Ukucindezela izinhlelo zokushisa kuyinqubo yokulawula ubuchwepheshe, okwenziwa ngemuva kokuphothulwa komsebenzi wokulungisa, esimweni sokufakwa kohlelo olusha lokushisa, ngesikhathi sokulawula ngaphambi kokuqala kwesizini yokushisa.

Kufanele kukhunjulwe ukuthi umoya obomvu kufanele wenziwe ngaphansi kwengcindezi encishisiwe, ngaphansi kwe-1.5 kgf / cm².

Ngosizo lokuqothuka, bayaqiniseka ngempilo yohlelo lokushisa, futhi esimweni sokuthola ukuvuza, umsebenzi wokulungisa wenziwa.

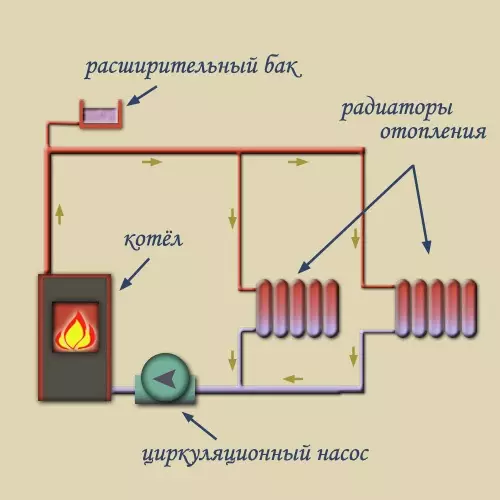

Umqondo ophambili wendlela ebomvu

Ukucindezela izinhlelo zokushisa kusho ukuphakamisa ingcindezi ohlelweni ngo-25-50% ophakeme kunalokho okukhohlisayo nokuvezwa kwaleli nani lamanani imizuzu engama-30.

Umdwebo wedivaysi yohlelo lokushisa.

Le nqubo ikuvumela ukuthi uqinisekise amandla ohlelo lokushisa ukumelana nengcindezi ebukhali ngesikhathi sokusebenza kwayo. Ezakhiweni ezinikwe amandla ngama-boilers amakhulu, uhlelo lokushisa lutholakala ngokuqinile ezimeni zokusebenza eziqinile. Lokhu kuboniswa ikakhulukazi ezakhiweni ezinama-multi-strey, lapho inani lengcindezi yokuphakama kumapayipi emijikelezo yokushisa ikhuphukile izinkomba. Lapho wethula okupholile ohlelweni lwe-hydraulic, kungenzeka ukuthi ama-hydroudars avela, okungukuthi, ingcindezi eyandayo eyandayo ye-coolant, eyavela ngenxa yokushintsha isilinganiso sokugeleza koketshezi.

Amapayipi alethelwa esakhiweni esifudumele ngokuvamile imbangela yezinguquko ekuhambeni kokugeleza kwamanzi nokuvela kwe-hydrowarder. Ngokwenyama, lokhu kungachazwa ngokunyakaza okubukhali okumisiwe kwesisindo esikhulu samanzi nokuvela kwe-hydroedar enhle. Umphumela ofanayo wenzeka lapho kuvalwa okubukhali kwe-trunk ibhola valves. Ngakho-ke, kumaphrojekthi wokushisa amasekethe lapho ungena esakhiweni esipholile, kusetshenziswa ama-valve, kancane kancane anciphisa izinga lokugeleza.

Umcimbi onjalo njengoba ukuqoshwa kwezinhlanzi zokushisa kwenziwa ngokuya nge-Technology Map yohlelo lokushisa lwesakhiwo. Inani lengcindezi kanye ne-coefficient of expression yayo likhethiwe ngokuya ngedivayisi yohlelo lokushisa, izici zomzimba zama-radiator, ukuba khona noma ukungabikho kokwakhiwa okuzimele kokwakhiwa kwaleli bhilidi. Uhlelo lokucindezela, njengomthetho, lwenziwa ngomoya noma ngamanzi.

Isihloko ngesihloko: I-Apron yamatshe ekhishini - ukuqina nobuhle ekhishini

Izinkomba Zokucindezela Nezindlela Zokusebenza

Inani lokucindezela ngesikhathi sokudumaza lisebenza ezinhlotsheni ezahlukahlukene zezakhiwo:

- Ezindlini ezizimele namakamelo amancane ezakhiwo ezifakwe uhlelo lokushisa oluzimele, ingcindezi izoba ngu-2 no-4 kgf / cm² (ibha), ngokulandelana.

