Kuma-boilers, njengokufaka okunye ukufakwa kokufudumeza, akuwona wonke ukushisa, okwabelwe ngesikhathi sokuhlanganiswa kophethiloli. Amanhle amahle okushisa anamaqabunga anemikhiqizo yokuvutha emkhathini, ingxenye ilahlekile ngezindlu ze-boiler kanti ingxenye encane ilahlekile ngenxa yokuntuleka kwamakhemikhali noma okwenziwe ngemishini. Ngaphansi kobudedengu bemishini buyaqondakala njengokulahlekelwa ukushisa ngenxa yokwehluleka noma ukwehla kwezinto zomlotha ngezinhlayiya ezingavinjelwe.

Ibhalansi yokushisa ye-boiler ukusatshalaliswa kokushisa okukhishwe lapho uvutha uphethiloli, ukushisa okuwusizo okusetshenziselwa inhloso yayo okuhlosiwe, futhi ekulahlekelweni kokushisa, okwenzeka ngesikhathi sokusebenza kwemishini ye-thermal.

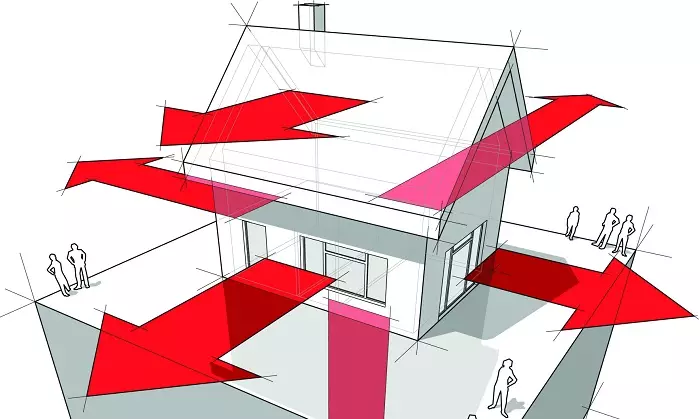

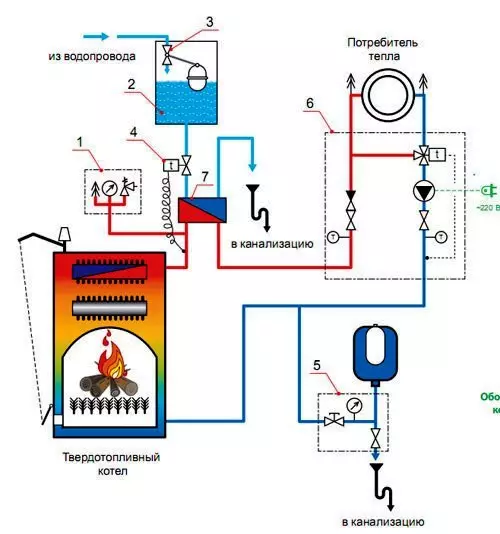

Uhlelo lwemithombo eyinhloko yokulahleka kokushisa.

Inani lobukhulu obungaqhamuka nokushisa okuphansi kokuvutha kwawo wonke uphethiloli kuthathwa njengenani lereferensi lokufika kokushisa.

Uma kusetshenziswa uphethroli oqinile noma owuketshezi ku-boiler, ibhalansi yokushisa ise-kilodzhoules okuhlobene nekhilogremu ngalinye lamafutha asetshenzisiwe, nalapho usebenzisa igesi, okuhlobene nemitha ngayinye ye-cubic. Futhi kulokho, kwesinye isimo, ibhalansi ye-thermal ingavezwa njengephesenti.

I-thermal Balance Equation

I-equation yokushisa i-equation ye-boiler lapho igesi evuthayo ingavezwa yifomula elandelayo:

Amapharamitha aphezulu omthwalo ahlinzeka ngokukhiqiza okuphezulu kohlelo lokushisa.

