Ukuze isakhiwo sendawo yokuhlala sifudumele futhi sithokomele, uhlelo lokushisa kufanele lufakwe kulo. Umdwebo wamandla nomdwebo wesakhiwo ungahluka, njengoba konke kuncike endaweni yendlu esetshenzisiwe. Yini engaba uhlelo lokushisa lwendlu yangasese enezitezi ezintathu, kanjani ukubala amandla ayo?

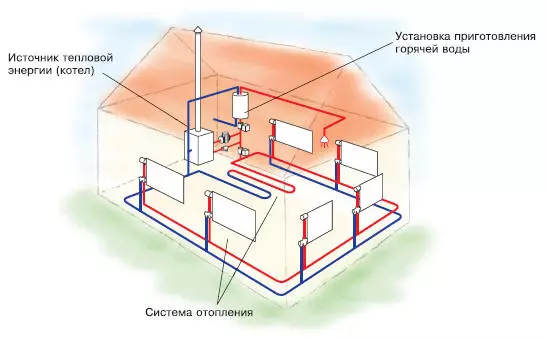

Uhlelo lokushisa ekhaya

Ukuphepha nezinhlelo zokushisa eziphoqelelwe

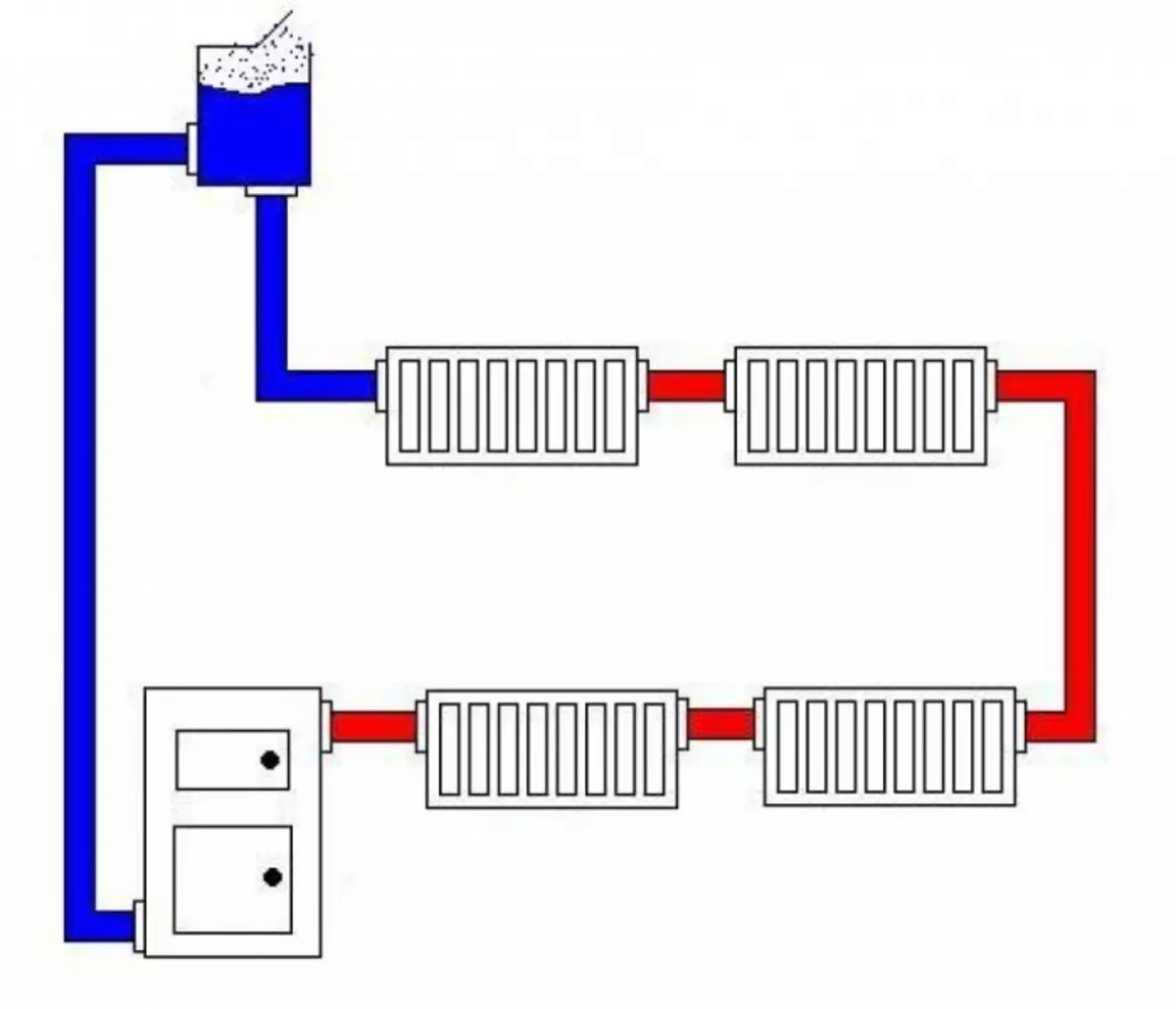

Ngokushisa ekhaya, ama-samotane noma amasistimu aphoqelelwe angasetshenziswa, ahlukile kwizimpawu zawo.Uma kwenzeka ufudumeza wokuzikhandla, uketshezi olungahambisani lusetshenziswa njenge-coolant, ngokwesibonelo, antifreeze, kepha amanzi ashisayo nawo angasetshenziswa.

I-coolont ijikeleza ngaphandle kwephampu, yenzeka kuphela ngokuvela komehluko wokushisa kokukhipha kanye nokungena kwe-boiler.

Namuhla, lolu hlelo lubhekwa njengelivele luphelelwe isikhathi, lube yinkimbinkimbi ngokwengeziwe, lapho ukunyakaza kwe-coolant kwenziwa khona kusetshenziswa iphampu efakiwe. Inketho enjalo ithembeke kakhulu, kukhethwayo ukuthi kufakwe ezakhiweni zokuhlala zangasese.

Ama-boilers ohlelweni lokushisa

Uhlelo lokushisa indlu yangasese empeleni lufaka i-boiler yokushisa amanzi. Imvamisa kuba ama-boilers wegesi wanamuhla okulula ukuwafaka ngezandla zakho, yize ukuxhumana kunconywa ukwenza ngokubamba iqhaza kochwepheshe. Amabili anjalo yizinhlobo ezimbili:

