Izici zomkhiqizo wamapayipi

Namuhla, imakethe yamapayipi igcwele imikhiqizo ehlukahlukene. Ezinye zezimpahla ezifunwayo zicwila ngensimbi engenasici. Ngokutholwa kwazo, i-hossess ngayinye ithola isengezo ekhishini ngokwenza okulungisiwe, inhlanzeko kanye nokusebenziseka kalula.

Ngaphandle kokucwila, akukho ndlu edingekayo. Lapho ukugeza kukhethwe, ungaqhubekela ekufakweni kwawo, okungekuhle ukwenze ngezandla zakho.

Ngaphezu kwalokho, ama-washers ensimbi engagqwali abonakala ngo:

- ukubukeka okukhangayo;

- ukulimala okumelana nokukhulisa nokulimala;

- ukuvumelana okuyingqayizivele nekhishi elihlotshiswe kunoma yisiphi isitayela;

- izindleko ezamukelekayo;

- Ukulula ukufakwa nokunakekelwa.

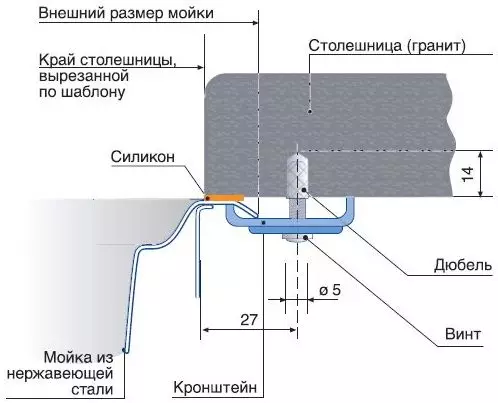

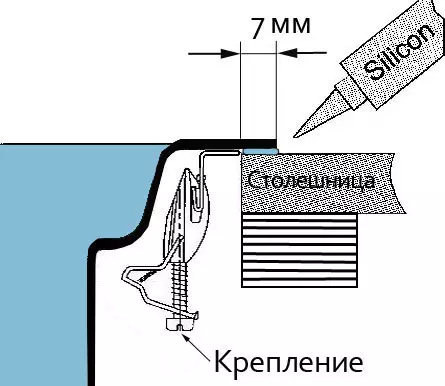

Isikimu sokufaka esikhwameni: 1 - gasket; 2 - I-Clamp.

Ama-fastener asezingeni eliphakeme angenakwenzeka ngaphandle kokusebenzisa izinto ezinjalo namathuluzi njengoba:

- ama-jigsaw kagesi;

- Uketshezi Olulazayo;

- ifayela;

- i-sandpaper;

- roulette;

- Izinga;

- amapuleti;

- ama-rafs;

- Isiponji se-Foam;

- ukuxubha;

- I-Sealant;

- ukumba;

- isikulufa;

- isikulufa;

- ipensela;

- Izikulufo zokuzishaya nge-washer yabezindaba;

- ama-dowels;

- ama-bolts;

- umshini we-welding;

- amabhodi efomu;

- ucingo;

- Isixazululo sikakhonkolo esinesitsha sokuxova;

- Master Kulungile;

- ibhakede;

- Imigoqo yensimbi;

- iqoqo lezinkinobho.

Ukufakwa komkhiqizo ohlukile wamapayipi

Ama-hasse fasteners angenziwa ngezindlela eziningana.

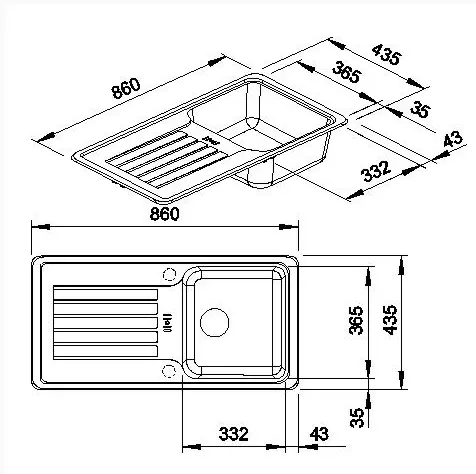

Ubukhulu bokucwila ekhishini.

Le nqubo incike ku:

- uhlobo lwendawo lapho ukugeza kufakwe khona;

- Bobunjwa nosayizi.

