Ngokwenza phansi kokhonkolo egalaji, ngemuva kwesikhashana uqonda ukuthi inketho yize ayilungile, kepha ayilungile. Okokuqala, ngesikhathi sokuhlanza kuwuthuli, uthuli luncane, luvalelwe izikhala ezincane kakhulu, lulele ngokuhlaselwa okumpunga okukhanyayo. Okwesibili, uketshezi luyamangala, futhi akukho khona ukubasusa. Uma ibala lingamafutha, ukungcola kuhlala kunamathela kukho. Ngemuva kwesikhashana, phansi kubonakala kungcole ngaso sonke isikhathi. Ngakho-ke umcabango ufika, yenza isitezi esimboze egalaji ukuze kungabi "uthuli" kahle, kodwa ngasikhathi sinye alusekushelela futhi luhlala isikhathi eside.

Ube nephansi elibushelelezi, eliqinile, elingejwayelekile kumaphupho egalaji wonke umnikazi wemoto

Ukufakwa (ama-primers, ama-primers)

Uma ungazi ukuthi ungasimboza kanjani phansi ngokhonkolo egalaji ukuze ungathuli, awulukhuni, futhi uchithe isikhathi, unake isikhathi sokufakwa kokhonkolo (okubizwa ngokuthi yi-primer for ukhonkolo). Lezi yizingoma ze-mulkomponut ezisuselwa kuma-polymers. Kune-organic kanye ne-inorganic. Njengoba lezi zibambiwa, azikhi i-film ebusweni, ngakho-ke ayinakukhishwa futhi iwe ngemuva. Izakhi zabo zingena kukhonkolo, bopha amaketanga we-polymer we-molecule. Ngenxa yalokhu, amandla ombuso ayaqina ngezikhathi ezi-2-3, ukumelana nemidiya enolaka (acid ne-alkali), amaconsi okushisa, kungcono ukuthwala isithwathwa, ukwakhiwa kothuli nakho kuyaqedwa.

Ngokuvamile, ama-primers okukhonkolo kukhona izinhlobo ezintathu:

- Polyurethane. Injongo yabo eyinhloko iyangena manzi, nayo isetshenziselwa ukwenziwa kwesisombululo sokulungisa: i-primer ixubene nesihlabathi kanye nale ngxube yavale imifantu nama-chip.

- Ukusatshalaliswa kwamanzi. Babhekana kahle ngokudideka futhi baqinise kancane ingaphezulu kokhonkolo. Izindleko zazo ziphakathi.

- Epoxy. Esikhathini esiningi, ziyinto ezimbili, zilungiselela ngaphambi kokufaka isicelo, injongo eyinhloko iyangena ngaphansi kwamanzi.

Ngemuva kwezendlalelo ezimbili zokutholwa kokhonkolo uPaul hhayi uthuli ngokuphelele

Uma ngemuva kokucubungula i-primer ukupenda phansi noma uthele kunoma iyiphi enye i-coating coating, khona-ke ama-primers ahluke ngamanzi afaneleka kakhulu ukuba athule izitezi egalaji. Ngaphansi kopende noma ezinye izimbozo ze-Primer zithatha uhlobo olufanayo: ngaphansi kwe-polyurethane Paint ngokhonkolo ukwakheka okufanayo kuthatha amalungiselelo, njll.

I-Polyurethane (polymer) ekufakweni kokhonkolo

Lokhu kuhlanganiswa kwegaraji kuhle kuwo wonke umuntu ngaphandle kwentengo - izindleko eziyi-1 litre cishe ngama- $ 5. Ungathola ukupakisha ama-3 kg no-20 kg. Ukusetshenziswa kokubika lapho usebenzisa ungqimba lokuqala 0.25-0.5 kg / m2, okwesibili - 0,15-0.2 kg / m2.

