Isigaba ngasinye sale phrojekthi kufanele sithuthukiswe kahle sinaka yonke imithetho, imithetho kanye nama-nuances. Ngaphambi kokubala phansi okufudumele kwamanzi, kufanele uzijwayeze ngezici zokufakwa kwawo. Lokhu kufanelekile ukuthi amaphutha azokwenzeka ngesikhathi sokusebenza azolungiswa ngeke akwazi.

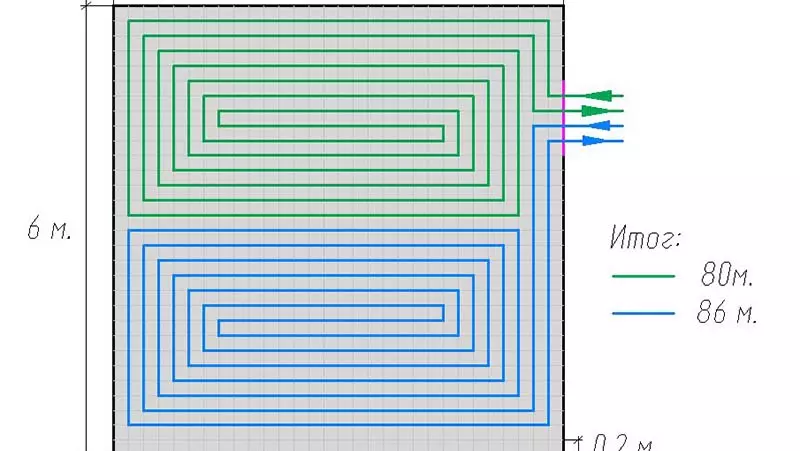

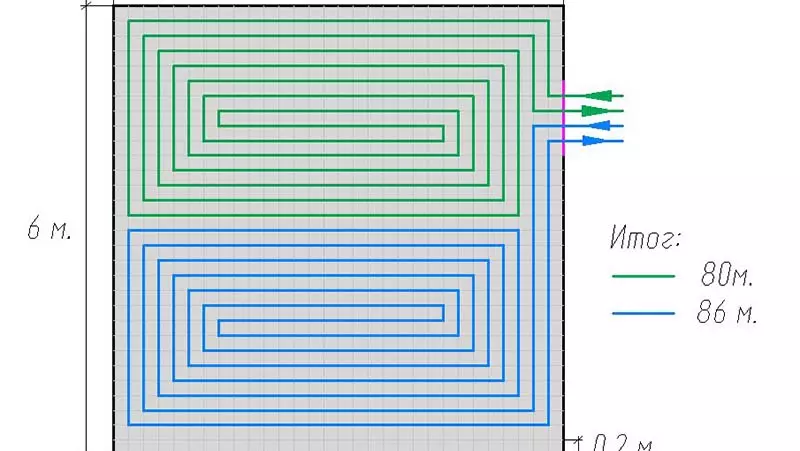

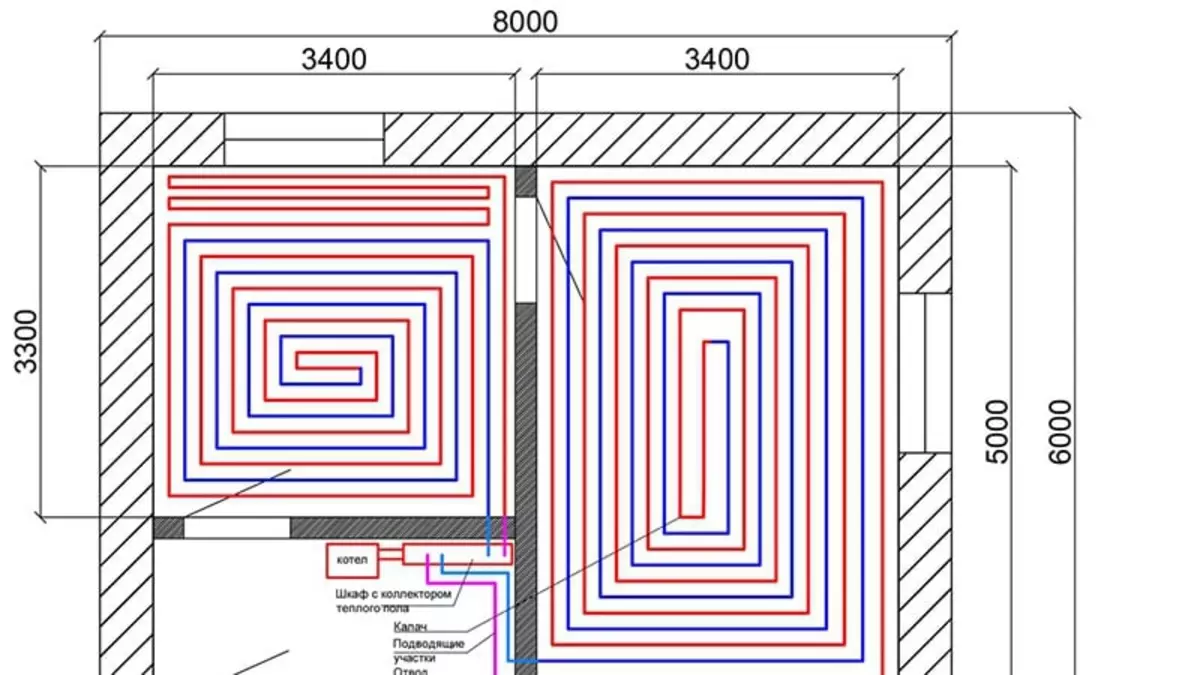

Ngaphambi kokuthi uqale ukuhlela phansi okufudumele, kufanele wazi isisekelo nomgomo womsebenzi. Isinyathelo sokuqala ukudonsa uhlelo olujwayelekile lwamapayipi, ngenkathi ukunakwa okukhethekile kufanele kukhokhwe endaweni ewusizo yegumbi, nakho nokuhlanza izinto zefenisha. Kucatshangelwa usayizi wekamelo, kwakhiwa umdwebo lapho kuphela izilinganiso ezinembile okufanele zisetshenziselwe.

