Ukudalwa kohlelo lokushisa kubandakanya ukuxhumana kwamadivayisi we-boiler and heating (ama-radiator, okuhambisa ama-convertors kanye nezitezi zamanzi ezifudumele). Futhi, uhlelo kumele lube namadivayisi ahlinzeka ngokuphepha. Inqubo yokuxhuma lonke ipulazi futhi ibizwa nge- "boiler".

Kuyini ukuvimba futhi yini eyenza

Ohlelweni lokushisa, izingxenye ezimbili eziphambili kukhona ama-radiator e-boiler and heating noma phansi okufudumele. Okuhlanganisa bona futhi kuqinisekiswe ukuphepha ukubopha. Ngokuya ngohlobo lwe-boiler efakiwe, kusetshenziswa izinto ezahlukene, ngakho-ke, kuvame ukubhekwa ngokwahlukana kokopela amayunithi kaphethiloli aqinile ngaphandle kwe-automation kanye ne-automated (okuningi - kaningi - igesi) ama-boilers. Banama-algorithms ahlukene omsebenzi, ayisisekelo - amathuba okushisa i-boiler ye-TT esigabeni esishisayo esivuthayo kuya emazingeni okushisa aphezulu nokuba khona / ukungabikho kwe-automation. Lokhu kubeka imingcele eminingana kanye nezidingo ezengeziwe okufanele uzenze ngesikhathi sokugibela i-boiler eqinile kagesi.

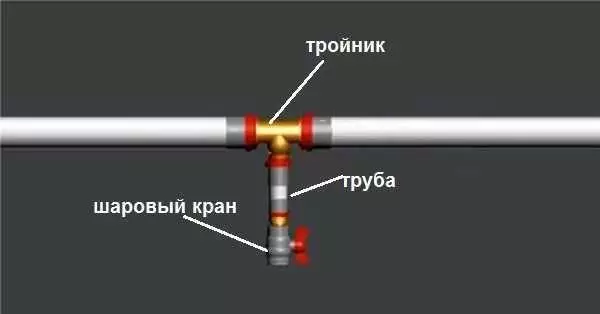

Isibonelo sokwehla kwe-boiler - okokuqala kuya ithusi, ke - amapayipi e-polymer

Yini okufanele ibe khona enhlangothini

Ukuqinisekisa ukusebenza okuphephile kokushisa, i-boiler kufanele ibe namadivayisi amaningi. Qiniseka ukuthi:

- Manometer. Ukulawula ingcindezi ohlelweni.

- Ukuphuma komoya okuzenzakalelayo. Yehla umoya owele ohlelweni - ukuze amajamu omgwaqo awakhiwa futhi ukunyakaza kwe-coolont akuvaliwe.

- Valve ephuthumayo. Ukusetha kabusha ingcindezi eyeqile (ixhumeka ohlelweni lwendle, ngoba inani elithile lokushisa lihlanganisiwe).

- Ithangi lokunweba. Siyadingeka ukunxephezela ukwanda okushisayo. Ezinhlelweni zohlobo oluvulekile, ithangi libekwe endaweni ephezulu yohlelo futhi isitsha esijwayelekile. Kuzinhlelo ezivaliwe zokushisa (okuphoqelekile ngephampu yokujikeleza), ithangi le-membrane lifakwa. Indawo yokufaka - epayipini lokubuya, ngaphambi kokungena kwi-boiler. Kungaba ngaphakathi kwe-boiler yegesi yodonga noma efakwe ngokwahlukana. Lapho usebenzisa i-boiler yokulungiselela amanzi kwe-DHW, kudingeka nethangi lokunwebisa kulesi sifunda.

- Ukujikeleza kwegazi. Okuphoqelekile ukufaka ezinhlelweni ngokujikeleza okuphoqelelwe. Ukwandisa ukusebenza kahle kokufudumeza kungaba zombili ezinhlelweni ezinokujikeleza kwemvelo (ukudonsela phansi). Kufakwa kokuphakelayo noma ukubuyela emuva ngaphambi kwe-boiler kuze kube igatsha lokuqala.