Ukuze uthole ukugeza okuhlukile ngaphandle kwesiteji, izisekelo zokhuni (noma ezifanayo nazo) zivame ukusetshenziswa. Kulezi zisekelo, kukhethwe ama-fasteners emishini. Isisekelo sibekwe kwifomu lokufika. Umgodi usikiwe: kufanele uphinde uphinde umjikelezo wesinki. Uma kunesidingo, udinga ukuphatha umphetho ngephepha lefayela noma nge-emery iphepha.

Ukufakwa kokufakwa kwenziwa endaweni elungiselelwe. Ihlolwe ngobuningi bokulungiswa kwensimbi engenasici emgodini owenziwe. Uma kukhona ukushiyeka, umgodi ucwengekile.

Isihloko ngesihloko: Ungayenza kanjani itafula eliyindilinga ngebhayisekili kagesi ngezandla zakho?

Isusa udoti osele ngemuva kwejigsaw. Ingaphezulu lihlanzekile, ama-rubs futhi acutshungulwe ngoketshezi olulalisayo. Akunasidingo sokusebenzisa amakhemikhali asendlini: inganekwane, i-domaset, njll. Ngale njongo, kuphela izindlela eziqinisekisiwe ezidingekayo: uphethiloli, i-acetone noma utshwala. Ngosizo lwesiponji se-foam, uketshezi lusetshenziselwa onqenqemeni lwangaphandle nangomkhawulo wesisekelo. Kumele ihwamuke ngokuphelele.

I-sealant isetshenziswa ku-sealer seal. Ubuningi bawo bunzima ukubala. Into esemqoka ukuthi nge-shrinkage ephelele yegobolondo endaweni yayo, i-sealant yamboza wonke umbuthano noma umkhawulo womklamo ofakiwe. Okusalayo kokuhlanganiswa kokubekwa uphawu kususwa i-rag eswakanyiswe kancane.

Ngomphumela omkhulu, ungasebenzisa i-glue engamelana nomswakama, exutshwe ne-sealant. Amabakaki abakhuphukayo atholakala ezansi kokugeza aqonde futhi ngosizo lokuzishaya ngezikulufo ezinamathele ezisekelweni. Ngemuva kwalokho i-mixer kanye nezinto ze-pul yendle zifakwa.

Ukwakha okusheshayo ngemingcele ephezulu eyize

Ukufaka isinki esingumbani.Ukufakwa kwamamayela anemingcele ephezulu ye-hollow, kwenziwa esisekelweni ngobukhulu okungenani abangama-75 mm. Isinki sinamathiselwe kwisiza sokufaka okuhlosiwe futhi sizoshiswa ngepensela. Nge-contour yayo, isihlalo esifanelekile siyanqunywa. I-jigsik ihlelwe kabusha kwimodi yokusika engahlukaniswanga futhi kukhethwe i-groove ngaphansi kohlangothi lwangaphandle lwe-borgo.

Inqubo eyehlazo yenziwa kusetshenziswa irabha le-foam noma ibhulashi. Isixazululo sokuhlanza sisetshenziswa kuyo yonke indawo yokucwila nesisekelo. Umklamo kufanele wome ekunyamalalweni okuphelele kwephunga elibukhali loketshezi. Insimbi engenasici ibekwe endaweni.

I-Outer Rim ngobumsulwa futhi ngaphandle kokuxhuma ngokweqile kwe-rush nge-groove elungiselelwe yona. Ukuhlangana kucutshungulwa yi-sealant. Impahla eyeqile isuswa nge-rag noma isiponji. Ukufakwa kwe-mixer kanye nokuxhumeka kokugeza ekuhlinzekeni kwamanzi kanye nezinhlelo zokudonsa amanzi kwenziwa.

Ukudalwa kohlaka nokwakhelwe ngaphakathi ekhishini ekhishini

Isifunda sokufaka isinki.

Ngendlela yokuqala, ibha yensimbi iyadingeka ngobubanzi obungu-16 mm. Igobile ngokuya ngefomu elingaphandle lensimbi engenasici. Ama-Fasteners ohlaka oluqediwe kwenziwa kusetshenziswa i-welding ejwayelekile noma ehlanganisiwe. Uhlaka luvunyelwa yizinga kanye nokulungiswa. Ukugeza izimoto kubhekwe ngakho futhi ukufakwa kwalo kokugcina kwenzeka.

Isihloko ngesihloko: Ukufaka ukusondela emnyango ngezandla zakho: amacebo (Imiyalo yevidiyo)

Izinto zisetshenziselwa ukunamathiselwa ngendlela yezibambo ezinqunyelwe zombili izinhlangothi. Ukuphela kwesidingo sokusebenzisa ukwakhiwa okunjalo kungukuhleleka okuphelele futhi okuthuthukile kwesisekelo (ukuhlela nokubala).

