Hood for boiler endlini yayo yangasese

Umnikazi wendlu yangasese ezimweni eziningi ubhekene nenkinga yokugcina i-microclimate kuwo wonke amakamelo atholakalayo, okungukuthi, ukufudumala kwabo.

Impilo yenkonzo yokukhishwa kwensimbi ingaphansi kwezitini nangama-ceramic.

Ukushisa Izinhlelo Zasekhaya zenziwa ukuhlukanisa ngohlobo lwamafutha asetshenziswayo:

- Uphethiloli oqinile (izinkuni, amalahle);

- Igesi (i-liquefied noma igesi yemvelo);

- Uketshezi (uphethiloli wedizili).

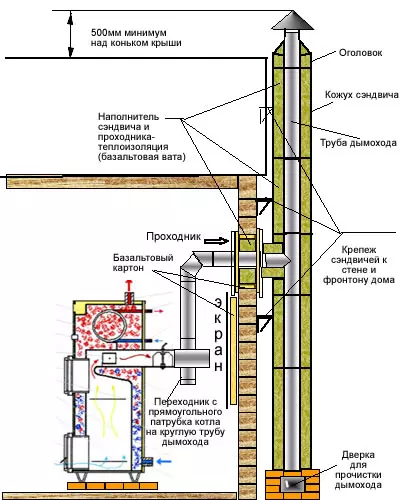

Isikimu se-Ceramic Chimney so-boiler endlini yangasese.

Uhlelo lokushisa indlu yangasese nge-boiler.

Bonke bahlanganisa umgomo wokuthola ukushisa - inqubo yokushisa. Ukuze ulondoloze inqubo yokuhlanganisa, udinga umoya-mpilo. Ngaphezu kwamandla amakhulu, i-boiler inalo, umoya ozungezile uzodingeka ukuze usebenze. Xazulula inkinga ngokufika kwenani elidingekayo lomoya kuma-boilers yakhelwe ukukhipha indlu ye-boiler yendlu yangasese.

Kuze kube manje, kunezinhlelo ezingama-2 zokuphefumula - eziphoqelelwe futhi zemvelo.

Umoya omncane wemvelo ulele emafasiteleni avulekile, ukuba khona kwezikhala okungenani kungu-2 cm phakathi kweminyango kanye phansi, ipayipi lokungena endaweni yophahla lwendlu, okusalungiswa kokufakelwa.

Ukungena komoya okuphoqelekile kungaba yizinambuzane zombili nokuphelelwa amandla. Kuzo zonke izimo, i-air duct inomhlobisi, ozoshayela umoya ungene endlini noma kuyo.

Ukuze uhlele umoya omncane wendlu ye-boiler yendlu yangasese, zombili izinhlelo zingaqhamuka, kepha kunomehluko owodwa oyisisekelo:

- Ngomoya omncane wemvelo, uzodinga ukuhlela ukungena komoya ngqo egumbini lokubilisa. Ngezansi kodonga lwalokhu (imvamisa kakhulu malungana no-boiler), kuphathwe umgodi. Ububanzi be-duct bukhethiwe amandla e-boiler e-boiler kusuka ku-150 mm nokuningi. Ukudla komoya kulawulwa yi-Fiaber (Valve), etholakala kugridi ye-hood yokuhlobisa. Ngesikhathi sokusebenza kwe-boiler, njengesihlanza se-vacuum, kuzodonsa umoya esithandweni somlilo, ngenkathi kungenzeki noma yikuphi ukuphuma egumbini lokubilisa.

- Akuvunyelwe ukubeka ingxenye yokungena komoya ophoqelelwe egumbini le-boiler. Kulokhu, kuyadingeka ukuqhubeka ngenxa yezizathu zokuphepha. Endabeni yokwehluleka okungenzeka emsebenzini we-boiler, ukuhlanganiswa noma imikhiqizo yegesi kungahlukaniswa kulo lonke umoya ongenayo.

I-hood egumbini lokugoba izosizakala. Kungadala ukunyakaza okwengeziwe ku-boiler yomoya. Ngaphezu kwalokho, ngumshuwalense uma kwenzeka kwezimo ezingalindelekile emsebenzini wemishini yokushisa.

