Ama-radiator kanye nokulungiswa kwawo

Emhlabeni wanamuhla, ama-radiator enza imisebenzi yokushisa nokupholisa. Bakhipha amaza ashisayo futhi bachitha ukushisa emoyeni. Amadivayisi enziwe ngezinsimbi ezahlukahlukene kanye nama-alloys awo. Ama-radaators avame ukuba nephutha elinjalo njengokuqhekeka, lapho kuqala ukugeleza. Lokhu kuphambuka kuqedwa ngezindlela ezihlukile, okuthembeke kakhulu okuzoba ukushiswa kanye nokuthengisa.

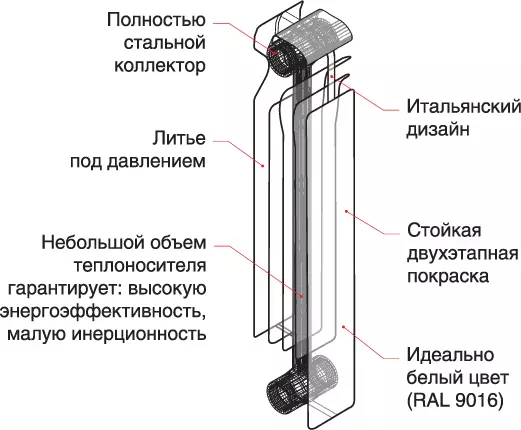

Idivayisi ye-Aluminium radiator.

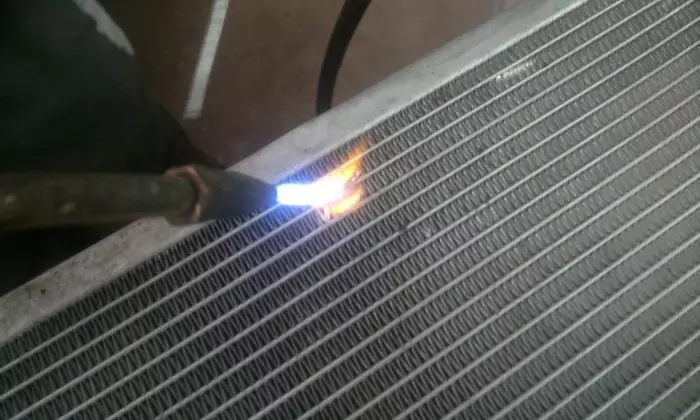

I-Welding (i-Arron) idinga ubuchwepheshe, isipiliyoni, imishini, okusebenzayo kuphela ngamashidi aminyene wensimbi, futhi, ngakho-ke, kunzima ukukuncoma ukuze ulungiselele ama-radiator. Ngenkathi i-soldering (ukuxhumana kwezingxenye ozifunayo nge-soler) inqubo etholakalayo yokwenziwa. Lokhu kulungiswa kwamadivayisi wethusi kanye ne-aluminium kwenziwa kahle ngobuchwepheshe obuvele bufakazelwe.

Ukulungisa i-aluminium radiator

Ukusetshenziswa kwe-radiator kungenzeka, ngokwesibonelo, ukupholisa izinjini zemoto, ukufudumala kwekhabethe emotweni, ukufudumeza kwamakamelo nezinye izakhiwo. Sebenzisa ama-radinomu a-aluminium kaningi, njengoba ukudluliswa kokushisa e-aluminium kuphakeme futhi, ngakho-ke, amadivayisi apholile ngokushesha futhi afudumele, acwebile futhi isisindo sawo sincane.

Ama-radiators we-Aluminium (ngokungafani nemikhiqizo yethusi) Akulula ukuwathela, ngoba ingaphezulu yawo isebenza ngokushesha futhi imbozwe ngefilimu eliqinile eliqinile elivimbela umthengisi ngensimbi.

Isigaba se-Radiator.

Ngaphambi kokulungisa i-radiator, udinga ukususa futhi ukhiphe uketshezi, womile kahle. Ukudalula amadivayisi we-aluminium kufanele kukhiqizwe, kube namathuluzi:

- Ceramic enombala;

- ifayela;

- i-sandpaper;

- I-soldering iron (kusuka ku-100 w).

Nezinto zokwakha:

- rosin;

- Umthengisi okhethekile (ngokwesibonelo, i-P150A, P250A, P300A);

- I-Iron sawdust (umbhede);

Okulandelayo, senza imiyalo ngokuningiliziwe.

- Silungiselela indawo yokuthengisa, ukuyihlanza nge-sandpaper kepha ngaphandle kokuhlamba ingaphezulu.

- Sincibilikisa i-rosin ebelekile futhi silungiselele ingxube (izingxenye ze-rosin 2 kanye ne-sawdust 1 ingxenye), esizoyisebenzisa (ngemuva kokupholisa) njenge-flux.

- I-Iron Condled Iron Clean the fayela elinosawoti bese uvula inethiwekhi. Manje ukufudumeza indawo elungiswa, ngosizo lwensimbi evuthayo yensimbi, kubangele ingxube kusuka ku-rosin. Sisebenzisa i-rosin ebusweni obufudumele, hhayi kwinsimbi ekhethekile, ngoba ingaqala i-Cherrring (ngo-315 ° C) futhi ilahlekelwe yizakhiwo ze-flux.

