Muva nje, ama-laminate athola ukuthandwa okwandayo. Hhayi iqhaza lokugcina elidlala lula ukufakwa kwalesi simbozo saphansi.

Kufanele kukhunjulwe ukuthi kuyadingeka ukufaka phansi phansi ngaphansi kwe-laminate, ngaphandle kwalokho kungenzeka ukuthi uhambe kuwo kuphela kuma-slipper.

I-Laminate ine-coating ehlala isikhathi eside futhi egqoke ngokuvimbela, kepha ngaphambi kokuba ukubeka isisekelo kuyinto efiselekayo ukugcizelela.

Uhlu lokufakelwa lusebenza luncike ezicini ezimbili:

- Lapho kufakwa khona ngokhuni noma ngokhonkolo;

- Hlobo luni lokufakelwa olukhethiwe.

Njengoba umnikazi ngamunye azi ukuthi yimuphi ucansi analo endlini, ake sixoxe ngokukhetha izinto zokufakelwa.

Kunokuba ungafudumeza phansi

Substrate

Enye yezinhlobo ezivame kakhulu zokufakelwa. Njengoba i-substrate isebenzisa i-faneur, eyondli, i-polyethylene, isol, ukugoqa izinkuni. Ubukhulu obuphansi buxhomekeka ekulweni kwesitezi, ukuphakama kophahla kanye nezinto ezikhethiwe. I-polyethylene ye-folyethylene ye-folyethlesyles izobe ishibhile, noma kunjalo, ngongqimba owodwa ingafakwa kuphela phansi ebushelelezi. Uma udinga ukushelela ngokungahambi kahle, kuzofanela ugoqe lokho okushiwo kaningi.

Ibungesi

I-Polystyrere Foam izosiza ukufihla ukungahambi kahle kwesisekelo lapho ngibeka i-laminate.

Kuyabiza kakhulu, kepha kuyinto enobungane bemvelo. I-substrate enjalo izohlala isikhathi eside, inikeze kuphela ukushisa, kepha futhi nokufakelwa okuzwakalayo, ukujikeleza komoya. Ngaphezu kwalokho, kuthatha ubuncane besikhala.

Imbande

Isetshenziselwa ikakhulukazi ukufakwa kwezitekisi zokhuni. Kuyinto efiselekayo ukuthi ungqimba lobumba okungenani u-10 cm, ngaphandle kwalokho ngeke kwenzeke ukufezekisa ukufakwa okuhle okushisayo.

Uboya bezimbiwa

Ukufakelwa okungabizi, okuhlala isikhathi eside. I-MinVata kumele ivalwe ngakolunye uhlangothi ngefilimu ye-foil noma yensimbi. Izinto zangaphandle zingasetshenziselwa kuphela ukufakwa okushisayo kwezakhiwo ezingezona ezesabelo.

Styrofoam

Izinto ezishibhile, ezikhanyayo futhi eziwusizo kakhulu. Kungaba mncane futhi kugotshwe. Ngokuyisisekelo iqukethe umoya, ophethe ukushisa. Inezici ezinhle kakhulu zokufakwa komsindo.

Uhlobo

I-Foil ivame ukusetshenziselwa i-substrate, ngoba lokhu kusebenza kuhlala isikhathi eside futhi kushibhile.

Kukhiqizwe kuma-rolls namapuleti. Ngokusebenza okufanele kuzohlala isikhathi eside. Misa impahla iyadingeka ukukhombisa ingaphezulu phansi, khona-ke ukushisa egumbini kuzokwazi ukusindisa.

I-Polyurene Folider

Ingafafazwa futhi igcwaliswe. Ithola ngokuphelele umswakama futhi igcine ukushisa, okuhlala isikhathi eside, ayilimazi impilo. Kudinga imishini ekhethekile ukuyisebenzisa, ngakho-ke ukubeka izinto ezibonakalayo kungcono ukunika ochwepheshe.