Ukuvinjwa okulinganiselwa kwe-boiler floor

Amanye ala madivayisi asevele efakiwe ngaphansi kokukhishwa kwegesi e-boller. Ukuvinjelwa kwalesi sigameko esinjalo kulula kakhulu. Ukuze ungabi nazinkinga ngohlelo ngenombolo enkulu yamompompi, igeji yengcindezi, i-air vent kanye ne-valve ephuthumayo iqoqwe eqenjini elilodwa. Kunecala elikhethekile elinezimpompi ezintathu. Amadivayisi ahlobene ahlanganisiwe kuwo.

Ngakho-ke iqembu lezokuphepha libukeka

Faka iqembu lezokuphepha epayipi lokuhlinzekwa ngokushesha lapho kuphuma i-boiler. Beka ukuze kube lula ukulawula ingcindezi futhi kungenzeka ukuthi ugqugquzele ukucindezela ngesandla uma kunesidingo.

Yimaphi amapayipi enza

Namuhla, amapayipi ensimbi awasetshenziswa kakhulu ohlelweni lokushisa. Baya ngokuya bathathelwa indawo yi-polypropylene noma i-metalplastic. Ukubopha kwe-boiler yegesi noma okunye okuzenzakalelayo (i-pellet, kuphethiloli owuketshezi, ugesi) kungenzeka kanye ngalezi zinhlobo zamapayipi.

I-boiler efakwe ekhasini efakwe odongeni ingaxhunywa ngamashubhu e-poypropylene ngokushesha kusuka kokufakwa kwe-boiler.

Lapho uxhuma i-boiler eqinile kaphethiloli, okungenani imitha yepayipi ekuhlinzekweni ayinakunyakaziswa ukuyenza ngepayipi lensimbi futhi ithusi elingcono kakhulu. Ngemuva kwalokho ungabeka inguquko epulasitiki yensimbi noma i-polypropylene. Kepha lokhu akusona isiqinisekiso sokuthi i-polypropylene ngeke iwe. Kungcono ukwenza ukuvikelwa okwengeziwe ekulahlekelweni ngokweqile (ukubilisa) TT Boiler.

Yikuphi amapayipi e-polymer angcono? I-polypropylene noma i-metal-plastic? Ayikho impendulo eqondile. I-blockage ye-polypropylene ilungele ukwethenjwa kwamakhompiyutha - amapayipi anama-welded afanelekile yi-monolith. (Ungaxhuma kanjani amapayipi e-polypropylene lapha). Kepha izinga lokushisa elivumelekile le-coolont ohlelweni aliphakeme kune-80-90 ° C (kuya ngohlobo lwepayipi). Futhi ukuthi, ukuvezwa isikhathi eside kokushisa okuphezulu kuholela ekubhujisweni okusheshayo kwe-polypropylene - kuba buthaka. Ngakho-ke, ukugibela ama-boiler yi-polypropylene kwenziwa kuphela ezinhlelweni zokushisa eziphansi ezisuselwa kuma-boilers ezenzakalelayo.

Phambi kokuvikelwa ekushiseni ngokweqile, ukugibela i-boiler kungenziwa ngamashubhu e-polyropylene

Ipulasitiki yensimbi inokushisa okuphezulu okusebenzayo - kufika ku-95 ° C, eyanele ezinhlelweni eziningi. Ungenza zombili izinhlangothi ze-boiler eziqinile zikaphethiloli, kepha kuphela uma kwenzeka ebukhoneni bokuphi okuvikelekile kuzinhlelo ezipholile zokushisa ngokweqile (ezichazwe kancane ngezansi). Kepha amapayipi epulasitiki anezinsimbi anezingqinamba ezimbili ezibalulekile: ukuncipha kwesiza sokuxhuma (ukufakwa kwedizayini) kanye nesidingo sokuhlola amakhompiyutha njalo, njengoba begeleza ngokuhamba kwesikhathi. Ngakho-ke ukopela kwe-boiler enensimbi-ipulasitiki yenziwa ngaphansi kwesimo sokusebenzisa njenge-coolant yamanzi. Ama-fluids ngokushesha ageleza kakhulu, ngoba kulezi zinhlelo, ukufakwa kwama-crimp kungcono ukungasebenzisi - asazophela. Noma singena esikhundleni se-gaskets simelana namakhemikhali.