- Ama-boilers egesi angaphandle angaba nabashisi abasemoshelweni. Lapho usebenza, imishini ayidali umsindo omningi, kungenzeka ukuletha amapayipi kusuka kwi-Pipeline yegesi ephelele noma ama-cylinders axhumeka. Amanye amamodeli ahlanganisiwe anamandla okusebenza hhayi kugesi kuphela, kepha futhi futhi kuphethiloli kadizili. Kusetshenziswe ukufakwa okunjalo kuvame kakhulu ukuthola uhlelo lokushisa lwendlu enkulu;

- I-Wall Gas Boiler inosayizi omncane, yenzelwe ukufudumeza indlu enezitezi ezintathu, kungenzeka ukuyifaka kunoma iyiphi indawo ekahle yesakhiwo, imvamisa kuyikhishi noma igumbi lokusetshenziswa. Amandla okushisa mancane, ukuze kube yindlu encane ezindaweni ezi-3 zanele. I-boiler ifakwe odongeni, ukwakheka okudingekayo sekuvele kuhambile.

Izinketho zamashubhu wokufudumeza

Uhlelo lokushisa aluwona kuphela ama-boiler nama-radiator, kodwa futhi namapayipi lapho okupholile kuhamba khona ngaphansi kwengcindezi. Ukufaka ukuhlangana okufudumele kwesakhiwo sangasese esinezitezi ezintathu, ungasebenzisa amapayipi kusuka ezintweni ezilandelayo:

I-athikili: Izidingo zokufakwa kukagesi wiring

Uhlelo lohlelo lokushisa ekhaya.

- Amapayipi ensimbi (galvanised, angenasici). Lapho ufaka amapayipi anjalo, kuyadingeka ukubheka ukuthi umshini we-welding uyadingeka ukuxhuma. Izinto ezinjalo zihlala isikhathi eside, impilo yayo yenkonzo inkulu kakhulu. Kepha kukhona nezinto ezimbi lapho kunesidingo sokusetshenziswa kwe-welding kanye nokutholakala kokuhlangenwe nakho ngezimpawu ezihlanganisiwe zensimbi. Namuhla, amapayipi okushisa ensimbi asetshenziswa kaningi, ngoba kunezinto ezishibhile, kodwa ezilinganayo eziphezulu;

