Lapho ukhetha amapayipi, kuyadingeka ukubheka inani elikhulu lezinto zabo. Isibonelo, ngaphezu kwe-accounting yezakhiwo ze-physichicochemical, kuyadingeka ukuthi ucabangele ukuthi yibuphi ubude nobubanzi obuzoba. Kuvela ukuthi ama-hydrodynamics wohlelo lonke lokushisa ancike kububanzi. Iningi elisetshenziswa kakhulu futhi elisetshenziselwa izindlu zangasese lingamapayipi anobubanzi obungaba ngu-16- 40 mm.

Umdwebo wedivayisi ye-polypropylene tube.

Amapayipi aloluyazana ayakwazi ukubekezelela ingcindezi ohlelweni lokushisa, ngaphezu kwalokho, kulula ukuyisebenzisa ekusebenzeni, ngeke idale izinkinga kwinqubo yokufaka. Ukuyisebenzisa, unganikeza ukuphakanyiswa kwepayipi elifihlekile.

Yikuphi ububanzi bamapayipi e-polypropylene esetshenziselwa ukufudumeza

Ukukhetha kahle usayizi, ububanzi obungaphakathi kwamapayipi bubalwa ngokuya ngefomula elandelayo:

d = √ (4-u-1000 / Πl),

lapho unenani elilingana nokusebenzisa amanzi okuphelele endlini oluzowela kulokhu kuthola amanzi,

Π - 3,14.

L yisilinganiso sokugeleza kwamanzi, ngoba amapayipi obuyimitha amakhulu kubhekwa njenge-1.5-2 m / s, okwesikhashana - 0.7-1.2 m / s.