- Qt = Q1 + Q2 + Q3 + Q4 + Q5 + Q5 + Q5;

- lapho i-QT inani eliphelele lokushisa okushisayo okwabhaliswa esithandweni se-boiler;

- Q1 - Ukushisa okuwusizo okusetshenziselwa ukushisa okupholile noma ukuthola umusi;

- Q2 - Ukulahleka kokushisa, okuhambisana nemikhiqizo yokuvutha emkhathini;

- Q3 - Ukulahleka kokushisa okuhambisana nokuhlanganiswa kwamakhemikhali okungaphelele;

- Q4 - ukulahleka kokushisa ngenxa ye-mehendical engabalulekile;

- I-Q5 - Ukulahleka kokushisa ezindongeni ze-boiler namapayipi;

- Q6 - Ukulahleka kokushisa ngenxa yokususwa komlotha kanye ne-slag esithandweni somlilo.

Njengoba kungabonakala kusuka ku-thermal esele equation equation, lapho kuvutha ama-gaseous noma uketshezi kamafutha, awekho amanani we-Q4 kanye ne-Q6 abonisa kuphela amafutha aqinile.

Uma ibhalansi yokushisa ivezwa njengephesenti lokushisa okuphelele (Qt = 100%), le equation ithatha ifomu:

- I-100 = Q1 + Q2 + Q3 + Q4 + Q5 + Q6.

Uma ilungu ngalinye le-equation yokushisa elilinganiselwe ukusuka ohlangothini lwesobunxele nangakwesokudla lihlukaniswe yi-qt futhi liphindaphindeke nge-100, khona-ke ibhalansi yokushisa izoba ngebhalansi eshisayo njengephesenti lenani eliphelele lokushisa.

- Q1 = Q1 * 100 / qt;

- Q2 = Q2 * 100 / qt nokunye.

Uma ugesi owuketshezi noma ugesi usetshenziswa ku-boiler, khona-ke ukulahleka kwe-Q4 ne-Q6 alahlekile, i-equation yokushisa i-equation ye-boiler iphesenti lithatha ifomu:

- I-100 = Q1 + Q2 + Q3 + Q5.

Uhlobo ngalunye lokushisa kanye ne-equation kufanele lubhekwe.

Ukushisa okwakusetshenziselwa inhloso (Q1)

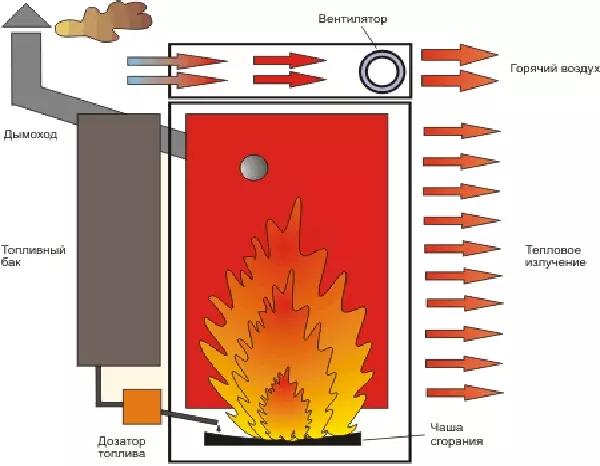

Uhlelo lomgomo wokusebenza kwe-standary yokushisa generator.

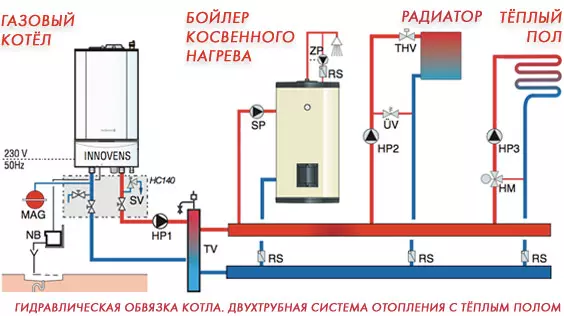

Ukushisa okusetshenziselwa inhloso eqondile ukuthi isithwali sokushisa sisetshenziselwa ukufudumeza kwe-coolant, noma ukulungiswa kwababili ngokucindezela okunikezwe kanye nokushisa, okubhekwa kusuka ekushiseni kwe-econaider yamanzi. Ukuba khona kwe-economizer kukhulisa kakhulu inani lokushisa okuwusizo, njengoba kwenza kwenzeke ikakhulukazi ukusebenzisa ukushisa, okuqukethwe kwimikhiqizo yokuvutha.

