Ungangezelela induduzo yokuphila ngesikhathi esibandayo ngokushisa phansi. Enye yezinketho iyisitezi esifudumele kagesi. Ifakwe ngokushesha futhi ilula kunamanzi, ungabhekana nezandla zakho ngaphandle kokuzibandakanya kochwepheshe. Kahle ngokuzimela phansi kagesi ngaphansi kwethayili, uLinoleum kanye ne-Laminate futhi kuzoxoxwa ngakho.

Idivayisi yokushisa yaphansi kagesi

Uma sikhuluma ngokujwayelekile ,phansi okufudumele kukagesi kuqukethe lezi zingxenye ezilandelayo:

- into yokushisa;

- inzwa yokushisa yephansi;

- Isilawuli sokushisa (Thermostat).

Kufanele kwaziwe ukuthi into yokushisa izosebenza ngaphandle kwenzwa kanye ne-thermostat, kepha umsebenzi ngeke uphumeleli futhi ube mfushane. Ukungasebenzi, ngoba kuzodingeka ukuthi uyivule / uvale ngesandla, futhi lokhu kuholela ekuchichimeni kukagesi. Futhi okufushane, ngoba kulawulwa ngesandla, ukucwilisa ngokweqile kwenzeka, okuthinta kabi imigqa yento yokushisa.

Izakhi zokushisa zikagesi

Izinhlobo zezinto zokushisa

Emakethe unganikela ngokushisa okuningana okuhlukahlukene:

- Ukufudumeza izintambo zokumelana. Banentengo ephansi kakhulu, bangama-single-core and bile, ngenxa yokuthi umdwebo wokuxhumana kwawo uguquko. Ububi babo abaphambili ukuthi kungenzeka ukuthi bashiye ngokweqile bendawo futhi bahluleke (esitezi sokufudumala sokumelana nentambo akufanele sifakwe isikhathi eside). Ngakho-ke, lapho ufaka izintambo, ungazibeki phansi ezihlalweni, lapho ifenisha nemishini yasendlini izoba khona. Enye insusi inqubo ende yokubeka lapho ufaka.

Izintambo Zokushisa Zokushisa

- Ukufudumeza ikhebula lokuzilawula. Inentengo ephakeme, kepha ikwazi ukulungisa amazinga okushisa ayo esigabeni esisodwa kwimodi ezenzakalelayo, evikela ukushisa ngokweqile futhi kunwebe impilo yayo yenkonzo.

Intambo yokuzilawula yokuzilawula

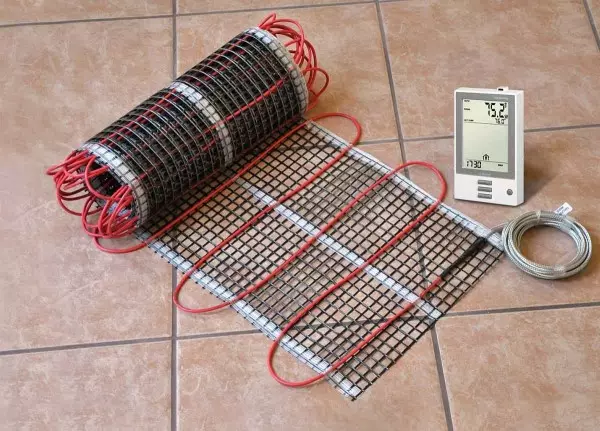

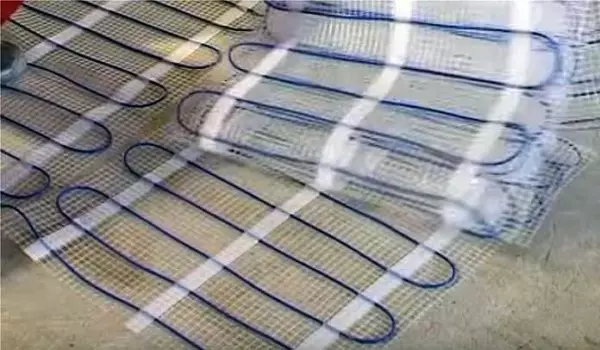

- Amakhethini kagesi kagesi phansi efudumele. Lezi yizintambo ezifanayo, zifakwe kuphela ngesimo senyoka kugridi ye-polymer. Zingakwazi futhi kusuka kukhebula lokumelana noma lokuzilawula. Ukubekwa phansi kukagesi kagesi kudinga amahlandla ambalwa.