Isihloko ngesihloko: phansi okufudumele ngaphansi kwama-laminate esitezi sokhuni ngezandla zawo

Phansi okufudumele

Uhlobo olukhethekile lokufakelwa kwe-float ngaphansi kwama-laminate. Kungaba ngogesi noma amanzi. Esimweni sokuqala, izintambo zitholakala ngaphansi kwe-laminate, ngesibili - amapayipi amanzi. Lapho uhlelo luvuliwe, amakhebuli noma amanzi emapayiphu afudumele, anikeze ukushisa kwangaphandle kwe-coating.

Isigaba sokulungiselela

I-Screed izosiza ukuvumelanisa isisekelo ngaphansi kwe-laminate.

Ukufakwa kukaPawulu kufanele kuqale ukuqeda ukushiyeka komhlaba. Isendlalelo sikakhonkolo sidinga ukuqondiswa: uthele ukucindezelwa noma imigodi ekhona, aphonsa izimbungu, ulule ama-chip kanye nemifantu. Uma isitezi senziwe ngokhuni, amabhodi kuzofanele adilizwe. Kungenzeka ukuhlomisa ukuthi umswakama ukuze umswakama ungangeni ekufakweni okulethwe.

Kungcono ukuthi unakekele ukuthi kwinqubo yokusebenza esekhona wonke amathuluzi adingekayo:

- I-Electrovik;

- isikulufa;

- Shayela ngama-nozzles ahlukahlukene;

- isando;

- Ama-dowels, ngokungazinaki;

- izinga noma umthetho;

- roulette;

- umaki noma ipensela;

- Isakhiwo Stale kanye Nommese.

Kuya ngohlobo lokufakelwa okukhethiwe, uhlu lwamathuluzi lungakhula ngandlela thile. Isibonelo, kuzodingeka ifosholo lokubeka ukubhoboza, futhi lapho usebenzisa izinto zokugcwalisa - isitsha sokuzipheka. Ongakukhetha ukuthenga amathuluzi adingekayo. Ungabolekisa okuthile kubangani noma ukuqasha - izinsizakalo ezinjalo manje sezinikezwe izinkampani eziningi zokwakha.

Ukufakwa kwezinkuni kwezitebhisi zokhuni

Ukufakwa kwezinkuni kungenziwa kusetshenziswa iMinvati.

Imvamisa isebenzisa indlela yokufudumeza yokufakelwa kwama-lags. Kufanele kukhunjulwe ukuthi inketho enjalo yokufakelwa izokweba kuze kube yi-10 cm yokuphakama kwegumbi, ngakho-ke udinga ukubheka ngokucophelela ukukhethwa kwezinto zokufaka okufakwayo kanye nobukhulu bayo. Izigaba zomsebenzi ekuletheni ukufakwa kungokulandelayo.

- Emholweni osalungiswa babeka uhlaka lwamabha okhuni (lag). Uma ama-lags asevele efakiwe, kepha abamba noma aqhekeka ngezikhathi ezithile, angashintshwa noma anqunywe ezingeni elilodwa. Ibanga phakathi kwamabha - 50-60 cm.

- Izikhala phakathi kwama-lags zigcwele ukufakwa. Kungaba ubumba, igwebu, uvolo wamaminerali. Uma okuqukethwe kusetshenziswa emapuletini, kufanele kulungiswe. UMinvata kuma-roll akakudingi lokhu.

- Ngaphezulu kokufakelwa kwabeka ungqimba lokufakwa kwe-vapor. Ungasebenzisa ifilimu elijwayelekile le-polyethylene. Ukubeka uphawu lokuhlangana, kunconyelwa ukubahlanganisa nabo ngeScotch.

- Ukuze phansi ukuze kube bushelelezi, ungabeka ama-osb slabs noma i-chipboard.

- Kumapuleti noma ngokushesha kungqimba yesithiyo se-vapor, phansi kokhuni kuyafakwa, futhi sekuvele kubo - i-laminate.