- I-Ludim Surface, uyihlikihla futhi yenza ukunyakaza okuyindilinga.

- Ukubona ukuthi i-rosin isakazeka, siyaqhubeka nokubheka, sengeza i-gram ye-soler (i-lead-tin), lapho i-iron sawdust ibonwa khona, iluthathe ngensimbi ebuhlungu yokuthengisa. Ama-sawmill ahlanze ebusweni efilimu le-oxide, alibhubhise (khona-ke uthini akha ukuxhumana ne-aluminium), kanye ne-rosin, ukuvikela ubuso emoyeni, kuvikeleke kwi-oxidation.

- Ngokulandelayo sinolusiwe ukuqhekeka komthengisi.

Isihloko ngesihloko: ukubekwa phansi kokushisa kagesi ngaphansi kwe-liquate netha

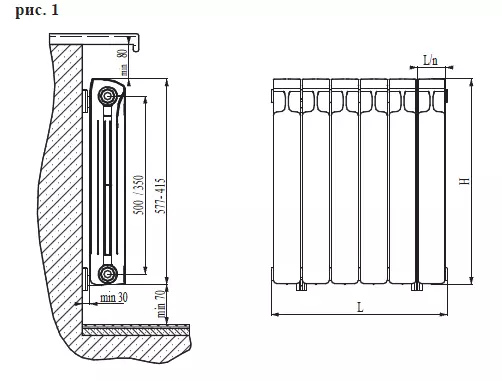

Umdwebo we-Diagonal wama-radiator wokushisa.

Ngale ndlela, kungenzeka ukuvala ukuqhekeka okuncane kuma-radiators a-aluminium, kepha uma kukhulu, umthungo onamandla aphezulu angatholakala kusetshenziswa ingxube ye-tin nge-flux. Ukupheka Soler: Sincibilikisa ebethelwe, ukuxuba, i-bismuth kanye ne-tin (5 no-95 izingxenye). Senza izibuko: gaya ngokwahlukana, bese kubaxuba, izithako ezinjalo:

- Potassium chloride (56%);

- I-Crylite (10%);

- chloride of lithium (23%);

- 6.5% upheke usawoti;

- I-sodium sulphate (4%).

Umkhumbi onengxube uvaliwe kahle, njengoba ithola ngokushesha umswakama. Manje udinga ukufaka umthambeka kulo lonke uzungu olusebenzayo, ufudumele ingaphezulu ngensimbi elungiselelwe, futhi uze, engeza ingxenye ye-solder ezovala umgodi.

Sisebenzisa enye inketho yokukhetha

Indawo eyonakele ngaphambi kokufaka ukusebenzisa i-soldering ingavalwa ngesendlalelo sethusi. Lungisa amathuluzi:

- ukuzulazula kwensimbi;

- i-sandpaper;

- Ibhethri.

Ubukhulu be-radiator ye-aluminium.

Izinto zokwakha ziyadingeka:

- Isixazululo se-Copper Sulfate (CUSO4);

- ucingo lwethusi;

- flux;

- umthengisi.

Benza kanjalo:

- Uhlanze kahle indawo okufanele ifunwe.

- Ngemuva kwalokho idonswe ngokucophelela kuyo kancane isimo (isixazululo) ukwakha "ukwehla" okukhulu.

- Isigxobo esingesihle sebhethri sixhumeke kwi-radiator (ngokwesibonelo, kusuka ephaketheni lantern), nesigxobo saso esihle sixhumeke kucezu lwe-wire (1 mm ububanzi) kusuka ethuneni ngaphandle kokufakelwa.

- Okunye ukuphela kocingo kufanele kube ukuncipha ku- "Drop" yomphunga, kepha hhayi ukuthinta insimbi. Maduze nje ngaphansi kokwehla, phezu kwe-radiator, ungqimba oluncanyana luzovela ithusi elibomvu, elisemizweni.

- Okulandelayo, ingaphezulu liyagezwa futhi yomiswe, bese likhiqiza i-timplel to a soldeling iron kanye nomthengisi ojwayelekile usebenzisa umthengisi. Manje ukuqhekeka kuzovalwa ngokuphephile, njengoba umthengisi ehamba kahle ePhalamende.

Isidingo sokulungisa i-radiator emandleni abo singavela uma lolu hlobo lomsebenzi lungenziwa kahle, uma isici sincane, kanye nangomcimbi wokushoda kwesikhathi. Ukuphofaza i-aluminium radiator ngokuzimela, ngaleyo ndlela uthole umkhiqizo ovuselelwe ngokufanele, welule impilo yaso, ugcine imali olungiselelwe kanye nokuthengwa kwemishini emisha. Kubalulekile futhi ukuthi amakhono atholwe ngesikhathi sokulungiswa, asiza ukwenza i-serleing yensimbi "eyinkimbinkimbi", njenge-aluminium, inenani langempela futhi lingaba wusizo esikhathini esizayo.

Isihloko ngesihloko: Amaphrojekthi wokuqamba alungele amakamelo anamagumbi amathathu