Lapho ufaka ukwakheka okushumeke ekhishini, kusetshenziswa i-glue kanye ne-sealant. Ithebhulethi iphuza umgodi wesihlalo, futhi imiphetho iyahlanzwa. Uma kukhona ithebhulethi eyenziwe ngetshe, ukusika kucutshungulwa ngefayela. Ngakho-ke kuvela indawo enzima.

Ungqimba lwe-glue lusetshenziswa ngaphakathi kwe-cutout. Ukunyakaza kwenziwa. Isikhathi esithile sinikeza i-glue ukuba babambe, ngemuva kwalokho i-sealant isetshenziswa endaweni yokuxhumana echibini nge-Worktop. Izici zamanethiwekhi okusebenzisa anamathiselwe.

I-Stubbornd Design

Ukugeza isixhumi "isigqila" sokugeza.

Lapho ukugeza imoto kuzosetshenziswa ngaphandle kwanoma yibaphi ama-Lockers namathebula wombhede, kususelwa kwinkomba yesikolo. Ukuze wenze lokhu, kuyadingeka ukwenza amaphuzu ama-4 okusekelwa, okufanele abe emakhoneni okuklanywa okubekiwe.

Ukugeza kufakwe odongeni futhi kunezinga elivundlile lendawo yalo nendawo yezimbobo ezikhuphukayo. Izimbobo ezingaphansi kwe-dowel 5 mm ziyavuthwa futhi izinto ezikhuphukayo zifakiwe. Ebambe ukucwila, izikulufa zisonta kuze kufike lapho.

Kunenye indlela yokuqinisa imikhiqizo yensimbi engagqwali. Kusetshenziswa lapho kudalwa izingxenye ezimbili zezingxenye ezimbili. I-Planck inamathiselwe:

- Ukugeza ngesikhafu sokuzishaya nge-washer yabezindaba;

- Odongeni e-dowel.

Lolu hlobo lokufaka lwenza umqondo lapho ubheka umthambeka phakathi komugqa wokugeza kanye nepuleti elisheshayo ngenani okungenani ama-degree angama-45. Ngaphezu kwalokho, ipuleti ekhuphukayo lingaba phansi. Ubukhulu bemithambeka buhlala bungashintshiwe, kepha izinto ezisetshenzisiwe kufanele zibe nesigcini senqaba.

Ukufakwa kwezesekeli ekhishini ku- "Shirt" kakhonkolo

Mhlawumbe le ndlela yokufaka iyinhle kakhulu. Yize inqubo edla isikhathi kunazo zonke. Okokuqala, ukusebenza kwamafomu kwenziwa ngamabhodi. Kumele iphinda kakhulu imidwebo yokucwila okufakiwe. Kwezinye izimo, ubukhulu obugcwele bungabukelwa ukucubungula ngamatshe emvelo. Engxenyeni ephakathi kwefomu kufakwa ishubhu yokuhambisa indle ngaphansi kokudonsa. Itholakala ngaphansi kwezinga lesinki esiphansi kakhulu.

Isihloko ngesihloko: Izici ze-Plywood Laser Cutting

Ukuthululwa kwesixazululo sikakhonkolo kwenzeka ngezigaba ezimbili. Owokuqala ukugcwaliswa okuphelele kwengxenye engezansi nephakathi yesisekelo esizayo. Ngamakhona ngamakhona afakwe izigaxa noma agqoke izingcezu ezinzima zocingo. Banikeza ukufakwa okuthembekile kwensimbi engenacala kwikhambi elivele elibanjwe.

Isigaba sesibili sihlinzekela ukumbozwa okuphelele kwezindonga zokugeza ngesisombululo esisebenzayo. Akunakwenzeka ukwenza ukhonkolo ezindongeni zangaphakathi. Uma lokhu kwenzeke, kuyadingeka ukuthi ususe ngokushesha okusalayo ngendwangu emanzi noma ucezu lwenjoloba le-foam.

Insimbi engenasici ingumkhiqizo omncane kakhulu. Ngakho-ke, kuphoqelekile ukuqeda umthelela wemishini kuyo. Ukuze ungafiphaza inqubo, kuyadingeka ukuyishiya ngamaphephandaba amadala ngokupenda i-scotch.