Izindlela ezisemqoka zokukhetha ama-radiator zohlelo lokushisa ziyizinga elanele lokusebenza kahle kwe-thermal, ukubukeka okukhangayo kanye nentengo yedivayisi. Khetha idivaysi evutha engabizi ngokuya ngendlu yangaphakathi ayinzima. Uhla lwemodeli yemikhiqizo enikezwa yimakethe ihlukahlukene. Kunzima ngokwengeziwe ukukhetha i-radiator ngokudluliswa kokushisa okudingekayo egumbini elithile.

Ukushisa ama-radiator ukushisa ukushisa kuyindlela ebalulekile lapho ukhetha idivaysi yokushisa. Kubalulekile ukwazi ukuthi ukukhuphula ukushisa okuphezulu, i-radiator ingabhekana nokushisa kwalo lonke igumbi.

Ukubalwa kwamandla adingekayo we-radiator

Ukudluliswa okushisa okudingekayo kwama-radiator, inani labo kanye nenani lezingxenye kuzo lincike kwikhwalithi yokufakwa kwezakhiwo okwakhayo. Amapharamitha nohlobo lwamadivayisi okushisa anqunywa ukubheka izinkampani ezibandayo ezivela kumafasitela nezindonga ezingaphandle. Uma iwindi elilodwa nodonga lwangaphandle olulodwa lusegumbini, lokushisa 10 m2 yegumbi elinjalo, 1 kw wamandla afudumele we-radiators afakiwe azodingeka. Amakamelo alngular anezindonga ezimbili zangaphandle, leli nani likhuphuka liye ku-1.3 kW. Lesi sibalo samukelekile ezakhiweni ezinokuphakama okujwayelekile kophahla - 2.7 m.

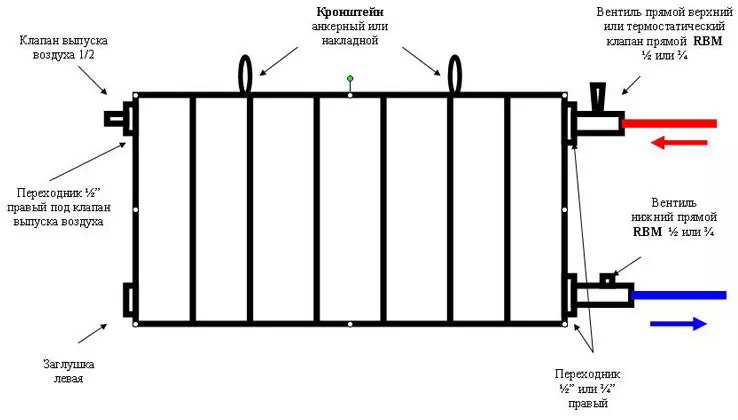

Umdwebo we-Connecting Radiator.

Ukubala ukudluliswa okushisa okudingekayo kwamabhethri okushisa ezakhiweni ezinophahla oluphezulu, idatha yomthombo olandelayo izodingeka:

- S yindawo yegumbi;

- h - ukuphakama kophahla;

- 41 w - amadivaysi aphansi okushisa okushisa okushisa 1 m3 ivolumu.

Ukushintsha amanani okuqala, uzokwamukela amandla aphelele aphelele wokushisa igumbi. Ukwehlukanisa umphumela okuholela ekudluliseleni okungukushisa kwesigaba esisodwa sama-radiator athengiwe, ungathola inombolo edingekayo.

Isibonelo, ukufudumeza igumbi lokulala elinobukhulu be-3x5 m kanye nokuphakama kophahla, ama-3.2 m kuyadingeka nge-radiator ngokushisa okushisayo 3x5x3.2x41 = 1968 W. Amandla we-Thermal engxenye ye-radiator ye-bimetallic ngu-185 W. Ukushisa, igumbi elibaliwe lizodinga (1968/185 = 10.63) izigaba eziyi-11 zebhethri lokushisa le-bimetallic. Uma ukubala kutholakala hhayi inani, kwandise inani layo ohlangothini oluningi kakhulu.

Isihloko ngesihloko: Yinikela ngempumelelo isihlahla kusuka kusibumba?