Ipayipi elifudumele elifudumele

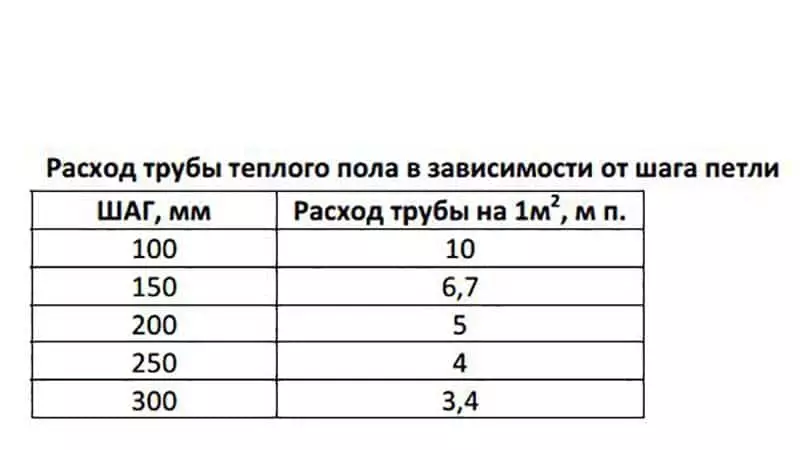

Ukubalwa kobude bamapayipi okufudumele kwamanzi phansi kususelwa esicini sokuthi ubude obukhulu banoma iyiphi indawo ngeke bube bukhulu kune-80-100 m.

Isikimu esifudumele sendawo yokubeka kanye nokubalwa okudingekayo

Ungalahlekelwa ukunakwa nobude bokubekwa. Ngokwesilinganiso, kungu-150 mm, kepha kwahle futhi kunciphe kuya ku-100 mm, okujwayelekile ezimeni ezipholile. Ipayipi ngokwalo kufanele libekwe kude ne-150-250 mm kusuka ezindongeni zekamelo.

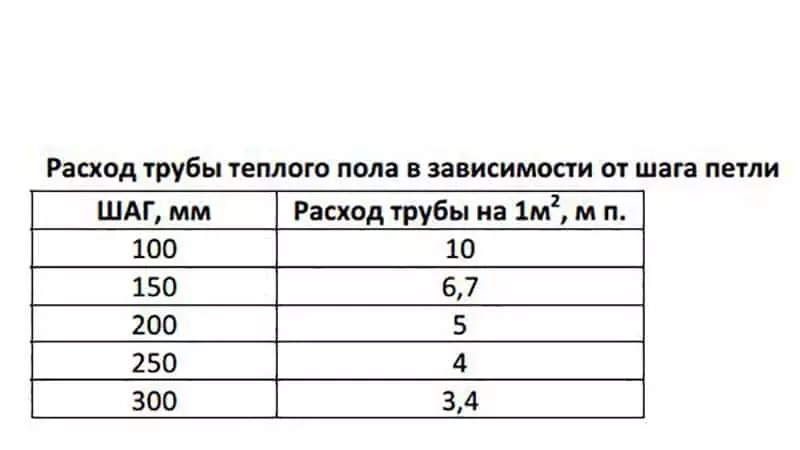

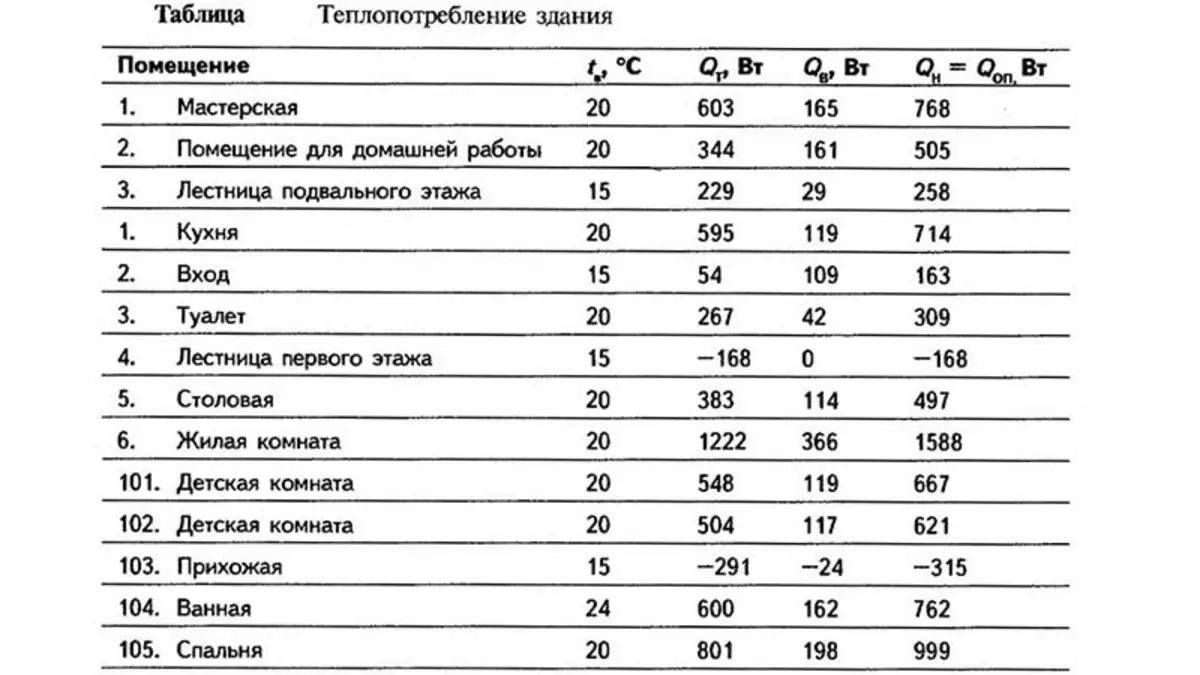

Ithebula lokusebenzisa elifudumele likaPawulu

Ukubala isikhathi esiphelele sepayipi okuhloselwe umjikelezo ohlukile, kusetshenziswa ifomula elandelayo:

L = s / n * 1.1,

-Phi S. - Indawo ezombozwa yilesi sakha, N. - Ukuhlala ubude besiteji, 1.1 - Isilinganiso se-coefficient esibonisa isitoko esidingekayo ekugobeni.

