Amathuluzi Amanzi Amanzi

Ama-heater amanzi amadivaysi asendlini asabalele ukufudumeza amanzi endlini noma efulethini. Ngohlobo lwamafutha asetshenzisiwe, ama-heater amanzi ahlukaniswe igesi, kagesi, uphethiloli oqinile, uketshezi. Ngenxa yezinye izici zokusebenza kokuhlinzekwa kwamanzi (ngaphandle kwamanzi ashisayo e-crane, akukho okushisa okuphezulu kwamanzi ahlinzekiwe) ezindlini eziningi ezinama-multi-streay izindlu ezinamanzi afakiwe afakwe ama-boiler. Ukusatshalaliswa okukhohlisayo kuthola ama-heather aqongelelayo wamanzi (lawo manzi aqashwa kuwo ethangini nasemaphepheni amahora ambalwa). Bachitha amandla amancane kakhulu, ngokungafani namadivayisi okugeleza. Ukufakwa kwama-heater amanzi ahlala efulethini kungazivikela, kepha ngasikhathi sinye kuyadingeka ukwazi ezinye izici zedivayisi nohlelo lokusebenza ukuvikela ingozi (isimo lapho i-heather yamanzi eqhunyulwa khona noma i-Communication ).

Isifunda sokuxhuma sikagesi sikagesi.