Ukuncika kokudluliswa kokushisa kusuka kokuqukethwe nokubekwa ama-radiator

Uhlelo lohlelo lokushisa ekhaya.

Ukusebenza kokushisa kwegumbi kuncike ekufakweni okufanele kwamadivayisi wokushisa.

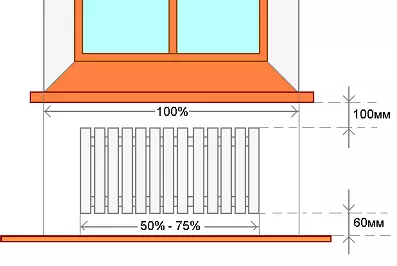

- Ukufakwa kwamabhethri kufanele kufakwe ngokuqinile ukuze ugweme ukunqwabelana komoya endaweni ephezulu yensimbi;

- I-Indent evela emigqeni yefasill kanye nobulili kufanele okungenani ibe ngu-10 cm;

- Ibanga ukusuka emaphethelweni aseceleni odongeni - okungenani 3 cm;

- Ifenisha nezinye izinto zasendlini akufanele ivikele ukushintshaniswa kokushisa kwensiza ngomoya. Akufanele basondele kuma-60 cm kusuka kumadivayisi.

Amandla we-Thermal ama-radiators ahluka kakhulu ngokuya ngalokho okwenziwe. Kukhuphuka inkomba yokuphakelayo eshisayo, izinto eziphambili ezisetshenziswe ngokulandelana okulandelayo:

- cast iron - 53 w / m * k;

- Insimbi - 65 w / m * k;

- I-Aluminium - 230 w / m * kuye.

Ukudluliswa okungcono kakhulu kokushisa kuma-radiators we-aluminium. I-Bimetallic Analogues ihlanganisa amandla afudumele we-aluminium kanye nezici zamandla zensimbi ezifakiwe ku-alloy. Ukudluliswa kokushisa kwamabhethri wensimbi kukhuphuka ngenxa yobukhulu obuncane bezindonga zabo. Ama-radiator wensimbi ama-cast anokudluliselwa okushisa okuphansi kanye ne-inertia ephezulu kakhulu ye-inertia.

Imvamisa, izinhlangano zokuhweba zihlangana ngohlu lwamanani zinikezela ngetafula ngamanani wokudlulisa wokushisa amamodeli ahlukahlukene nosayizi. Kwamabhethri wesigaba, amandla afudumele wesigaba esisodwa akhonjisiwe. Ithebula livame ukuhambisana nohlobo lwenothi: "Ukudluliswa kokushisa kukhonjiswa emazingeni okushisa angama-90/70/20 ° C.» Izinombolo ngokulandelana zisho izinga lokushisa lokuphola kokuphakelayo, endaweni yokuphuma kanye nokushisa ngaphakathi endlini.

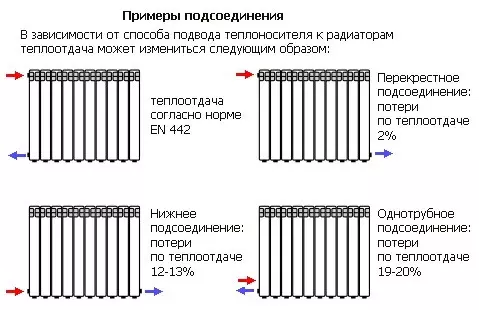

Umphumela wohlelo lokuxhumeka lwe-radiator ekudluliseni kwabo kokushisa

Isikimu sokuxhumeka kwebhethri futhi sithinta izinga lokudluliswa kwabo kokushisa.

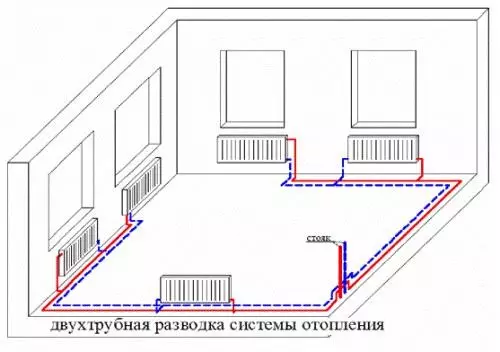

Ukushintshana okushisa kakhulu kwe-heath kwenzeka ngokuxhuma kwepayipi okubili kwamadivayisi wokufudumeza ku-pipeline.