Ugesi kagesi

- Amafilimu e-carboxylic aff Phakathi kwezendlalelo ezimbili ze-polymer, unamathisela we-carboxyment uyathunyelwa, okuthi, lapho udlula kuwo, ukuncoma okugqamile kukagesi kwamanje kubukhazikhazi obunama-infrared. Kuyathandeka ekukhishweni kokushisa kwe-infrared, ngekhwalithi efanelekile yokuhlala okuhlala isikhathi eside - uma belinyazwa yingxenye ethile, kuphela abakhishwe emsebenzini, abanye basebenza. I-PLUS futhi ukufakwa okusheshayo, kepha ukuxhumana kukagesi kuyinkimbinkimbi kakhulu kunasezikhabeleni. Akujabuli kakhulu ngentengo futhi lokhu kubuya okuphambili.

Ifilimu leCarboral - Ukushisa Okuphansi Kwe-infrared

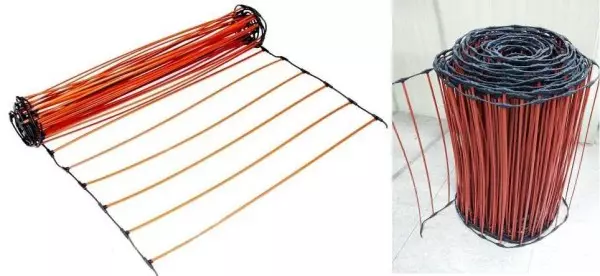

- Ama-Mats we-Carbon. Lezi yizinduku ezinamakhabhoni ngaphakathi, ezixhumene nezintambo zikagesi. Uhlobo olubiza kakhulu lwezinto zokushisa zesitezi sokufudumeza kagesi, kepha, ngokusho ukubuyekezwa, okungathembeki kakhulu. Bavele bengakaze babe kudala futhi ubuchwepheshe bokukhiqiza bebugqoke kabi, ngoba inkinga enkulu ukwehluleka ngenxa yokuphazamiseka kokuxhumana endaweni ye-carbon kanye nomqhubi wesifundo.

Ama-carbon mats for floor floor heating

Yikuphi kwalezi zinhlobo zikagesi ezingcono kakhulu, akunakwenzeka ukusho ngokungagangeli. Wonke umuntu unezinto ezinhle nokubizela, izici zokufaka. Ngokusekelwe kulokhu, bakhetha inketho engcono kakhulu yokwehla okuphansi - ngaphansi kwethayela kungcono ukubeka amakhebuli noma ama-mats, futhi ngaphansi kwe-linoleum - i-linoleum - i-heater yefilimu.

Izinhlobo ze-thermostat

Amarejista wokushisa we-Electric Heating Floor Kunezinhlobo ezintathu:- I-Mechan. Ngokubukeka kanye nomgomo wokusebenza kufana ne-thermoregulator ku-iron. Kunesilinganiso lapho ukhombisa khona izinga lokushisa elifunekayo. Lapho nje yehla ku-1 ° C ngezansi okunqunywe kusengaphambili, ukufudumala kuvula, iba yi-degree engenhla - icisha.

- I-electro-mechanical. Ukusebenza akuhlukile kunoma yini, kudla kuphela isikrini esincane se-crystal screen kanye / phansi. Isikrini sibonisa izinga lokushisa lamanje laphansi, futhi izinkinobho zilungiswa ohlangothini olufunayo.

- Kuhlelwe ngogesi. Okubiza kakhulu, kepha futhi okusebenzayo kakhulu. Ungasetha imodi yokusebenza (lokushisa) ngehora, nakwamanye amamodeli namaviki esonto. Isibonelo, uma konke kuhambile ekuseni, kungenzeka ukusetha amazinga okushisa aphansi - cishe ngo-5-7 ° C, futhi ngehora nesigamu ngaphambi kokufika, kulungiselelwe ku-Standard. Kunamamodeli athile akwazi ukulawula i-Intanethi.

Kwamanye amamodeli we-thermostat we-underfloor, kukhona izinzwa zokushisa zomoya ezakhelwe ngaphakathi kanye nekhono lokuvumela / ukukhubaza ukufudumala kulezi zinkomba, hhayi ngokuya ngokushisa kwaphansi. Ngakho-ke ukukhetha kulapho.