Isihloko ngesihloko: Ukuhlela indlu eyi-1-streay enamakamelo okulala amathathu - khetha iphrojekthi yokunambitha

Lapho ama-boiler egijima, ukuqina nokucindezela komusi ngaphakathi kuyanda. Iphuzu lamanzi abilayo lincike kule nqubo. Uma, ngaphansi kwezimo ezijwayelekile, iphuzu lamanzi elibilayo lingu-100 ° C, lapho-ke ingcindezi ye-pair iyanda, lo mkhongo uyanda. Ngasikhathi sinye, ngababili, okukodwa okukodwa kanye namanzi abilayo, kuthiwa kugcwele, futhi iphuzu lamanzi elibilayo ngokucindezela okunikeziwe okubizwa ngokuthi amazinga okushisa agcwele.

Uma kungekho amaconsi amanzi ku-pair, khona-ke ibizwa nge-ferry eyomile. Ingxenye enkulu yomusi osomile ogcwele endaweni enombhangqwana omanzi izinga lokuma komoya, elivezwe njengephesenti. Ngama-boilers kaSteam, umswakama wamaSteam asukela ku-0 kuye ku-0,1%. Uma umswakama udlula lezi zinkomba, i-boiler ayisebenzi ngemodi efanele.

Ukushisa okuwusizo, okusetshenziselwa ukufudumeza okungu-1 l wamanzi kusuka ekushiseni okungu-zero kuya endaweni ebilayo ekucindezelweni okungapheli, kubizwa ngokuthi i-Entholpy ye-liquid. Ukushisa okudliwe ukuhunyushwa kuka-1 l koketshezi olubilayo ku-Vapor State kubizwa ngokuthi ukushisa okufihliwe komumo. Isamba salezi zinkomba ezimbili okuqukethwe okushisa okujwayelekile komusi ogcwele.

Ukulahleka kokushisa ngemikhiqizo yokuvutha, kushiya umkhathi (Q2)

Lolu hlobo lokulahleka kwamaphesenti lukhombisa umehluko esibonelweni samagesi aphumayo kanye nomoya obandayo ongena e-boiler. Amafomula wokunquma lokhu kulahleka kwehluka lapho usebenzisa izinhlobo ezahlukene zezinto zikaphethiloli.

Ukushiswa kwamafutha kaphethiloli kuholela ekulahlekelweni kokushisa ngenxa yokulethwa kwamakhemikhali.

Lapho usebenzisa uphethroli oqinile, ukuncipha kwe-Q2 yile:

- Q2 = (Ig-αg * i) (100-Q4) / QT;

- Lapho i-IG iyisikhundla samagesi esigeleza esibhakabhakeni (KJ / KG), i-IVG iyisikhuthazo somoya ongeqile, i-IV yisikhuthazo somoya esidingekayo sokuvutha, ekushiseni kokutholwa kwayo ku-boiler (KJ / KG).

Inkomba ye-Q4 yethulwa kwifomula ngoba kufanele icabangele ukushisa okukhishwe ngesikhathi sokushiswa okungokomzimba kwamafutha ayi-1 kg, hhayi i-1 kg kaphethiloli efakwe esithandweni somlilo.

Lapho usebenzisa ama-gaseous noma ama-liquid fuels, ifomula efanayo linefomu:

- Q2 = (((Ig-íg * iv) / qt) * 100%.

Ukulahleka kokushisa okunamagesi aphumayo kuncike esimweni se-boiler yokushisa nemodi yokusebenza. Isibonelo, lapho ukulayisha kwamafutha kaphethiloli ekulahlekelweni kokushisa kwalolu hlobo kukhuliswe kakhulu ngenxa ye-periofpinic of air entsha.