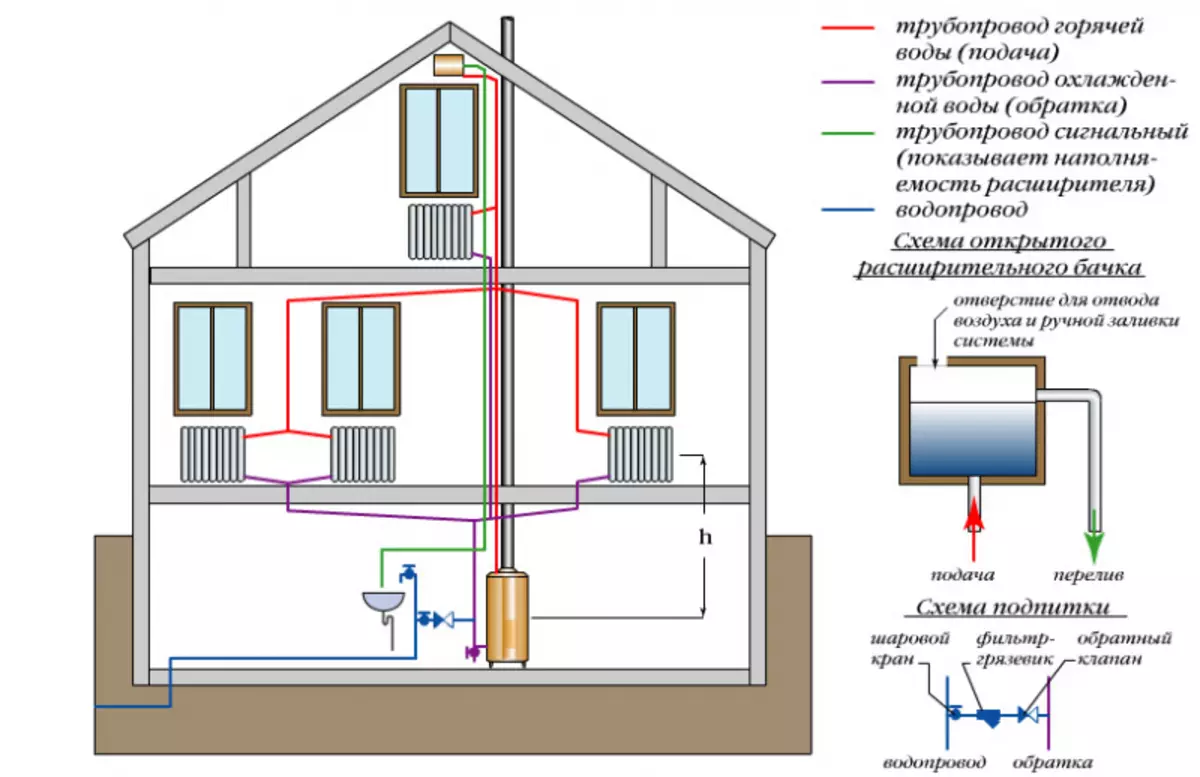

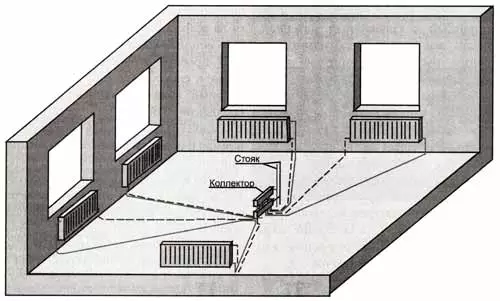

Uhlelo lohlelo lokushisa ekhaya.

Izinto ze-polypropylene zokushisa zisetshenziswa ububanzi obungaba ngu-20-32 mm. Ukubeka phansi phansi okufudumele, ipulasitiki enobubanzi obungu-16 mm bavame ukusetshenziswa kakhulu. Kubalulekile futhi ekuqaleni komsebenzi ukukala lonke inkinga yako bese ukhetha impahla edingekayo. Njengoba kunikezwe izici ezahlukahlukene ohlelweni lokushisa, udinga ukubala kahle isigaba se-Pipe Cross. Kubalulekile lapha okuningi: izinga lokushisa lomthwali, izinga lokugeleza, ubude bepayipi, ububanzi bepayipi nokucindezela kwamanzi kuyashisa.

Kukholakala ukuthi ngusayizi ofanele kuphela we-diameter oyifunayo yamapayipi e-polypropylene wokushisa azosiza ekwenzeni lonke uhlelo luthembekile futhi lusebenze kahle. Ezimweni zosayizi okhethwe ngokungalungile, ukushiyeka okuthile ohlelweni kungenzeka. Isibonelo, uma ububanzi bukhulu, ingcindezi ohlelweni lokushisa izoba ngaphansi kokwephulwa, okuzoholela ekwephulweni kokusakazwa kwamanzi kuwo wonke amakamelo eBig House. Futhi umsebenzi wokulungisa kuphela ozokwazi ukusungula ukusebenza kohlelo, okubonisa ukushintshwa kwamapayipi kumapayipi osayizi ofanele.

Ungayikhetha kanjani amapayipi anobude obungakwesokudla

Ezimweni lapho ukufudumeza kwenziwa khona endlini yangasese noma ekotishi, amapayipi kufanele akhethwe, kubhekwe iqiniso lokuthi ububanzi bungaguquki kuphela uma kukhona ukuxhumana okuqondile ohlelweni oluphambili lokushisa. Endabeni yohlelo lokuzimele lokuzimela, ungasebenzisa noma yiluphi usayizi (ububanzi obuhlukile nobude), kuya ngokuncamelayo komsizi uqobo.

Isihloko ngesihloko: Lunjani ujantshi wethawula likagesi?

Ukukhetha amakhono adingekayo, kufanele ubheke zonke izici, ikakhulukazi uma sikhuluma ngohlelo lokushisa lwemvelo, lapho isilinganiso sesigaba sesiphambano emandleni epompo ngeke kube uphawu lokuqala. Leli qiniso libhekisela ezinhlekeleleni zalolu hlelo lokushisa.