Futhi, leli nani kufanele lingeze amapharamitha omude wepayipi okudingeka ukuthi afake umugqa wokuphakelayo, kanye nokwakha igatsha elibuyisela emuva kumqokeleli.

Ukubeka amapayipi phansi okufudumele

Izinto ezilandelayo zizodingeka futhi zenzele phansi izitezi zokushisa amanzi:

- Ukugoqa amanzi - Inani lalokhu okushiwo ngokubala indawo yaphansi nge-10%, okuzodingeka ngokugcwala amalunga;

- ukwahlukanisa Ngesimo sePolystyrene - wasebenzisa i-5% ngokufanele nokuncipha;

- Itheyiphu ye-wempfer - Kufakwe ezungeze umngcele wekamelo, kanye nasemalongeni okuhlanganiswa;

- Ukuqiniswa kwe-Mesh - Inani legridi lilingana nendawo yegumbi, elikhuphulwa ngezikhathi eziyi-1,4;

- ukhonkolo - Kuya ngobukhulu obulinganisiwe be-screed.

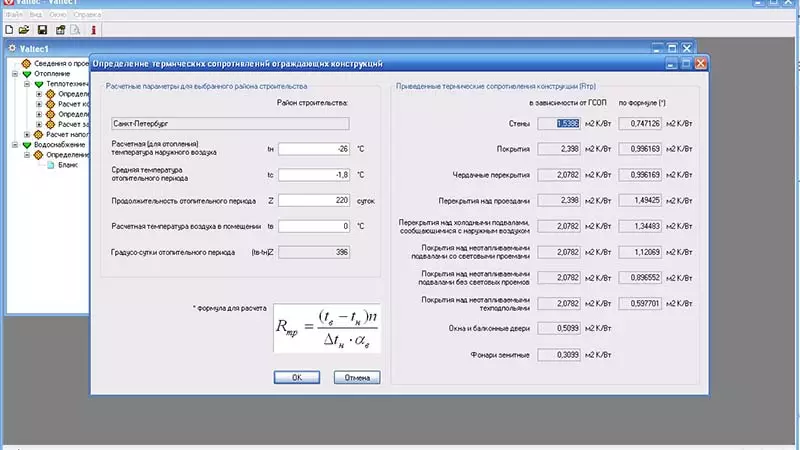

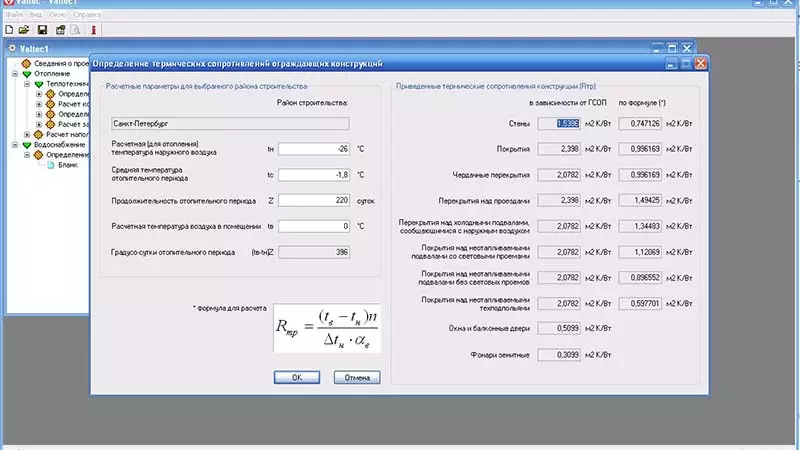

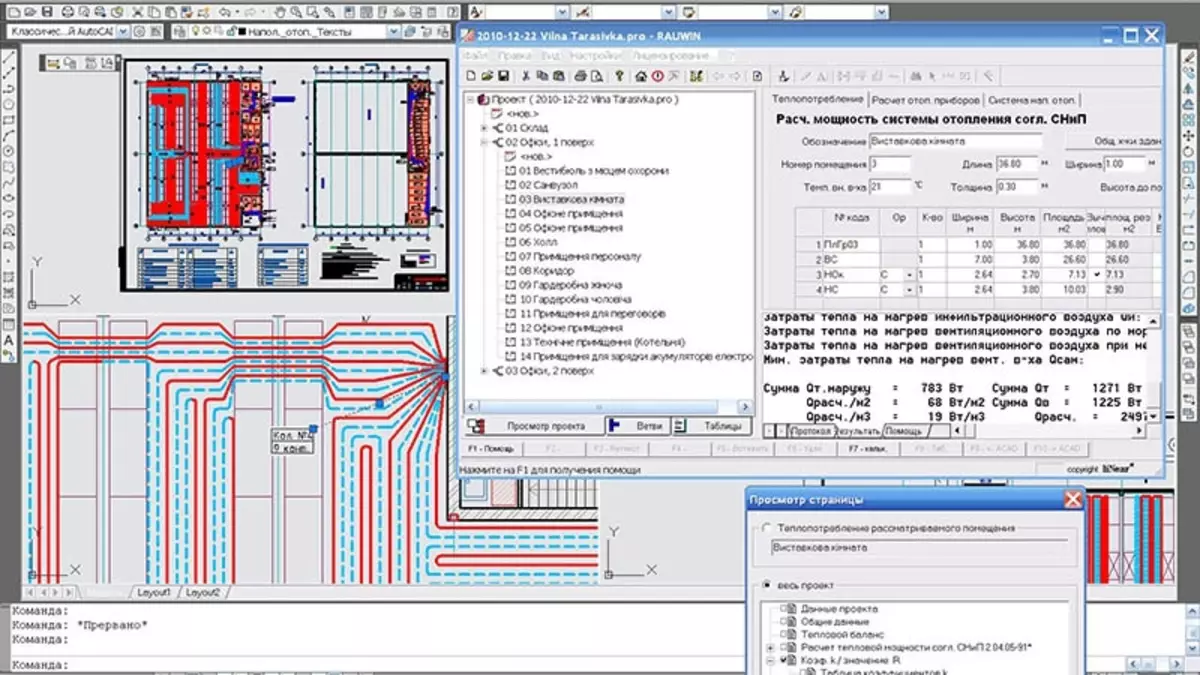

Ukubala ukunemba okuphezulu, kufanele ufune usizo kusuka kuhlelo olukhethekile olubizwa ngeValtec.prg. Yenzelwe ukubala amapharamitha ayisisekelo wezinhlelo ezahlukahlukene zobunjiniyela.

Ezenzakalelayo zenqubo yokubala uhlelo olufudumele

Amandla okushisa amanzi

Umgomo wokusebenza kokushisa kwamanzi uhlukile kakhulu kunendlela yendabuko yokushisa ekhaya, ngakho-ke ngendlela ejwayelekile yokushisa, umehluko wokushisa unesici. Njengomphumela wento enjalo, umsebenzi wokugoqa ukugeleza uyanda. Ukungathandeki kwale ndlela yokushisa izakhiwo kungamathuba aphezulu okulimala. Lokhu kubangelwa ukweqisa kwezinto zedivayisi yokushisa, okungaholela ekomeni kwesikhumba nokwakheka kokushiswa.

Isihloko ngesihloko: Ungakwenza kanjani ukubalwa kokuqukethwe ku-gazebo ye-cottage

Enhliziyweni yendlela yokushisa yegumbi ngokusebenzisa isitezi sokufudumeza samanzi, umgomo wokusebenzisa awushisi, kepha amanzi afudumele.

I-thermostat eqinile

Ngokwesilinganiso, inani layo lingasukela kusuka kuma-degree angama-35 kuya kwangama-45, kepha ngasikhathi sinye inkomba yayo ephezulu yi-50 degrees Celsius. Ngakho-ke, ngokushisa kwegumbi elisebenzayo, amanzi asetshenziswa okushisa okuphansi, okuzofinyelela hhayi kuphela umphumela ofanele, kodwa futhi anciphise amathuba okulimala ku-zero.