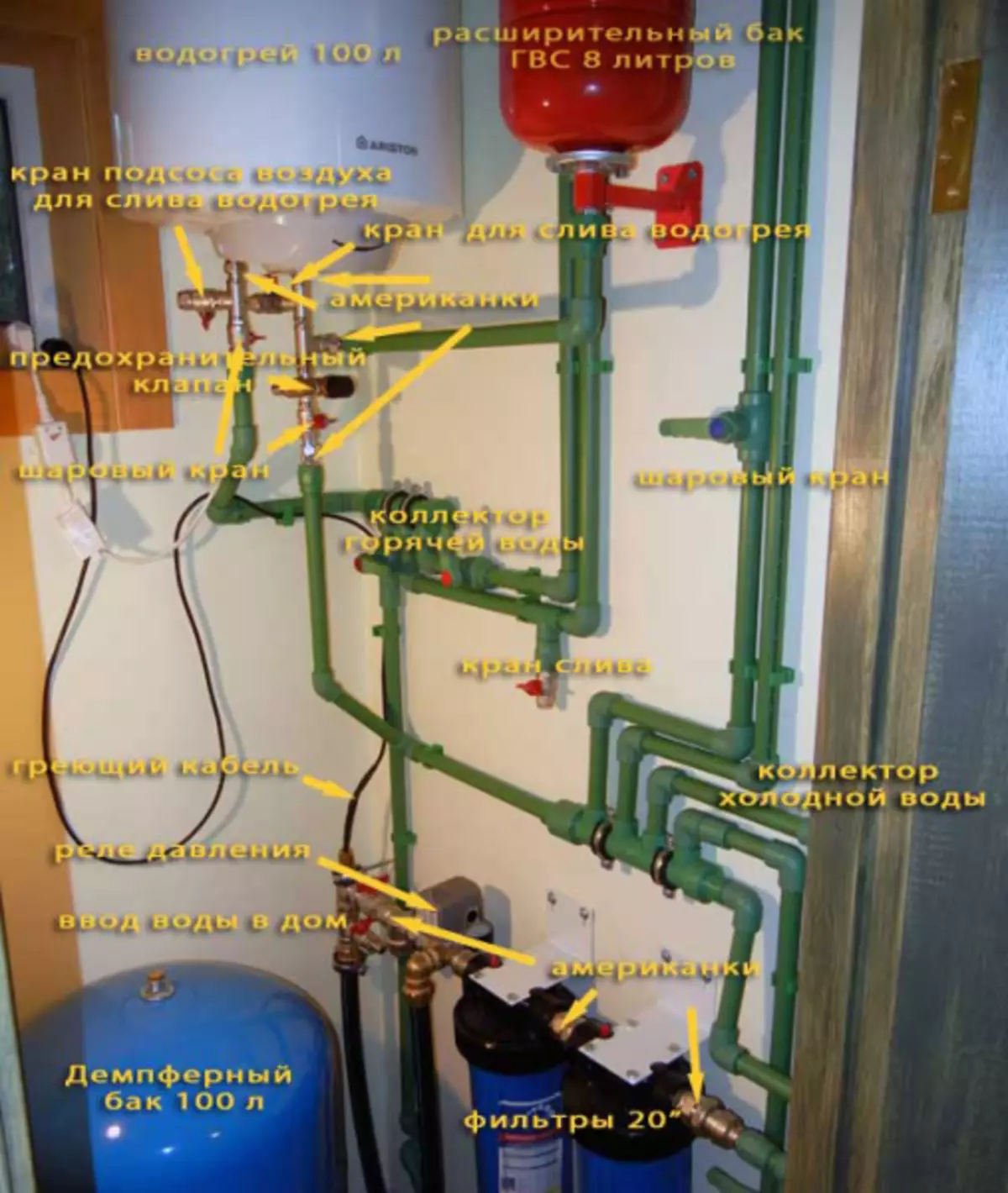

I-heater yamanzi ifaka ithangi (isitsha lapho kwenzeka khona ukufudumeza) kanye namadivayisi okukhonza. Ama-valves amabili avaliwe atholakala ngokulandelayo: munye - lapho ungena emanzini abandayo, owesibili - ekuphumeni kokushisa.

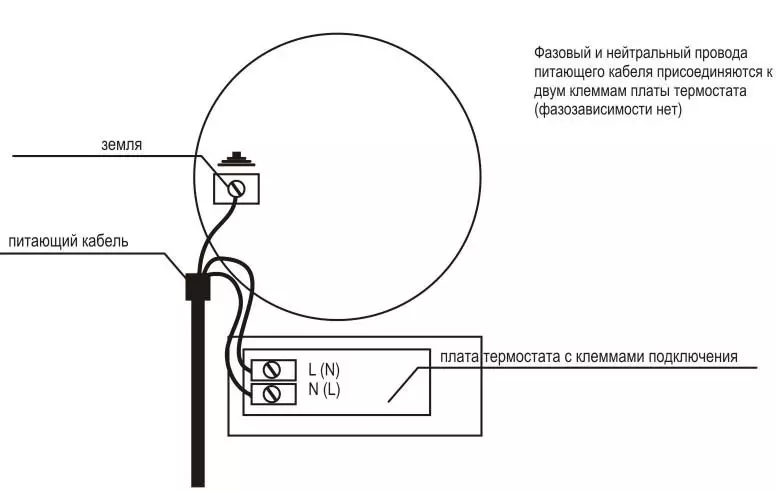

I-thermostat iyithuluzi elivimba ukufudumala kwe-heater yamanzi ngaphezulu kokushisa okucacisiwe.

I-Reverse Safety Valve - efakwe kwishubhu ebandayo engenayo futhi inamavalvu amabili. Okokuqala (ukubuyela emuva) akunikezi amanzi ethangini ukuze abuyele ohlelweni lokuhlinzekwa kwamanzi abandayo (lapho amanzi engekho okwesikhashana ekunikezelweni kwamanzi okubandayo). Okwesibili (ukuphepha) kumele kuvulwe futhi kwehlise amanzi ngesikhathi sokucindezela ohlelweni. I-valve yezokuphepha iqala ukugibela emgodini okhethekile wokudonsa lapho ingcindezi yesistimu idlula atmospheres e-6.

Umdwebo wedivaysi yamanzi.

