Ukufakwa kohlelo lokushisa phansi phansi ngaphansi kwethayela - inqubo ilula, kepha idinga ukuhlela ngokucophelela nokunaka. Ukuze wenze ukukhetha okulungile futhi ngemuva kwalokho faka phansi phansi okufudumele ngaphansi kwethayela ngezandla zakho, kubalulekile ukwazi ukuthi yiziphi izinhlobo ezansi ezifudumele, kanye nezici zawo.

Izitezi eziqinile ezintantayo

Kaningi, abaniniyo bazibuza ukuthi yini indawo efudumele okufanele uyikhethe ngaphansi kwethayela. Ukuze uthole impendulo engavuthwa, kuzodingeka ukuthola izici zayo yonke imikhiqizo eyethulwe. Ukukhethwa kwesitezi esifudumele ngaphansi kwethayili kuphazanyiswa ngenxa yezinhlaka ezifudumele zezinhlobo ezahlukene zezinhlobo ezahlukene nezakhiwo ezenzeka.

Ngaphambi kokukhetha uhlobo oluthile lokufudumala phansi kanye nokufika phansi, udinga ukuthola ukuthi yini engathinta inqubo yokusebenza kohlelo lokushisa.

Imvamisa, izinhlobo zezimbozo zaphansi zingukulandelayo:

- Izinto eziphilayo okubandakanya i-parquet, ibhodi yocansi, i-linoleum yemvelo ne-laminate;

- Izinto ze-polymer , njengamathayili we-PVC nanoma yiluphi uhlobo lwe-linoleum kusuka ezintweni zokwenziwa;

- Izintombi Zeminerali - I-Tile, i-Cement Screen, isembozo se-bulk floor.

I-tile izoba yisinqumo esihle kakhulu sokugezela phansi.

Amathemba okukhangisa akhuluma ngokuba khona kwe-laminate enezakhiwo eziphindayo zamanzi, kanye nezingubo ze-hydrophobic ezinyaweni zokhuni. Kodwa-ke, kufanele wazi ukuthi izinto zemvelo kanye nomswakama azifaneleki kakhulu.

Ama-polymers atholakala kalula ethonyeni lamanzi, kepha ngokuhamba kwesikhathi ngaphansi komthelela omkhulu womswakama, ukunamathela kulezi zinto kungabhujiswa. Isibonelo, uLinoleum uqukethe izingqimba eziningana, nalapho uketshezi luphakathi kwabo, okuqukethwe kuzovuvukala.

Isembozo samaminerali phansi asisabi ngokuphelele amanzi. Ngakho-ke, izindawo ezinjalo zizoba ukukhetha okuhle kwamakamelo anomswakama ophezulu. Isixazululo esifanelekile sendlu yokugezela sizobe sibhekene nama-tile aso ceramic.

Izinhlobonhlobo zezakhiwo zokushisa phansi

Abanikazi abaningi bakhathazekile ngenkinga yokuzikhethela: phansi okufudumele ngaphansi kwethayela, okungcono. Ukubuyekezwa kwezinhlobo ezahlukene zezinhlelo zikhona zingqubuzana kakhulu. Ngakho-ke, kuyadingeka ukuthola izici ezinhle nezingalungile zayo yonke imikhiqizo ukuze uthenge kahle lokho okufanele.

Abanye ochwepheshe bathi i-tile akuyona inketho engcono kakhulu yokusebenzisa ezakhiweni zokuhlala, ngoba lokhu kusebenza kubanda kakhulu ukuya nge-arefoot. Kodwa-ke, lokhu kumane nje kufana neqiniso.

Indawo efudumele yamanzi isebenza kusuka ku-boiler noma i-boiler

I-Tile ibheka amandla aphezulu okusebenza okushisayo. Le mpahla izoba yinzuzo lapho ibeka isakhiwo sokushisa. Ngaphezu kwalokho, i-tile idlulisela ngokuphelele umehluko wokushisa, odalwe lapho oxhumana nabo befudunyezwa ngesikhathi sokusebenza ngokufudumele. Kuzoba wusizo ukucacisa umehluko phakathi kwabo ukuze uqonde ukuthi ungasikhetha kanjani phansi okufudumele ngaphansi kwethayela. Abaniningi sebevele befake lokhu noma lokho kusiza ukuzulazula nokukhetha inketho efanelekile.

