Izinto zokwakha zesimanje azivumeli ulwazi olukhulu ekuqedeni umsebenzi kubantu ngokuzimela ukudala ama-angaphakathi asezingeni eliphakeme ezindlini zawo. Ikulekelele kakhulu impilo yamakhosi ama-amateur okuthiwa abizwa ngokuthi yi-bulk sex, esebenzisa okuyinto abaningi efulethini baxazulule inkinga yendawo ebushelelezi ngokuphelele emakamelweni. Ukugcwalisa phansi ngezinto ezintsha zenqwaba kudla isikhathi esincane kunokufakwa kwaso kwendabuko, ngakho-ke kumvumela inani elandayo labathuthukisi.

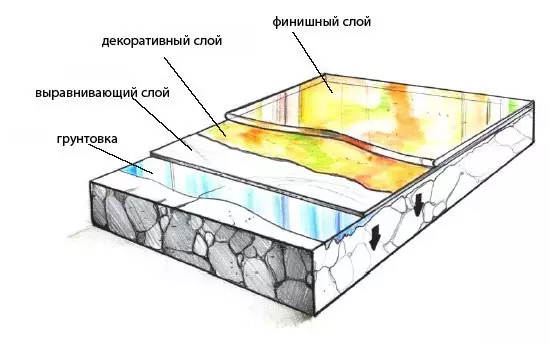

Uhlelo lwedivayisi yaphansi ewuketshezi.

Izinzuzo zobulili obuningi

Ukukhetha ubulili obuningi bokuqedela ukuqeda kulungisiswa ngezinzuzo zako ngaphezu kwezinye izinto. Ubulili obuningi:- kuhlala isikhathi eside;

- kuhlala isikhathi eside;

- ama-racks ekulweni kokushisa okwedlulele;

- Ukwakhiwa komswakama;

- inezimpawu ezinhle kakhulu ekumelaneni nomthelela wamakhemikhali;

- I-FireProof;

- Ezemvelo.

Ngenxa yenhlanganisela yezakhiwo ezifakwe ohlwini, isembozo salolu hlobo iminyaka eminingi sibukeka simsulwa ngokuphelele. Akudingi ukunakekelwa ngokucophelela. Akukhiwa ngesikhunta. Ngaphezu kwalokho, inketho yenzuzo ingasetshenziswa njenge-coating yokuqedela phansi efudumele, okwenza kube ngumncintiswano ophambili kwi-tile coating, esebenza nayo edinga isipiliyoni esithe xaxa.

Izinhlobo zezitezi eziningi

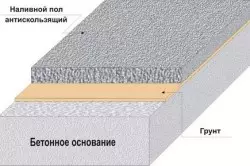

Uhlelo lwe-liquid anti-slip floor.

Kunezinhlobo ezi-2 zalezi zinto ezinjalo - i-polymeric kanye namaminerali.

I-1st ihlukaniswe nge-epoxy ne-epoxy urethane. Zombili zikhiqizwa kusuka kuma-epoxy resins, kepha izimbobo ze-epoxy irethane zisetshenziselwa ukuqeda izindawo ezitholakala emithanjeni ephakeme yemishini, futhi i-epoxy isetshenziswa emakamelweni anomswakama ophezulu.

Uhlobo lwe-2nd lwe-Bulk Floors - Amaminerali. Izici eziphambili zalokhu okuqukethwe yimifutho evela kumaminerali, ama-modifiers kanye nosimende. Izingxube ezisezingeni eliphakeme ezisuselwa kumaminerali zinikezela ngezinto zokwakha eziphakeme ngesikhathi sokugcwalisa, ijubane lokuqina kwesendlalelo kanye nempilo yenkonzo ende. Izingxube zamaminerali zinezakhiwo zokuzilinganisa futhi zisakazeke kahle ngaphezulu kobuso obucutshungulwe. Kuliqiniso, lezi zici azikhiphi umakhi esibonelweni sokusatshalaliswa komfaniswano wokwakheka okulungiselelwe ngesisekelo. Izinto zezezimbiwa zivame ukusetshenziselwa ukuvumelanisa ingaphezulu ngaphambi kokuqeda kwalo kokuqedwa. Izitezi ezisuselwa kumaminerali ezisuselwa kumaminerali zivame ukusetshenziswa phansi phansi phansi kwezandla zazo ezindlini.

Isihloko ngesihloko: Ungayibeka kanjani i-Iron ophahleni ngezandla zakho

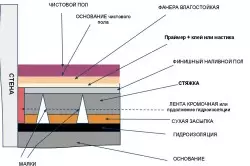

Izinyathelo zokugcwalisa phansi phansi.

Zisetshenziselwa ukugcwalisa izisekelo ngezimo ezahlukahlukene ezingaphezulu. Ngakho-ke lowo msebenzi ngenhlanganisela yenqwaba yenziwa kahle, izingxube zamaminerali zahlukaniswa zaba ngamaqembu ama-3.

- Qeda. Izingoma eziphathelene nalo zenzelwe ukuqeda kokugcina. Ukuze usebenzise izinto zokuqeda, kuyadingeka ukuthi umehluko ekuphakameni endaweni elungiselelwe ayidluli ku-10 mm.

- Isilinganiso. Izingxube zisetshenziselwa ukuvumelanisa ama-Century-based Screeds, lapho ibanga lokuphakama lingadluli ku-30 mm.

- Okuyisisekelo. Izingoma zaleli qembu zivumelanisa izindawo ezinama-curvature ziye ku-80 mm.