Ngenxa yohlelo lokushisa ngendlela yesitezi sokufudumeza kwamanzi, kungenzeka ukudala izimo zokushisa ezinhle, usebenzisa i-40-150 kuphela imitha yesikwele. Naphezu kweqiniso lokuthi le nkomba incane, kepha yanele ukufeza inhloso. Ukusatshalaliswa okufanayo kokugeleza kwamanzi kulo lonke i-perimeter yegumbi kwenza kube nokwenzeka ukunciphisa amandla wedivayisi yokushisa.

Izibalo ezidingekayo

Inani likagesi elidingekayo ekufuneni 1 kv. m., isisekelo esiyisisekelo. Ngibonga kuye, kungenzeka ukunquma uhlobo lokushisa kwekamelo, okungukuthi ukubukeka okuphambili noma okwengeziwe. Ngasikhathi sinye, kufanele kucutshungulwe kulezo zinto ukuthi isikhala esivezwa ukufudumeza ngenkuthalo kufanele sidlule kancane ingxenye yendawo ephelele yaleli gumbi. Imvamisa le nkomba inenani le-60-70%. Uma isitezi esifudumele samanzi sibonakaliswa njengoMthombo wokushisa, bese inkomba ka-150w / m² ithathwe inani lamandla e-Thermal film.

Ukunquma amandla okuya ocansini okufudumele ngezinhlelo ezikhethekile

Uma le ndlela yokushisa isetshenziswa njengesengezo ku-main eyodwa, khona-ke inkomba ethile yamandla ingu-110-120 w / m².

Ukuze ulondoloze izindleko zokukhokhwa kwamandla kagesi, asetshenziswa yidivaysi yokushisa, kunconyelwa ukuxhuma i-thermostat kwinethiwekhi ye-infrared floor floor. Ngenxa yalokhu, lokhu kwenza ukuthi kwenzeke hhayi kuphela ukuthola amandla okusebenza kwezinto zikagesi, kepha futhi kunciphisa izindleko ezingama-35%. Ngakho-ke, kungaphikiswa ukuthi okupholile kukagesi kudla ama-65% kuphela amandla ahlelwe ekuqaleni.

Ngokusekelwe kwidatha engenhla, kungenzeka ukubala kalula inani elidingekayo lamandla okushisa kwendawo yamamitha-skwele angama-18. m. Ihora eli-1.

18 m² x 0.7 x (150 w / m² x0.65) = 1229 w / h,

lapho u-0.7 u-coefflement wayo okhombisa isabelo sendawo esihilelekile ngaphansi kwesakhiwo se-heater infrared,

I-0.65 - inkomba ecazle iphesenti lezinto ezingaphansi kwesimo sokusebenzisa i-thermostat.

Uma izindleko ze-1 kW zikagesi zingu-3.58 k., Khona-ke intengo yehora elingu-1 yile:

1229 x 3,58 / 1000 = 4.40 k., Kanye namahora angama-7 okusebenza kosuku lonke: 7 x 4 4,40 = 30.8 k.