Isihloko ngesihloko: Izinhlobo zezitini zokubhekana nezindawo zokucima umlilo nezitofu

Izinto zokushisa zikagesi futhi zisebenza ngomgomo wamabhethri okushisa, emanzini, igesi efudumele noma ugesi.

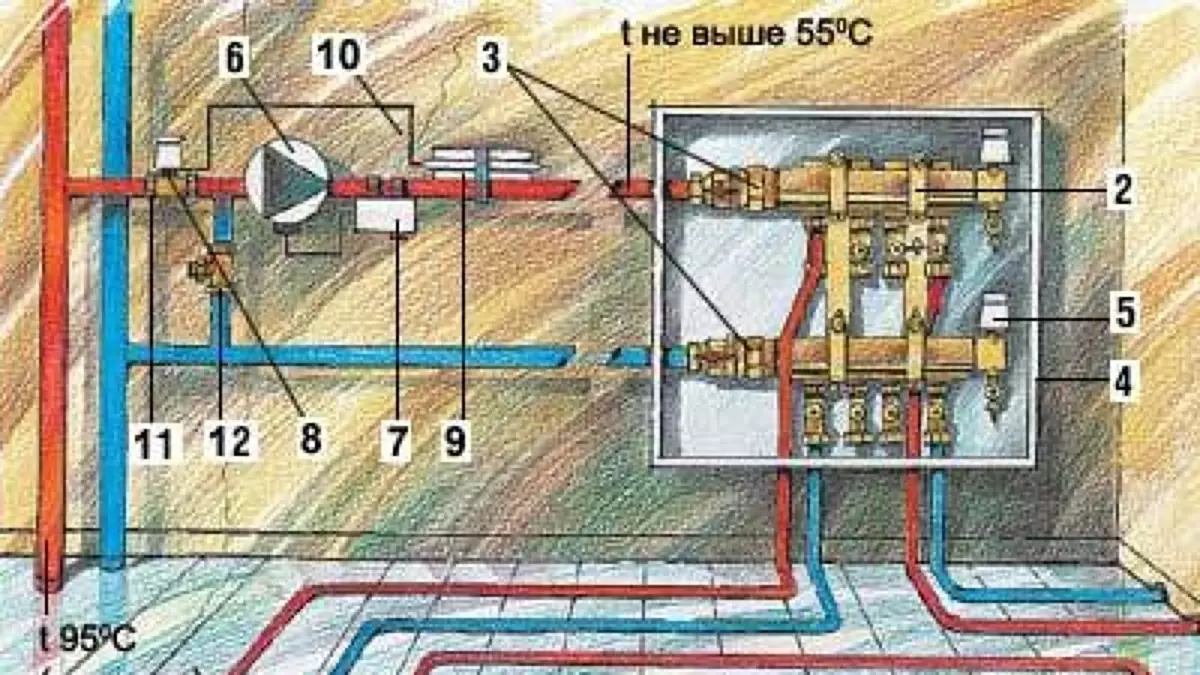

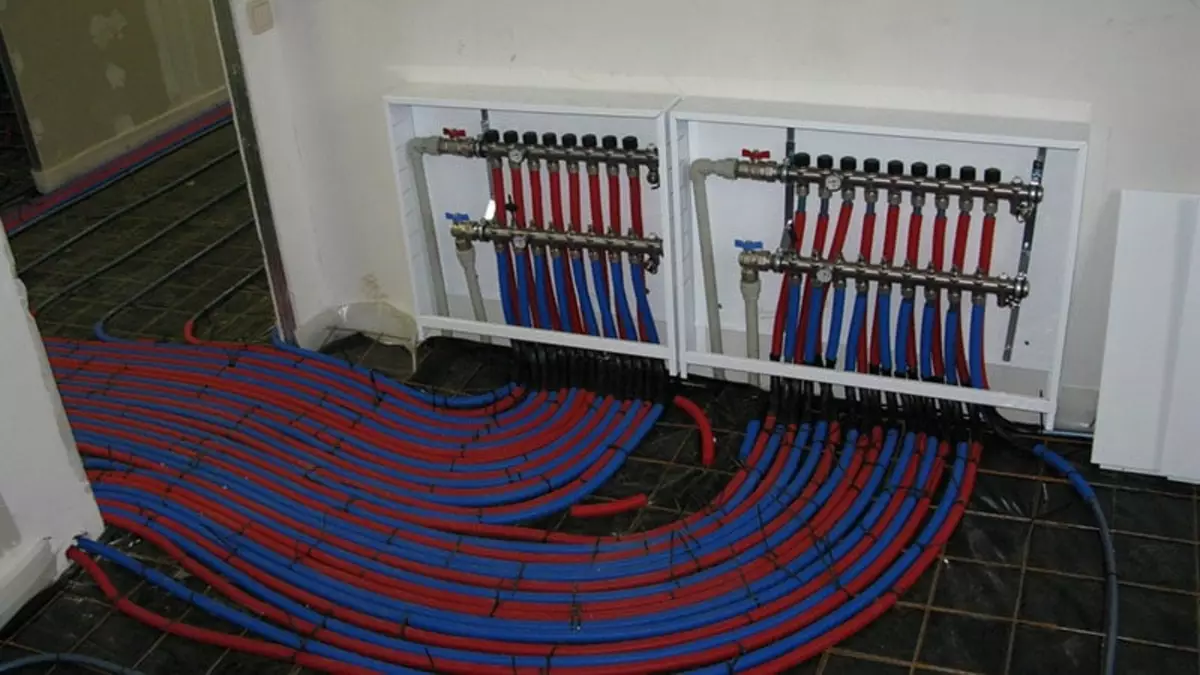

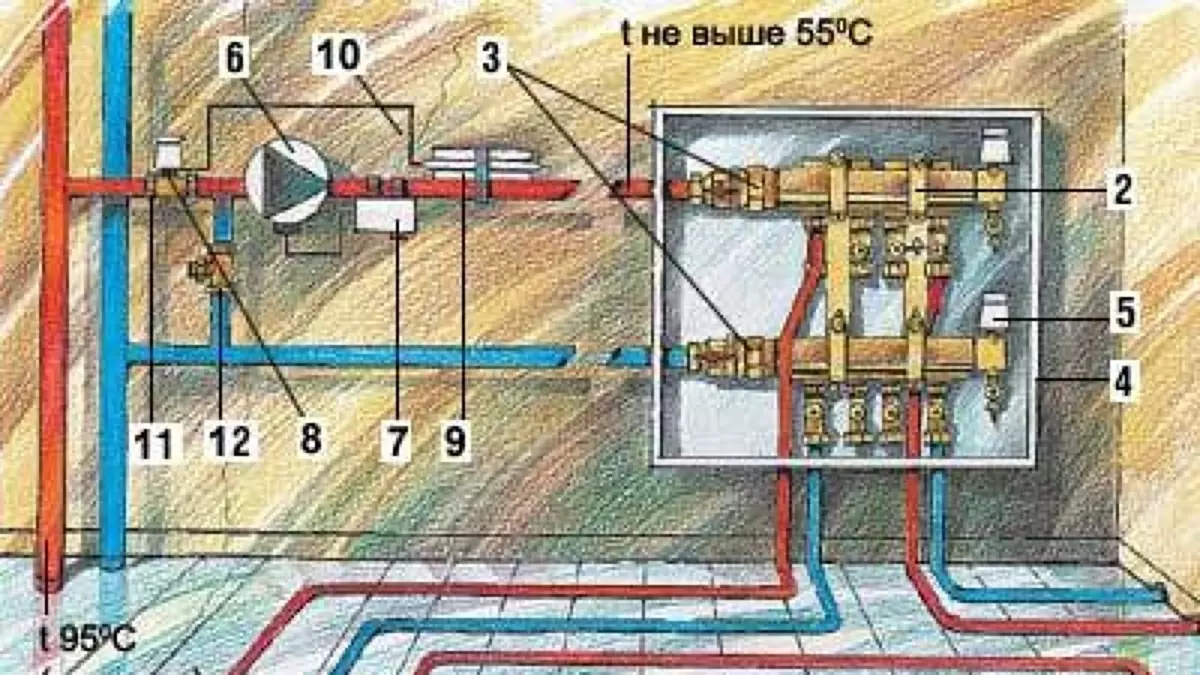

Ukwakhiwa kwamanzi kokushisa - Lolu uhlelo oluvaliwe lapho uketshezi olufudumele luhamba ngamapayipi kusuka ethuneni noma ama-polymers. Uhlobo olunjalo lwesitezi esifudumele lungaxhunyaniswa esikhungweni sokushisa (efulethini) noma ku-boiler noma i-boiler (ekotishini).

Uhlelo lokufudumeza lwamanzi luzoba lungabizi kakhulu ekusebenzeni.