Ukulahleka kwamandla afudumele ngokugeleza emoyeni ngamagesi okubhema kwanda ngokushisa okukhulayo kanye nenani lomoya osetshenziswayo. Isibonelo, izinga lokushisa lamagesi ligeleza lingena emkhathini lapho kungekho khona umnotho kanye ne-heater yomoya kungu-250-350 ° C, futhi lapho bekhona, kukhuphuka kaningana inani le Kusetshenziswa ukushisa okuwusizo.

Isikimu se-boiler string.

Ngakolunye uhlangothi, izinga lokushisa elinganele lemikhiqizo yokuhlangana ephumayo lingaholela ekwakhekeni kwama-condensate wamanzi we-vapensate ezindaweni zokushisa ezifudumele, futhi okuthinta ukwakheka kokukhula kweqhwa kumapayipi we-flue ebusika.

Isihloko ngesihloko: Kungenzeka yini ukwenza i-balcony uma kungenjalo: konke "" ngokumelene "

Inani lomoya osetshenziswayo lincike ohlotsheni lomngcele kanye nemodi yokusebenza. Uma kukhuphuka kuqhathaniswa nenani elifanele, lokhu kuholela kokuqukethwe komoya okuphezulu kumagesi aphumayo, aqhubeka nengxenye yokushisa. Le yinqubo engenakugwenywa engeke isuswe, kepha ingalethwa amanani amancane. Ngamaqiniso anamuhla, i-air flow coefficient akumele yedlule i-1.08 yabashisi abanomjovo ophelele, ongu-0,1 - abashiseli abanokudla okuphelele komoya kanye nomoya wokuxuba kanye ne-1.15 - kokungashintshiwe kokunye okuhlanganisiwe. Ukwandisa ukulahleka kokushisa nomoya ophumayo, ukuba khona komoya ongezekile omoya esithandweni somlilo namapayipi e-boiler. Ukugcina ukugeleza komoya endaweni efanelekile kunciphisa i-Q2 kuya ubuncane.

Ukunciphisa inani le-Q2, kuyadingeka ukuxubha indawo yangaphandle nengaphakathi ye-boiler ngesikhathi esifanele, landela ukuntuleka kwesilinganiso, okunciphisa ukudluliswa kokushisa kusuka kumafutha ahlanganisiwe ku-coolant, kuhambisane nezidingo zamanzi asetshenzisiwe Ku-boiler, qapha ukuntuleka komonakalo ku-boiler ne-pay pay ukuze kungavumeli ukuvulwa komoya. Ukusetshenziswa kwezindawo zokushisa zikagesi ezingeziwe ephethini legesi ukuchitha ugesi. Kodwa-ke, ukonga kusuka ekusetshenzisweni okuphelele kukaphethiloli kuzoba okuphakeme kakhulu kunezindleko zikagesi ezidliwe.

Ukulahleka kokushisa kusuka kumakhemikhali wamakhemikhali wamakhemikhali (Q3)

Lolu hlobo lohlelo luqinisekisa ukuvikelwa kohlelo lokushisa kusuka ekushiseni ngokweqile.

Isikhombisi esiyinhloko sokungaphelele komlilo wamakhemikhali wamafutha ukuba khona kwamagesi e-carbon monoxide (lapho usebenzisa ama-fuels aqinile) noma i-carbon monoxide ne-methane (lapho kuvutha uphethiloli). Ukulahleka okufudumele okuvela ku-Chemical Nosta kulingana nokushisa okungavezwa lapho kuvutha izinsalela.

Ukuhlanganiswa okungaphelele kophethiloli kuncike ekuntuleni komoya, ukuxubana kwamafutha ampofu nomoya, kunciphisa izinga lokushisa ngaphakathi kwe-boiler noma lapho uthinta ilangabi likaphethiloli ovuthayo ngezindonga ze-boiler. Kodwa-ke, ukwanda ngokweqile kwenani le-oksijini engenayo akuqinisekisi ukuhlanganiswa okugcwele kwamafutha, kepha kungaphazamisa ukusebenza kwe-boiler.

