sekushiwo ngenhla, izinhlanga ezikhethekile.AmaMandrels ayimiphetho. Zingaba izinhlobo ezimbili:

- kwangaphakathi;

- ngaphandle.

Ngokwemvelo, ukugoba ipayipi lensimbi-ipulasitiki kuyadingeka masinyane ema-engeli angakwesokudla - kuyogotshwa nakanjani futhi kwephule, - kancane kancane, okungukuthi, i-arc.

Ngale ndlela, kunomthetho owodwa othi i-band radius kumele ibe yiminyaka engu-7 noma ngaphezulu amadayimane wepayipi lokugoba. Isibonelo, uma ipayipi linobubanzi obungu-20 mm, khona-ke irediyo yokugoba kufanele okungenani ibe ngu-140 mm.

Uma udinga ukugoba ipayipi ngakwesokunene ngokushesha, khona-ke udinga ukusebenzisa ukufakwa kwama-angular.

Ukuqinisa amapayipi ezindongeni

Amapayipi afakwa ngama-clip ezindongeni. Iziqeshana ngokwazo zihlelwe ezindongeni ngezindlela zokuzenzela. Ngemuva kwalokho ipayipi lifakwa esiqeshini ekuchofozeni kwesimo.

Iziqeshana kufanele zifakwe njalo ngama-40-50 cm noma ngaphezulu, kuncike kububanzi bepayipi.