Ukuze ufunde ukuthi ungawenza kanjani phansi okufudumele ngaphansi kwethayela egumbini lokugezela, cabanga ngolunye uhlobo lwezinhlelo zokushisa.

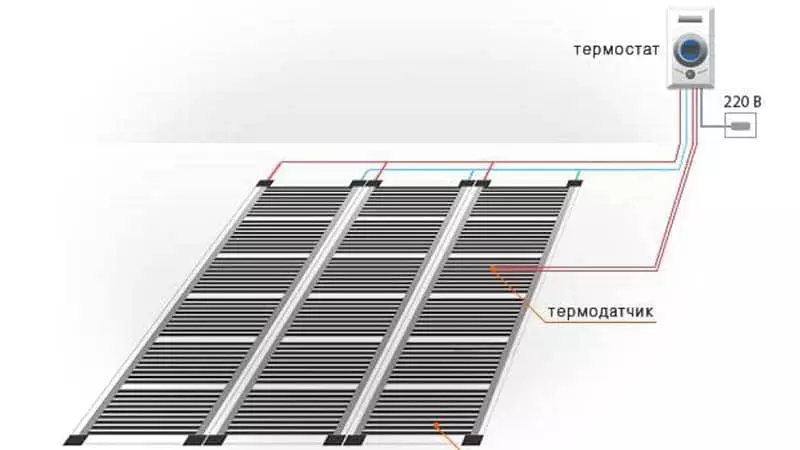

Kwazo zonke izinhlelo zikagesi, amafulethi afudumele amafilimu angokomnotho kakhulu

Izinhlelo Zogesi - Indlela ethandwa kakhulu yokusatshalaliswa kokushisa okufanayo ngaphezulu komhlaba. Isebenza ngenxa yengxenye ekhethekile yokufudumeza ngesimo socingo oluhlanganiswe ngokuphelele phansi ngokuphelele phansi. Lapho kushukumisa lokhu okucacisiwe, i-tan iyavutha. Kunezindlela eziningana zokuhlonguswa ngamakamelo okufudumala kagesi:

- ukufaka Ifilimu Elikhohlisiwe;

- UPawulu ngu Ikhebula kagesi;

- Ukubeka umklamo I-termomatov.

Izici zohlelo lokufudumeza lwamanzi ngaphansi kwe-ceramic ebheke

Ukuthola ukuthi ungayenza kanjani phansi efudumele ngaphansi kwethayili kahle, udinga ukuhlola umgomo womsebenzi wayo futhi wazi ama-nuances ukufaka umklamo.

Ubungqayizivele bokusebenza kwamanzi afudumele amanzi aqukethe ukusakazwa kwamanzi afudumele ngamapayipi avela epulasitiki yensimbi noma yethusi, ebekwe ngaphansi kokuqedela phansi phansi. Uhlelo lunikwa amandla ngokushisa okuphakathi noma okuzimele. Izindleko, ukufakwa kanye nokusetshenziswa kwamandla kwalolu hlobo lokushisa kwaphansi kushibhile kakhulu, uma kuqhathaniswa nama-analog kagesi.

Kepha kunezinkinga ezingathandeki - ezindlini eziphakeme zokwakhiwa kwamashumi ayisithupha, ukufakwa kokushiswa kokushisa kwamanzi akunakwenzeka. Njengoba ukubheja kwabo kungenzeka kungabekezeleli imithwalo eyengeziwe. Ngaphezu kwalokho, kunzima impela ukuthola imvume yokwengeza uhlelo lokushisa ezindlini eziphakeme.

Ukufaka amasistimu anjalo anama-nuances alo. Okokuqala, i-Polyethylene band babekwa eceleni kwezindonga ukuze baqede izikhala futhi banikeze ukuqina komthungo. Kufanele ifakwe kwindawo ehambisanayo ye-concrete screedes usebenzisa ama-dowels noma ama-parachutes akhethekile ".

Okulandelayo, isikrini esibonisa isitayela siphakanyiswa. Lokhu kuyinto eyinhlanganisela kusuka ku-polypropylene fiber kanye nefilimu eyenziwe nge-metallized, enezakhiwo zokubonisa imisebe eshisayo kanye nokufakwa kwe-hydrocariolar. Ifilimu kumele ilungiswe ngokuqinile kwitheyipu yekhambi isebenzisa itheyipu.