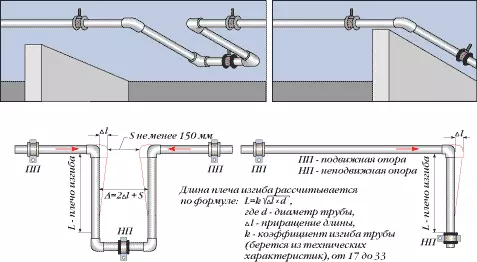

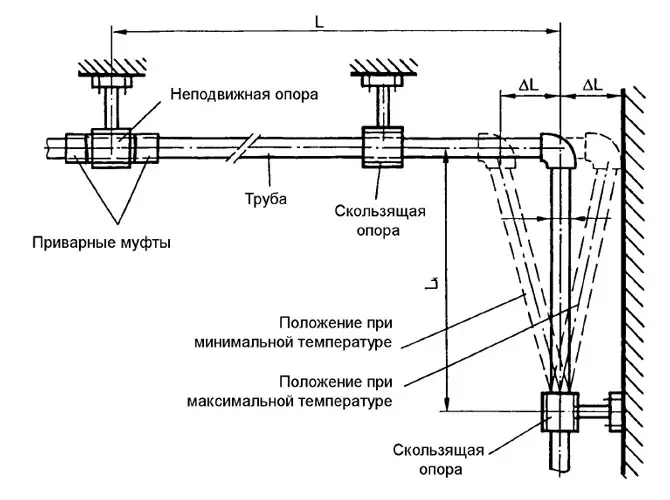

Isikimu sokukhuphuka kwepayipi.

Ukungathandeki kohlelo olunjalo kungumsakazo omncane wesenzo kanye nezindleko ezinkulu zezakhi zosayizi omkhulu osetshenziswe kuleli cala.

Ukuqinisekisa ukusebenza kahle kohlelo, kuyadingeka ukugcina izinga elithile lokucindezela, okuvumela ukuhamba ngaphakathi kwamanzi ukunqoba zonke izithiyo endleleni yalo. Ukumelana (izithiyo) kungaba ngesimo sokungqubuzana kwamanzi mayelana nezindonga, ukususwa noma i-crane kanye nensimbi yokushisa. Into ethakazelisa kakhulu ukuthi ngokunembile kusuka kubude nobubanzi bamapayipi epayipi kuya ngokumelana kanye nejubane lapho amanzi azogeleza ngalo. Ngejubane elikhulu lamanzi, isigaba esincane sesiphambano kanye nepayipi elide, izinga lokumelana nendlela yamanzi liyakhuphuka.

Yimaphi amapayipi alungele uhlelo lokushisa

Noma yiluphi uhlelo lokushisa lubandakanya ukubhala uhlelo lwephrojekthi. Emva kwalokho, kuyadingeka ukulungiselela kusengaphambili futhi ukhethe konke okudingekayo (izinto zokwakha kanye namathuluzi okufaka): Amapayipi, ukuqiniswa kabusha kanye namathuluzi adingekayo. Futhi kuphela emva kwalokho, kungenzeka ukuqala ukufakwa kwamapayipi e-polypropylene.

Izinto zikhethwe egumbini elithile, zinikezwe zonke izici zalo nohlobo lokushisa. Kubalulekile esigabeni sokulungiselela ukunquma amandla abo futhi baqonde ukuthi yimuphi umsebenzi ozoba yikho. Ngemuva kwakho konke, ukufakwa akulula ngaso sonke isikhathi ukukwenza ngezandla zakho, kwesinye isikhathi kufanele ufune usizo kochwepheshe.

Ngezinhlelo zokufudumeza, ukusetshenziswa kwe-polypropylene, insimbi nezinsimbi zensimbi-zepulasitiki kungenzeka. Zonke lezi zinto zokwenziwa zinezinzuzo zazo nokubi okudingeka kubhekwe lapho kukhethwa uhlelo lwazo. I-Polypropylene ibhekwa njengento efanelekile yezinto zohlelo lokushisa. Futhi, insimbi yehluka ngentengo eyeqile, kanye nokusetshenziswa okuyinkimbinkimbi, ayizinzile ekugqwaneni, okuholela ekwehliseni empilweni yabo. Izinto zensimbi-zepulasitiki zishibhile, kulula ukuzisebenzisa, kepha ukuthembeka kwazo nokuqina kwazo zishiya kufanele zifuneke, ngakho-ke kungcono ukungabhekisi le nketho yokwenza uhlelo lokushisa.

Uhlelo lokufudumeza kusuka kumapayipi aqinisiwe ePoyppropylene.