Ukwenza ukubalwa kwalolu hlobo kuthwala imininingwane ebalulekile edingekayo enhlanganweni yepayipi elifudumele. Imiphumela yokubalwa izoba wusizo olukhulu ekuthuthukiseni ukwakheka kwensiza yokushisa.

Ukubonakala komklamo we-flam floor

Isikhombi sokushisa sendawo yangaphansi yendawo yokugezela ngale ndlela yokufudumeza ingafinyelela amanani ahlukahlukene, okuphezulu kwawo okulungiselelwe ama-degree angama-33.

Isihloko ngesihloko: Ukwenza kanjani igatsha kusuka ocingweni

Ngakho-ke, ukuze babale isikhathi sepayipi elifudumele lamanzi, umuntu kufanele aqondiswe amanani anjalo, okungukuthi ukulahleka kokushisa, ingxenye yendawo yegumbi, eqhutshwa ngaphansi kokushisa, kanye nenkomba ye lokushisa elawulayo.

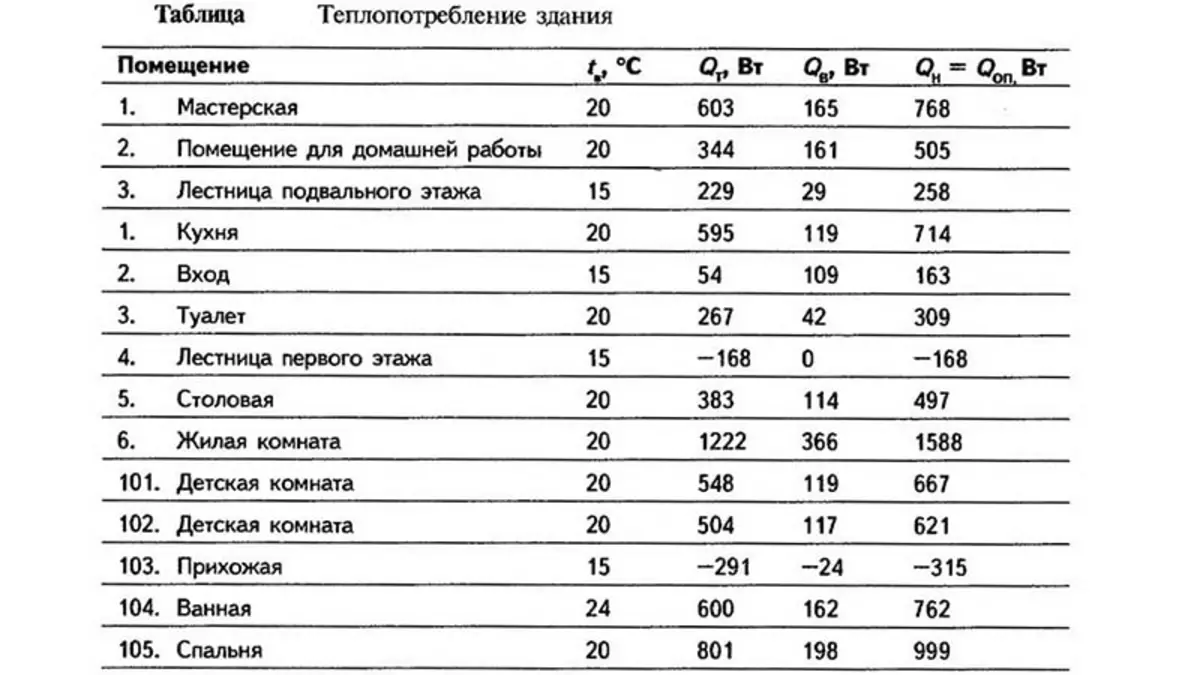

Inani lamandla athile ngokuya ngohlobo lwamakamelo afudumele

Ngokuya ngohlobo lwegumbi, oluzoshisa, labela izidingo ezahlukahlukene zamakamelo ngamanye.

Ukubalwa kwamandla netafula lokusetshenziswa kokushisa kwezingxenye ezahlukahlukene zesakhiwo

Isigaba esinjalo senzeka ngenxa yenhloso esebenzayo yendawo ebhekwayo. Uma siqhathanisa igumbi lokulala ne-loggia elikhazimulayo, bese kuthi inketho yesibili udinga amandla amaningi kunawokuqala. Imininingwane elandelayo ibhekwa njengezinkomba ezijwayelekile: Ikhishi - 110-150 w / M², Bathroom - 140-150 w / M², Loggia ngaphansi kwe-Glass Coating - 140-180 W / M².

Amanani wamandla athile nawo afanele ukukhombisa ngokubhuka okuthile. Isinqumo esinjalo senziwa ngesisekelo seqiniso lokuthi isitoko senziwe ngama-30% wohlelo olusebenza kwimodi 70%.

Inani lamandla liyadingeka ukufudumeza imitha yesikwele

Inkomba eyinhloko umuntu agxile kuyo lapho ekhetha indlela yokushisa idivaysi yokushisa ibalwa amandla afudumele wangaphandle wamamitha ngasinye. Uma isitezi esifudumele ukuphela komthombo wokushisa, amandla alo athile kufanele abonakaliswe ngamanani anjalo - I-150-180 w / m² . Uma le ndlela yokufudumeza isebenza njengokungeziwe, khona-ke inani lamandla lilingana no 110-140 w / m².

Ukubalwa kwesitezi sokufudumeza samanzi namandla aso kwenza ukuthi sikwazi ukuklama uhlelo lokushisa ngokusebenza kahle okuphezulu, okuzogcina kuthinta isikhathi sokusebenzisa kwayo.

