Umbuzo wangempela wokushisa kwezakhiwo ubelokhu efuna ukutholwa kwezixazululo ezimisiwe. Sebenza ekufakweni kohlelo lokushisa okusezingeni eliphezulu lubiza kakhulu, njengoba ukulinganiselwa kufaka phakathi umsebenzi wochwepheshe, kodwa futhi nemishini uqobo - amapayipi, ama-radiator kanye nemishini ye-boiler.

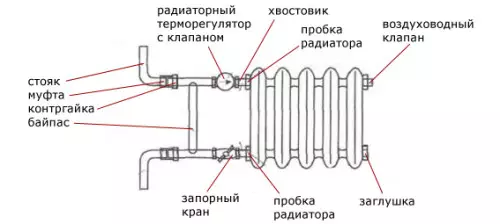

Uhlelo lwesakhiwo se-radiator yokushisa.

Ngezansi kuhlaziywa kokuqhathanisa kwamadivayisi wokushisa atholakalayo. Njengoba sesifunde zonke izici zobuchwepheshe, kuzokwenzeka ukusindisa isikhathi esiyigugu sokukhetha nemali yokuthenga kwale ndlela (ngesisombululo esamukeleki ngokungafanele, imali eyengeziwe iyachithwa).

Kunezinhlobo eziningi zama-radiator ezifudumele. Ukukhetha uhlobo olufunayo lwemishini, kuyadingeka ukuthi ufunde izici zobuchwepheshe zalezo zinhlangothi, ezinhle nezinhle.

Ama-radiator wensimbi (iphaneli). -Yisimilo

Amadivayisi afanayo wokushisa abizwa ngokuthi aqinisekisiwe. Amapuleti amapuleti ensimbi ahlanganiswe ngomunye nomunye nge-welding, akha imigodi ye-coolant. Ukubalwa kokudluliswa kokushisa kwamabhethri ensimbi kwenziwa yindawo enjalo futhi akuxhomekeki enanini lezigaba eziqukethe ngalo. Lapho ubala, inani elilinganiselwa le-4 KW nge-1 sq.m. Indawo yedivayisi, ngokwesibonelo, idivaysi yokushisa yensimbi enamapharamitha 500 × 500 mm izokhiqiza cishe i-1 kW. Uma idatha enembile kakhudlwana iyadingeka, itafula lokudlulisa lokushisa lezinhlobo ezithile zamabhethri liyasetshenziswa, elingatholakala kumhlinzeki wale mishini, kanti ama-nuances ezobuchwepheshe abhekwa.

Izinzuzo zamabhethri wephaneli:

Umdwebo we-Connection we-radiator yensimbi.

- Ukudluliswa okuphezulu okuphezulu.

- Inani elikhulu lamasayizi (amathuba okukhetha inani elidingekayo lokudluliswa kokushisa).

- Hhayi inani eliphakeme kakhulu.

- Idizayini enhle.

Lezi zinzuzo zenza ama-radiator wensimbi adume phakathi kwabathengi abangaba khona. Amadivayisi wokushisa wephaneli asebenza kahle ezinhlelweni zokufudumeza ezizimele.

Okubi kwama-radiator panel:

- Ingcindezi yokusebenza ephansi.

- Ukuzwela okukhulu kuma-hydddrouds (ngenxa yalokho - ukuqhakaza nokuphula idivaysi yokushisa).

- Indawo ende yamabhethri ngaphandle kwamanzi.

Isihloko ngesihloko: Ungahlanganisa kanjani itafula lekhofi ngezandla zakho

Lokhu kushibhiswa akuvumeli ukusetshenziswa kwamabhethri ensimbi ezinhlelweni eziphakathi nokushisa.

Ama-radiator wensimbi

Uhlobo oluvame kakhulu lwamabhethri ezakhiweni eziphakeme kakhulu ezivela ezikhathini zaseSoviet.

Izinzuzo:

- Ukucindezela kokusebenza kuphakeme impela - kufika kubha ayi-10.

- Ukuthambekela okuphansi kokungcoliswa kanye nemithelela enolaka.

- Umthamo wokushisa ophakeme.

- Cishe ayikho ngaphansi kokugqwala.

- Amandla aphezulu.

Okubi:

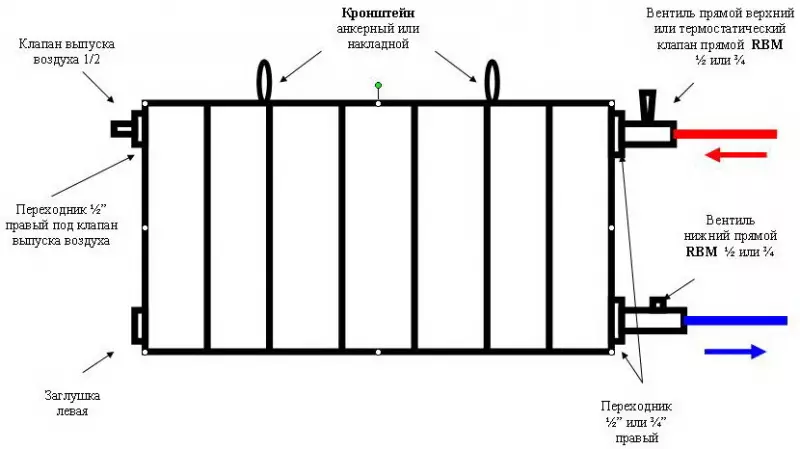

Umdwebo we-radiator ye-bimetallic.

- Isisindo esikhulu (ngenxa yalokho - ubunzima bokufakwa).