Lapho ucubungula, ungazali, unqikazeke, okungenani amahlandla amabili. I-Polyurethane ekutholeni ukhonkolo ibopha izinhlayiya ngaphandle kokwenza ifilimu. Ukuthulisa phansi kangaka kokhonkolo kuyaphela, ukudonsa uketshezi kuzoba ngaphansi. Lezi zingoma ziqinisa indawo ekhonkolo ekhonkolo. Uma inqubo iqhubekele kude, ngeke basize, kepha uma kuphela iminonjana ye-abrasion ibonakala, ukuwohloka kuzosiza ukubambezela inqubo.

Kufaka isicelo se-polyurethane

Ukutholwa kwe-polymer kusetshenziswa kuphela ezindaweni ezomile. Umswakama kakhonkolo akufanele ube ngaphezu kwama-5% (kumele okungenani abe nezinsuku ezingama-28 kusukela ngomzuzu wokugcwalisa). Ukwakheka kuthululelwa phansi ngezingxenye, ukusabalalisa kusetshenziswa i-roller noma i-mop ekhethekile ngaphezulu komhlaba wonke. Amanye amafemu angangeza i-kel, ngakho-ke ungathola ngasikhathi sinye ngasikhathi sinye egalaji. Lokhu kucubungula kungasetshenziswa njengokulungiselela ukusetshenziswa okulandelayo kopende noma i-polymer floore.

Izici zokufaka isicelo: izinga lokushisa kufanele lisuka ku-0 ° C libe ngu-17 ° C, umswakama womoya awekho ngaphansi kwama-70%. Uma umswakama ungezinyawo, kuyadingeka ukumfudumeza ngokungemthetho - ama-admivifer kagesi noma omanzisa izimbambo ezimanzi egalaji, zibalandela njalo ukuze zingamenzi. Kuphela kulezi zimo i-polymerization izoba yinhle.

Ama-epoxy primers

Lolu hlobo lokufakwa okufakiwe luqukethe izakhi ezimbili ezixutshwe ngokushesha ngaphambi kokusebenzisa. Kungenzeka ukusebenza nabo emazingeni okushisa angenhla + 5 ° C, azikho ezinye izidingo. Izindleko ziphakeme kunalezo ze-polymer - $ 7 nge-kg, ukusetshenziswa kwenze okufanayo.

Ukufakwa kabusha kwe-epoxy kwezocansi egalaji

Upende kakhonkolo

Phezu kwenhlabathi ungafaka upende okhethekile ngokhonkolo. Bagcina ezikwakheni isikhathi eside badweba phansi amabanga ayikhulu, amagalaji, njll. Lokhu kukude nopende ojwayelekile, kepha izingoma eziningi ezisuselwa kuma-polymers, ezingeza imibala yokufaka imibala. Kuyadingeka ukukhetha ngokuya ngemisebenzi isembozo saphansi okufanele kwenziwe egalaji:

- Ngoba uthuli, upende ulungele ukhonkolo osuselwa ku-PVC.

- Ukuvikela kuma-acid, i-alkali kanye nezinye izinto ezinolaka, upende we-polyurethane ufanelekile.

- Ukukhulisa amandla, ukumelana ne-abrasion - amapende e-epoxy amabili.

Uma sikhuluma ngokuqondile ngamagalaji, kungenzeka ukuthi kusondele kuzingoma ze-epoxy. Bakha ifilimu eliqinile elixhumeke kahle kakhulu ngesisekelo sokhonkolo. Upende onjalo awuvuvungu futhi ungandizeli. Ngokuhamba kwesikhathi, angahlikihla kancane, bese ezindaweni zomthwalo omkhulu kakhulu. Ingasetshenziswa ikhulu, emakamelweni nasemagalaji.