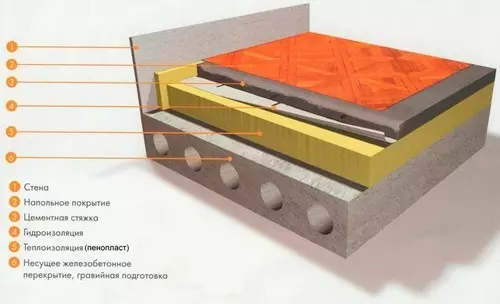

Ukufakwa kwe-Thermal kwesitezi sikakhonkolo

Isikimu sokufakwa kwekhonkolo kwesitezi sikakhonkolo nge-foam.

Ku-Lags ungafudumeza futhi ukhonkolo phansi ngaphansi kwe-laminate, kodwa kuphela uma ingaphezulu yalo lilimele kakhulu. Ngaphandle kwalokho, kuzofanela uvumelanise kuqala bese ubeka uhlaka lwamapulangwe, olusazonciphisa ukuphakama kwegumbi. Ngaphezu kwalokho, kunezindlela ezimbalwa ezikhulisa abasebenzi bokufakwa okushisayo kwezitezi zikakhonkolo.

Isihloko ngesihloko: I-CRAFTS kusuka ku-Fomung Foam ngezandla zawo

Okokuqala, kuyadingeka ukuthola ukuthi mangaki amasentimitha aphakeme anganikelwa ukuze abeke ukufakwa. Yebo, uma uphahla luphezulu futhi luvumela ukweba kuze kufike ku-10 cm. Okungcono kakhulu uma uthayi lukakhonkolo luphinde londliwa ngokungeza iClamzite kulo. Ukulala ngaphansi kothango lwamapuleti aminyene oboya bezimbiwa noma umbala omibalabala we-polyfoam kungenzeka futhi. Inketho enhle - ukusetshenziswa kokubhaka okuphindwe kabili. Okokuqala, ungqimba lwamabhodi ezinkuni ubekwe ngaphezulu kwawo - i-substrate, futhi kusuka phezulu - i-laminate.

Uma ukufakwa kutholakala kungabe kungukungabi ngaphezu kwe-3 cm, kunconyelwa ukusebenzisa izingxube ezilinganiselayo. Kuyadingeka ukuthi ugobeke isixazululo ngokuya ngemiyalo esephaketheni, uthele phansi bese usabalalisa ngokulinganayo i-spatula. Ngemuva kwamahora ambalwa, ingxube yenza ngamandla, kuzokwazi ukubeka i-substrate, bese kuzala. Uma isisekelo sikakhonkolo singaqukethe iziphambeko ezibalulekile, ungqimba lokufakelwa kungangeqi 1 cm. Ngaphandle kwalokho, kuyadingeka ukuyikhulisa ukuze wonke ama-bumps afihle leyo ngxube.

Kumakhonkolo ukhonkolo noma izinto ezinjalo zingabekwa:

- I-Polyurethane Foam;

- Amashidi wefayiji;

- i-polyurethane;

- Isololoni.

Ubukhulu bokufakwa komlimi ngeke bungaphezu kwama-2 cm, kepha buzovumela ukuqinisekisa ukufakwa okuhle kokushisa.

Uma kungekho kungenzeka noma ufise ukulahlekelwa amasentimitha okuphakama kwegumbi, ungathenga ukushisa okuncane okulethelwe i-membrane. Izinto ezibonakalayo zinokuguqulwa okubili: nge-foil noma ngaphandle kwangaphandle. Ulwelwesi lugxishwe ngqo phansi usebenzisa i-glue ekhethekile.

Sidweba phansi okufudumele

Umdwebo wamanzi wephansi.

Lolu hlobo lokufakelwa luphumelela kakhulu ngoba luqinisekisa ukusatshalaliswa komfaniswano wokushisa okuzungeze igumbi. Izinzuzo zalezo zinhlelo zingahlolwa ngokushesha ebusika, ngoba amabhethri awashintshiwe. Inqubo yokuhlelwa incike ekutheni hlobo luni lohlobo lokushisa olukhethiwe.