Kuyadingeka wazi ukuthi ukuhlanganiswa kungenzeka hhayi ezimweni eziphuthumayo kuphela. I-Work Destcent of Surpplus yamanzi ingenzeka lapho i-heater yamanzi ifudunyezwa. Ukwanda kokushisa kwamanzi kuhambisana nokunwetshwa kwalo, lapho kufuthelwa ku-90˚C, umthamo wamanzi unyusa ngo-3%. Lokhu kusho ukuthi kwi-boiler eyi-100-litre, 3 "Amalitha amanzi angeziwe angavela. Kumanzi asezingeni eliphakeme wamanzi, indawo yokunwetshwa ihlinzekwa ethangini ukuze amanzi amaningi angenile le ncwadi eyengeziwe lapho kufudumeza. Lapho ivolumu eyengeziwe selinele, imvelaphi yamanzi (okungezona ephuthumayo) ngeValve Yezokuphepha yenzeka. Ukuze kube lula ukwehla ku-valve, i-tube yokukhipha endaweni yokuswayipha noma esikhundleni esinqunyelwe ngaphansi kwesitsha.

Isihloko ngesihloko: kungani kwenqatshelwe ukuvula amawindi lapho unamathela iphepha lokunamathisela

Ukuncipha kwengcindezi kufakwa e-Inlet ukuze kulungiswe ingcindezi (imvamisa design we-boiler yakhelwe ukucindezela amanzi e-Indowr kuze kube yi-3 Atmorsheres kuze kube yi-3).

Uhlelo lokukhipha lungakhiwa ethangini ukuze likhiphe esitsheni uma kunesidingo.

Ohlelweni lokuxhasa i-boiler, kuhlinzekwa amadivaysi amabili abalulekile ekuvikelweni ngengozi okungenzeka.

Leli yi-thermostat ne-vormostat valve. Ingozi emsebenzini we-heater yamanzi (ipayipi elibopha noma ukuqhuma) kwenzeka lapho amadivaysi okuvimbela amaphutha. Uma lapho kufuthelwa ekushiseni okunikeziwe kungavali i-heater ku-thermostat, amanzi ethangini kukhuphuka kanye nengcindezi iyakhuphuka. Insalela yengcindezi engakhishwe yi-valve yezokuphepha ingaklebhula ukuhanjiswa (okukhiphayo) amapayipi avela ku-heater yamanzi noma aphule i-heater yamanzi uqobo.

Izimo eziphuthumayo emsebenzini we-Water Heater

Ukwephula amapayipi okuxhumana

I-Water heater uxhumano lokuxhuma kwamapayipi okuxhumana.

Ukwephulwa kwamapayipi okuxhumana kuthwala umonakalo omncane kakhulu kunokuqhuma kwesibambiso. Lapho bephula amapayipi, okokuqala banganikela ngokugeleza, khona-ke inani lamanzi eligeleza lisuka ku-boiler liyakhuphuka futhi kwenzeke ukwehla okubukhali kwepayipi, kulandelwe ukuthulula okuvela ku-hopor wamanzi. Ngemuva kokukhishwa komgodi we-boiler kusuka ku-liquid uketshezi olushisayo nomoya womoya, ungalungisa izinto zokuxhumana, futhi ukuthola imbangela ye-water heater fluid ngokweqile futhi uyiqede.

Endabeni lapho amapayipi enamathiselwe kwikhwalithi yamanzi ephezulu kakhulu futhi ethembekile, ukwehlukana kungenzeka kungenzeki. Ingcindezi yokuqongelela futhi eyandayo iphupha umgodi ngamanzi, kanti ukuqhuma kokuqhuma kwenzeka. Lapho kwenzeka ukuqhuma, imiphumela yayo ebhubhisayo iyabanzi. I-boiler ngokwayo ichithwe ngokuphelele (hhayi ngaphansi kokulungisa noma ukululama). Futhi, lokhu kuqhuma kungabhujiswa ifenisha, uthayela, umnyango, umnyango wokuxhumana kwamanzi noma igesi, futhi izindonga zezindonga zingabhujiswa.

Ukuqhuma kwe-heater yamanzi

Ungazivikela kanjani enkingeni enjengesilinganiso samanzi we-heater?