Isihloko ngesihloko: Izimbali ezifundwayo ekotishini: Imfihlo yempumelelo

Ngenqubo yokubeka amanzi ngaphansi komhlaba, wonke amapayipi axhumeke kwi-Distribution Manifold

Esigabeni esilandelayo, amapayipi ayabekwa. Udinga ukusebenzisa amashubhu akhethekile abekwe kugridi. Ngasikhathi sinye, ibanga ukusuka ezindongeni kufanele okungenani kube ngamasentimitha ayishumi.

Enqubweni yokubeka amapayipi, kufanele unake iqiniso lokuthi libekwe ngokuqinile emikhondweni etholakala kugridi ekhethekile. Ngemuva kokudluliswa kokulungiswa kwe-thermometer kufakwe. Ekupheleni kwenqubo yokwakhiwa, imbozwe ngesendlalelo sikasimende Screed.

Ukuhlukaniswa kwezitezi ezifudumele kagesi zikagesi

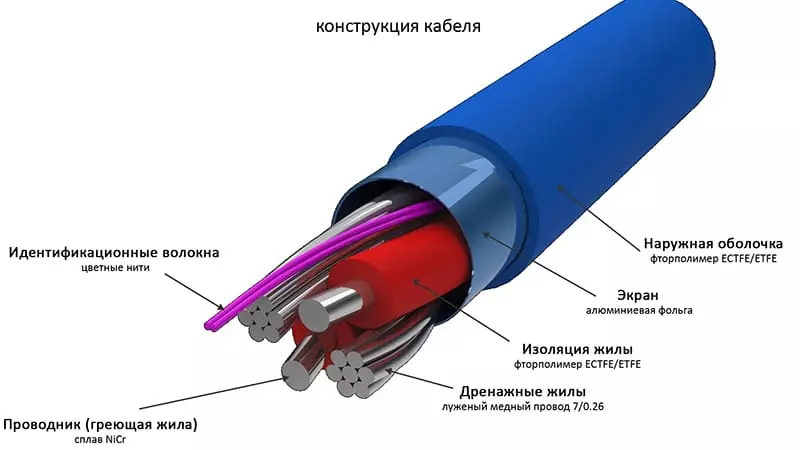

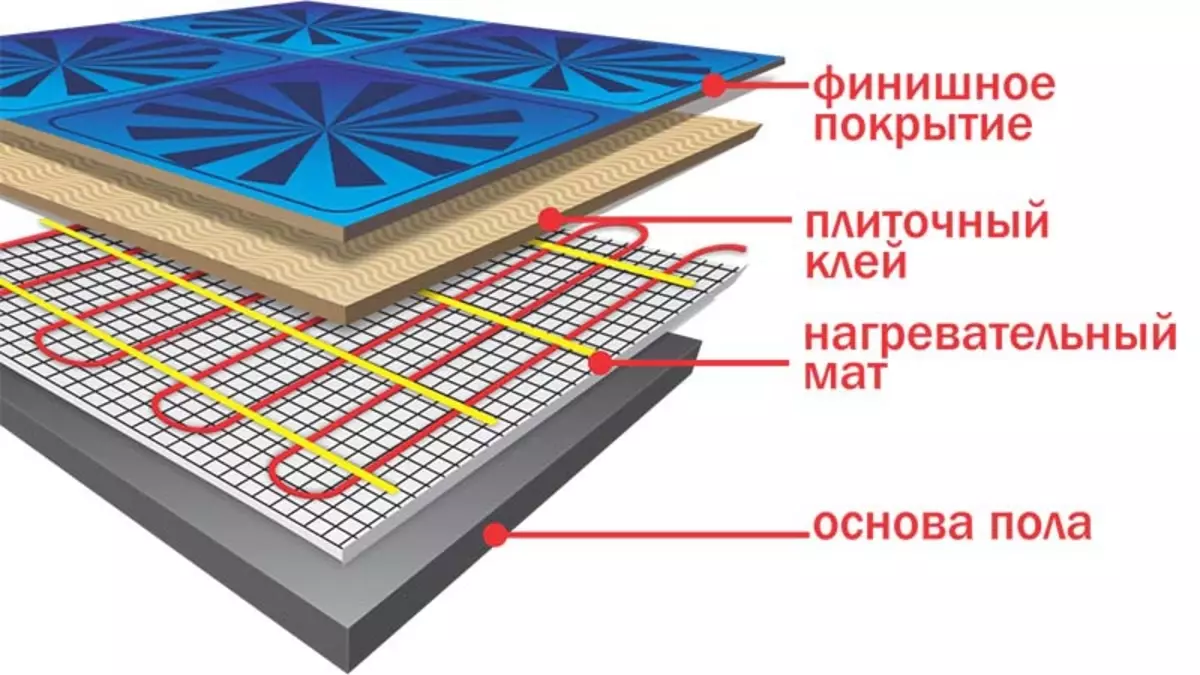

Ukufakwa kwesitezi esifudumele ngaphansi kwethayili kusuka ezinhlelweni zokushisa kagesi kungenzeka. Imvamisa lolu hlobo lokufudumeza oluphansi luhlinzekelwe njengomthombo wokushisa okukodwa kokushisa okuphakathi noma okuzimele. Kunezinhlobo ezintathu zokushisa kagesi - infrared, ikhebula nangendlela yama-thermomats. Ukuthola ukuthi yisiphi isitezi esifudumele esingcono ngaphansi kwethayela, udinga ukwazi imininingwane mayelana nalezi zinketho.Uhlelo lwekhebula likagesi

