Iyunithi yokulawula ezenzakalelayo imele inhlanganisela yemishini namadivayisi aklanyelwe ukuhlinzeka ngokulawulwa kokushisa okuzenzakalelayo kanye nokusetshenziswa okupholile, okukhiqizwa lapho kwethulwa isakhiwo ngasinye esidingekayo esakhiweni esithile. Ukulungiswa kungenziwa futhi ngokuya ngezidingo zabantu abakhileyo.

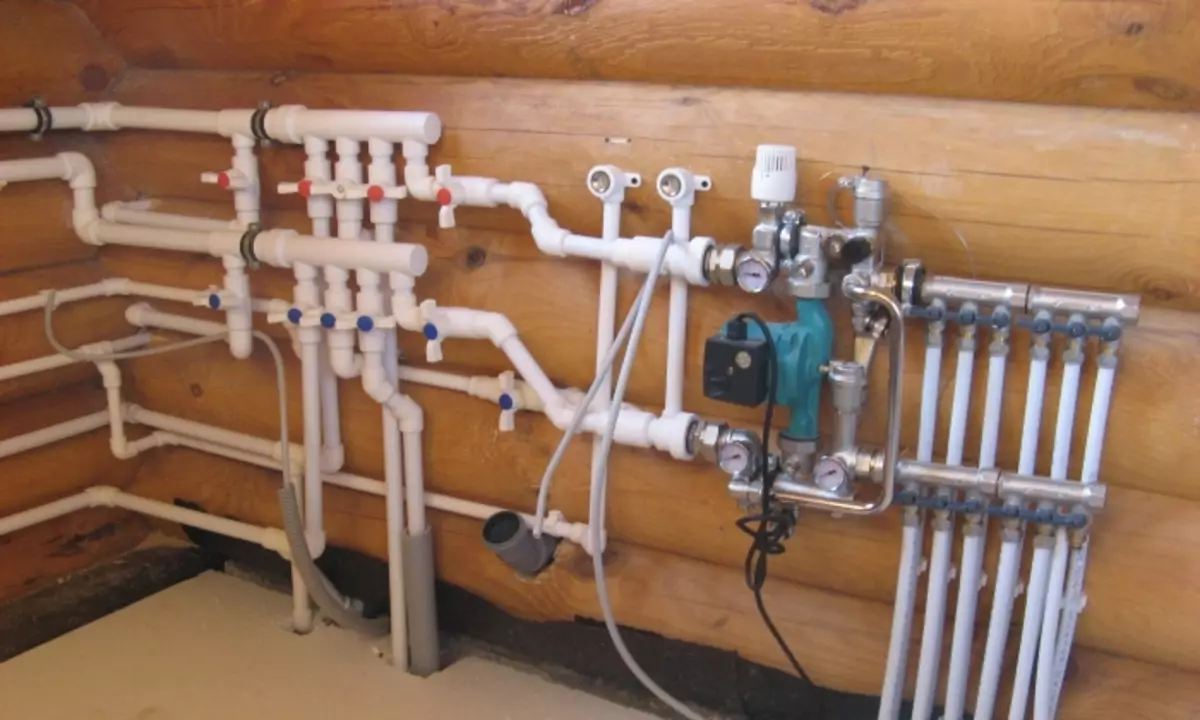

I-Node of the string ye-canofer yamanzi.

Phakathi kwezinzuzo ze-AuU, uma kuqhathaniswa nezindawo eziphakanyisiwe nezindlela ezishisayo, ezinesigaba esisezingeni eliphakemeyo somgodi odlulayo, kungenzeka ukuthi kuqhathaniswa nenani elipholile, kuya ngokushisa kwamanzi okuphambene nalokho okuphakelayo amapayipi.

Iyunithi yokulawula ezenzakalelayo ivame ukusethelwa koyedwa esakhiweni sonke, esihlukanisa ukusuka endaweni ye-lifti, ebekwe esigabeni ngasinye sendlu.

Ngasikhathi sinye, ukufakwa kwenziwa ngemuva kwendawo ebheka amandla ashisayo wohlelo.