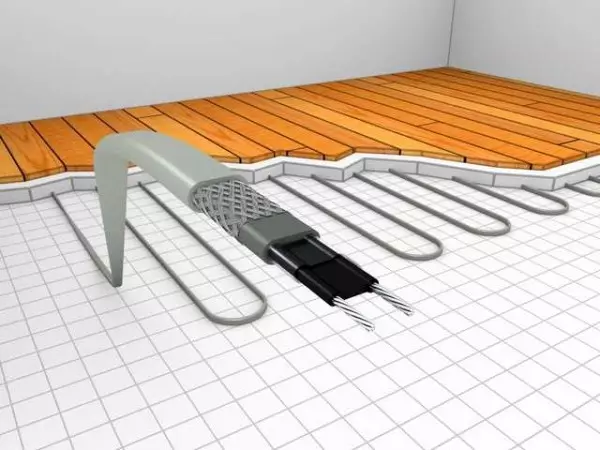

Phansi ngogesi ngaphansi kwethayela - ikhebula kanye ne-cable mat

Ama-Mat Mats alungele kakhulu i-tile. Kulokhu, indawo efudumele kagesi enjalo kufanele yenziwe ngendlela elula, ikakhulukazi uma isivele ifakwe futhi ihlelwe. Ukufakelwa kuyadingeka ukuthi izindleko zokushisa azizinkulu kakhulu, futhi zisekusukeni - ukuqinisekisa ukufudumala okufanayo futhi kugweme ukubukeka kokuba yithemba ngaphansi kwentambo. Uma ikhebula lingumota, lizodlula futhi linesibindi. Ngakho-ke, qala wenze ukufakwa kanye nokuqondanisa okunzima phansi, bese kuthi-ke ubeka ikhebula lokufudumeza noma mat.

Kunzima ukusebenza ngezintambo zokushisa - kumele zibekwe isikhathi eside, bopha kugridi noma zilungiswe kukhiye. Kepha ngaphandle kwalokho - futhi inketho enhle.

Phansi ngogesi ngaphansi kwethayela

I-Cable Mata yokukhwela

Sicabanga ukuthi phansi kufakwa futhi kuqondaniswe. Kunezimo ezihlukile kakhulu futhi nakanjani usho ukuthini okufanele kube yikhekhe le-screen kungaba maqondana necala ngalinye.

Lapho ufaka ukufudumala kukagesi phansi kwanoma yiluphi uhlobo, kufakwa ekufakweni kwe-thermostat. Itholakala odongeni ngokuphakama okuthe xaxa, kepha hhayi ngaphansi kwama-30 cm ukusuka phansi. Ifakwe ebhokisini elijwayelekile lokufakwa (njengesokhethi). Ngaphansi kwebhokisi emgodini odongeni oludonswayo. Ukuze wenze lokhu, sebenzisa i-drill nge-nozzle efanele - umqhele.

I-Drill Hole yebhokisi lokukhuphuka

Izicathulo ezimbili zivinjelwe ebhokisini phansi. Kokunye, izintambo zikagesi zizobekwa ezintweni zokushisa, kuya kolunye - inzwa ekuhlanganisweni. I-groove, ihloselwe ukubeka inzwa yokushisa yaphansi, iyaqhubeka phansi. Kusuka odongeni, kufanele ivikele okungenani ama-50 cm.

Unhlangothi ngaphansi kwenzwa yokushisa kufanele ungene esitezi okungenani ama-50 cm

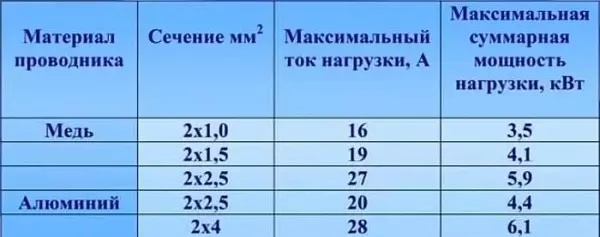

Ukuqinisekisa phansi okufudumele ngogesi ku-thermostat, kufanele uthathe ama-220 v. Isigaba se-Wire sikhethwa ngokuya nge-DAMADICED. Imininingwane ikhonjiswa etafuleni.

Ukukhetha ukulungiswa kwezintambo ukuxhuma amandla ku-Electric Heating Floor Thermostat

Ngemuva kwezicathulo zenziwe, ungaqala ukubeka phansi kukagesi okufudumele ngezandla zakho. Ukuze wenze lokhu, wonke udoti ususwa emphemeni wephansi (qaphela ngokucophelela).

Ingaphezulu lesitezi kufanele lihlanzeke ngokuphelele

Ukuze uthuthukise i-clutch ye-glue e-screed nethayili, kungumhlabathi.

I-Primer yokunamathela okungcono nge-glue

Ngemuva kokumisa i-primer ku-groove elungiselelwe, ungabeka inzwa yokushisa. Wehliswe ebhodini elihlanganisiwe (livame ukuza). Inzwa ngokwayo isesiqongweni socingo olude. Iphakanyiswe emaphethelweni epayipi, ivalwe yi-plug. Ipulagi iyadingeka e-glue noma isisombululo sonakalisa inzwa. Ngemuva kwesheke lomhloli, alizange lilimaze inzwa ngesikhathi sokusebenza. Uma konke kuhamba kahle, ungayifaka.

