Isidingo sokwehlisa ama-radiator sokushisa senzeka emacaleni lapho baqala ukuvuza khona, enye yezimbambo yanikeza ukuqhekeka noma ukuqhuma. Ezakhiweni ezindala, lapho kungekho mbuzo ngokulondolozwa kwamandla, ama-radiators abebekwe, lapho izimbambo zazifakwe ngaphezu kwalokho ezidingekayo, ngakho-ke imiphetho engadingekile idinga ukususwa.

Ukushisa i-radiator yedivayisi.

Ngaphambi kokuvula ama-radiator afudumele, kungakhathalekile ukuthi uhlobo lwabo, kufanele uqiniseke ukuthi amanzi awahlinzekwe emapayipi. Kungcono ukwenza umsebenzi ndawonye.

Uma uhlelo lokushisa lufakwa ku-polypropylene noma amapayipi epulasitiki, ama-couplings ahlukaniswa.

Uma uhlelo lokushisa lubekwe emapayipi ensimbi, udinga ukuzama ukukhuthaza izimpawu kokufaka nokukhishwa kwezigaba. Uma wehluleka, futhi kwenzeka kaningi emafulethini esakhiwo esidala, ukwahlukana kumele kunqunywe nge-grinder noma i-autogen.

Kusele ukususa ibhethri ngezingwegwe, okunamathiselwe odongeni, bese zibeka endaweni eyisicaba.

Ama-radiator wensimbi ehlukanisa ukufudumeza

Ukuhlukaniswa kwe-radiators yensimbi yezingulube kwesinye isikhathi kuba inqubo edla isikhathi, kepha kunesidingo.

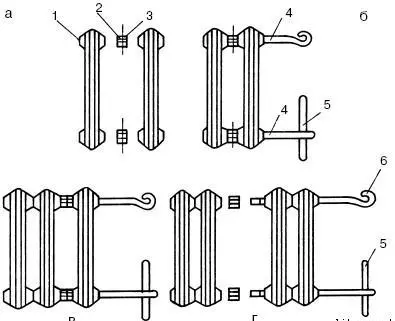

Umdwebo wokuhlukaniswa kwama-radiators we-cast-iron Heating radiator: A - Ukuthwebula ngama-peples wezingxenye zezigaba ngemicu engu-2-3 yentambo; b - Ngokusho kwezingono nezingxenye zokuhlanza; ku - Ukuxhuma isigaba sesithathu; G - Ukuqoqwa kwama-radiator amabili; 1 - Isigaba; 2 - ingono; I-3 - gasket; 4 - Ukhiye omfushane we-radiator; 5 - Lomik; 6 - Ukhiye we-radiator omude.

I-radiator entsha noma endala ibekwa endaweni eyisicaba. Okungenani ngakolunye uhlangothi, kuyadingeka ukususa ama-funks ajwayelekile noma izithulu - ama-plugs. Ezingxenyeni ezihlukene zama-radiator, zingaba ngentambo yesobunxele noma kwesokudla. Imvamisa ama-hoods we-cast-iron anentambo efanelekile, ama-plugs asele. Uma kungekho amakhono we-disassembly, futhi kungcono isigaba samahhala, kungcono ukwazi ngaphambi kokusebenzisa amandla alolo hlobo lwentambo futhi lapho ukhiye kufanele ujikeleze khona. Uma intambo yesobunxele, lapho amabhethri e-cast-iron-iron-iron, udinga ukujikeleza ukhiye emcibisholo wewashi.

Isihloko ngesihloko: Sikhetha izimbali ze-balcony: uhlangothi lwelanga

Njengakwenziwanga kwanoma imaphi amantongomane, okokuqala kudingeka "ukuphazamisa" ama-hoods kusuka endaweni, isb. Baphendule ngekota ye-inzuzo zombili zebhethri. Lapho-ke ama-hoods asontekile ukuze igebe libe ngamamilimitha ambalwa lakhiwa phakathi kwezigaba. Uma ukhulula ama-hoods ngaphezulu, yonke design izoqala ukugoba ngaphansi kwesisindo sayo nangomzamo ohambisana nawo. Ngasikhathi sinye, intambo ingajaja. Ukuthi lokhu akwenzeki, umsizi kufanele akwazi ukuthola umsizi webhethri elihlangene elizovimbela isisindo sakhe.