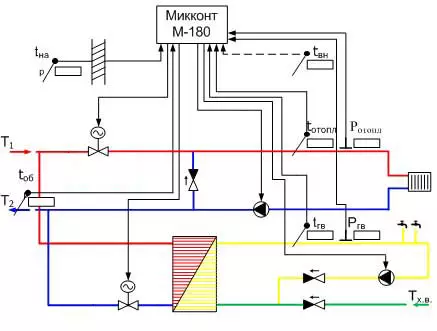

Image 1. Ukubekwa phambili komdwebo we-AuU ngamaphampu wokuxuba ekushiseni kwe-jumper kuya ku-auu t = 150-70 ˚c ngezinhlelo ezizodwa nezinsuku ezimbili nge-thermostats (P1 - P2 ≥ 12 m wamanzi. Art.).).

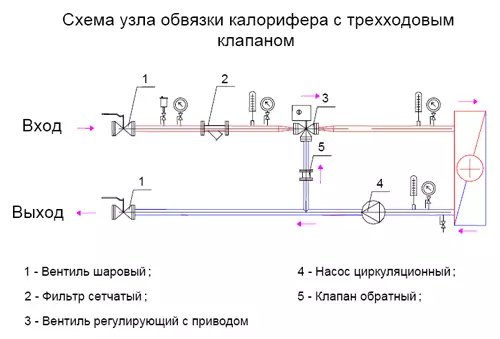

Iyunithi yokulawula ezenzakalelayo imelelwa yi-Scheme eboniswe yisithombe 1. Uhlelo luhlinzeka: Iyunithi ye-elekthronikhi (1), elimelelwa yiphaneli yokulawula; Inzwa yokushisa yangaphandle (2); izinzwa zokushisa ezipholile kumapayipi abuyela emuva futhi anikeze amapayipi (3); I-valve yokulungisa ukusetshenziswa, ifakwe nge-reducer drive (4); I-valve yokulungisa ukwehla kwengcindezi (5); isihlungi (6); Iphampu yokujikeleza (7); Bheka i-valve (8).

Njengoba uhlelo lubonisa, i-node yokulawula ngokuyisisekelo inengxenye yezingxenye ezi-3: inethiwekhi, ukujikeleza kanye ne-elekthronikhi.

Ingxenye yenethiwekhi ye-AUU ifaka i-valve yokulawula ingcindezi nge-drive drive ye-reducer, i-valve ye-pressure ye-dropper ngento elawulwa yintwasahlobo nesihlungi.

Ingxenye yokusakazwa yendawo yokulawula ifaka iphampu yokuxuba nge-valve yokuhlola. Ngokuxuba kusebenza amaphampu. Kulokhu, amaphampu kufanele asetshenziswe azokwanelisa izidingo ze-automatic node: kumele zisebenze ngokuhlukile nge-cyclicality ngehora lesithupha. Ukulawula umsebenzi wabo kufanele kwenziwe ku-Sensor Signal, ebhekele ukwehla kwengcindezi (inzwa ifakiwe kumaphampu).