Emakhaya amasha azimele afakwe ama-boilers afudumele, ukuze aphambukise amagesi we-flue, ezimweni eziningi izitini zendabuko zezitini ziyasetshenziswa, futhi zivame kakhulu futhi abantu baqala ukusebenzisa ubumba kanye nama-hoods ensimbi.

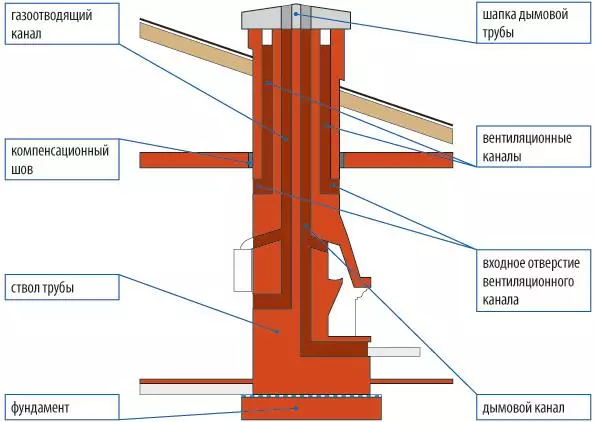

I-Hood kusuka izitini ze-boiler eqinile kawoyela endlini yangasese

Isikimu Sokuphenya Ngezitini Sokugcotshwa Kokufutha Amafutha.

I-Brick tube ezimweni eziningi zibiza eshibhile kunohlelo lwesimanje lwe-chimney. Ishubhu yendabuko yamapayipi endabuko iyakwazi ukubekezelela kalula amazinga okushisa aphezulu. Ipayipi lingamelana nomlilo we-soot clusters.

Ukukhishwa kwezitini ku-boiler endlini yangasese kuyindlela enzima. I-hood itholakala kwisisekelo noma ukugcwala okuhlala isikhathi eside kusuka kukhonkolo oqinisiwe. Ukwakhiwa komklamo onjalo kudinga amakhono athile, ngoba izimpahla zokuphelelwa amandla okuhlala isikhathi eside kanye ne-hermetic kunconyelwa ukukhokhisa i-mason efanelekile ye-peckhok.

Isihloko ngesihloko: umnyango usondele ngezandla zakho: Ungayenza futhi ufake?

Izindonga ezilukhuni ze-hood zizofaka isandla ekuqongeleleni kwezinhlayiya eziqinile zensikazi kuzo. Ukwakheka okungunxande kanye nokuqina kodonga lwesiteshi kwenza kube nzima ukuhlanza umdwebo ovela ekuvutheni okuhlukahlukene.

I-Brick Hood isikhathi eside futhi ngokuthembekile isebenza kuphela ekushiseni okuphezulu kwamagesi aphumayo, akwazi ukuvimba ukwakheka kwe-condensate kupayipi. Lesi simo ezimweni eziningi senziwa lapho kwenziwa ukuqedwa nge-boiler evamile eqinile kaphethiloli.

Enqubweni yokusebenza nama-boilers anamuhla kuphethiloli owuketshezi noma igesi, kanye ne-plellesis boilers kaphethiloli, i-pellet kanye nabanye, isikhathi eside basebenza kwimodi yokuhlangana kancane, i-brick extractor ngokushesha kubhujiswe.

Ama-boilers anamuhla aklanyelwe ukuze amagesi aphelele anokushisa okuphansi okuphansi. Ku-chimney, umphumela udonga lwamanzi we-vapor, aqukethe amagesi we-flue. Izindonga zamaphayipi zizohlala zinomswakama njalo. Ngaphezu kwalokho, amanzi, ukuxhuma kanye nokuhlangana okusele, kuzokwakha amakhemikhali anolaka engxenyeni engaphakathi yepayipi.

Emagameni aphumayo e-boiler, iqukethe isibabule axhumana namanzi azoba semklameni wokwakha i-sulfuric acid. I-acid efanayo iyakwazi ukubhubhisa izindonga zokuqeda amandla. Izimpawu zangaphandle zokubhujiswa - amabala amnyama amnyama ebusweni bangaphandle kwepayipi lezitini.

Imodi yokusebenza kwe-pyrolysis solid kaphethiloli inomthelela ekwakhekeni kwe-condensate enolaka, ekwazi ukubhubhisa ngokushesha ukwakheka kwezitini.