Sensor siletha ekwakhekeni

Ukulungiswa kufakwa kunhlangothi ephekiwe elungiselelwe kusengaphambili, sizoletha ucingo ebhokisini elikhuphukayo elilungiselelwe i-thermostat.

Sibeka inzwa ku-groove

Izintambo singena ebhokisini elikhuphukayo le-thermostat.

Siletha ikhebula kusuka enzwaneni kuya ebhokisini elikhuphukayo

I-groove ene-sensor ivaliwe nge-glue ethayiliwe, landela amaconsi.

I-groove ivaliwe nge-glue tag

Okulandelayo, ukunciphisa izindleko zokushisa, kungenzeka ukuthi ungangeni ungqimba oluncane lokufakelwa ngendawo evuthiwe.

Ukunciphisa ukulahleka kokushisa, kungenzeka ukusakaza ungqimba wokufakelwa okushisayo okuhlaselwe

I-Heath Infation Cannons ifakwe eduze komunye nomunye, icwila amalunga eScotch.

Sula amalunga we-scotch

Ngalesi sendlalelo - ukufakwa okushisayo okushisayo - akuyona yonke into elula kakhulu. Uma kuthathwa, i-screed noma ithayela iyantanta, ngoba ngeke kube nokuxhumana nesisekelo. Abanye abakhiqizi banconyelwa ukuhlinzeka ngokuxhumana ukuze banqume "kwi-Windows" Substrate, lapho ukhonkolo ne-glue (noma khona) kuzohlotshaniswa. Ukuxhumana okunjalo akubonakali kuthembekile.

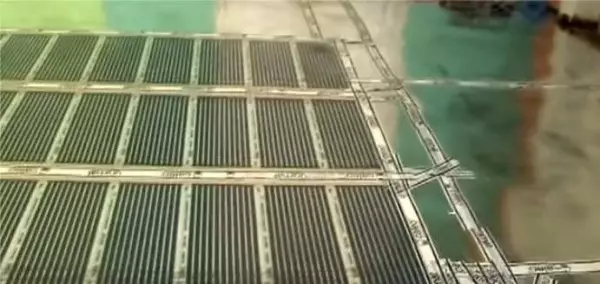

Okulandelayo, beka indawo ezofuthelwa. Asifaki izindawo lapho ifenisha nemishini emikhulu yasendlini izoma khona. Futhi buyela ezindongeni nakwamanye amadivayisi wokushisa (ama-risers, ama-radiator, njll.) Ngo-10 cm. Indawo esele kufanele imbozwe ngama-mat mat. Baxoshwa esikhaleni esidingekayo. Endaweni lapho kufanele khona umakethi kufanele athunyelwe, ukusika igridi, hhayi ikhabhomu yokufudumeza.

Igridi lisikiwe, ikhebula alithinti

Ukuvuka kwe-mat (ikhebula lisebenza njengesixhumanisi) bese libekwe kwelinye icala (noma ku-90 ° uma kunesidingo).

Mbumbano

Uyacelwa ukuthi uqaphele ukuthi amaphaneli ama-mat akufanele anciphise omunye komunye, futhi izintambo zokufudumeza akufanele zithinti. Phakathi kwezintambo ezimbili kufanele kube nebanga okungenani elingama-3 cm. Futhi ukubeka phansi esitezi esifudumele kagesi, ukubala ukuze inzwa yenqwaba iphakathi kwama-canvases amabili.

Inzwa yokushisa ye-Paul kumele ibe phakathi kwekhebula.

Izintambo zikagesi ezivela kumakati wokushisa nazo ziqala ebhokisini lokuhlanza. Ngemuva kokufaka, badinga ukushayela, ukubheka ukumelana. Kusuka kwiphasiphothi (kunemiyalo yesethi ngayinye) kufanele ihluke ngaphezu kwe-15%.

Ihlola ukumelana

Ngemuva kwalokho, ungaxhuma i-thermostat. Umdwebo wokuxhumeka usesodongeni lwangemuva (uqokwe kahle ukuthi yini nokuthi ungaxhuma kuphi).

Xhuma kuma-terminals afanele

Ukuxhumana kangcono, ucingo lungcono ukuhlasela (kufudumele insimbi yokuthengisa eRosifoli noma e-soldering flux). Ukufakwa kwabaqhubi kulula: bafakwa kwisokhethi, ngemuva kwalokho isikulufa sengcindezi siqiniswa nge-screwdriver.