Bopha ama-boilers egesi

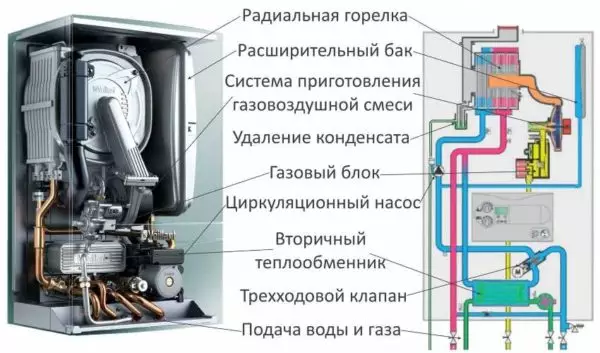

Ama-boilers wegesi wanamuhla anokuzenzakalelayo okuhle okulawula yonke imingcele yemishini: Ukucindezela kukagesi, ukuba khona kwelangabi ku-burner, izinga lokucindezela kanye nokushisa kokuphola ohlelweni lokushisa. Kukhona ngisho ne-automation engaguqula umsebenzi ngaphansi kwesimo sezulu. Ngaphezu kwalokho, ama-boilers egesi odongeni ezimweni eziningi aqukethe amadivaysi adingekayo njengoba:

- Iqembu Lezokuphepha (Ingcindezelo yegeji, i-air boom valve, i-valve ephuthumayo);

- ithangi lokunweba;

- ukujikeleza kwegazi.

Kuma-boilers wegesi odongeni, ithangi le-membranene lokunwetshwa kanye neqembu lezokuphepha eselifakiwe

Amapharamitha awo wonke la madivayisi akhonjiswa kwidatha yezobuchwepheshe yamakati egesi. Lapho ukhetha imodeli, udinga ukunaka yona bese ukhetha imodeli hhayi kuphela ngamandla, kodwa futhi ngevolumu yethangi lokunweba kanye nevolumu ephezulu ye-coolant.

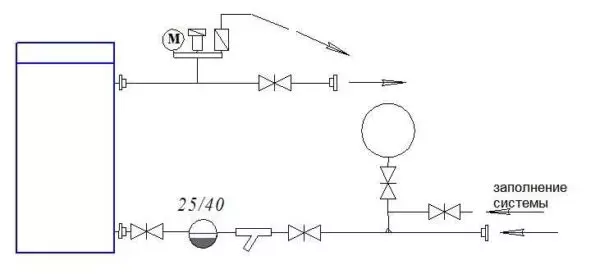

Isikimu sokwehla se-boiler we-WALL

Esikhathini esilula kakhulu, ukopelo we-boiler kuqukethe ama-cranes avaliwe kuphela lapho u-boiler - ukuze kukwenzele umsebenzi wokulungisa uma kunesidingo. Okuningi kupayipi lokubuya, okuvela ohlelweni lokushisa, babeka i-Filter-Mud - ukususa okungcona okungenzeka. Yilokho konke okubophayo.

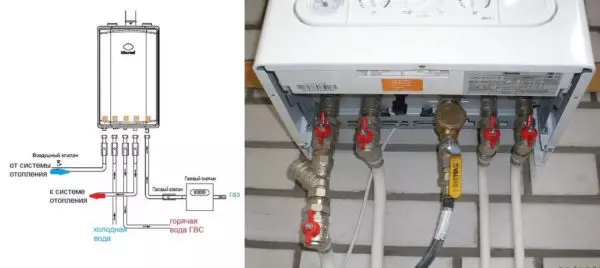

Isibonelo Sokugobhozela Kwe-Boiler efakwe odongeni (umjikelezo omatasa)

Esithombeni ngenhla kunama-valves webhola angular, kepha yile ndlela oyiqondayo, akudingekile - kungenzeka kakhulu ukubeka amamodeli ajwayelekile, futhi amapayipi avela eduze kosizi ngosizo lwamakhona. Futhi qaphela ukuthi kuzo zombili izinhlangothi ze-Mud Face Cranes ukuze zikwazi ukuyikhipha futhi zihlanzeke ngaphandle kokudonsa uhlelo.