- Ukushisa kungenziwa ngosizo lwamapayipi ethusi, namuhla abhekwa njengekhwalithi ephezulu kakhulu futhi ethembekile. Zibhekele ukucindezela okukhulu, azikho ngaphansi kokugqwala, kepha izindleko zamapayipi anjalo ziphezulu, zisetshenziswa namuhla kuphela zokwakhiwa okukhethekile. Ukuxhumeka kusebenzisa ukuthengiswa okukhethekile okushisa okushisa ngesiliva. Ngemuva komsebenzi, zonke izindawo zezinhlanganisela zivaliwe ngokucophelela;

- Amapayipi e-polymer yiqembu elikhulu elifaka i-polyethylene, insimbi-ipulasitiki, i-polypropylene enomthetho we-aluminium. Imikhiqizo ifakwe kalula, zisezingeni eliphakeme, ezinye zingenziwa ngaphakathi kodonga, oluthinteka kahle ngaphakathi kwendlu. Uhlelo lokushisa lubekwe ngokushesha, izindlela ezahlukahlukene zisetshenziselwa ukuxhuma, kufaka phakathi umshini wokushicilela, ukusetshenziswa komshini okhethekile we-welding, ukuxhumana kokushisa kwamapayipi.

Lapho ukhetha amapayipi, kuyadingeka ukubheka ukuthi uhlelo luzoba nzima kangakanani ukuthi kungenzeka yini ukubeka ipayipi ezindongeni, yiziphi izidingo ezethulwe ekuxhumeni.

Isibonelo senhlangano yohlelo lokushisa

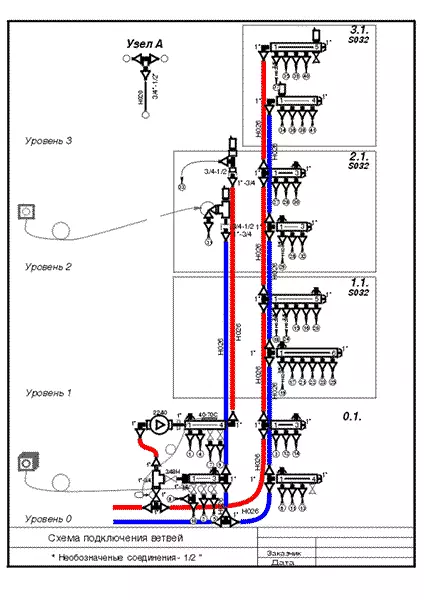

Isibonelo sohlelo lokushisa lwendlu enezitezi ezintathu, lwenziwe ngokuhambisana nayo yonke imithetho, amazinga nezidingo, kufanele kubhekwe.

Idatha Ejwayelekile:

- Lokushisa komoya ngaphandle kwasekhaya-28 degrees;

- isikhathi sonke sokushisa kwezinsuku ezingama-214 ngonyaka;

- Izinga lokushisa elibaliwe lezakhiwo ngazinye alidluli ama-degree angu-2.

Uhlelo lohlelo lokushisa lwendlu enezitezi ezintathu.

Njengoba okupholile kuzoba ngamanzi ashisayo, kufuthelwe emazingeni okushisa angama-70-90 degrees.