Isihloko esihlokweni: Crima ngezeluleko zokuqothuka

Izinzuzo kanye nomgomo wokusebenza kwendawo ezenzakalelayo

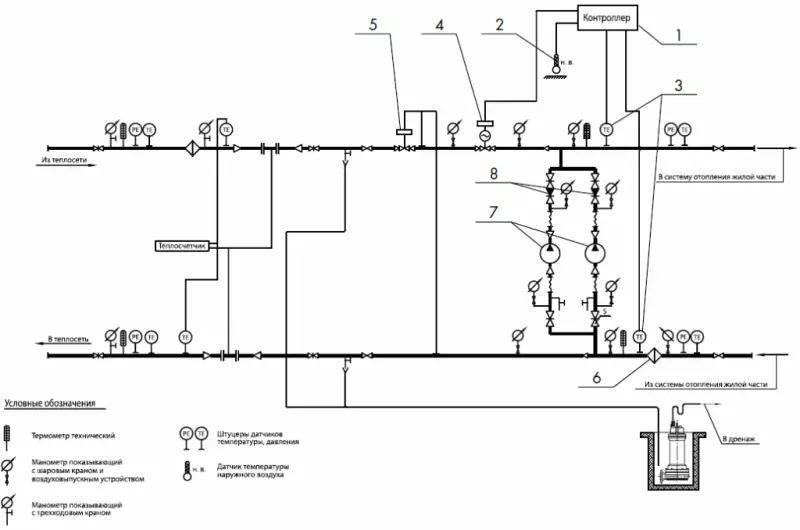

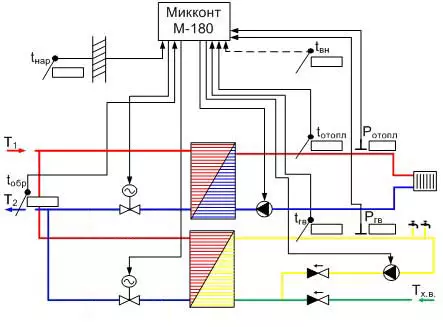

Iyunithi yokulawula ukushisa kanye ne-DHW ngokuya ngokujikeleza okuvulekile.

Ingxenye ye-elekthronikhi yendawo yokulawula ineyunithi ye-elektroniki noma lesi sihlangu esibizwa ngokuthi yi-Control Shield. Kwenzelwe ukuhlinzeka ngokulawula ekuphambuleni okuzenzakalelayo okususelwa kokuzenzakalelayo kanye nemishini yokushisa ukuze ulondoloze uhlelo lokushisa oludingekayo. Ngalo, ukusekelwa kusekelwa isithombe semodi ye-hydraulic, okumele kubekele phansi uhlelo lokushisa lwesakhiwo sonke.

Ingxenye ye-elekthronikhi iqukethe ikhadi le-ecl okuhloswe ngalo ukuhlela isilawuli, okwedlule kubhekele imodi yokushisa. Kunohlelo kanye sensor yokushisa yangaphandle, efakwe enyakatho yesakhiwo. Phakathi kwezinye izinto, kunezizwe zokushisa ze-Heat Carrier ngokwayo ekhondweni eliphambene nolondlayo.

Amaphutha kwinqubo yokusebenzisa i-othomathikhi

Ukushisa kanye neyunithi yokulawula i-DHW ngokuya ngohlelo oluzimele lokushisa kanye ne-DHW ngesikimu esivaliwe.

Amaphutha angavela ngesikhathi sokuhlela nenhlangano elandelayo yokusebenza esethulweni sohlelo lokushisa. Imvamisa, amaphutha athile avunyelwe ngesikhathi sokukhethwa kwekhambi lobuchwepheshe. Ungalahlekelwa yimithetho yedivayisi yephuzu elilodwa lokushisa. Ekugcineni, ngesikhathi sokufakwa kweyunithi yokulawula ukushisa, ukuphindaphindwa kwemishini yokusebenza kungenzeka, okufakwe ku-CTP, lokhu, nakho, kuphambanisa imithetho yokusebenza kokufakwa okushisayo. Ngakho-ke, ukufakwa kwezindawo zokulawula ukushisa nge-valve yokulinganisa kungaholela ekuphikiseni okuphezulu kwe-hydraulic ohlelweni, okuzofaka isidingo sokufaka esikhundleni noma ukwakha kabusha imishini eshisayo neyomashini.

Kungabizwa ngephutha nokufakwa kwe-Nonklexlex ukufakwa kwezindawo zokulawula ukushisa, okuzokwehla ngokuqinisekile ukushisa okusunguliwe kanye ne-hydraulic esele kumanethiwekhi we-intravadal. Lokhu kuyimbangela yokuwohloka kohlelo lokushisa cishe kwalo lonke isakhiwo esinamathiselwe. Kuyadingeka ukwenza ukukhishwa kwe-thermal ngesikhathi sokusebenza kwemishini yokushisa.