Uma ucabanga ngesimo sesisekelo ezakhiweni zokuhlala kanye nemibandela yokusebenza okwengeziwe phansi, ungakhetha okuqukethwe esitolo impahla efanelekile.

Umsebenzi wokulungiselela

Mhlawumbe isigaba esikhulu kunoma yimuphi umsebenzi yilungiselelo. Kusuka ekutheni i-Ikhwalithi ephezulu izoqedwa kangakanani, umphumela wokugcina uncike. Ukulungiselela ukugcwala ekugcwalisweni kwesiteji kuyadingeka:

Floor screen device.

- ayikhulule kusuka ku-Old Screed;

- Qoqa yonke imfucuza, izixazululo eziyinsali nothuli;

- Yigcine kusuka kunoma yiluphi uhlobo lwezindawo ezinesibindi;

- yenza ukuhlanzwa kwasekhaya emanzi;

- seal imifantu ngesisombululo;

- Qondanisa ukucindezelwa kwabo.

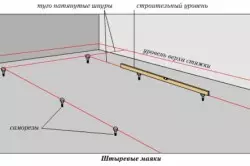

Amathuba okuthi kufanele wenze i-screed entsha, ngoba kunesizathu esengeziwe, kube lula ukuyithola ngokuzayo. Kungcono uma ifilimu yepulasitiki izobekwa ngaphansi kwayo. Ukubeka umkhonto omusha, udinga ukufaka amaphrofayili e-beacon. Lokhu kwenziwa kanjena:

- Udinga ukuthola iphuzu eliphakeme kakhulu lesitezi.

- Kuzo zonke izindonga ngosizo lwezinga nentambo yokupenda, umkhathizwe umakwe ngokuphakama kwama-beacons.

- Phakathi kwezindonga eziphambene, ungadonsa imicu eboshwe ezindongeni ngokuzikhandla, okusolwa eceleni kophawu oluvundlile. Imicu izonquma indiza ye-screed.

- Kufakwe ama-beacons asheshayo. Ukukhwela kwabo phansi kwenziwa ngodaka.

Ngemuva kokuthi i-gypsum iqandisiwe, ikhambi lithululelwa futhi liqondaniswe kanye nokukhanyiswa kwezibani ngomthetho, ubude bawo okufanele babe ngu-10-20 cm okukhulu phakathi kwamaphrofayili. Manje kuzofanela ulinde ukubola kwesisombululo ukuze uqhubeke nenqubo yokugcwalisa ubulili obuningi. Ngokushesha kufanelekile ukuthi aqaphele ukuthi i-screed izogcina isilungele ukusebenza okwengeziwe emavikini ama-4. Ngalesi sikhathi, kufanele aniselwe kaningi ngamanzi futhi aqinisekise umfaniswano weqhwa ngaphansi kwefilimu ye-polyethylene.

Isihloko ngesihloko: Kuzosiza kanjani ukuguqula i-bamboo yakho yangaphakathi nomdwebo wayo?

Ukubekwa kwezocansi ngobuningi

Ngemuva kokomiswa okuphelele, isisekelo singacutshungulwa kwinqubo yokugcwalisa ye-coating yokuqeda. Kepha ngaphambi kwalokhu, i-screed kumele iphathwe nge-primer, eyenza ama-microcracks futhi izokwakha ungqimba ngaphezulu ngezimpawu eziphezulu zokunamathela. Ngasolangeni kanye neminyango iminyango ihlanganiswe ngetheyipu embi. Ngemuva kokuphela komsebenzi ekuthuleni kuzokwazi ukukususa, ngoba igebe eliphumela lizoqinisekisa ukunxeshezelwa kwezandiso ze-thermal. Ukugijima phambili, udinga ukwengeza ukuthi isikhala esikhishwe ngemuva kokuthi i-gasket kufanele ifakwe nge-elastic sealant.

Ukufaka amalambu we-PIN.

Kuyadingeka ukuhlinzeka egumbini eliphezulu ngokugcwalisa phansi (15-25 ° C) nokungabikho kokusalungiswa, okuvimbela umfaniswano ophindwe kayunifomu. Manje ungaqhubeka nokupheka. Ikhwalithi yephansi ithonywa ukunemba kokuzala kwayo. Ingxube akufanele iwuketshezi ngokweqile. Ngenxa yalokhu, ukumbozwa kungenzeka. Isixazululo esihlanjululwe ngokungafanele ngeke siphakanyiswe. Ukulungiselela ingxube akufanele kwenziwe ngaphambi kwamahora we-½ ngaphambi kokuba kuphindeke kususelwa esisekelweni. Ngalesi sikhathi, kungakuhle ukuthi uthele futhi uvumelanise phansi phansi egumbini lonke. Uma ungenaso isikhathi sokwenza lokhu, finyelela lezi zitembu ezilandelayo ukufanisa 1st.

Ungqimba wobubanzi kufanele uhambisane ne-½ cm. Uma kunesidingo sokwenza ukunamadlwana okuqinile, lokhu kungatholakala ngokugcwalisa izingqimba eziningi. Umsebenzi uqala ekude nodonga lokungena lwegumbi. Isixazululo senziwa kabusha nge-spatula noma inkabi. Ukususwa kokugcina kwama-bubble kusuka ku-coating kwenziwa yi-roller yenalithi. Ngaphezu kwalokho ivumelana nobuso.

Ngemuva kwamahora ama-2-3, ukuhlanganiswa kuzokoma, kepha ukuqina okuphelele kuzokwenzeka kuphela ngemuva kwezinsuku ezi-3. Ungavele uthele ungqimba oluqediwe kakhulu, olumbozwe nge-varnish ngemuva kokomiswa.