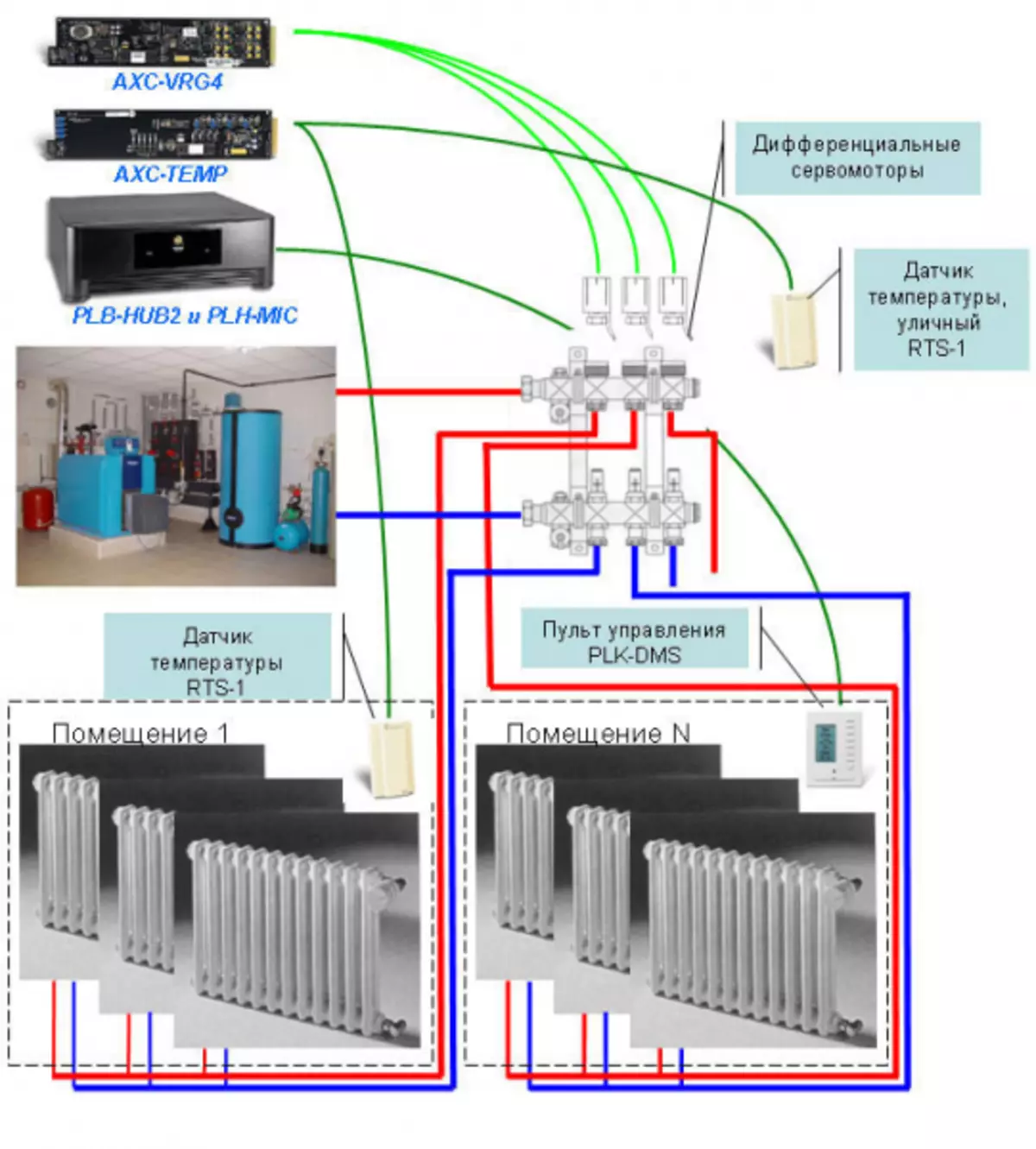

Uhlelo lonke lokushisa lwendlu enezitezi ezintathu luhlanganisa i-wiring eyi-wiring, ukuxhumana okuhlangenwe nakho kwamadivayisi wokushisa (I.E. Ama-radiator). Njengoba izinto zohlelo lokushisa lwendlu yezindaba ezintathu zamukelwa:

- I-Collector Wiring;

- Amapayipi e-Metal-Plastic noma ama-polypropylene;

- Ama-eyeliners, ama-risers aya kubaqoqi;

- Amapayipi okushisa akhethekile avela ku-Metalplastic ngokufakelwa.

Isihloko ngesihloko: Ungasusa kanjani upende kusuka ku-Windows? Izindlela Zokususa Upende Wakudala

I-Gasket yePipeline yenziwa ngale ndlela:

- Amakamelo angaphansi - esimweni esivulekile;

- Izimpikiswano zohlelo lwe-mpo - ekuhlathini okukhethekile;

- Ngokubekwa phansi phansi - ezakhiweni zaphansi.

Ukunxephezela ukuvela kokushisa, kuyadingeka ukusebenzisa isinxephezelo sezingosi ngazinye, njengokugoba, ukuguquka, njll. Kwezinye izigaba, uhlelo lwendlu yendlu kufanele luhlukaniswe ama-fasteners ahleliwe.

Isibonelo sohlelo lokushisa.

Uhlelo lokushisa lwendlu enezitezi ezintathu lufaka ukulungiswa kwephrojekthi kanye nokuxhumana kwalo. Emva kwalokho, ungafaka i-boiler yohlobo olukhethiwe, yenza intambo yayo ngokuya ngomklamo ohlanganisiwe. Akufanele kukhohlwe ukuthi amapayipi, yonke imishini kumele ibekwe phansi ngokwezindinganiso. Ekamelweni le-boiler, lapho iningi lemishini litholakala khona, kuyadingeka ukuqinisekisa ukuba khona komoya omncane ukuze kuqinisekiswe umoya kanye ne-hooding yemikhiqizo yokuvutha.