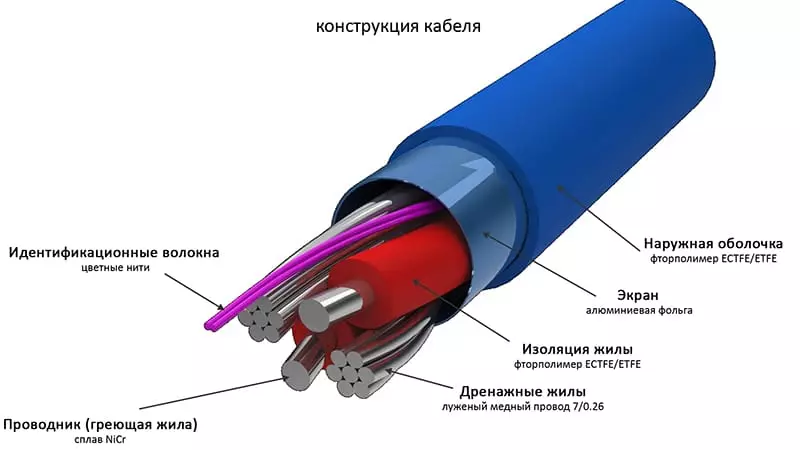

Kulezo zinhlelo zokushisa ezinjalo, ucingo olukhethekile lwezindlu ezimbili luhlukaniswe nezinto ezibonakalayo njengomqhubi wokushisa. Ububanzi bekhebula akufanele bube ngaphezulu kwe-8 mm.

Amandla kagesi adlula ngentambo, ngokuya ngemithetho ye-physics iphenduka ibe yi-thermal.

Uhlelo lokushisa phansi oluphansi luthululelwa ngocingo olufinyelela ku-60 mm obukhulu. Tile ephezulu tile. Usayizi wesinyathelo lapho ubeka ikhebula kusuka ku-80 kuya ku-250 mm. Inzuzo eyinhloko yokwakheka kwamakhebula kuzoba lula ukufakwa nokudluliswa okuphezulu okuphezulu. Kulokhu, i-tile esitezi esifudumele izoba yi-coating efanele.

I-wire-yezindlu ezimbili ingumthombo wokushisa ohlelweni lukagesi lwe-Cable of the Flock Floor

Kodwa-ke, kunezinye izindlela. Ukufaka lolu hlelo kudinga ukunamathela nge-screen, ukushuba okungenani kwamasentimitha amane. Esikhathini sokuphakama kwentambo, ukuhlanganiswa okukhohlisayo kanye ne-ceramic kungaba cishe amasentimitha ayisithupha - okuzokwehlisa kakhulu ukuphakama kwendlu yangasese.