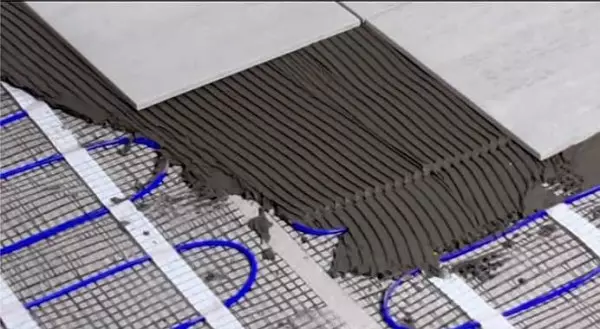

Okulandelayo, faka kafushane i-voltage - cishe imizuzu engu-1-2. Bheka ukuthi ama-Mats afudumele nokuthi zonke izigaba zifudumala yini. Uma kunjalo, ungaqhubekela phambili. Sivale i-glue ye-tile (ekhethekile ngesendlalelo esifudumele) nasezindaweni ezincane sisebenza ku-mat mat. Ubukhulu bengqimba bungu-8-10 mm.

Faka i-glue ezindaweni ezincane

Lapho kufakwa, i-glue icindezelwe kahle. Akufanele kube khona ukungabi nalutho noma ama-bubble amoya. Ungqimba oluvinjelwe udlula i-spatula efakwe emanzini, eyakha ama-grooves.

Sakha i-groove

Manje sibeka i-tile.

Ku-glue faka ithayela

Kuyadingeka ukusebenza ngokucophelela, ngaphandle kwalokho ungalimaza ikhebula. Kuyadingeka futhi ukuqinisekisa ukuthi imilenze ayihambisi imaksi kusuka endaweni noma ingaphuli intambo. I-Electric Cable Floor Floor Floor ilungele ukusebenzisa ngemuva kokomiswa okuphelele (kukhonjiswe kwiphakheji).

Le ndlela ayiyona ehamba phambili. Kulula ukulimaza izinto zokushisa ngesikhathi somsebenzi. Ukuze uqinisekiswe ukugwema lokhu, ungathela ama-mat amakhethini ngesendlalelo esincanyana seleveli - ukwakheka kokuqondanisa okuphansi komhlaba. Ukhuphuke u-fluidity, ngakokhokho akuwona ama-bubble nama-voids. Ezingeni ezomile, ungabeka kalula i-tile ngaphandle kwezinkinga.

Izici zokubeka phansi kukagesi kusuka kumakhebuli okushisa

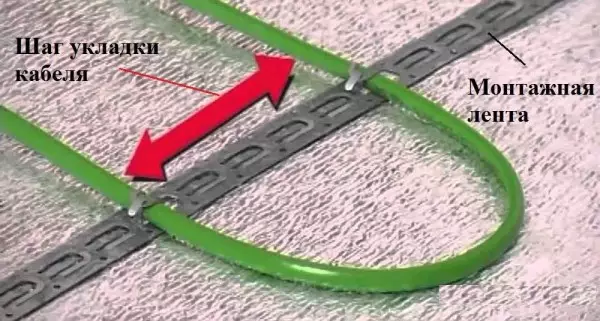

Umehluko omkhulu lapho ubeka phansi ugesi ofudumele kusuka kukhebula lokufudumeza eqinisweni lokuthi ikhebula ngokwalo kufanele ligoqwe ngokusho kwenye yezinhlelo (inyoka noma umnenke kanye nokuguqulwa kwazo) kanye neqiniso lokuthi lokhu kuthululelwa ukuguquguquka okusobala Okungenani ama-3 cm. Kuphela ngemuva kwesethi yamandla okuqamba ukhonkolo (ngemuva kwezinsuku ezingama-28 emazingeni okushisa angu-20 ° C) angabekwa uthayela. Ngakho-ke le nguqulo efudumele ngaphansi kwethayili idinga isikhathi esithe xaxa, kepha ilungele ezinye izinhlobo zaphansi - ngaphansi kwe-parquet, i-linoleum, i-linoleum kanye nekhaphethi.

Manje inqubo uqobo. Izimbambo zokufaka noma i-metal mesh zilungisiwe ku-Screen Emnyama Eqediwe ngokufakwa. Kanye nalapho ubeka ama-mat, kungenzeka ukubeka ungqimba lokufakwa okushisayo okuvuthiwe (ngendawo ecwebezelayo), kepha ungakwenza ngaphandle kwawo.

I-teping ekhuphukayo yokufudumale phansi yenzeka eceleni kolunye uhlangothi olwengeziwe ngo-50-100 cm ekhuphukeni. Kunamathiselwe esisekelweni esikwi-dowel noma sokuzishaya ngesikhafu. Iteyipu inezilimi ezibonakalayo ezilungiswe yikhebula.