Endabeni yokuxhuma i-boiler ye-loll-polling yegesi eyodwa, kuselula - kusetshenziswe kuphela igesi (okuhlinzekwayo yigesi), ukuhlinzekwa kwamanzi ashisayo kuma-radiator noma ukushisa kwamanzi kanye nokubuya kubo.

Amacebo okopela ama-boilers egesi

Amamodeli angaphandle ama-boilers afudumele egesi nawo ahlome nge-automation, kepha awunalo iqembu lezokuphepha noma ithangi lokunwetshwa, noma iphampu yokujikeleza. Wonke la madivayisi kufanele afakwe ngaphezu kwalokho. Isikimu sokwehla ngenxa yalokhu sibukeka siyinkimbinkimbi ngokwengeziwe.

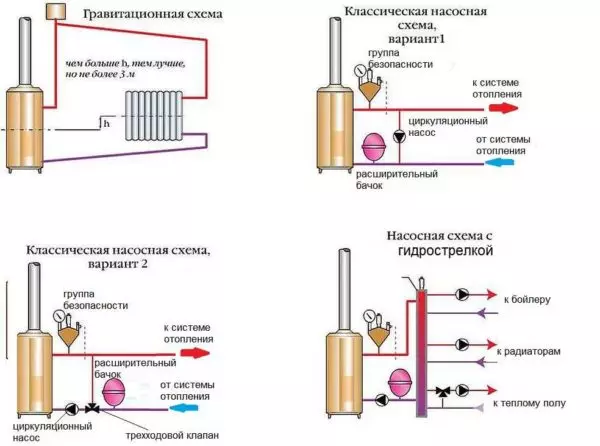

Isikimu se-soileme ye-boiler yangaphandle

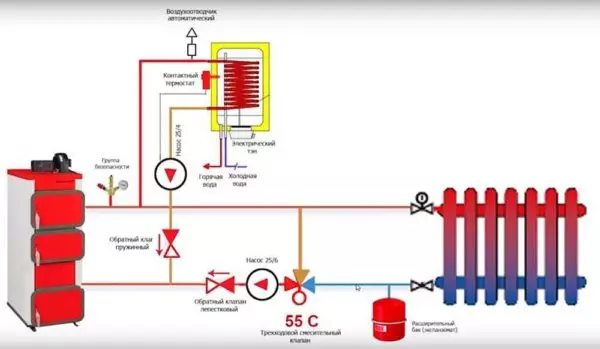

Kumacebo amabili okukhipha ama-boiler afake i-jumper eyengeziwe. Le yi-loop ebizwa ngokuthi "i-anti-entense" loop. Kuyadingeka ezinhlelweni ezinkulu uma izinga lokushisa lamanzi epayipi lokubuya liphansi kakhulu, kungadala ukwakheka kwe-condensate. Ukuqeda le nto futhi uhlele le jumper. Ngosizo lwayo, amanzi ashisayo avela ekuhlinzekeni ahlanganiswe nepayipi elibuyela emuva, izinga lokushisa ngaphezulu kwephuzu lezodon (imvamisa engama-40 ° C). Kunezindlela ezimbili eziphambili zokusebenzisa:

- Ngokufakwa ku-jumper yephampu yokujikeleza ngenhlamvu okukude (nesithombe phezulu kwesokudla);

- Usebenzisa i-valve enezindlela ezintathu (esithombeni esingezansi kwesokunxele).

Esisekelweni esiseduze nokujikeleza kwe-jumper (iphampu yokuvuselela), kwenza ipayipi esigabeni sobubanzi obuncane kunomgwaqo omkhulu. Inzwa inamathiselwe kwipayipi lokuphakelayo. Lapho izinga lokushisa lincipha, isifunda sokuhlinzekwa kwamaphampu sivuliwe, kufakwa amanzi ashisayo. Lapho amazinga okushisa eba ngaphezu komkhawulo, iphampu icishiwe. Iphampu yesibili uhlelo lokushisa uqobo, lusebenza ngaso sonke isikhathi ngenkathi i-boiler isebenza.

Ohlelweni lwesibili olune-valve enezindlela ezintathu, livula amanzi ashisayo ukwehlisa amazinga okushisa (akhonjisiwe kwi-valve). Iphampu kuleli cala isepayipini lokubuya.