Ukubekwa phansi kwamanzi afudumele kwamanzi

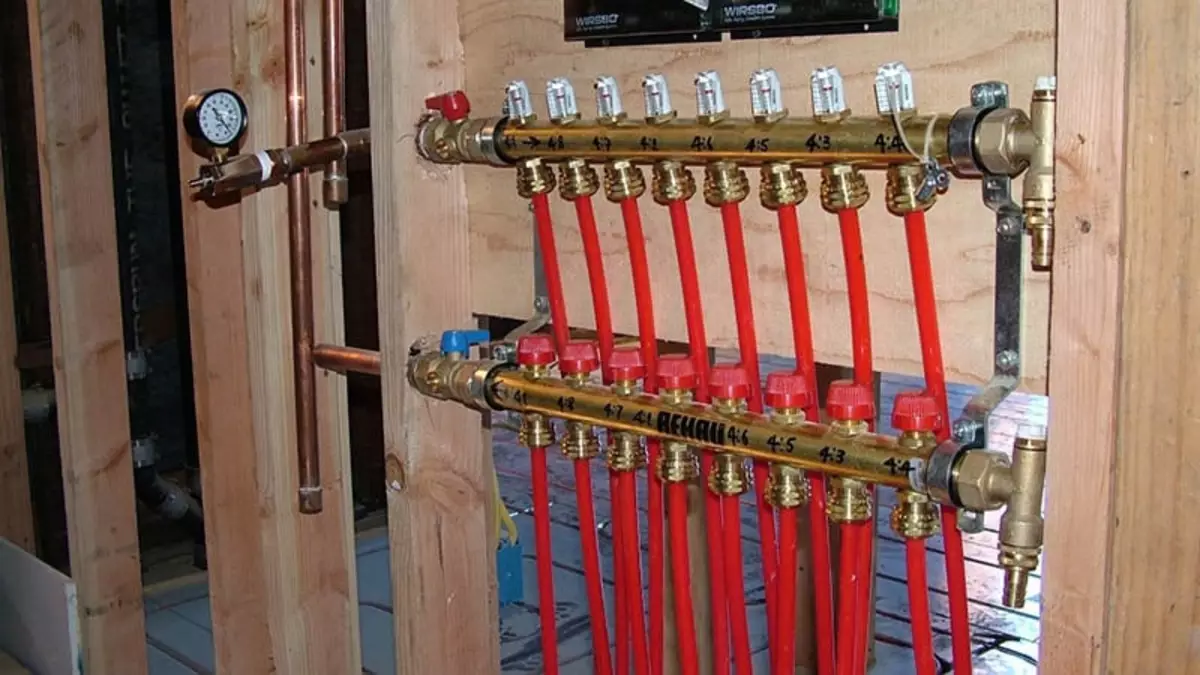

Njengoba isimo sezulu siguquliwe futhi isidingo sokushisa kwalezi zakhiwo zishintsha, abalandeli kufanele basetshenziswe. Hlukanisa uhlobo lwabo lwencwajana yezandla kanye ne-othomathikhi.

Uhlobo lokuxhumana olufudumele lwaphansi egumbini lokugezela - kusuka kujantshi wethawula elifudumele

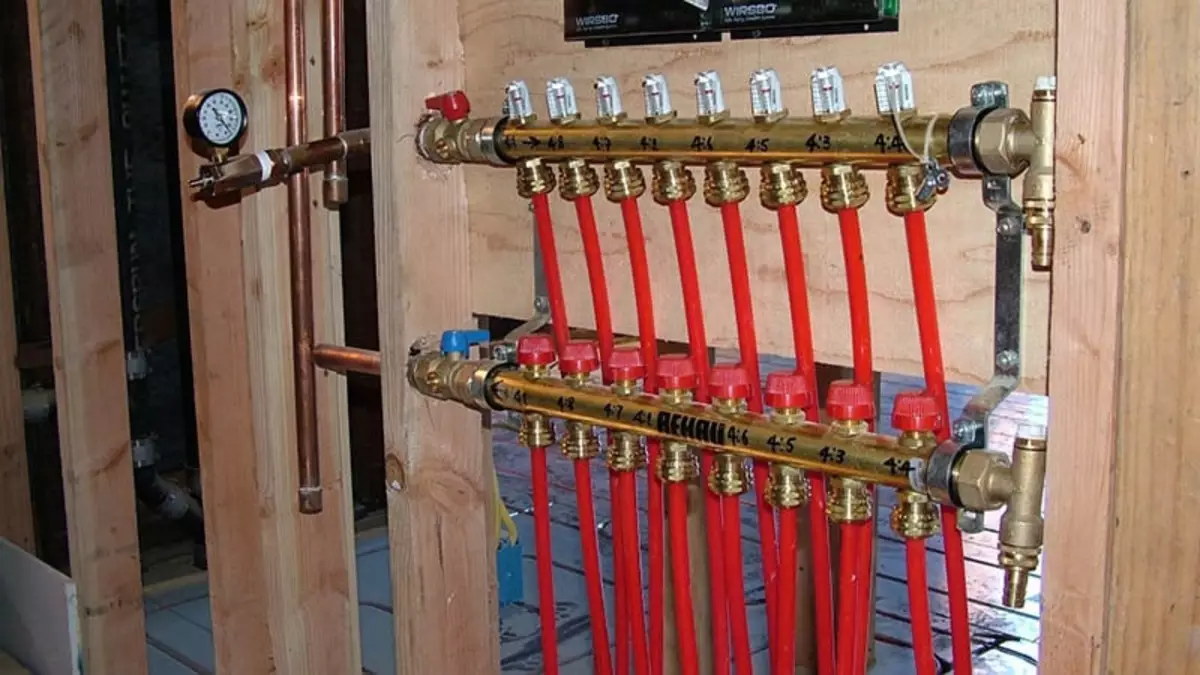

Lapho kwakheka umjikelezo ophansi oshisekayo, kufanele kubhekwe ukunakwa okukhethekile kufanele kukhokhwe ekukhetheni kwendlela yokuxhuma kwayo. Njengendawo yokuxhuma ohlelweni olujwayelekile, i-radiator, i-trunk tube, ujantshi ovuthayo wethawula kungaba.