Umgomo wokulungisa ikhebula kwiribhoni ekhuphukayo

Indlela yesibili yokuqinisa kumaseli wegridi aqinisiwe. Le nketho ilungile lapho ikhekhe lesitezi esifudumele senziwa ngokufakwa. Igridi bese isaqinisa i-screed futhi ngokulinganayo ibeka kabusha umthwalo ekufakweni.

Ukubeka igridi yokufaka ikhebula lokushisa

Igridi kumele yenziwe ngocingo okungenani 2 mm ubukhulu, usayizi weseli - 50 * 50 mm. Le inketho elula kunazo zonke lapho ubeka inketho - ungabeka ikhebula ngesinyathelo osifunayo. Izingxenye zegridi zibopha ngocingo noma ama-clamps epulasitiki, ngendlela efanayo ahlelwe kumaseli nekhebula.

Ikhebula lizodonswa nge-clampisi epulasitiki

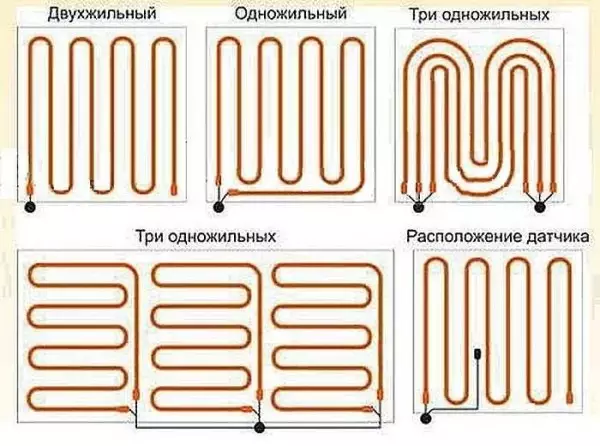

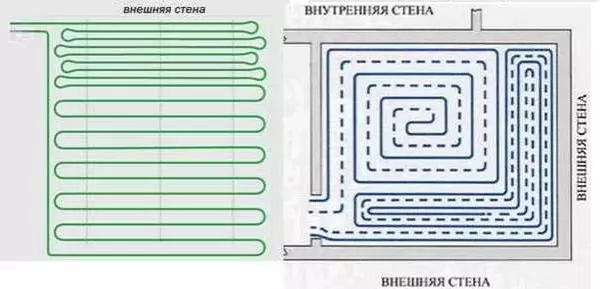

Kungani ukhethe ikhebula, hhayi umake ongaphansi kwethayela? Intambo ingabekwa ngesinyathelo esihlukile, inikezwe izici zegumbi. Isibonelo, ukubeka kaningi ezindongeni zangaphandle, futhi ama-Indoor athatha isinyathelo ngaphansi kwesinye isikhathi. Ngama-mats kukhona okunye ukuphuma - sebenzisa ezigcekeni ezibandayo zeZanes ngamandla amakhulu.

Imidwebo evamile yekhebula yekhebula

Amaphethini wesakhiwo ngezindawo ezibandayo ezivuthayo ezithuthukisiwe

Ngemuva kokubeka ikhebula lokushisa, izintambo zokuphakelayo zifinyelelwa ebhokisini lokukhuphuka kwe-thermostat, ukumelana kwazo kulinganiswa, khona-ke i-thermostat ngokwayo ixhunyiwe futhi uhlelo luhloliwe. Uma zonke izingcezwana ze-CHECK zitholwe ngokujwayelekile, ungathela isitezi esifudumele kagesi ngesisombululo sikakhonkolo. Ngemuva kokomiswa okuphelele, noma yisiphi isembozo saphansi singafakwa, kufaka phakathi amathayili.

I-Electric efudumele phansi ngezandla zazo ngaphansi kwe-laminate ye-linoleum

Ngalolu hlobo lokuhlanganisa, ukusetshenziswa kwethonsi efudumele yefilimu kuzobe kulungile. Ngesisekelo (isidingo sokusebenza okujwayelekile, uma kudingeka ijika lejika, kudingeka ukufakwa okulinganiselwe kwe-screen) Ukufakwa kuthatha isikhathi esincane, akudingi imisebenzi emanzi noma eminye.Inqubo yokufaka esithombeni