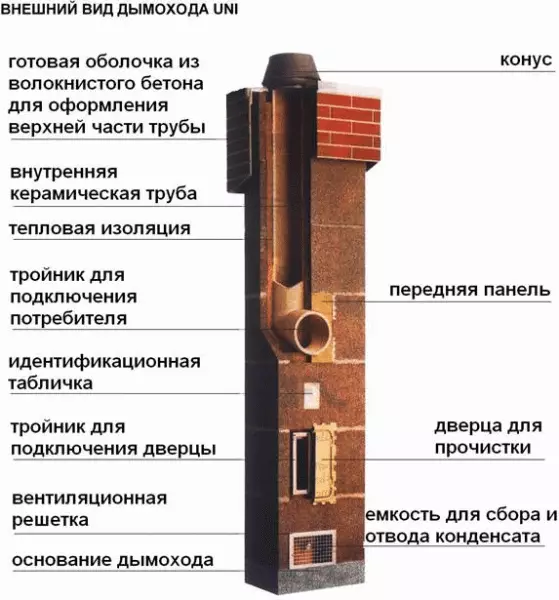

Hood for boiler kusuka kumapayipi e-ceramic endlini yangasese

Khipha uhlelo lwe-boiler kusuka kumapayipi e-ceramic endlini yangasese.

Kuwufanele ukwazi ukuthi ukwakheka kwamapayipi e-ceramic kuyikhambi lendawo yonke le-boiler endlini yangasese. Lokhu kungenxa yokuthi ama-hoods amapayipi akhethekile e-Curamic Chimney angasetshenziselwa zonke izinhlobo zama-boilers. Lokhu okuqukethwe akumelanga nanoma yiziphi izinkwa ezinolaka amakhemikhali akwazi ukwakha ekuqedeni inqubo yokuvuselela kwezinhlobo ezahlukahlukene zamafutha. Okuqukethwe kuzinzile kumazinga okushisa aphezulu. Uhlobo olufanayo lokuqothuka luhlala isikhathi eside kakhulu.

Amapayipi e-CHAMIC CHIMNEY ahluka ngokushisa okuvunyelwa okuphezulu kwamagesi aphelele.

Okwama-boilers aqinile kawoyela, kuyadingeka ukusebenzisa amapayipi avumela amazinga okushisa amagesi awohlokayo ngo-600-650 ° C. Ngaphezu kwalokho, kufanele ngabe zimelana nomlilo we-soot idiphozi kumapayipi futhi kuhloswe ukusebenza esimweni esomile.

Okwama-boilers kuphethiloli owuketshezi kanye nama-boilers wegesi, izinhlelo zokuphelelwa amandla kwe-ceramic zisetshenziswa ngokushisa kwegesi okuvumelekile kwe-400-450 ° C, eziklanyelwe ukusebenza ngesimo esimanzi - kufanele zifakwe nge-condensate.

Ipayipi le-ceramic lizomunca umswakama, futhi ngenxa yalokho kufanele liphumelele ngaphandle.

Inhloso nemibandela yohlelo olunjalo kukhonjiswa kumadokhumenti anamathiselwe ngumenzi.

Ukwakheka okuyindilinga nobushelelezi obushelelezi bepayipi bayakwazi ukuqinisekisa ukuqina kwezindonga ukungcoliswa nokuhlanza kwabo okulula ngokuzayo.

Umklamo Wokuphelelwa yi-Ceramic

Umjikelezo wokuqamba amandla we-ceramic.

Amapayipi okuphelelwa yithemba avame ukubekwa esiteshini esithe mpo ngokukhethekile kusuka kumabhulokhi angenalutho noma izitini. Isiteshi sokudweba singaba sekwakhiweni koPhiko Oluphonliselwe Endlini Lwezimfihlo Ekhona.

Okwe-masonry, amabhlokhi anezelelesi okungu-1 noma okungu-2 kufanele asetshenziswe. Endabeni yokugcina, isiteshi sesibili sisetshenziselwa ukufaka igumbi le-boiler noma ukulethwa komoya ku-boiler burner enegumbi elivaliwe lokuvutha.