Isihloko ngesihloko: Ukubuyiselwa okulula kwesofa ngezandla zabo

Okokuqala, kuyadingeka ukubona umsebenzi we-heater. Kuyavela noma cha, amalambu okushisa ayakhanya. Idivaysi ngayinye ilawulwa ngesikhathi sokushisa okugcwele kwawo wonke amanzi okushisa okuphezulu. Ngemuva kwalesi sikhathi, i-thermocouple ku-boiler kufanele icime ukusebenza kwe-thermostat. Uma i-thermostat iyekile ukulawula ukufudumala kwe-boiler, nqamula ngokushesha insiza ekufudumaleni ukuze ingakunikeli. Ungavuli ama-cranes ukudonsa amanzi ashisayo. Ngokucindezela okukhulu ku-heater yamanzi, iphuzu elibilayo le-liquid livela. Evula i-crane, sinciphisa kakhulu ingcindezi, lokhu kuholela ekubizweni kwamanzi okusheshayo, okungakeki ukubila, ukwakheka kwenani elikhulu lomphunga wamanzi nokuqhuma. Ngemuva kokucisha uhlelo kusuka ekushiseni, i-boiler ivunyelwe ukupholisa futhi ibangele uchwepheshe.

Uhlelo lokuxhumeka kwe-thermostat.

Kuma-boilers asezingeni eliphakeme, ukuze ithangi lingaqhunyiswanga, kufakwa ama-thermostats amabili. Enye iyashintshwa, eyesibili yahlelwa esitshalweni sokushisa kuka + 94˚c. Uma kwenzeka ukwephulwa kwe-thermostat yokuqala, i-thermostat yesibili izovimba ukusebenza kwalo lonke uhlelo lapho izinga lokushisa lamanzi lifinyelelwa ku-94˚c Boiler. Ukuvula i-thermostat yesibili, kuyadingeka ukuhlukaniswa ngokwengxenye ye-heater.

Okwesibili, qala kuphela imishini esezingeni eliphakeme. Isibonelo, i-valve ye-shutter ephuthumayo ephuthumayo ingakhishwa ngabakhiqizi abahlukahlukene. Ungazisoli ngemali futhi ufake i-valve ebizayo ephezulu. Amanye ama-valves kungenzeka angasebenzi uma kunesidingo futhi angadonseli umusi, ngenxa yalokho, kwavela ukuqhuma kohlelo. I-valve yezokuphepha ingaphansi kokuqinisekiswa kanye nokubuyiselwa emuva njalo eminyakeni emibili.

Ukulandela ukusebenza kwe-valve yezokuphepha, ungabona ngokubona: Kufanele ugibele kancane lapho i-boiler ifudumele.

Okwesithathu, lapho ufaka uhlelo lwe-angenayo futhi ushiye ama-nozzles, sebenzisa amapayipi epulasitiki. Ukuxhumeka kwamapayipi epulasitiki noma wensimbi nge-boiler kuvame ukuba yintambo, eqinile ngokwanele. Ngokwanda kwengcindezi, ukuxhumana okunentambo akuqhumeki, esimweni esiphuthumayo kuhlala ukuqagela kuphela ukuthi yini engenziwa ngokushesha okusheshayo: intambo noma udonga lwethangi lokushisa. Inhlanganisela yamapayipi epulasitiki wensimbi yenziwa ngokufakwayo okucindezela ipayipi. I-Compound ecindezelwe enjalo inamandla aphansi okuphula umthetho, ngokwanda kwengcindezi, ipayipi lensimbi liyaphuca ukuphuma kwe-boiler, elivimbela ukuqhuma okulandelayo kwethangi.

Isihloko ngesihloko: Sebenzisa ngaphakathi kwephephadonga le-isitshalo seqanda

Okwesine, kuyadingeka ukwazi ukuthi lapho uhlela amadivaysi aqhuma emakamelweni, amawindi ahlanganiswe kalula afakiwe. Uma izingxenye zemishini yokushisa ziqhuma, amafasitela azophuma kuqala, futhi izindonga zizobhujiswa.

Ukufakwa okulungile kwemishini esezingeni eliphakeme, isheke elifike ngesikhathi futhi ukufakwa kwezingxenye kuzoqinisekisa ukusebenza okungenazinkinga zedivayisi ye-WAME HETHETE KUSONTO isikhathi sonke senkonzo.