Imvamisa amaphutha enzeka enqubweni yokufaka i-Heating Control Unit endaweni yokuklama. Lokhu kungenxa yokuntuleka kwamaphrojekthi okusebenza, ukusetshenziswa kwephrojekthi ejwayelekile, kuncishwe izibalo, ukubopha nokukhethwa kwemishini ezimeni ezithile. Umphumela uba ukwephulwa kwemibuso yokushisa yokushisa.

Isihloko ngesihloko: Ukubekwa kwe-laminate ku-parquet yakudala kwenze ngokwakho (ividiyo)

Izidingo ezingeziwe zokufaka i-Heating Control Unit

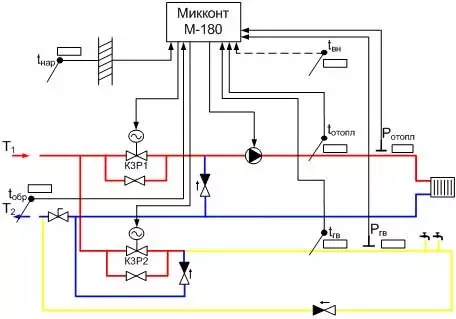

Ukushisa kanye neyunithi yokulawula i-DHW kuhlelo oluzimele.

Izinhlelo zokufaka ezikhethiwe zamayunithi wokulawula ukushisa kungenzeka zingahambisani nalokho okudingekayo okukhombisa ukungahambi kahle ekunikezelweni kokushisa. Kwenzeka futhi ukuthi ngesikhathi sokungena ohlelweni, imininingwane esetshenzisiwe ayihambelani namapharamitha wangempela. Lokhu kungaholela ekukhetheni okungalungile kwe-node schema.

Ngesikhathi sokufaka i-automation node, kufanele kukhunjulwe ukuthi uhlelo lokushisa lungakwazi ukulungiswa ngaphambili kanye nokwakhiwa kabusha, lapho uhlelo lungashintshwa ngethayi elilodwa ngepayipi elilodwa. Izinkinga zingavela lapho umhlangano we-node wenziwa ngohlelo olwalungelokwakhiwa kabusha.

Inqubo yokuqalisa ukusebenza kufanele yenziwe hhayi ebusika, ukuze ukuqala kohlelo kwenziwe ngesikhathi.

Umjikelezo we-automated Heating System Control Unit (AUU) ekhaya.

Kufanele kukhunjulwe ukuthi izinzwa zokushisa zomoya kumele zifakwe ohlangothini olusenyakatho, okudingeka ukuguqula kahle imodi yokushisa, kulokhu imisebe yelanga ngeke ikwazi ukusula inzwa.

Ngesikhathi senqubo yokufaka, i-node kumele inikezwe, ezosiza ekugwemeni ukumisa uhlelo lwe-CLC lapho ugesi ucishiwe. Umsebenzi wokulungiswa nokulungisa, kanye nemisebenzi yokuzivocavoca, ukugcinwa kwendawo kumele kwenzeke. Kumele kwaziwe ukuthi ukungalandeli kweMithetho eyodwa noma eminingi kungaholela kumthelela wohlelo, futhi ukungabikho kwemishini ye-plug-in umphumela.

Ukuqaliswa kokuphathwa kwe-node kumele kuhambisane nokubheka izimo zobuchwepheshe ezikhishwe, kufanele zihambisane nedatha yangempela. Futhi ukubhekwa kwezobuchwepheshe kumele kwenziwe esigabeni ngasinye somsebenzi. Ngemuva kokuba wonke umsebenzi ohlelweni usuqediwe, ukugcinwa kwendawo kufanele kuqalwe, okwenziwa yinhlangano ekhethekile. Ngaphandle kwalokho, imishini elula ebizayo yendawo ezenzakalelayo noma insizakalo yayo engafanele ingaholela ekwehlulekeni neminye imiphumela emibi, kufaka phakathi ukulahlekelwa nguchwepheshe.