Okuqukethwe okulungile kwe-carbon monoxide endaweni yokuzithandela yesithando somlilo endaweni yokushisa engu-1400 ° C akufanele kube ngaphezu kwe-0.05% (ngokuya ngamagesi owomile). Ngamanani anjalo wokulahleka kokushisa kusuka ku-UNJIT, azoba ngu-3 kuye ku-7% ngokuya ngophethiloli. Ukuntuleka komoya-mpilo kungaletha leli nani lifinyelela ku-25%.

Kepha kuyadingeka ukufeza izimo ezinjalo ukuze ubuze bamakhemikhali bube ngogesi bungekho. Kuyadingeka ukuqinisekisa ukuthathwa komoya okuphelele esithandweni somlilo, gcina amazinga okushisa ahlala njalo ngaphakathi kwe-boiler, uzuze ukuxuba kahle kwengxube kaphethiloli nomoya. Umsebenzi wezomnotho omkhulu kakhulu we-boiler utholakala lapho okuqukethwe yikhabhoni diokmide emikhiqizweni yokuvutha, ukufinyelela emkhathini, ezingeni le-13-15% kuya ngohlobo lwamafutha. Ngokudla ngokweqile komoya, okuqukethwe yikhabhoni dioksijwati ebhemoshi eliphumayo kungancipha ngo-3-5%, kepha ukulahleka kokushisa kuzokhula. Ngokusebenza okujwayelekile kwemishini yokushisa, ukulahleka kwe-Q3 kungu-0-0.5% wekhabhoni yothuli kanye ne-1% yokuhambisa ungqimba.

Isihloko ngesihloko: I-Quad Bike yenze ngokwakho

Ukulahleka okufudumele kusuka ekuntulekeni ngokomzimba kokulethwa (Q4)

Lolu hlobo lokulahleka kwenzeka ngenxa yokuthi izinhlayiya ezingenasisekelo zikaphethiloli ziwela nge-grate kubha ye-ash noma zithathwe nemikhiqizo yokushisa ngepayipi emkhathini. Ukulahleka kokushisa okuvela ekungangeni kahle ngokomzimba kuncike ekuklameni kwe-boiler, indawo kanye nokwakheka kwethuna, amabutho apholile, isimo sikaphethiloli nesiqu sawo.

Ukulahleka okubaluleke kakhulu okuvela eduzane le-mehendi ngokushiswa kwengqimba eqinile futhi kuyachithwa. Kulokhu, inani elikhulu lezinhlayiya ezincane ezingenasisekelo liyahlanganiswa kanye nentuthu. Lokhu kubonakaliswe kahle lapho usebenzisa uphethiloli onobuhlakani, lapho ushintsha izingcezu ezincane nezinkulu. Ukushiswa kwesendlalelo ngakunye kutholakala emforogeneuous, njengoba izingcezu ezincane zivutha ngokushesha futhi zigqokwa ngentuthu. Ngezikhathi ezithile, ukugeleza komoya, okupholisa izingcezu ezinkulu zikaphethiloli. Ngasikhathi sinye, zimbozwe nge-slag crust futhi ungapheli ngokuphelele.

Ukulahleka kokushisa ku-mechanical insommly kuvame cishe cishe i-1% yemicibisholo yothuli kuze kufike ku-7.5% ukuthola izimfanelo zama-under.