Ukusika i-boiler eqinile kawoyela

Noma yimuphi umnikazi we-TT Boiler uyakwazi ukuthi ngesikhathi sesigaba esishisayo esishisayo kunokushisa okuningi. Njengoba isipiliyoni saso sivela ngezikhathi ezithile - nini futhi kanjani ukumboza isimo sengozi, ngasiphi isikhathi, njll. Kepha kufanelekile ukuphazamisa okuncane, futhi amanzi ohlelweni azodlula ngokweqile futhi angabilisa. Ukuvimbela into enjalo, ukopelo we-boiler ngaphandle kwe-automation kufanele aqukethe amadivaysi ambalwa avimbela uhlelo olubilayo. Kuleli cala kuphela kungahle kube ngentambo endlini ukuze enze amapayipi e-polymer. Ngaphandle kwalokho, kungekudala, isithwali sokushisa esishisayo sithambisa okuqukethwe, amapayipi azodlula nawo wonke imiphumela elandelayo. Ngakho-ke, ukuvinjelwa kwe-boiler eqinile kaphethiloli ngaphezu kwezinto zendabuko - amaqembu ezokuphepha, ithangi lokunwebeka kanye nokujikeleza kokujikeleza - liqukethe inani eliqinile lamadivayisi angeziwe futhi livame ukudinga imali eqinile.

Enye yezintambo ezilula ze-boiler eqinile kawoyela

Isimo se-cyclic somsebenzi wama-boilers ophepheni oqinile asiholeli kuphela ohlelweni olubilayo, kodwa futhi naseqinisweni lokuthi kushisa kakhulu endlini (lapho uphethiloli uvutha ngenkuthalo), khona-ke kubanda - lapho konke kushiswe. Ukuqeda lezi zinto kunesisombululo: ukusungula i-boiler efudumele yokushisa noma i-accelerator yokushisa. Womabili amathangi amanzi, amane enza imisebenzi ehlukene futhi, ngokufanele, axhunyiwe ngezindlela ezihlukile.

Ukusatshalaliswa nge-boiler yokushisa engaqondile

I-boiler yokushisa okungaqondile ifudumeza amanzi i-DHW futhi ixhume ngakolunye uhlangothi kuya ohlelweni lokushisa, nakwelinye - kuya kwesinye isikhathi - ukusatshalaliswa kwamanzi okushisayo. Ngakho-ke, ukwehluka lokushisa kuthanjiswa, futhi amanzi afudumele ngezidingo zobuchwepheshe. Isixazululo esihle.

I-schema yokuphuma komoya oqinile we-boiler ene-boiler yokushisa engaqondile

Ngabe lolu hlelo lusebenza kanjani? Uma amazinga okushisa amanzi ase-heater amanzi angaphansi kwalokhu kuchaziwe, ama-boiler axhumeka ekushiseni kwamanzi ethangini. Uhlelo lokushisa ngalesi sikhathi luphenduka ukunqanyulwa futhi lupholile kancane. Ngemuva kokufudumeza kwamanzi emazingeni okushisa adingekayo, ukushintshwa kwe-boiler ukuze usebenze nomjikelezo wokushisa. Lapho amanzi afudumele esetshenziswa, izinga lokushisa ethangi liwa futhi, ukuxhumana kuxhumeke futhi ngokushisa.

Kulula, kepha ngohlelo olunjalo, ukushisa ngokweqile kusenokwenzeka - hhayi njalo ukusetshenziswa kwamanzi okushisayo kuhambisana nesigaba sokushiswa kwamafutha asebenzayo. Kulokhu, ukucwilisa ngokweqile kungenzeka.

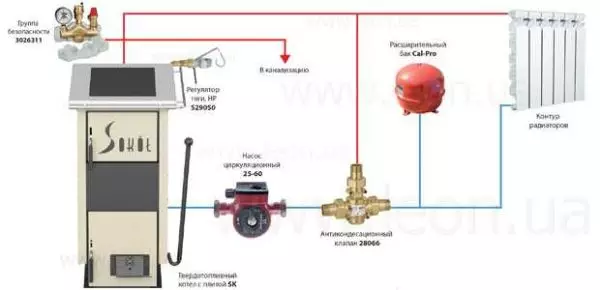

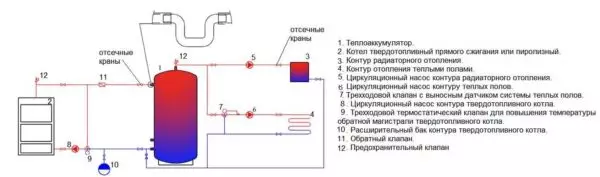

Isikimu nge-Heat Accumulator

Indlela yesibili ukusungula i-accelerator yokushisa. Lesi futhi isitsha samanzi, kepha sixhumeke kuphela ohlelweni lokushisa. Isetshenziselwa ukunciphisa umehluko wokushisa ohlelweni.