Imvamisa ukungahlukanisi kwama-radiator amadala okushisa kuphazanyiswa yilokho i-funki nezingxenye "eziqhekekile". Ukuze uhlukanise ibhethri elinjalo, kuzodingeka usebenzise isibani se-autogen noma i-soldering. Isayithi lokuxhuma lifudumeza ukunyakaza okuyindilinga. Lapho nje sephula ngokwanele, ama-hoods asontekile. Uma wehluleka ukukhombisa kusukela okokuqala, izenzo ziyaphindwa.

Uma kungekho mandla anele okuhlukanisa ibhethri, udinga ukwandisa ubude obuhle. Kusetshenziswa ipayipi elijwayelekile, elisebenza njengoRacchag.

Ngokufanayo, izingono ezishunyekiwe zisontekile kuma-radiator asindayo.

Ukube bekungenzeki ukuhlukanisela ibhethri le-cast-iron ngezindlela ezithathwa njengezindlela, kusaqhubeka nokugawulwa ku-grinder noma i-autogen noma ukuhlukaniswa kube yisikhundla sokulala kwe-sledgehammer. Shaya noma usike, udinga isigaba esisodwa. Ngemuva kwalokhu kusebenza, mhlawumbe uHeens a clutch phakathi kwezigaba, ibhethri lizokwazi ukuhlukanisa izingxenye ezisele zokusindisa.

Ukusetshenziswa kwe- "liquid ukhiye" noma uketshezi lwe-wd alinikezi, kusukela kumabhethri amadala we-cast-iron-iron, i-homethis yavalwa ngefilakisi nopende, futhi uketshezi ngeke luwe emucu.

Ukuhlukaniswa kwe-Aluminium Heating Radiator

Isikimu se-Aluminium Heating Radiator.

Ama-radiator e-aluminium noma ama-bimetallic eshisa ahlanganisiwe ngokufanayo ukuze abeke insimbi, kepha kukhona umehluko omncane:

- Kungamasayizi amancane ezikhiye nezingono;

- Njengomthetho, le yimikhiqizo emisha, ngakho-ke uma sebehlukanisiwe, akudingekile ukuthi basebenzise imizamo enjalo enkulu njengasesimweni se-cast-iron;

- Ngasohlangothini olungaphambili lwama-plugs nama-hoods, kukhona ama-syntheases s no-d, ngokulandelana, ngentambo yesobunxele nesokudla.

Isihloko ngesihloko: Shayela phansi: Ongakwenza, ngaphandle kokuhlakazeka, izeluleko zochwepheshe

Phakathi kwezigaba zokubopha ama-gaskets wensimbi Ngemuva kokuhlukaniswa, kufanele basule, bahlanze futhi bagcine emhlanganweni owalandela.

Ngaphansi kwama-plugs, i-gasket ivame ukwenziwa nge-silicone, lapho ihlangana nayo ngeke isetshenziswe futhi kufanele ithathelwe indawo entsha.

Amamodeli amaningi ezingxenye ze-aluminium asabiwe. Ungazihlukanisa, kepha ngeke kwenzeke.

Ukuze uthole ukwahlukaniswa, uzodinga amathuluzi nezinto zokwakha:

- okhiye be-disasqweb (ama-intshi angama-5/4 - amabhethri we-iron cast, 1 inch - ye-aluminium noma i-bimetollic);

- Ukhiye wegesi;

- Inombolo ebalulekile (i-sanitary) engukhiye 2-3;

- IsiBulgaria nge-disc ngensimbi;

- blowtorch;

- Umsiki wegesi (autogen);

- Ucezu lwepayipi lensimbi.

Kuyadingeka ukubheka ukuthi umsebenzi ochaziwe ungcolile futhi unomsindo. Ngakho-ke, kufanele kuhlanganiswe nomakhelwane.

Kusetshenziswa amathiphu alandelayo nezincomo futhi uma kukhona ithuluzi, ukuqaqa futhi uhlanganise amabhethri okushisa ngezandla zakho.