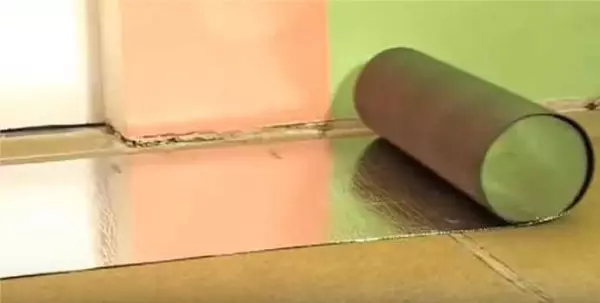

Ukufakwa futhi kuqala ngophawu lwendawo evuthayo (hhayi ukwethula ngaphansi kwefenisha, imishini nezinto ezilengiswe eziphansi) nokufakwa kwe-thermostat kanye nensor yokushisa yaphansi. Okulandelayo, i-foil substrate eshisa ukushisa igingqe. Njengoba kungekho khona-ke, ingasetshenziswa ngaphandle kokwesaba.

Gingqa phezu kwe-foil substrate ekhombisa ukushisa

Imichilo yezinto ezibonakalayo ivaliwe eduze komunye nomunye. Kuhlelwe phansi kungahle kube ngosizo lwetheyipu ye-maphakathi noma ngaphezulu ukudubula ngamabakaki avela kwi-stapler yokwakha.

Ukulungisa ngokushesha i-stapler

Izigxobo zemichilo ziyagula. Ngaphezu kwalokho, kuyathandeka futhi ukuthatha i-foil - ukunciphisa ukulahleka kokushisa.

Sicwila amalunga weScotchball

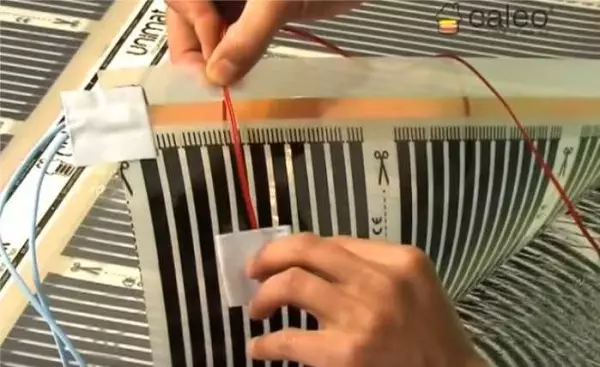

Okulandelayo, gingqa ifilimu yokushisa. Inquma imigqa esetshenziswe kuyo ibe yizicucu zobude obufunayo.

Kwifilimu kukhona ukusikeka okukhethekile kokusikwa

Imivimbo yefilimu ifakwe eduze komunye nomunye noma ngegebe elincane, kepha hhayi uhlobo. Ukugcwala kwesondo le-Copper akunakuvunyelwa nganoma iyiphi indlela.

Imivimbo igoqa yedwa eduze kolunye

Omunye komunye urekhodwa ngetheyipu.

Amahlaya agula iScotch

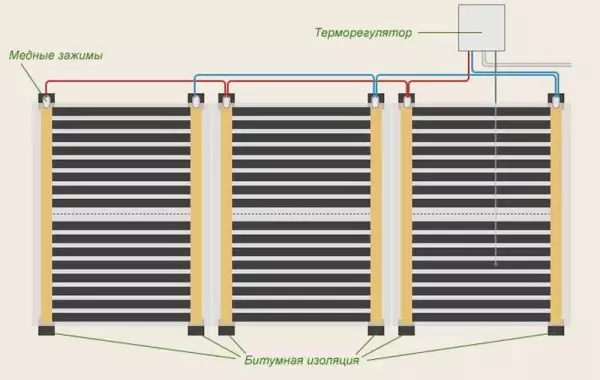

Okulandelayo, ungaqhubeka nokuxhumeka kukagesi. Umdwebo wokuxhumeka wethulwa esithombeni.

Umjikelezo kagesi wokuxhuma phansi kwefilimu efudumele

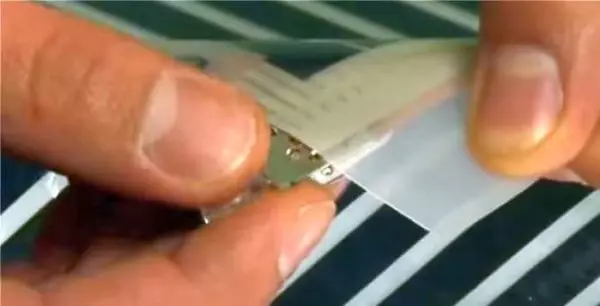

Okokuqala, ukufakwa kwe-Bluminous (kuza kwikhithi noma kuthengwe ngokwahlukana) kuvala amathayi ezindaweni zokusikeka. Thatha ucezu lokufakelwa, susa ukumboza okuvikela ngakolunye uhlangothi, kusebenza ukuze wonke umhlaba wethayi uvaliwe ngokuphelele, kufaka phakathi oxhumana nabo. Ugoba ugobe ngakolunye uhlangothi futhi ucindezelwe ngokucophelela.