Upende wokhonkolo uzogcinwa ngasikhathi sinye, nikeza ukubukeka okukhangayo, ukunciphisa ukumuncwa komswakama

Upende we-epoxy wokhonkolo esisekelweni sikakhonkrithi esilungiselelwe. Iphansi kufanele lome (kusukela lapho ukugcwaliswa kumele kudlule okungenani izinsuku ezingama-30). Uma i-screed igcwaliswa muva nje, ubisi lukasimende lususwa ebusweni bebhulashi eliqinile (lensimbi). Uma isitezi sesidala, kukhona ama-chip kanye nemifantu, vala, susa amabala amafutha. Ngemuva kokucubungula, susa udoti.

Ngaphambi kokufaka isicelo ngopende, phansi kuyagezwa nge-dilite PVA amanzi. Inketho yesibili yisisombululo esibuthakathaka samanzi se-hydrochloric acid (1: 9). Ngemuva kosuku, ingaphezulu lihlanzwa nge-vacuum cleaner noma ibhulashi elithambile. Emva kwalokho, phansi kokhonkolo kulungele ukusebenzisa upende we-epoxy.

Isisekelo ne-hardoner ngosuku singena egumbini elifudumele. Lokushisa kufanele kube ngaphezulu kwe-18 ° C. Izakhi ngayinye zixube ngokwahlukana, esitsheni sayo. Lapho-ke i-hardener ingezwa kwisisekelo se-Base kanye nokwakheka kuxutshwe. Uma kunesidingo, ungasebenzisa i-solvent echazwe kwimiyalo. Ukusebenza kopende onjalo kuncane (isikhathi sokwenqatshwa), ngakho-ke kuyadingeka ukusebenza ngokushesha.

Upende werabha

Lolu hlobo lwepende seluphakamisile izici ezingavunyelwe, indawo yokukhosela enhle, ukumelana okuphezulu, kulula ukugeza, kungenzeka ngisho nokusetshenziswa kwama-detegents, isitaki. Ingasetshenziswa emazingeni okushisa ukusuka ku-50 ° C kuya ku-60 ° C. Lapho ukupenda kudala ukuhlanganiswa, okufana kakhulu nerabha, ngokufanayo, empeleni, izakhiwo. Kukhona ababi - ingaphezulu libushelelezi kakhulu, futhi ebusika lingashelela. Isikhathi sesibili esingemnandi lapho imoto ishayela egalaji bese islayida kancane, amasondo angakhipha izingcezu zopende. Phuma - udonga ngaphansi kwamasondo enjoloba. Inketho ethandwa kakhulu isuka kumhambisi. Abagqokile iminyaka, futhi ngopende werabha bazohlala ndawonye.

Upende werabha lungasetshenziswa njengesembozo saphansi egalaji

Ukulungiselela ububanzi kuqukethe ukususa izimbotshana ezindala zokubopha, ushoko, uthuli, amafulethi amafutha. Uma kukhona ukunamathela esicwebezelayo phansi ukuze aphathe i-sandpaper ukuze ubuze. Isigaba sokugcina ukugeza phansi ngesisombululo se-soda, bese ugeza amanzi bese womile.

Faka upende ngezingalo ezi-2-3. Ngaphambi kokusebenzisa i-Stiring, akunconywa ukunciphisa, kepha esimweni esibi kakhulu, i-solvent echazwe emyalweni ingasetshenziswa. Lapho usebenza, upende uxuba njalo.

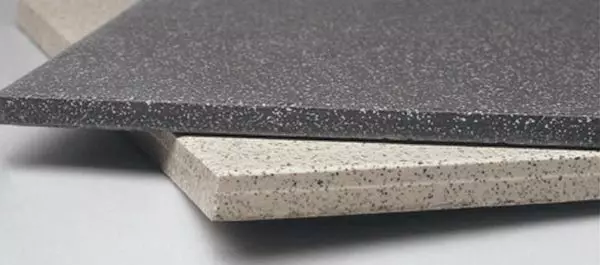

I-Rubber flooring egalaji

I-Floor coating kusuka enjoloba izokwazi ukulula futhi isebenze. I-minus yayo iyintengo eqinile - kusuka ku- $ 18 ngemitha yesikwele, uma sikhuluma nge-Rubber modular coating.