Amapayipi akhiqizwayo design ezimweni eziningi afakwa ukuvikela izinhlaka ezizungezile ezivela kumazinga okushisa aphezulu. Eduze kwepayipi le-ceramic kulokhu kungukufakwa koboya bezimbiwa. Ngaphezu kwalokho, ukufakwa kwenza ukuthi kwenzeke ukukhulisa izinga lokushisa lamagesi aphelele. Ukupholisa epulazini legesi ye-flue kungakhuphula inani le-condensate futhi kunciphise ukugcwala kwemvelo ngepayipi.

Isihloko ngesihloko: Ungasusa Kanjani amaphephadonga we-Vinyl odongeni: ukukala okudala kalula, ukusula ngokushesha, susa, ukusula kahle, isithombe, ividiyo

Phakathi kokufakelwa kanye nodonga lwesiteshi kwashiya ukukhishwa komoya ngokungena komoya omncane wepayipi le-ceramic kanye nokufakwa komdwebo.

Kuze kube manje, imakethe yokwakha iyakwazi ukunikela ngamasethi wezinto zokwakha nezingxenye zokwakhiwa kwama-hoods we-ceramic ama-boilers ezindlini zangasese. Kunezinketho zokwakhiwa kwama-heramic hoods ecaleni lensimbi - ngegobolondo lensimbi yangaphandle. Idizayini enjalo yokubekwa kwayo ngeke idinge insiza yeziteshi ezikhethekile kumadivayisi wokwakha wendlu yangasese futhi ingafakwa ngokuphelele noma kuphi, ngaphakathi kwendlu nangaphakathi kwayo.

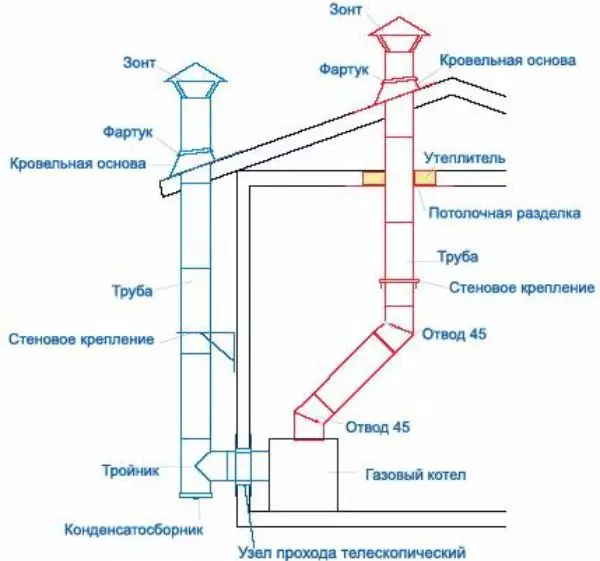

I-Steel Hood ye-boiler endlini yangasese

Amapayipi ama-boilers egesi aphelelwa ngamandla anokushisa kwegesi okungekho emthethweni kwe-400-450 ° C enziwe ngensimbi engenacala, enobukhulu obucishe abe ngu-0.5-0.6 mm. Amapayipi anjalo amelana ngokwanele nemiphumela ye-condensate enolaka ezindongeni.Ama-boilers kawoyela aqinile asebenzisa amapayipi kusuka kunsimbi engasho lutho, enobukhulu be-1.0 mm.

Impilo yenkonzo ye-hoods yensimbi ayiphansi kakhulu, futhi izindleko zazo zisezimweni eziningi eziphakeme kunezitini nangama-ceramic.

Kodwa-ke, okukhishwe kwensimbi yokuhlunga kushesha futhi kulula ukuyifaka, ngaphezu kwalokho, banesisindo esincane futhi abadingi iziteshi ezikhethekile nezizathu eziqinile zokufakwa ezakhiweni zokwakha. Bayatholakala ukuze balungiswe.

I-Steel Hood ye-boiler endlini yayo yangasese ilula kakhulu ukuhlanganisa ngezandla zazo ezintweni eziqediwe. Idivaysi yensimbi, kanye ne-ceramic, ayithambeki ekuqongeleleni kokungcola ezindongeni ezikhona, futhi ingaphezulu lezindonga zingahlanzwa kalula.

Inkiya yensimbi yokuphekela ngensimbi

Umdwebo wedivaysi yensimbi.