Ukufaka ucezu lwamathayi

Ukusuka ohlangothini, iziqeshana zokuxhumana zifakwe eduze kwe-thermostat (kufakiwe, kepha ungathenga ucingo ngokwehlukana noma okusole ebhasini lethusi). Ukuxhumana kuqukethe amapuleti amabili. Umqulu owodwa ethayi, owesibili ngaphansi kwefilimu.

Ukufaka amapuleti okuxhumana

Ipuleti elifakiwe lihlehlisiwe ngama-passps. Bheka amandla okufakwa, ukudonsa kancane oxhumana naye.

Sika oxhumana naye ngePasaltalpa

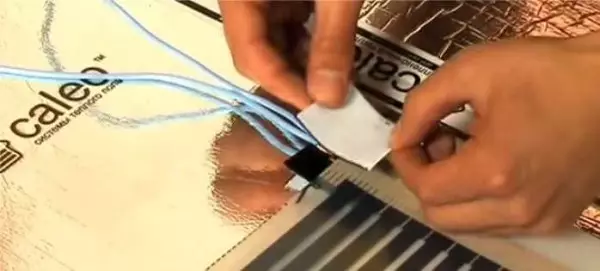

Sithatha izintambo zikagesi ngemithambo yeCopper, ngokusho kwesifunda ngenhla faka umqhubi wesiqeshana esiqeshini kwipuleti yokuxhumana futhi futhi ushaye amaphasithi. Uma kukhona amakhono okudayisa, kungcono ukuphuza okuhlanganisiwe.

Izintambo ezifakiwe

Isinyathelo esilandelayo sokufaka isitezi sefilimu kagesi kuwukufakelwa kwezindawo ezixhumayo zabaqhubi. Ngokuxhumeka ngakunye kunamapuleti ama-2 wokufakelwa kwe-bitumen. Enye ibekwe kusuka ngezansi, owesibili. Futhi landela amathayi noxhumana nabo bavaliwe ngokuphelele.

Izindawo zokufaka imichilo exhuma

Futhi ukufakwa kwe-Heating Floor Temperature Sensor nakho kuhlukile. Imane ithathelwa umucu omnyama (ikhabhoni) wecezu le-scotch.

Namathisela inzwa yephansi emcudweni wekhabhoni

Ukuze inzwa ingathuthukisi, iwindi linqunywe egumbini elingaphansi.

Sika iwindi ngaphansi kwalo ku-substrate

Amafasitela afanayo anqunywa ngaphansi kwamapuleti kanye nezintambo ezilimele. Kuyadingeka ukuthi i-laminate noma i-linoleum ilele ngqo, ngaphandle kwezimbungulu.

Sika amawindi ngaphansi kwamapuleti okuxhumana nezintambo

Kukhiywe izintambo, sinamathela ngeScotch.

Sibeka izintambo, sifaka kusuka ngaphezulu kwe-scotch

Izintambo ezitholakala

Abaqhubi baxhuma ku-thermostat efakiwe (ukufakwa akuhlukile kulokhu okungenhla), sihlola uhlelo, sibonisa ukufudumeza akukho ngaphezulu kwama-30 ° C. Ukuhlola ukuthi wonke ama-band afudumele, asikho isizathu noma iphunga lesici sokuhlukaniswa okuncibilikayo, lifudumele ngaphansi kokucima.

Okulandelayo, inqubo incike ngohlobo lwephansi olusetshenzisiwe. Uma kungukuguquguquka kwama-laminate, ungasakaza ngokushesha i-substrate bese uyiqala ngokubekwa kwayo. I-substrate kuphela okufanele ibe yinto ekhethekile, ehloselwe phansi efudumele, njenge-liquate ngokwayo.

Uma kukhona i-linoleum ukuze ilingane, ifilimu eliminyene eliminyene ligibela phansi phansi kwefilimu efudumele kagesi.

Film fit

Ukusuka phezulu kubeka isisekelo esiqinile - Phaneur, amashidi angenasisekelo. Zinamathiselwe kwizikulufo zokuzishaya phansi phansi, ngasikhathi sinye kuphela okudingeka ukulandela ukuze ungangeni emathangeni. Futhi kusuka phezulu, ungavele ubeke ukhaphethi noma i-linoleum.

Izifundo zevidiyo ekuletheni

Isihloko ngesihloko: Ukuthunga i-lambrequin yamakhethini - indlela esheshayo!