Namuhla kunenhlanganisela yerabha ezinguqulweni ezintathu:

- amapuleti ajwayelekile osayizi abahlukahlukene;

- Ukuhlanganiswa kwenjoloba okugoqwe;

- Irabha imvuthuluka nge-polymer birmer.

I-rolled ne-modular coating ibonakala ngohlobo lokubekwa kanye nohlobo lokukhululwa. Izici ezisele ziyefana. Ayikho indlela yokufaka, kuphela kwelinye icala eliqoqwe kusuka ezingcebelweni, okuvame kakhulu ukwakheka kwesikwele, ngemiphetho ehlotshiswe ngesimo sokhiye wokucushwa okuhlukile. Ukugoqa ama-coating coating phansi. Zombili lezi zinhlobo zifakwa ku-polyurethane glue. Ukulungiselela ukhonkolo Okujwayelekile: Ama-Chips okubopha uphawu kanye nama-dents, ukususwa kothuli kanye nokungcola, i-primer (polymer impregnation).

Ukubekwa phansi kweRubber modular floor - Izikhiye zokuxhumanisa "umsila we-Olochkin"

Ukukhetha ukuhlanganiswa kwenjoloba noma okugoqiwe, naka ubukhulu benjoloba. Kungasukela ku-4 mm kuya ku-50 mm. Phansi kakhulu phansi egalaji noma kuye, kepha mncane kakhulu kungalimala ngamasondo. Ubukhulu obufanele bungu-10-15 mm. Lokhu akubizi kakhulu ngentengo, futhi ngokuya ngezimpawu ezingaphezu kwanele.

I-Rubber Crumb noma usho ukuthi asphalt kakhudlwana i-coating coating ezimbili. Ingane uqobo ingena ezikhwameni futhi inombala omnyama. Ukumnika omunye umbala kunamadayi. Zingezwa ku-crumb eyomile bese zixuba kuze kupendwe ngokuphelele. Bese ufaka i-binder. Lokhu kuvame ukuba ne-polyurethane glue. Isisindo sivuswe kuze kube ukufana. Kepha inqubo kufanele yenzeke ngokushesha - isikhathi esinzima sincane kakhulu. Imvuthuluka nge-polyurethane ibeka esisekelweni esilungiselelwe (iqondaniswe, icatshangelwe, ihlanganiswe ngengqimba ye-polyurethane glue), gingqa bese ucindezelwa nge-rink.

I-PVC tile

Lolu hlobo lwephansi luvele muva nje, lube yi-polyvinyl chloride (PVC) ngezithasiselo ezahlukahlukene. Kukhona zombili izinketho zekhaya (PVC Lamiate) kanye nezakhiwo zezobuchwepheshe nezezimboni. Uma sikhuluma ngezakhiwo, isembozo saphansi egalaji le-PVC sithatha imisindo, senza ukuthi i-Floor ifudumele, i-sollents, amafutha, amafutha, aqinile, aqinile. Ngentengo eqhathaniswa nezindleko ze-linoleum yezentengiso.

Ngendlela yokubeka kunezinhlobo ezimbili zamathayili we-PVC - ukuhlanganiswa okuzenzakalelayo okuxhumeke kuma-Locks futhi akuxhunyiwe esisekelweni, kanye ne-coating egcotshwe nge-polymer glue. Ngaphansi kokubekwa kudinga isisekelo ngisho namaconsi angadluli ku-5 mm / m2. Lokhu mhlawumbe kungukuphela kokubuyisa emuva kwalokhu okubalulekile: indawo ebushelelezi egalaji ihlukile kunomthetho.