Ama-Steel hoods angenziwa ngokuhlukahluka okuningana:

Ipayipi lensimbi eyodwa elenziwe ngomklamo lingafakwa mpo okubekwe ngokukhethekile esakhiweni sokwakha. Idivaysi yokuphelelwa yileli cala iyafana nokwakhiwa kwe-ceramic.

Le nketho nayo isetshenziselwa ukwakha kabusha izitini ze-hoods, ngaleyo ndlela zilifaze ukusebenza ngama-boilers egesi. Ipayipi lensimbi eyodwa lingafakwa nje ngaphezulu kwesiteshi seshubhu lezitini.

I-Hood isuka ezingxenyeni ezenziwe ngomumo zokukhiqizwa kwefekthri. Isigaba ngasinye yi-tube ye-sandwich e-axis axis sandwich. Ipayipi lenziwa ngokwakha ngaphakathi kwelinye ipayipi lensimbi - igobolondo lokuvikela, izindlu. Isikhala phakathi kwegobolondo bese ipayipi ligcwele ukufakwa okushisayo.

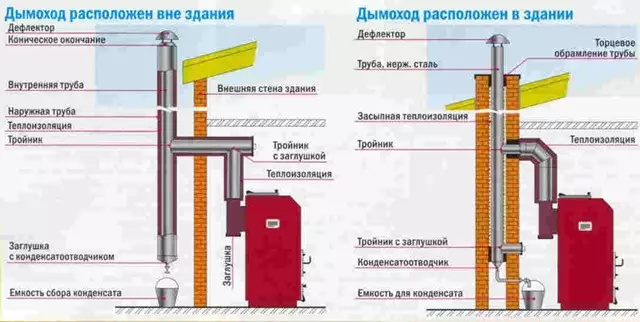

Ukunwetshiswa kukhiqizwa okuhloselwe ukufakwa kokubili ngaphandle kwezakhiwo nakuzo ngaphakathi kubo. Umklamo onjalo ungahlanganiswa kalula kusuka kumamojula we-sandwich ahlukile. Ukusetshenziswa kwamadivayisi afanayo kwenza kube nokwenzeka ukumane uwafake emakamelweni lapho kungekho khona iziteshi ezikhethekile ze-chimney ekwakheni izakhiwo. Zingafakwa futhi zingaphandle ezindongeni.

Ngama-boilers anegumbi elivaliwe lokuhlanganisa, izinhlelo zensimbi zokukhipha umoya ziyatholakala - iziteshi ze-coaxial, lapho ishubhu elilodwa likwelinye. Ngokusebenzisa ishubhu langaphakathi lizonikezwa amagesi we-flue, futhi umoya uhlinzekwa ku-boiler ngamafutha avuthayo. Izindleko zalezi zinhlaka ziphakeme impela.

Ungayenza kanjani i-hood ukuze uthole i-boiler endlini yangasese kahle

Uhlelo lwe-chimney.

Ukukhetha kahle i-hood ye-boiler endlini yangasese, kuzodingeka ukuthi unqume amapharamitha wamagesi we-flue kanye nezimo zokusebenza. Lawa mapharamitha ancike ohlotsheni lokushisa boiler kanye nohlobo lwamafutha ahlelelwe ukusetshenziswa.

Isihloko ngesihloko: Ungahlanganisa kanjani i-Foam Ceiling Plinth: Inqubo yokushaya (ividiyo)

I-extractor ikhethiwe ngokuya ngamapharamitha alandelayo:

- Ekushiseni kwamagesi aphelelwe amandla. Amazinga okushisa okusebenza aqanjiwe we-hood akufanele abe ngaphansi kwamazinga okushisa amagesi aphumayo e-boiler ngesikhathi sokusebenza okujwayelekile.

- Ekucindezelweni kwamagesi ku-hood. Eminye imiklamo ingabalwa ukuze isebenze ngokuqina kwemvelo (ukuphuma kwamapayipi), ezinye ihloselwe ukusebenza nama-boilers anokwedlula okuphoqelekile nokwabiwa okuphoqelekile kwemikhiqizo yokuhlanganisa (ngokweqile ngamapayipi). Ukukhishwa kwe-Universal kule pharamitha kuyatholakala.