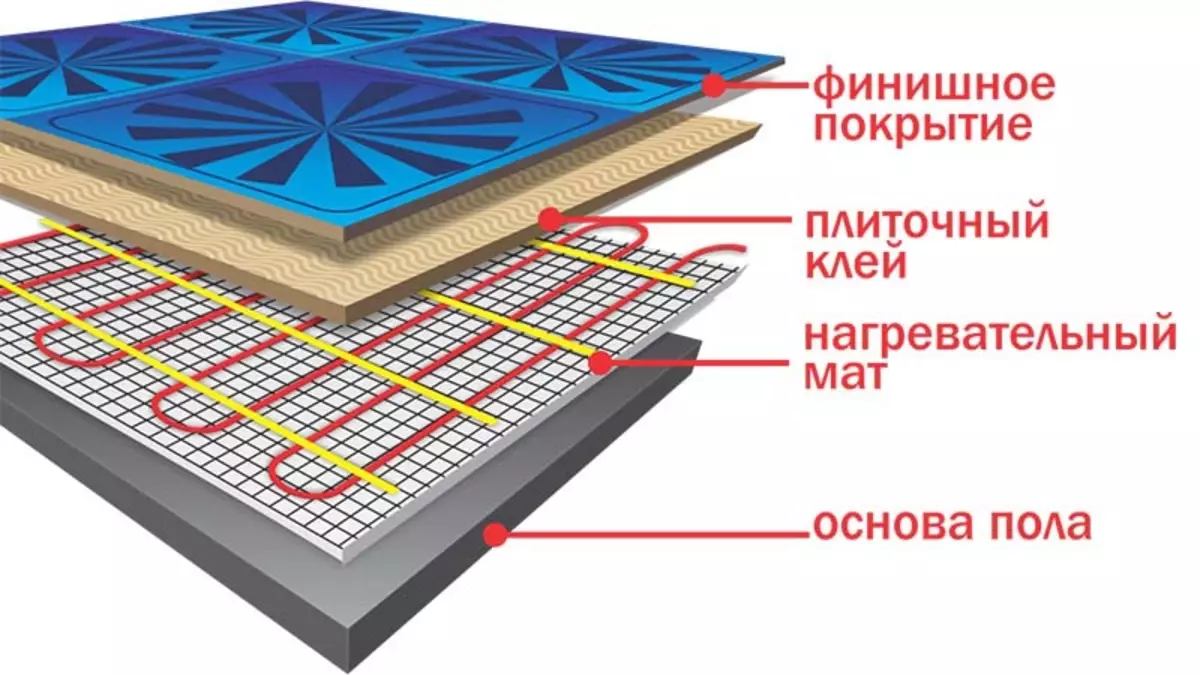

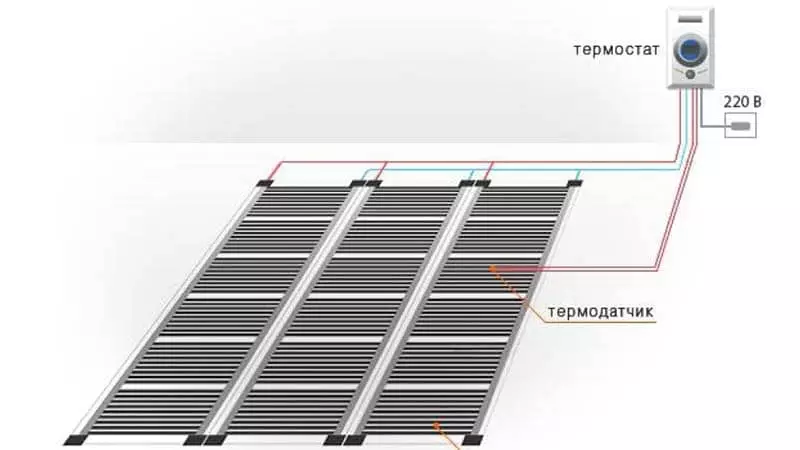

Ukushisa uhlelo lokushisa ngendlela yama-thermomats

Isikimu esinjalo sivame ukusetshenziswa uma kunesidingo, hlela phansi okufudumele ngaphansi kwe-PVC Tile. Lo mklamo uqukethe amaseli asekelwe ngokuqinile we-polymer, lapho ikhebula lwamanje lwesigaba esincane liyaqiniswa.

Uhlobo olunjalo lwesitezi esifudumele lunethuba lokungabi nalutho lokuthi aludingi ukubikwa kwe-screen, kepha uma kunesidingo, kungathululelwa.

Ukufakwa kwenziwa ngokulandelayo. I-Thermomats enentambo yokufudumeza isatshalaliswa phezu kwefenisha yamahhala futhi enamapayipi, khona-ke ungqimba lwe-glue lwe-tile luhle kakhulu futhi kudlula amathayili.