Ukusuka lapha singaphetha ngokuthi i-polypropylene isetshenziselwa kangcono uhlelo lokushisa, ngoba lusebenza njengenketho enhle yokubeka amapayipi amanzi. Kubalulekile ukwazi nokwazi ukuhlukanisa izinhlobo ezahlukene zamapayipi e-polypropylene enzelwe amanzi ashisayo noma abandayo. Sebenzisa izinto zokwakha kuphela ngohlobo oluthile lomsebenzi. Isibonelo, amapayipi okushisa, lapho amanzi ashisayo azohamba khona, akufanele usebenzise amapayipi ngamanzi abandayo, njengoba umbuso wokushisa uzoba ukwahlukahlukana okuhlukile futhi ukuphazamiseka kungenzeka.

Isihloko ngesihloko: Ukufika Phansi izandla zakho: I-Syclishishing ye-Syclishing yepulangwe edwetshwe ngokhuni, ividiyo enjalo yebhodi, ithuluzi lidala

Ukubeka phansi phansi okufudumele noma uhlelo lokushisa, ungakhetha ngokuphepha izinto ze-polypropylene ezinenombolo enkulu yezimpawu ezinhle, phakathi kwazo kufanele zikwazi ukungama amaphuzu alandelayo:

- Ukuthembeka.

- Ukuqina (kusebenze iminyaka eyi-100).

- Ukugcwala inzalo.

- Ukuntuleka kwemvula yamaminerali.

- Ukumelana okuphezulu kwemiphumela yamakhemikhali amakhemikhali.

- Intaba elula.

- Amandla okufeza umsebenzi wokulungisa ezimweni zokungasebenzi kahle noma zokuqhekeka.

- Ukutholakala kwentengo.

Okuwukuphela komuntu, kepha ukungathandeki okuyinhloko kwalolu hlobo lwezinto zokwakha kuyancibilika nokungazethembi kwamazinga okushisa aphezulu.

Ngezinhlelo zokushisa, ukukhetha okulungile kuyadingeka, okuncike kwisilinganiso esikhethwe kahle.

Ububanzi bamapayipi kufanele bube buncane kakhulu, kepha hhayi bukhulu, ukuze bungathinti izindleko zohlelo nekhanda lamanzi kulo.

Ukufakwa kohlelo lokushisa kusetshenziswa amapayipi e-polypropylene

Ukufakwa kohlelo lokushisa kubandakanya ukukhetha okulungile kohlelo lomsebenzi. Isibonelo, ukusetshenziswa kwamapayipi e-polypropylene kuhlinzeka ngezinketho eziningana:

Isikimu esikhuphukayo samapayipi amanzi ashisayo.

- Ukujikeleza kwamanzi okuzithandela kuhlelo. Kulokhu, asikho isidingo sokufaka iphampu yokujikeleza, ngoba ukuhamba kwamanzi kuzozikhandla. Le nketho ilungele izakhiwo lapho kuvame ukuba khona amathuba ezinkinga ngokusebenza kwemisebenzi kagesi, ezoholela ekutheni ingenele ukusebenzisa iphampu.

- Uhlelo oluphansi lwe-spill ekufudumaleni. Kulesi simiso, kunesakhiwo semisebe ethatha ubukhona bepompo esetshenziselwa ukukhulisa ingcindezi yamanzi, lapho kudingeka khona ubukhulu obuncane.

- Kungenzeka ukusebenzisa amasistimu angashadile futhi amabili amapayipi ngokuxhuma kwi-radiator usebenzisa uhlangothi noma uhlobo oluphansi lokuxhuma.

Ukufakwa kohlelo lokushisa kusuka kumapayipi e-polypropylene

Ukufakwa kwezinto ze-polypropylene kungenziwa kalula bobabili, futhi akudingekile ukwethemba le nqubo yokusebenza kumakhosi. Lapho ufaka, i-welding (soldering) isetshenziswa, akunakusebenza kungasebenzi amakhompiyutha ahlanganisiwe wamapayipi e-polypropylene.