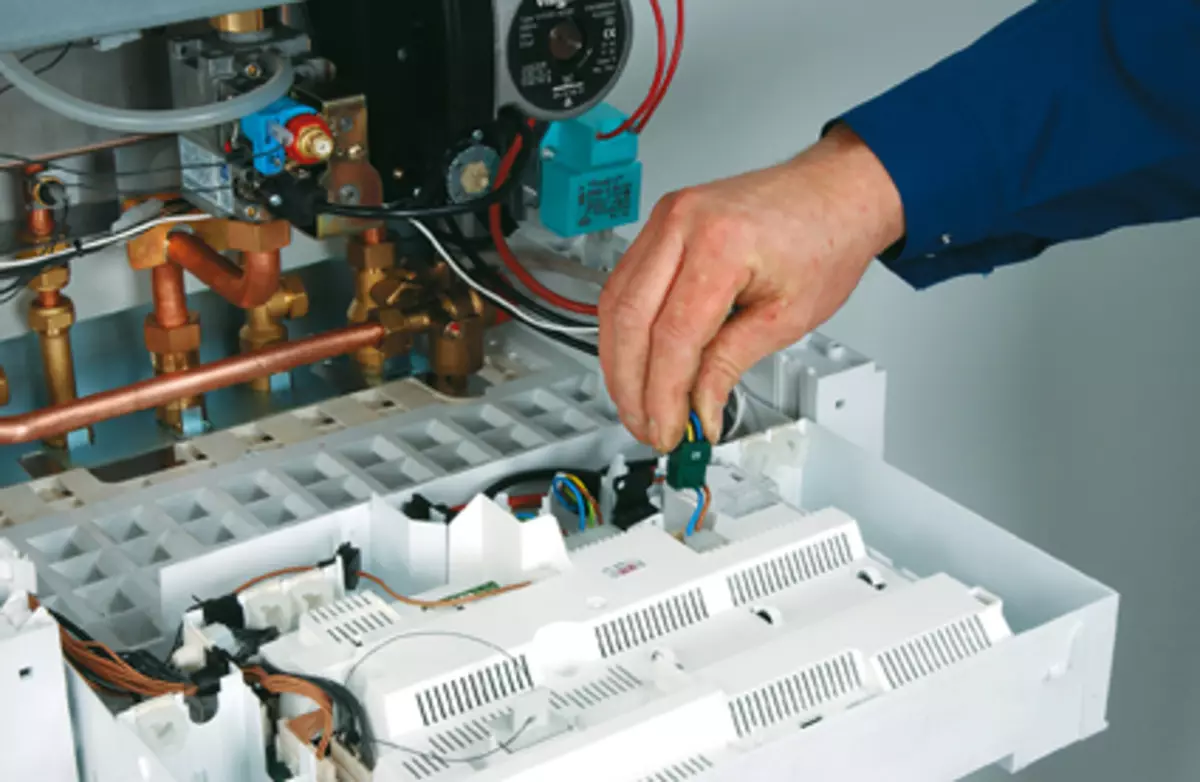

Ukulahleka kokushisa ngqo ezindongeni ze-boiler (Q5)

Lolu hlobo lokulahlekelwa luncike esimweni nasekwakhiweni kwe-boiler, ubukhulu kanye nekhwalithi yophahla lwazo zombili izipewu namapayipi e-chimney, ukuba khona kwesikrini sokushisa esifudumele. Ngaphezu kwalokho, ukwakhiwa kokudubula ngokwako kunethonya elikhulu ekulahlekelweni, kanye nokuba khona kwezindawo ezingezelelweyo zokushisa kanye nokushisa kukagesi endleleni yentuthu. Lokhu kulahleka kokushisa kwanda phambi kokusalungiswa egumbini lapho imishini yokufudumeza isuku, kanye nenombolo nesikhathi isikhathi sokuvulwa kwesithando nomugqa wohlelo. Ukunciphisa inani lokulahleka kuncike ekutholeni okulungile kwe-boiler kanye nokutholakala kwe-economizer. Kuyathandeka ngokwehla kokulahleka kokushisa kuthinta ukufakwa kwamapayipi okushisayo, lapho amagesi aphelelwa yiwo asuswa emkhathini.

Ukulahleka kokushisa ngenxa yokususwa komlotha kanye ne-slag (Q6)

Lolu hlobo lokulahlekelwa lubonakaliswa kuphela ngophethiloli oqinile endaweni ethile enomumo nothuli. Ngezinhlayiya zakhe ezingaphelele, izinhlayiya zophethiloli ezingaphelele ziwela ku-ash bar, ukusuka lapho zisuswa khona ngokufeza ingxenye yokushisa. Lokhu kulahlekelwa kuncike emhlane kaphethiloli nokudumiswa kwe-slag.

Ibhalansi yokushisa ye-boiler ubukhulu obukhombisa ubuhle nokusebenza kahle kwe-boiler yakho. Ubukhulu bebhalansi ye-thermal bunganquma ngezinyathelo ezizosiza ukonga uphethiloli ohlanganisiwe futhi wandise ukusebenza kwemishini yokushisa.