Ukufaka uhlelo lokushisa okunjalo kwaphansi kulula kakhulu futhi akudingi amakhono akhethekile. I-Thermomats iyintambo efanayo yokushisa, ubukhulu obuncane kuphela futhi buhlelwe esisekelweni se-mesh, ngenxa yokuthi ama-mat afakwe kuwo ngqo engxenyeni ye-tile glue, kanye nokuhlanganiswa kwengxenye yokufudumeza kuyo, kuzosebenza njengokuqiniswa kwayo.

Isihloko ngesihloko: I-Homemade Kneseseseses Sperning Machine

Ukubekwa phansi okufudumele kwamabutho ama-thermomats ngisho nakamuva

I-Heating Mats ivame ukukhiqizwa ngobukhulu obufinyelela ku-3 mm, ngenxa yokuthi ukuphakama kwaphansi ngemuva kokufaka uhlelo lokushisa aluguqulwanga.

Uhlelo lokushisa oluphansi lwe-infrared floor

Lo mklamo uyifilimu yokufaka insulatiting, ehlukaniswe izingxenye ezihlukene ze-500x500 mm ngosayizi, lapho isikwele ngasinye sigcwele ngenombolo enkulu edlulisela phansi inethiwekhi yoxhumana nabo exhunywe kwinethiwekhi yokuhlinzekwa kwamandla futhi ixhunyiwe. Umehluko wesimo phakathi kohlelo olunjalo kusuka kwamanye ama-analogue ukuthi akukhiphi imisebe ye-electromagnetic. Ngasikhathi sinye, ukufudumala okufanayo kwegumbi kwenziwa ngenxa ye-convection kanye nokugcwaliswa komoya ngama-ion athelwe kabi.

Isitezi esifudumele se-infrared sinezinzuzo eziningi. Inobukhulu obuncane kakhulu (cishe ngo-0,3 mm) kanye nokusetshenziswa kwamandla okuncane. Enye inzuzo kuzoba ukuguquguquka kwalolu hlelo. Cishe noma yisiphi isivalo saphansi ngale ndlela. Kwesinye isikhathi lezi zinhlaka zisetshenziselwa ukushisa ithayela likakhonkolo ngisho nangaphandle.

Uhlelo lwe-infrared floor flour luzoba yisixazululo esifanelekile sokubeka i-tile ngaphandle kwesihlahla

Akungabazeki ukuthi izinhlelo zokushisa ezifudumele - indawo efudumele efudumele ngaphansi kwethayili ngaphandle kwesihlahlana. Izithombe zamasampula emiklamo efanayo ongayibona kugalari yalesi sihloko.

Kodwa-ke, kunama-nuance athile wokubeka phansi okunjalo ngaphansi kwethayela. Ukunamathelisa okuphezulu kwefilimu kusuka kuma-polymers kunomthelela ekubhujisweni kancane kancane kwe-alkaline medium ye-glue tag. Ngakho-ke, ochwepheshe banconyelwa ukuba babunjwe phakathi kwezitezi ezifudumele zefilimu kanye namashidi acwebezelayo we-ceramic wepulangwe.

Ngokuqhathanisa izici zamanzi nezinhlelo zokushisa kagesi, ungazitholela ngokwakho ukuthi yimuphi umklamo ofanelekela egumbini lakho lokugezela. Kumele kushiwo ukuthi bonke banezinzuzo zabo nokubi. Ngakho-ke, indlela yokuxazulula inkinga yokuzikhethela kufanele ibe ngumuntu ngamunye.

Ukufaka izitezi zamanzi ezifudumele Kubaluleke kakhulu ukukhetha kahle ukhethe ukufakwa futhi wenze ngokunembile ukubalwa kwamapayipi

Ukubeka i-tile ngaphandle kwesihlahlana kumakamu kagesi

Uhlelo lwe-infrared floor flour luzoba yisixazululo esifanelekile sokubeka i-tile ngaphandle kwesihlahla

Ukubekwa phansi okufudumele kwamabutho ama-thermomats ngisho nakamuva

I-wire-yezindlu ezimbili ingumthombo wokushisa ohlelweni lukagesi lwe-Cable of the Flock Floor

Ngenqubo yokubeka amanzi ngaphansi komhlaba, wonke amapayipi axhumeke kwi-Distribution Manifold

Kwazo zonke izinhlelo zikagesi, amafulethi afudumele amafilimu angokomnotho kakhulu

Indawo efudumele yamanzi isebenza kusuka ku-boiler noma i-boiler

I-tile izoba yisinqumo esihle kakhulu sokugezela phansi.