I-PVC tile isetshenziswa emagalaji okuhweba nasesiteshini senkonzo, lapho umthwalo uphezulu kakhulu

Phansi egalaji kusuka kuthayela

Qedela, kepha hhayi ukukhetha okuhle. Okokuqala, udoti uhlala uqongelela kuma-seams. Okwesibili, ukuhlanganiswa kuyashelela, ngaphandle kokuthi kuthathe i-tile ekhethekile nge-anti-slip ebusweni, kepha kungumgwaqo. Okwesithathu, i-tile ihlukaniswe kusukela ekuweni kwezinto ezisindayo. Kodwa-ke, phansi kusuka kuthayela egalaji kwenza, ngoba okuhle futhi kungu: kulula ukugeza, ubuchwepheshe obuziwayo bokubeka kahle.

Uma sikhuluma ngokukhethwa kwamathayili, khona-ke inketho engcono kakhulu izoba yi-porcelain yobuchwepheshe. Akukuhle njengokuhlobisa, kepha futhi nentando yeningi ethe xaxa. Indawo yayo ephukile ayislayidi, ibeka ubuchwepheshe obujwayelekile be-tile technology. Umuntu angazama kuphela ukwenza ama-seams amancane ukuze kube nezinkinga ezimbalwa nabo.

Izincwadi zobuchwepheshe ze-porcelain zingasetshenziswa ukumboza phansi ngegaraji

Kukhona ukuphela okubiza kakhulu phansi okubiza kakhulu egalaji - Thenga ukulwa futhi wenze "uMoseic". Kuliqiniso, isikhathi sokusebenza kwalolo msebenzi sizodinga okuningi, kepha impi ethayiwe iyathengiswa cishe i-snot.

Izitezi ezizimele

Izici ezinhle kakhulu zobuchwepheshe nokubukeka kunezitezi eziningi. Bangama-racks kakhulu amathonya angaphandle, aqinile futhi aqinile. Ukususa kwabo kuyisizathu. Ikakhulukazi ku-polymeric ne-epoxy. Ukubukwa kwesithathu - amakhonkrothi we-conkcrete bulk phansi - unentengo eyengeziwe yentando yeningi. Imvamisa isetshenziswa ngokwenza indawo yokuhlala eqinile nengeyona eyaphansi yegaraji.

Leli gama litholwe ngenxa yokuthi banokuvumelana okuwuketshezi futhi basakazekela ngesisekelo. Lezi zinhlaka zibizwa ngokuthi zizazi zisezingeni eliphezulu, ngoba ngenxa yezithelo eziphakeme, zisatshalaliswa ngaphezulu kobuso. Kepha ungacabangi ukuthi akudingeki adingeke ngisho na. Ukudonsa ukwakheka endaweni eyodwa, kuyadingeka ku-spatula noma uhlobo oluthile lwethuluzi, "kuhlakazeke" ngaphezulu kobuso, kusatshalaliswa ngokulinganayo. Ekugcineni, ikhambi lidalulwa lodwa, kepha ezikwakheni ezahlukahlukene izinga le-fluidity lihlukile, kepha ukusatshalaliswa kwesandla akusoze kwalimaza (imikhiqizo ebizayo imvamisa yasakazeka kangcono).

Ngaphansi kwalolu hlobo lokufakelwa phansi kwegaraji kudinga isisekelo esibushelelezi nesibonakalayo. I-Primer ikhethwe ngasikhathi sinye njengamafulethi amaningi. Njengoba ukwakheka okuqediwe akushibhile, zama ngangokunokwenzeka ukuvumelanisa isisekelo - ukunciphisa izinga lokugeleza inqwaba.

Khetha isembozo saphansi egalaji akulula - izinto eziningi ezihlangabezana nezidingo. Ukuphela kwento engama isabelomali esilinganiselwe kanye nesidingo sokuba nesisekelo esibushelelezi (futhi kudinga izindleko ezinkulu). Ukusuka kuleli phuzu lokubukwa, inketho yentando yeningi ebabazekayo - ukufakwa kabusha kanye nopende ngokhonkolo.

Isihloko esihlokweni: Yimiphi iminyango enhle ye-powder coating