Ngaphambi kokushiswa, amabhilithi anqunywa ezingxenyeni zobude obufunayo besebenzisa isikhafu esikhethekile, ukuze imiphetho ibusheleleke, ngaphandle kwemingcele, futhi konke lokhu kuvela ngokushesha okukhulu. Inqubo ye-welding yenziwa kusetshenziswa izinto ezikhethekile ezihloselwe le njongo. Ukushiswa kwe-welding, kuyadingeka ukufaka ipayipi ku-nozzle ye-nozzle yobubanzi obulungile (ububanzi kufanele buhambisane nama-nozzle) nokushisa kuze kube ukushisa kwamazinga angama-2 degree. Isikhathi sokushisa sepayipi sincike kububanzi baso, ngokwesibonelo, ipayipi le-20 mm lizofudunyezwa imizuzwana emi-5, kodwa ipayipi elinombala ongama-50 mm lizobe licwila imizuzwana eyi-18.

Isihloko ngesihloko: Ukwenza kanjani i-plasterboard arch - ubuchwepheshe obuhleliwe bokufakwa kanye nomhlobiso

Ngemuva kokuphela kwepayipi kufudumele, kufanele kuxhunywe ngokufaneleka okufudumele nokubamba ngemizuzwana engu-7 ukupholisa izingxenye futhi kwakha ukuxhumana okubekwa uphawu futhi okuthembekile ngenxa yalokho. Kubalulekile ukwazi futhi unaka ukuthi kwinqubo yokusebenza kuyadingeka ukusebenzisa izinto ezomile nezihlanzekile, lokhu kuthinteka kakhulu ngokuqina nokwethenjwa kwalo lonke uhlelo nohlelo lokushisa luzonke.

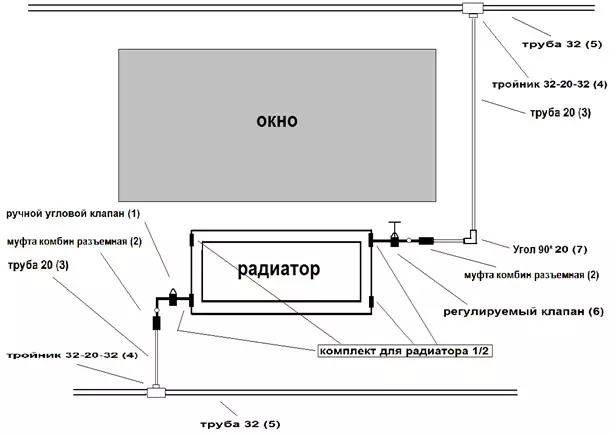

Scheme of iqoqo le-pipo wiring.

Uma kudingeka ukulungisa ohlelweni lwe-Pipeline esevele lwenziwe, kuyadingeka ukukhipha wonke amanzi ngaphambi kokuqala umsebenzi. Ukusetshenziswa kwezinto eziqinisiwe kusuka ku-polypropylene kusho ukuthunjwa kokuqala, okubandakanya ukususwa kwe-foil kusuka kupayipi esiteyeni esingu-15 mm usebenzisa ummese okhethekile. Ezimweni lapho ungqimba lwe-aluminium lutholakala ngaphakathi, khona-ke i-welding yenziwa ngaphandle kwalokhu kuhlubula.

Enqubweni yamapayipi okuthengisa, kubalulekile ukuqapha umbuso wokushisa, akunakwenzeka ukuvumela ukushisa ngokweqile, ngaphandle kwalokho ukwakheka kokunamathela kwangaphakathi kungenzeka.

Lapho inqubo yonke seyoqedwa, lonke uhlelo lwamapayipi kufanele luhlolwe futhi lukhiqize. Endabeni yokudlula komoya okulula ohlelweni, ungaqiniseka ukuthi akukho phunga. Uma kunesithiyo esithile emoyeni, kuyadingeka ukuyikhipha ngesikhathi esifushane kakhulu futhi ungakuhlehlisi lapho. Ngaphandle kwalokho, lokhu kube neziphambeko kungabe usuthela enkingeni enkulu. Yebo, futhi ubuyela emsebenzini owenziwe, khona-ke akufuni.

Lapho wonke umsebenzi usuqediwe ngokuphelele futhi uqinisekiswa, amanzi angaxhunyaniswa futhi ahlole uhlelo oluvele ngamanzi. Kubalulekile ukubheka wonke amalunga, qiniseka ukuthi amanzi awapholi noma kuphi futhi angadli. Wonke umsebenzi kufanele wenziwe ngamapayipi wobubanzi ukuze uhlelo luthembeke. Into esemqoka ukungakhohlwa ngohlangothi lobuhle lwalo.