Isitimela sethawula esifudumele sokuxhuma uhlelo olufudumele lwaphansi

Lapho kwakheka uhlelo lokushisa, kuyadingeka ukubheka isici esisebenzisa ipompo yokupompa uketshezi ohlelweni olusendlini yokugezela akusona. Lokhu kulungisiswa iqiniso lokuthi iningi lale ndawo alinayo indawo enkulu kanye nokujikeleza kwemvelo kuzokwanela. Ngaphambi kokuthi ukhule phansi kwamanzi afudumele, ukubalwa kweshubhu kufanele kwenziwe ngokucophelela futhi kulungiselele kahle indawo, okungukuthi, susa i-coating yakudala.

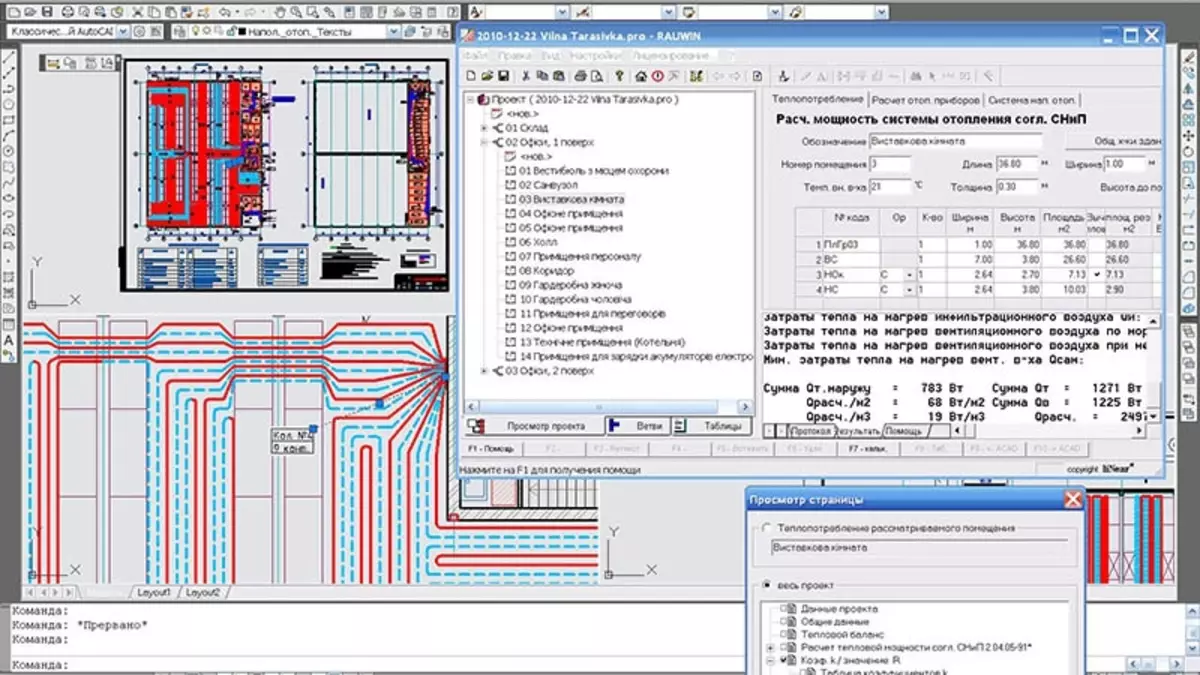

Ukwenza iphrojekthi yamanzi efudumele yaphansi

Uma ukukhethwa kwendlela yokuxhuma ohlelweni lokushisa kwenziwa kuvunywa ujantshi wethawula elivuthayo, khona-ke kufanelekile ukuhlinzekwa nge-crane, okungukuthi, i-maevsky noma uhlobo olujwayelekile. Ngenxa yalezo zinto, kungenzeka ukususa umoya ohlelweni.

Lapho amanzi efudumele egumbini lokugezela esuka eTowel Rail eshisa asebenza, i-Hermeostatic RTL Valve kufanele ifakwe ekuphindweni kwayo. Ngenxa yale divayisi, hhayi kuphela ukulungiswa kwamanzi, kepha futhi nemodi yokushisa izokwenziwa. Ukubuyela emuva kuleli cala kunconyelwa ukuxhuma ohlelweni oluphambili.

Isihloko ngesihloko: Ukulahlwa kwamanzi eduze kwendlu

Ngokuphepha kanye lula, insizakalo elandelayo akufanele ikhonkini yokuxhuma. Ngaphandle kwalokho, ukufinyelela kuyo kuzokhishwa, okungekuhle kakhulu. Imvamisa, isikhala ngaphansi kwendlu yangasese noma i-niche odongeni ukukhetha njengendawo yokufakwa kwayo odongeni. Nge-Embodiment yesibili, imvamisa ifihlwe ngaphansi komnyango wokuhlobisa noma uthayela osuswe kalula.