- I-endertia eshisa kakhulu (ngenxa yalokho - ukungakwazi ukulungisa ngokushesha okushisa okudingayo).

- Hhayi design yanamuhla (ngenxa yalokho, isidingo sokupenda okujwayelekile).

- Indawo encane engaphezulu inika amaphesenti amancane okusetshenzelwa (ama-20%) kusuka kunani eliphelele lokushisa.

- Lawa madivayisi okushisa anenhlamba enzima (ngenxa yalokho - ukunqwabelana kothuli).

- Ama-radiator wokuphonsa aletha ukulimala kwama-hydrowards.

Amapharamitha wokudlulisa wokushisa wamabhethri we-cast-iron - kusuka ku-100 kuye ku-200 w esigabeni esifanayo, kunokuncika kosayizi bezigaba. Imininingwane edingekayo ekudluliseni kokushisa kwamabhethri we-cast-iron ivela kumphakeli wale mishini. Lapho ubala izingxenye zokudlulisa ukushisa ze-radiator, izinga lokushisa le-coolant libhekwa ngaphakathi kwama-degree angama-90, kepha ngesikhathi sohlelo lokushisa oluphakathi, lokhu kushisa akusekelwa.

Ama-radiator wensimbi (tubular)

Izinzuzo:

- Ukukhetha okukhulu kwezixazululo zomqambi.

- Ingcindezi yokusebenza ngaphakathi kwebha ye-10 (ngenxa yalokho - sebenzisa ezinhlelweni zokushisa eziphakathi).

- Ingaphezulu limbozwe ungqimba lwe-anti-corrion.

- Esigabeni esisodwa sokudlulisa ukushisa kuyashintsha ngaphakathi kwe-80-120 W.

Okubi:

- Ubukhulu odongeni bungamamitha ayi-1.5 mm (ngenxa yalokho - ubumfushane).

- Izingxenye zebhethri azivuli futhi zinenani elichazwe ngokuhlukile - 2, 6, 8, 14, 16 izigaba.

Amadivayisi wokushisa we-aluminium

Izinhlobo zamabhethri e-aluminium:

I-Aluminium radiator ekhuphukayo yesikimu.

- I-Alloyed - konke ukukhetha kwe-solo.

- Ukukhishwa - Isigaba ngasinye siyizinto ezintathu ezixhunywe ngokuqinile noma ngomshini, noma ngama-bolts akhethekile.

Isihloko ngesihloko: Ungakusebenzisa kanjani ukubuyiselwa kwetafula ngezandla zakho?

Izinzuzo zamabhethri e-aluminium:

- Ukudluliselwa kokushisa okuphezulu (kusuka esigabeni esisodwa se-100-200 w).

- Yiba nezinhlobo ezahlukene zezixazululo zoMklami kanye nokubukeka kobuhle, njengoba kwenziwa kusetshenziswa ukuphonsa.

- Ukushisa okuguquguqukayo ngenxa yenani elincane lomthwali wokushisa ngaphakathi kwedivaysi yokushisa kanye nokusebenza okukhulu okushisayo.

- Ube nesisindo esincane futhi ufakwe kalula.

- Ingcindezi yokusebenza ngaphakathi kwebha ye-6-16.

Okubi:

- I-hydroedar ingabhubhisa amadivaysi okushisa ama-aluminium (ngenxa yalokho - akuyona inketho engcono kakhulu yezinhlelo zokushisa eziphakathi).

- Kubonakaliswa ukuzwela ukukhulisa i-acidity, okungokwemvelo kokwakheka kwamakhemikhali kwe-coolant.

- Kumabhethri e-aluminium, kunomphumela wokwakheka kwegesi (ngenxa yalokho, uhlelo lwakamuva lokushisa).

Ama-radiators e-bimetallic

Lolu hlobo lwamadivayisi wokufudumeza lubhekwa njengokulungiswa kahle kakhulu.

Izinzuzo zama-radiator ze-bimetallic. Izici eziyinhloko:

- Amandla wepayipi ensimbi kanye nokuvuselelwa okungcono kakhulu kwe-aluminium okuhle kakhulu kwe-aluminium - okupholile kuhamba ngamapayipi ensimbi, futhi ukukhuphuka kwezinga lokushisa kukhishwa izimbambo ze-aluminium.

- Inani lamanzi esigabeni liphansi kakhulu, uma uqhathanisa nezinye izinhlobo zemishini efanayo - ngaphakathi kwe-150 ml (ngenxa yalokho - ukusebenza kahle).

- Zine zonke izimfanelo ezinhle zamabhethri ensimbi nama-aluminium.

- Njengoba amapayipi ensimbi angafaki ngokuphelele ukuxhumana kwe-aluminium nge-coolant, khona-ke akukho ukwakheka kwegesi.

- Amandla ezakhiwo (njengomphumela - ingcindezi yokusebenza efinyelela kubha engu-30).

- I-Aluminium inika amadivaysi e-Bimetallic Heating design enhle futhi ihlinzeka ngokuvuselelwa okuhle okushisayo.

- Ilungele kahle ukukhwela ezinhlelweni eziphakathi nendawo ezizimele.

Amabhethri e-Bimetallic anokubuyiselwa okukodwa kuphela - izindleko eziphakeme impela.

Ukwenza isinqumo sokugcina, ukuthi yimaphi ama-radiators athola, zonke izici zemishini kufanele zibhekwe, zenze uhlu lwezidingo zamadivayisi wokushisa atholakele futhi kuphela ngemuva kwalokho uthenge ama-radiator adingekayo ezakhiwo ezidinga ukufudumeza.