- Ezakhiweni ezinama-5- 90 phansi futhi zamukele okupholile egumbini eliphakathi le-boiler, ingcindezi ilingana ne-6-7 kgf / cm² (ibha).

- Ezakhiweni zezakhiwo ezandayo, ingcindezi ebomvu yi-10 kgf / cm² (ibha).

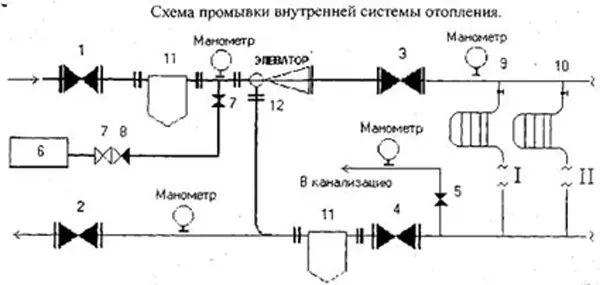

Uhlelo lokugeza uhlelo lokushisa.

Lawa manani wokucindezela ayasebenza kuphela ngesikhathi sokubumba ngamanzi. Ngesikhathi sokwelashwa usebenzisa ubufakazi be-AIR, igeji yokucindezela akufanele ibe ephakeme kune-1.5 kgf / cm².

Kubalulekile ukubheka uhlobo lwama-radiator afakwe ohlelweni lokushisa. Enqubweni yokuqothuka, akunakwenzeka ukwedlula inani lokucindezela ababalwa ngalo noma lapho kuhlolwa khona izivivinyo efektri.

Ukucindezela kwenziwa ngomoya noma emanzini. I-AIR iyakuhleka ukukhiqiza umsebenzi ezakhiweni ezincane noma ezindlini zangasese. Kuleli sebenti amaphampu wesandla akhethekile noma ama-compressors kagesi. I-High Prestor HOSE ihlelwe empompini wokondla noma ukusetha kabusha okupholile kwi-thermal node. Uma indlu isuka egumbini eliphakathi ne-boiler, okuphakelayo nokubuyisa emuva kokugqagqana okupholile. Uma ukuqina kunganele futhi indlela yokulawula ye-pneumatic iyasetshenziswa, ukwehla kancane ezinkomeni zegeji yengcindezi ngenxa yokuxinana komoya kufanele kubhekwe. Ngakho-ke, kudingeka kakhulu isikhathi esithe xaxa ukuze ubekezelele ama-contours ngaphansi kwengcindezi eyeqile. Indlela ye-Hydraulic, ngokuhlukile, ngesikhathi sokuvuza cishe ngokushesha izoyibonisa ngokushesha kudivayisi.

Ukuhlola ukuqina kwemibuthano yokushisa usebenzisa umoya ocindezelwe kufanele kwenziwe ngokuqapha. Uma kwenzeka kuba nepayipi noma i-radiator, ukukhishwa okusheshayo komoya ocindezelwe kwenzeka, okugcwele ukulimala. Ngakho-ke, umoya obomvu kufanele wenziwe ngaphansi kwengcindezi encishisiwe, ngaphansi kwe-1.5 kgf / cm².

Bheka ukuqina kwamapayipi kungcono ukukhiqiza nge-hydraulically. Lokhu kwenza kube nokwenzeka ukubheka ngengcindezi eyandayo, enesici esibucayi sama-radiator, akukho igebe elisheshayo, kulula ukuthola indawo yokuvuza kusuka kumasekhethi okushisa. Inqubo yokwenza umsebenzi wokulawula ngokuqina kwemijikelezo yamanzi nge-hydraulic indlela kumele yenziwe ekushiseni okuhle okukhona.

Isihloko ngesihloko: Ama-Disk Saws for Woodworking: Ungayikhetha Kanjani?

Cindezela ivolumu yomoya yamapayipi elokwakha kungenzeka kuphela uma izitezi zalo zingeqi ezansi ezinyaweni ezi-2 futhi okupholile kuvela emthonjeni wokushisa ozimele. Isitatimende esinjalo sinengqondo ukuthi ukuhlolwa komoya kokuqina kwezakhiwo ezinama-multi-streaty ngeke kulethe umphumela oyifunayo, ngenxa yokuthi indlela ye-pneumatic ayivumeli ukukhomba ukwehluleka kwemikhuba. Ukushintsha ubufakazi begeji yengcindezi ngendlela ye-pneumatic iyahamba kancane, yingakho akwenzeki njalo ukubakhomba.