Ngasikhathi sinye, ukubalwa okunjalo kubhekwa: Ngayinye i-1.16 kw yamandla okushisa idinga amamitha amahlanu okunikezwa komoya, kodwa hhayi ngaphansi kwe-150 sq. M. Umgodi wokupholisa umoya kufanele utholakala ungaphansi kwama-30 cm kusuka ezingeni eliphansi. Ukuthola umoya omncane, inani elinjalo liyabhekelwa: Kuwo wonke ama-17 kW, amandla okushisa ezindlu adinga i-decimeter eyodwa yomoya. Zonke amapayipi okuvuselela umoya kudingeka asongwe ngesendlalelo sezinto zokufaka ukushisa.

Igumbi le-boiler, lapho uhlelo lokushisa luzotholakala khona, kudingeka ukukhanyisa. Ukubalwa kungokulandelayo: I-Cubic M ngayinye kufanele ibe ukusuka ku-0.03 sq. M. M. Imvelo Lighting. Kuya ku-boiler Kuyadingeka ukuhlinzeka ngogesi nge-cable 3 * 1.5 sq. Mm.

Lapho i-chimney isuselwa ophahleni, izimo ezinjalo kufanele zibhekwe:

- Kwelinye izinga, ngesiketi sophahla lwendlu, uma itholakala amamitha amathathu kuyo;

- Ngaphezulu kwendawo yomoya ophahleni, kepha hhayi ngaphansi kwengxenye yemitha ngokuvundlile.

Ukuhlinzekwa kwamanzi kohlelo lokushisa lwendlu yezindaba ezintathu kwenziwa kusetshenziswa uxhumano lwayo ohlelweni lokuhlinzekwa kwamanzi okuphelele kusuka emthonjeni noma kunoma iyiphi indlela elula ngokusho kwephrojekthi.

Isihloko ngesihloko: Iselula enezimvemvane yenza ngokwakho

Isibonelo sokubala amandla okushisa

Manje udinga ukucubungula isibonelo sokubala amandla okushisa endlu yangasese enezitezi ezintathu. Ukushisa igumbi ngokujwayelekile, indawo yayo engamamitha ayi-10 skwele, kuyadingeka ukusebenzisa i-1 kw yamandla okushisa. Ukubala amandla, kuyadingeka ukuhlukanisa inani eliphelele lekamelo ukuthola ishumi, kepha lokhu kungukumaphakathi, ukulungiswa kwe-coefficients kufanele kubhekwe:

Ithebula lezinketho eziyisisekelo zokubala amandla we-boiler.

- Ezakhiweni zendlu enamafasitela amabili aqhamuka ohlangothini olusenyakatho - 1.3;

- Ezakhiweni ngamawindi amabili, aya kohlangothi lwasempumalanga nangaseningizimu - 1.2;

- Amakamelo anewindi elilodwa, eliqondiswe entshonalanga noma enyakatho, - 1.1.

Okungukuthi, kuyadingeka ukumane ukuphinda inani kwi-coefficing ehambisanayo.

Isibonelo, kuyadingeka ukubala amandla okushisa ekhaya endaweni engamamitha ayi-10 10 phambi kwamakamelo amane, ngalinye linamawindi amabili. Kulokhu, kuyadingeka ukulungiselela ama-boiler afakwe ngawo, amandla awo azoba ngu-25 kw, asebenza kugesi, noma i-boiler ejikeleze kabili nge-28 kW, eyenzelwe ukwelapha amanzi.

Kungcono ukukhetha amabhethri e-Steel Heating njengama-radiator, esitezi sokuqala ungathatha izingcezu eziyisishiyagalombili, iwindi ngalinye lizohamba izingcezu ezi-2 ngosayizi wesigaba esingu-500 mm nge-1645 W. Isitezi sesibili nesithathu ungasebenzisa izingcezu ezine ngewindi ngalinye. Ngaphansi kwewindows ngalinye kune-radiator eyodwa enobukhulu bama-600 nge-1000 mm nangamandla ka-2353 W. Amapayipi e-polypropylene ayadingeka futhi, kubakaki bama-radiators alenga, ama-cranes, amakhona, ezinye izinto ze-fastener.

Ukuhlela ukufudumeza indlu enezitezi ezintathu, ngeke ufake kuphela ama-boiler bese ulenga ama-radiator, kuyadingeka ukubala lonke uhlelo, cabanga ngezici zokufakwa. Izinketho zohlelo lokushisa zingaba ziningi. Izibalo ngokwazo aziyinkimbinkimbi kakhulu, into esemqoka ngeke ikhohlwe ngama-coefficients, inani lalapho lishicilelwa ngaloso sihlalo sendlu.