Le ndlela ithembeke ngokwengeziwe, kepha idinga idivaysi yemikhuba eminingana ehlukene. I-boiler ifudumeza amanzi emhlanganweni wokushisa - ixhumeke ekungeneni kwalokho. Lolu munye uhlaka oluvaliwe. Uhlaka lwesibili luya ekufudumaleni - kusuka ekuphumeni kwe-accumulator yokushisa (engxenyeni engenhla yethangi), amanzi ashisayo angena ohlelweni lokushisa, futhi amanzi apholile avela epayipi elibuyisela emuva ethangi elifanayo. Uma kunesidingo, ungaxhuma uhlelo olufudumele lwamanzi.

Uhlelo lokukhipha i-tibir ye-TT enenhlangano yokushisa

Ngokwakhiwa okunjalo, akukho okujwayelekile ukuze kukhuphuke kakhulu ngophethiloli wokushisa okuvuthayo ngesikhathi sokuvutha okusebenzayo. Konke ngoba ivolumu yethangi ingeziwe, ngakho-ke ukweqiwa kwamanzi empeleni akunjalo. Ngemuva kwalokho, lapho uphethiloli ushiswe futhi ohlelweni olujwayelekile, indlu iqala ukuphola, ukushisa esihlabeni sokushisa kuyaqhubeka kusetshenziswe ohlelweni. Ngale ndlela, ingemuva lokushisa liqondaniswe futhi isikhathi phakathi kwebhokisi lomlilo lenyuka.

I-lining enjalo ye-boiler kuphethiloli oqinile ithembeke ngokwengeziwe futhi i-wiring kusuka kwaleyo ingenziwa ngamashubhu we-poypropylene, kepha i-contour evela ethangini kufanele yenziwe ngamapayipi wensimbi. Kulokhu, kungenzeka ukusebenzisa insimbi, kepha kangcono ngemuva kwayo yonke ithusi.

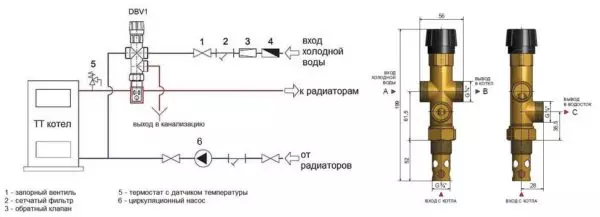

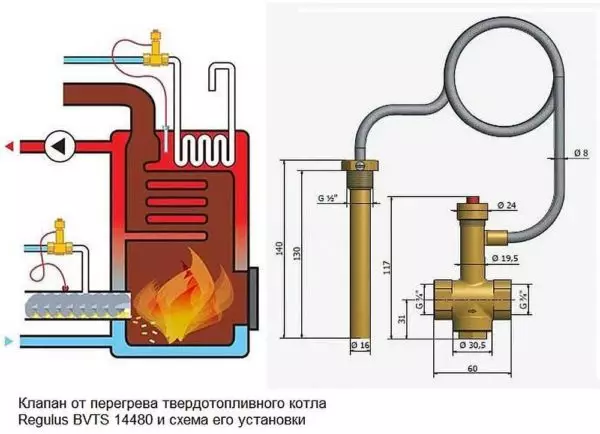

Ukukhipha i-boiler ye-tt nge-valve eshibhile

Indlela yesithathu yokuvikela ekubhekeni ngokweqile kwe-boiler eqinile kaphethiloli ukusungula idivaysi etholwayo yokuzenzakalelayo. Leli yi-valve ekhethekile enenzwa yokushisa. Umgomo wokusebenza ulula: lapho izinga lokushisa elithile selidlulile (imvamisa 95-97 ° C), i-valve ivula indawo yokungena emanzini abandayo ukusuka epayipi lamanzi, futhi lagcwala ngokweqile endle. Ngakho-ke imisebenzi, ngokwesibonelo, u-Relulus DBV 1-02, u-Relulus Bvts 14480.