Isihloko ngesihloko: ukuhambisana kahle kwefenisha egumbini elingunxande

Ukusetshenziswa okusebenzayo kweyunithi yokulawula ukushisa okuzenzakalelayo

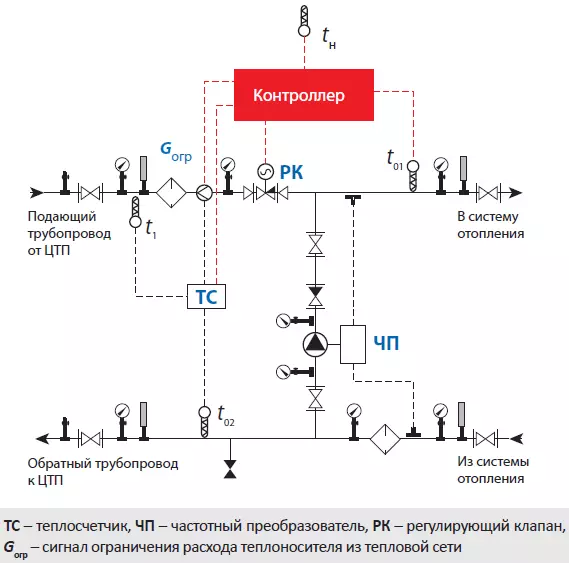

Isibonelo sokuqaliswa kweyunithi yokulawula ngezinhlelo zokushisa nezinhlelo zokushisa zokushisa.

Ukusetshenziswa kwe-node kuzoba okusebenzayo kakhulu ezimweni lapho indlu inezindawo eziphakanyisiwe ze-Elevator yezinhlelo zokushisa ezinamathiselwe ngqo kuma-armal mains. Okusebenzayo, ukusetshenziswa okunjalo kuzoba nemibandela yezindlu zokugcina ukuze kubhekwe kwi-CTP, lapho amaconsi anganele aphathwe khona ngokufakwa okuphoqelekile kwamaphampu we-TSO.

Ukusebenza kahle kokusetshenziswa kuyabikwa futhi emakhaya afakwe ama-heater amanzi okushisa kanye nokushisa okuphakathi, izakhiwo ezinjalo zingaba nokuhlinzekwa kwamanzi okushisayo.

Ukufaka ama-node azenzakalelayo kunconywa ngokuphelele, ukumboza zonke izakhiwo ezingezona ezendawo yokuhlala nezohlala ezindlini ezazinamathiselwe kwi-CTP. Ukufaka nokulethwa, kanye nokwamukelwa okulandelayo kokusebenza kwalo lonke uhlelo kanye nemishini ye-NODED ehambisanayo kufanele yenziwe ngasikhathi sinye.

Kumele kwaziwe ukuthi imicimbi elandelayo izosebenza ngokufakwa kwe-node ezizenzakalelayo:

- Ukuqaliswa kokuguqulwa kwe-CTP, okunesikimu esincike ekunamathiselwe kwezinhlelo ngazinye zokushisa, kulowo ozozimela. Kulokhu, ukufakwa kwethangi lokulwa nolwelwesi lokunwebeka esigabeni esishisayo kuzosebenza.

- Ukufaka ngaphansi kwezimo ze-CTP, okubonakala yi-DEAGRENT ONET PREENTIPAL CENCEPAM, efana ne-automated control node.

- Ukulungiswa kwamanethiwekhi we-Intra-Quarter we-CSO ngokufakwa kwe-throttle diaphragms kanye nokubalwa kwama-nozzles ezingeni lokungenisa kanye nokusabalalisa.

- Ukuqaliswa kokudluliswa kwezinhlelo zokuphela kokuphela kwe-GW kuya kuma-Circuits ajikelezayo.

Ukusebenza kwezindawo ezizenzakalelayo ezizenzakalelayo kukhombisile ukuthi ukusetshenziswa kwe-Auu kanye nama-valves alinganiselayo, ama-valves arrmostatic kanye nokwenza imisebenzi yokufaka inyose kungagcina amandla afinyelela kuma-37%, okunikeza izimo ezikhululekile zasekamelweni ngalinye.