Ukufakwa kwama-radiator we-aluminium wokushisa.

I-coolant, edlula kwi-radiator, ingena emgqeni wokubuyela emuva ngaphandle kokuwela kudivayisi elandelayo. Izinto zesistimu kulesi sikimu zixhunyiwe ku-parallel.

Isihloko ngesihloko: I-Laminate Treatment ngemuva kokubeka: izici

Kuhlelo lwebhethri olulodwa lwe-tube luxhumeke ngokulandelana. Ngakho-ke, wonke umdluliseli wokushisa we-radiator ukushisa okulandelayo kuzoba ngaphansi kwesokuqala. Ukulahleka kwamandla okushisayo kungasukela ku-25 kuye ku-45%. Isakhiwo esinjalo sisetshenziswa ezakhiweni ezijwayelekile zesakhiwo esidala.

I-ORTAMPAL maqondana nokusetshenziswa kwamandla kanye nebhalansi yokudluliswa kwe-radiator ukushisa okuhlangenwe nakho okunenye uhlangothi kumadivayisi wokushisa. Ukuxhumana okunjalo kwenziwa zombili nge-tube eyodwa kanye nokuhlelwa kwamapayipi amabili kohlelo. Umkhiqizi-ofunwayo kanye nokudluliselwa kokushisa okubaliwe kuthatha lolu hlelo lokuxhuma ngqo.

Lapho usebenzisa ama-radiator ngenombolo yezigaba eziningana, kwenziwa ukuxhumana kwe-diagonal. Lolu hlelo luqinisekisa ukumbozwa kwazo zonke izigaba lapho ujikeleza okupholile. Esikhundleni sedivaysi enezingxenye eziningi, ngaphezu kwe-10 kunconyelwa ukufakwa okulandelanayo kwama-radiator amabili anenombolo encane yezigaba.

Ukuqinisekisa amandla aphezulu we-armal, ishubhu yokuthenga ixhumeke kwipayipi eliphezulu lebhethri. Ukukhishwa kwe-coolant kwenziwa kusuka phansi kwezindlu. Ngakolunye uhlangothi lokugeleza okupholile, izinga lokudluliswa kokushisa lincishiswa libe ngu-50%.

Izinyathelo zokukhulisa ukudluliselwa kokushisa

Imithetho yokufaka ama-radiator okushisa.

Ukuze uthuthukise ukusebenza kwamadivayisi wokushisa ngemuva komzimba wedivayisi, isikrini se-Foil sinamathele odongeni. Idivayisi ikhombisa imisebe evuselelwa ukushisa eqondiswe ngaphakathi egumbini. Umkhandlu owengeziwe ungasebenza njengesakhiwo sensimbi esibekiwe esimisiwe odongeni. Kufanele kube umbala omnyama futhi uhlukanise odongeni.

Ibhethri lihlome ngensimbi ekhethekile yensimbi noma ye-aluminium. Izinhlaka ezinjalo zandisa indawo yokushintshanisa ukushisa. Engxenyeni engenhla yamaphakethe webhethri noma ukuxhumana, kufakwa amadivayisi ezindiza. Ukususa ama-air Stoppers kudivayisi kuthuthukisa ukuxhumana kwe-coolant ngendwangu yecala.

Ukukhuphula usayizi wokushisa kwekamelo, ama-radiator afushanise afudumele noma lonke uhlelo alonke. Umcimbi uvumela ukulinganiselwa kwesikali namanye amadiphozithi angaphakathi kwamapayipi namadivayisi. Ukuhlanza uhlelo kwenziwa ngamakhemikhali, i-hydrodynamic kanye ne-pneumohydrountump.

Isihloko ngesihloko: Ukufundela umnyango kwenze ngokwakho: Izincomo zokufaka

Indlela Egqamile yokwandisa amakhono okukhiqiza okushisa kwamadivayisi wokushisa ukuwafaka esikhundleni sanamuhla futhi esebenza kahle. Kepha ukufudumala okuseqophelweni eliphezulu kunganikezwa kuphela endabeni yokusebenza okwanele kohlelo lonke kanye namapharamitha ahambisanayo we-coolant.