Ukuvikelwa kwe-boiler eqinile kaphethiloli kusuka ekushiseni ngokweqile usebenzisa i-valve regrulus dBV

I-Valve yize ekhiqizwa yinkampani eyodwa, inesakhiwo esihlukile nohlelo lokufaka. Ngakho-ke u-Relulus DBV ufakiwe e-Outlet of the Boiler, unenzwa yokushisa eyakhelwe ngaphakathi (uhlelo lokufaka - ngenhla). I-valve eshibhile ye-boiles eshibhile ye-tioler Relulus Bvts 14480 inenzwa eyihlane, ingafakwa zombili kokufakwayo nasekukhishweni (uhlelo lokufaka ezansi). Yini enhle le nketho? Iqiniso lokuthi lingasebenza ezinhlelweni zokujikeleza kwemvelo - akudingi ingcindezi yomsebenzi.

Ukubuyisa i-boiler efudumele nge-valve yokuvikela kusuka ekubizweni kwe-searring yokushisa

Izindleko ezilinganiselwayo zingu-40-60 € - zincane kakhulu kunezindleko zokufaka i-accumulator yokushisa noma i-boiler yokushisa okungaqondile, kepha le ndlela ayixazululi inkinga yokushintshashintsha. Lawa ma-valves, ngendlela, angasetshenziselwa ukwenza ngcono ukuthembeka kwesifunda ngokuqanjwa okusunguliwe kanye nokunembile ukuqeda amathuba okubilisa uhlelo.

Yini enye edingekayo ohlelweni

Ukubopha kwe-boiler kuzobe kungaphelele uma kungekho crane yokudonsa nokugcwalisa uhlelo. Futhi kungcono uma behlukile. Indawo ethize yokufaka incike ekwakhekeni kohlelo, kepha kukhona imithetho ethile:

- I-crane ye-plum yenza endaweni ephansi kakhulu. Lokhu kubaluleke kakhulu uma uhlelo lokushisa ludinga ukulondolozwa ebusika - kuyadingeka ukuthi luhlale luncane ngangokunokwenzeka okupholile. Uma uhlelo luzosebenza ebusika, luhlala lunokwenzeka ukusebenzisa i-crane (nge noma ngaphandle noma ngaphandle noma ngaphandle kwe-nozzle) kwelinye lama-radiator, kuzoba ukumiswa kohlelo.

I-crane enjalo yohlelo lokukhipha ingafakwa kunoma iyiphi indawo ekahle (kwipayipi lokubuya)

- Uma amanzi esetshenziswa ohlelweni lokushisa, okokufaka okuvela ekuhlinzekeni kwamanzi kuvame ukuxhunywa. Endabeni ye-boiler ebekwe ngodonga walokhu kukhona i-nozzle ekhethekile nge-crane emile. Amanzi abandayo axhunyiwe kulokhu okufakiwe, uma kunesidingo, isikulufu esiyisimangalo sitholwa isikhashana. Uma i-boiler isetshenziswa ngaphandle kwe-nozzle ekhethekile, ngepayipi lokuphakelayo (mhlawumbe ngaphezulu) futhi isetha i-crane. Njengendlela - engxenyeni yepayipi eliya ethangini lokunweba.

Enye yezinketho zokufaka i-crane ukugcwalisa uhlelo lokushisa

Kwezinye izinhlelo, amaplamu kanye ne-bay of the system kwenziwa kusuka ku-crane eyodwa. Lokhu kungenzeka uma kukhona iphampu, epompa okupholile futhi kukhona igeji yokucindezela, engalawulwa yingcindezi eyakhiwe. Uma kukhona i-crane ehlukile ye-bay of the system ngephuzu eliphakeme, ungayigcwalisa ngamandla adonsela phansi.

Isihloko ngesihloko: Khetha amaphephadonga wemfashini wehholo le-2019: izithombe nezinhlobo eziyi-7