- Ngokusho kobukhona be-condensate ku-hood. Amanye amadivaysi enzelwe ukusebenza esimweni esomile, ngaphansi kwezimo lapho i-condensate ingeke yakhiwa ngepayipi. OLUNYE Ukwakhiwa kufakwe izicupho ze-condensate kanye nabaqoqi be-condensate - okwazi ukusebenza ngaphansi kwezimo zokuvuselelwa komswakama ezindongeni zamapayipi.

- Ngokumelana nokuqina. Kunqunywa ngokuqukethwe kwesibabule kuphethiloli, esishisiwe. Izakhiwo ezinjalo ezenziwe zihlukaniswe izigaba ezi-3 zokumelana nokugqwayiza amakhompiyutha sulfur: Ikilasi eli-1 - Izakhiwo zokususa imikhiqizo yokuhlanganisa igesi; 2 Iklasi - Imiklamo yama-boilers asebenza ngophethiloli owuketshezi kanye nezinkuni, ngokuqukethwe kwesibabule kuze kube ngu-0.2%; Ibanga 3 - amadivaysi ama-boilers ku-coal, uphethiloli owuketshezi kanye ne-peat enokuqukethwe kwesibabule ngaphandle kwe-0.2%.

- Ukumelana nokulahla kokuqongelela kwe-soot. Izinhlaka ezinjalo zingamelana noma zingamelanga umlilo we-soot. Lapho uvutha amaqoqo asola e-hood, izinga lokushisa lingakhuphuka liye ku-1000 ° C okwesikhashana.

- Ebanga elivumelekile kumadivayisi ahlanganayo. Endlini, izakhiwo ezivuthayo kufanele zitholakale kusuka egobolondweni elingaphandle lomdwebo alisaseduze nebanga, elivezwa emibhalweni yezobuchwepheshe ye-duct egesi, noma ngaphezu kwalokho ivikelwe emiphumeleni yokushisa okuphezulu.

Amathiphu odinga ukuwazi

Umdwebo wokuxhumeka ku-chimney.

Ishubhu lezitini elijwayelekile, njengenketho yesabelomali kunazo zonke, kufanele isetshenziswe njengokuqedwa kwama-boilers ajwayelekile kaphethiloli asebenza ngokhuni. Uma kwenzeka, ngokuzayo, kuhlelwa ukuthi kuguqulwe kuphethiloli kagesi, uzodinga ukufaka i-liner yensimbi engenasici eshubhu lezitini.

Kwama-boilers anamuhla, asebenza kugesi, uphethiloli owuketshezi, kanye nama-boilers aqinile kaphethiloli asebenza ekhoneni, i-peat noma ngombuso wokuvuselelwa kancane (i-pellet, i-plellysis) kufanele isetshenziswe ama-chimneys eze-ceramic.

I-Steel Chimney ikhethiwe esimweni sokwakhiwa kabusha kokufudumeza emakhaya angasese - lapho ufaka ama-boilers emakamelweni, lapho kungekho siteshi ekwakheni izakhiwo zokuhlalisa i-Ceramic Chimney.

Lapho usebenzisa ama-boilers ama-multi-ful noma ama-boilers amabili, asebenza ezinhlotsheni ezahlukahlukene zikaphethiloli futhi axhumeke ekuqedweni okujwayelekile, amapharamitha alo mklamo onjalo kufanele ahambisane nezimo zokusebenza eziqinile.

Akuvunyelwe ukusebenzisa ama-hoods wensimbi ancishwe odongeni ahloselwe ababili ama-boilers, ukusebenza nge-boiler eqinile kawoyela, ngoba izogijima.

Ama-hoods ahloselwe ukusebenza ezimeni zokuvuselela anethuba lokusebenza esimweni esomile, kepha akunakuphikisana nalokho okuphambene nalokho.

Okwama-boilers asebenza ngophethiloli oqinile, kukhethwe izithasiselo, ezimelana nomlilo we-soot.

Kufanele kwaziwe ukuthi umoya omncane wemvelo uyithuba elincane futhi ulula, kuya ngesimo sezulu futhi ngokuphelele akukho okuzenzakalelayo. Ukuhlinzekwa komoya okuphoqelekile kanye nomoya wokuphoqelelwa kunamandla okuhlinzeka ngezimo zokuhlala okunethezekile, kunganaki isimo sezulu, kepha kuzodingeka ukuthi sikhokhe.