Abaqambi abaningi basebenzisa udonga lwe-semicircular lwe-plasterboard ezifundweni zabo zokungaphakathi kwefulethi. Umdwebo 1. Ukuze uzenzele ngokwakho, kuzofanele usebenze kancane. Ukwenza lula inqubo yokwakha i-septum enjalo ngezandla zakho, ngaphambi kokuqala umsebenzi, udinga ukujwayelana nezincomo kanye nenqubo yokukhiqiza umsebenzi, okuzonikezwa ngezansi.

Udonga lwe-semicircular lubukeka lungajwayelekile futhi luthakazelisa, kungenzeka ukulenza ku-drywall.

Okudingayo ukwazi ukwenza udonga lwe-semicircular lwe-plasterboard

Ubunzima obukhulu bokudala nokufaka umklamo onjalo kufakiwe kokulandelayo:

Umaki wodonga lodonga wenziwa ngepensela usebenzisa intambo njenge-Circula.

- Ukuze uthole amandla wokwakha, kuphela iphrofayili yensimbi okufanele isetshenziswe.

- I-Plasterboard inamandla aphansi aphansi, ngakho-ke kuyadingeka ukusebenzisa izifanekiso ezikhethekile zokugoba kwayo.

- Uma udonga oluvinjelwe lune-radius encane yokugoba, ngaphambi kokufaka i-plasterboard kuyadingeka kumanzi - kuzokwenza ukuthi kukwazi ukugoba kunoma iyiphi i-angle.

- Kuyinto efiselekayo ukuthi ukuphakama kodonga kuya ophahleni, kulula ukukufaka.

Uma ingayifinyeleli, lapho-ke ukuqina okwandayo kuzodingeka ukuthi usebenzise amaphrofayili wensimbi ukuze uvikele i-semicircle kusuka ngaphezulu.

Ubuchwepheshe bokukhiqizwa komsebenzi

Ilele kulezi zenzo ezilandelayo:

Isizinda sohlaka senziwe kusuka kuphrofayela ye-U-U-CEPROPT, sinqume futhi sigobe ububanzi obufunayo.

- Phansi Dweba umugqa lapho udonga luzokwenziwa. Kulokhu udinga intambo kanye nomaka (ipensela). Ukuphela okukodwa kwentambo (Iphoyinti lokuqala lesethenjwa) licindezelwa phansi, kanti elinye lidonswa ngobude obulingana nemisebe yesikhathi esizayo. Kule ndawo umaka alungisiwe futhi, egcina intambo esesimweni eseluliwe, chitha isigaxa phansi phansi.

- Okokusebenza okulandelayo, i-metallic u idinga iphrofayili kusuka kusethi yokufaka i-drywall. Kwenza ukusikeka ngesikhafu sensimbi. Ezinhlotsheni eziningi zamaphrofayili anjalo kukhona umenzi we-cutout, ukuze aqhubeke nezinga olufunayo.

- Into eqediwe kufanele ilungiswe phansi ngezikulufo ezinde noma ama-dowels wensimbi.

- Manje kudingeka senze ukuqagela kokuqala kophahla. Ukuze wenze lokhu, sebenzisa i-plumb noma i-rack ende ebushelelezi. Ukuphawula umaki okutholwe ngokuxhumanisa, ukuchitha ophahleni ngentambo nepensela (njengasesigabeni sokuqala) semicircle.

- Ukufaka izisekeli eziqonde mpo, uhlobo olunye lwephrofayili yensimbi lusetshenziselwa i-drywall, okungukuthi, ukuguqulwa kwalo okumele kuxhunywe kwizikulumo ze-U-Roby ngekwenqatshelwe phansi. Ukuqinisekisa isikhundla esifanele se-rack mpo, i-plumb noma isikwele sensimbi ngamadigri angama-90.

- Lungiselela iphrofayili ye-U ophahleni, usinqume ezindaweni ezifanele. Ihlanganiswe ngezikulufo eziya e-rack vertical, kepha azilungisiwe ophahleni, ziyixhumanisa isiphetho sesibili ku-wedge. Ngokwesikimu esinjalo, kuyadingeka ukuhlanganisa elinye u-u-jail phakathi kwe-rack mpo.

- Umgodi uchithwe kuphrofayela ye-semiconductor ophahleni bese ulukulungisa nge-dowel yensimbi.

- Usebenzisa amaphrofayili we-C, udinga ukubethela ama-racks ver-chain racks. Isinyathelo sikhethwe ebangeni lama-18-25 cm. Zixhumeke ngezikulufo kuwo wonke imichilo ekhephiwe ye-U phansi, uphahla futhi phakathi komklamo.

- Uhlaka oluholayo lusetshenziswa njengesisekelo sokubopha amashidi ezinto ezibonakalayo. Umsebenzi kufanele wenziwe ngohlangothi lwe-convex lwe-semicircle. Ukuhlikihla izikulufa kufanele kube ngaphakathi kwe-12-16 cm.

- Ngemuva kwalokho, amashidi anganamathiselwa odongeni kusuka ngaphakathi. Uma kunesidingo, ukuze kungaqhubeki umsindo, khona-ke phakathi kwezendlalelo zezinto ongazilungisa ngoboya lwamaminerali kumaphrofayli noma enye into emnandi. Lapho ufaka ngaphakathi, umsebenzi uqala kusuka enkabeni yesimo semiphetho.

- Zonke izingxenye ezivelelayo zisikiwe futhi zigaye.

- Ingxenye yokugcina yokwakheka isondele imivimbo ye-GCL.

- Amalunga asothayela kufanele ahluthwe yi-grid ekhethekile yegridi.

- I-putty yenziwa kuzo zonke izingxenye ze-angular of the design kanye nekhoneni elihlanganisiwe lifakiwe. Emva kwalokho, wonke umuntu uqondaniswe ne-angularlala. Umsebenzi ofanayo wenziwa ngaphansi kophahla, emhlanganweni. Ukwakheka kwe-putty kusetshenziswe odongeni olwakhiwe, futhi ngemuva kokushiswa, konke kuvinjelwe ngenombolo ye-zero ye-sandpaper.

- Isigaba sokugcina sisemhlabani indawo yokuklama kanye ne-stain ngombala oyifunayo.

Isihloko ngesihloko: Ukugoqa kompheme emgwaqweni. Sikhetha izinto ezifanele.

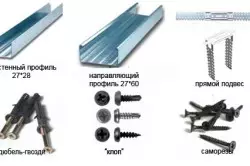

Izinto zokwakha namathuluzi asetshenzisiwe

Izinhlobo zephrofayili edingekayo ukufaka ifreyimu yodonga.

- Amashidi we-glkl.

- Amaphrofayili wensimbi.

- Izikulufa nama-dowels.

- Beka.

- Primer.

- Upende.

- Ukushayela kagesi.

- Isikhafu sensimbi.

- Spatulas - ezejwayelekile nekona.

- I-roller noma ibhulashi.

- Ummese wokwakha.

- Isando.

- I-Plumb, izinga lokwakha.

- Isikulufu.

- I-Roulette, umbusi, ipensela.

- Indophi kanye nomaka.

Ukwenziwa okuzimele kwemiklamo emincane kusuka kumashidi we-GLC - Umsebenzi uxazululwa impela uma ufaka kahle zonke izincomo namathiphu angenhla futhi ungabuyeli emuva kubuchwepheshe bokubutha lemikhiqizo enjalo.

Umklamo owenziwe uzosebenza iminyaka eminingi.