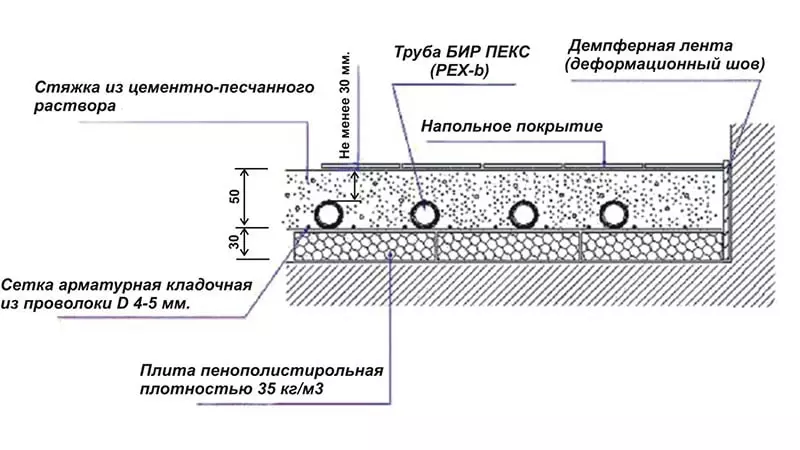

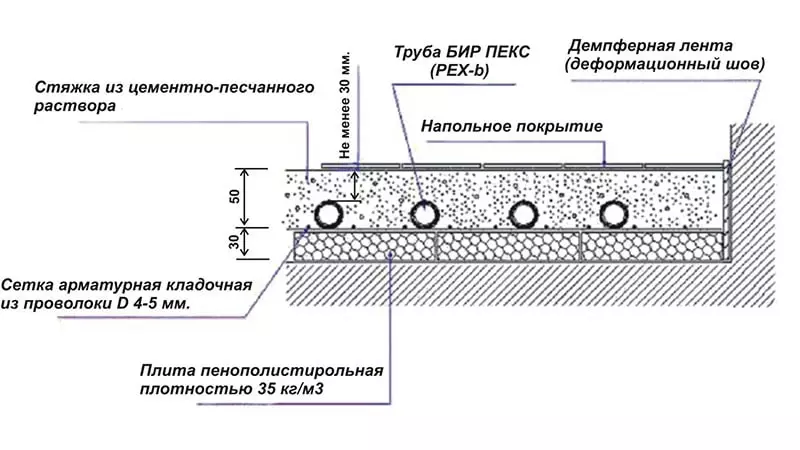

Okubaluleke kakhulu komsebenzi womhlangano

Ukuze kudluliselwe ukushisa kwamanzi afudumele kuya kubukhulu, kusetshenziswa ukufakwa okushisayo. Okuqukethwe kuthathwe i-polystyrere foam engama-50 mm obukhulu obukhulu kanye nobude be-35 kg nge-cube noma i-foil nge-foil. Isinyathelo esilandelayo ukubeka ifilimu ebonakalayo, umsebenzi wakhe wokuqondisa amandla okushisa phezulu. Ukumboza izindonga, kusetshenziswa itheyiphu enqenqemeni elingamakhambi. Umsebenzi wakhe ukuvikela i-screed kusuka ekwakhekeni kwemifantu.

Ngemuva kwalokho kufika ithuba lokubeka amapayipi epulasitiki wensimbi.

Amapayipi epulasitiki ensimbi ekwakhiweni komhlaba ofudumele

Indlela esetshenziswa kakhulu yindlela ethi "umnonke". Kuye, kunesici:

- Isinyathelo phakathi kwamapayipi singama-15 cm, eduze kwezindonga zangaphandle - 10 cm;

- Intaba yabo yenziwa kusetshenziswa ubakaki nocingo, noma ngabe i-Mountal Mesh isetshenziswa noma isabalalisi sepulasitiki.

Uma ukwenziwa kwe-thermal kwenziwa ngenxa yefilimu, kufanele ifakwe esitezi esisesitezi ngokuzikhandla.

Ukuqina kwepayipi nothayi

Ukuze ugweme inkathazo ngokuzayo ngekhwalithi yokubekwa kwephansi elifudumele, kuphoqelekile ukuyihlola ngokuqina kokuxhumeka.

Ihlola uhlelo lokuqina

Le nqubo yenziwa ngokugcwalisa uhlelo ngamanzi. Ngomphumela omuhle, i-brace yokhonkolo yokuthulula yenzeka, kepha wonke amapayipi kufanele agcwaliswe ngoketshezi olunengcindezi ye-2 ATM. Le nhlanganisela kufanele ibe ngu-6 cm. Ngemuva kokuthi ingxube ilukhuni, ibambe iribhoni elinqenqemeni, eliphuma emaphethelweni, bese liqala ukubeka i-tile.

Ngemuva kwezinsuku ezingama-21 kuya kwangama-21 kuya ku-21 kusukela osukwini lokugcwaliswa kwengxube kakhonkolo, uhlelo lungathunyelwa. Kepha ngasikhathi sinye kufanele kwenziwe kancane kancane - ukwandisa umbuso wokushisa nesikhathi. Ngaphandle kwalokho, kusongela ukubonakala komehluko ekuhlanganisweni kokwanda.

Ngakho-ke, kungenzeka ukuxhumanisa phansi kwamanzi okufudumele kunoma yisiphi isici sohlelo olujwayelekile, kepha kufanele kubhekwe kuyo yonke imithetho nezidingo. Kepha ukunemba kwezibalo kwenza ukuthi kwenzeke impilo yendlela yokushisa isikhathi eside.

Isikimu esifudumele sendawo yokubeka kanye nokubalwa okudingekayo

Ithebula lokusebenzisa elifudumele likaPawulu

Ukubeka amapayipi phansi okufudumele

Ezenzakalelayo zenqubo yokubala uhlelo olufudumele

I-thermostat eqinile

Ukubonakala komklamo we-flam floor

Ukunquma amandla okuya ocansini okufudumele ngezinhlelo ezikhethekile

Ukubalwa kwamandla netafula lokusetshenziswa kokushisa kwezingxenye ezahlukahlukene zesakhiwo

Ukubekwa phansi kwamanzi afudumele kwamanzi

Isitimela sethawula esifudumele sokuxhuma uhlelo olufudumele lwaphansi

Ukwenza iphrojekthi yamanzi efudumele yaphansi

Amapayipi epulasitiki ensimbi ekwakhiweni komhlaba ofudumele

Ihlola uhlelo lokuqina

Ukhonkolo kaPawulu ofudumele

Ukubalwa kwenani elidingekayo lezinto zokwakha zokufaka uhlelo olufudumele lwaphansi

Ukubeka uHipleme nokubala amapayipi