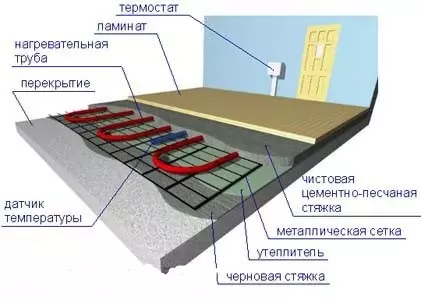

Amanzi pol

Eshibhile kakhulu ngezindleko zikagesi. Ngokuhleleka kwayo, kuzodingeka ishubhu lensimbi eliqinile lensimbi, elibekwa inyoka yonke phansi. Ngokufanelekile, ipayipi kufanele lifakwe kwi-screed. Ibanga phakathi kwepayipi futhi ingaphezulu elingaphandle le-laminate akufanele libe ngaphezu kwama-3 cm, ngaphandle kwalokho umphumela wokushisa ngeke uzwe. Uma kungekho khona ukubeka amapayipi ku-screed, amapuleti e-aluminium okusatshalaliswa kokushisa abekwe esitezi sikakhonkolo eqondanisiwe, futhi afakwa emapayipi. Lonke design ligcwele amashidi we-chipboard, i-drywall noma i-plywood ebekwe izingqimba ezimbili eziqongweni, futhi zibonge ngokuzikhandla.

Isihloko ngesihloko: Ukufakwa kokushushuluza etafuleni phezulu ekhishini

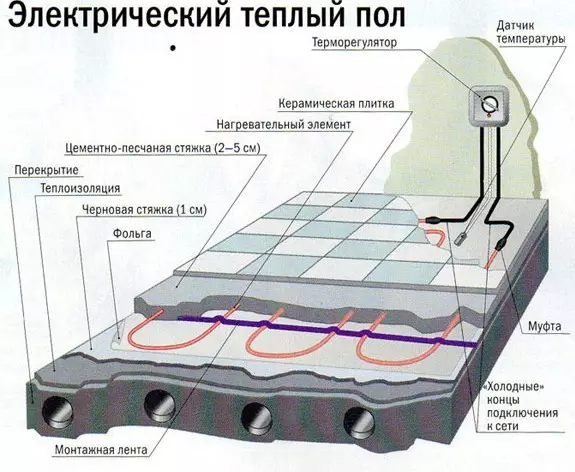

Phansi kukagesi

Injabulo ebizi kakhulu, njengoba idla ugesi omningi. Kepha lobu bobulili buthatha isikhala esincane kunamanzi, futhi izinga lokushisa kwalo lingashintshwa ngokunembile. Kuya ngezinto ezisetshenziswayo, ihlukaniswe ngezinhlobo ezi-3:

Ukushisa kagesi kwephansi.

- Phansi kwe-infrared. Kufakwe kalula futhi ngokushesha, njengoba ungafaka phansi usebenzisa ifilimu elikhethekile. I-substrate yokudlulisa ukushisa ibekwe endaweni ehlanziwe. Ifilimu linqunywe emabhendi obude obudingekayo futhi abekwe phansi izinduku. Okulandelayo xhuma i-wiring bese usetha i-thermostat. Konke ukuxhumana kumele kunwetshwe.

- Induku mats. Hlala endaweni eyisicaba. Ezindaweni, ukuphenduka kwama-mat kunqunywe ukuze kungalimazi ikhebula. Ekugcineni, kuyadingeka ukubuyela endaweni lapho ukubekwa khona kokuqukethwe kwaqala khona, futhi kuxhuma iziphetho zentambo ku-thermostat. Manje udinga ukubheka ukumelana nobuqotho bezinhlanganisela. Uma konke sekuhlelekile, ungabeka i-laminate.

- Phansi ikhebula. Uhlobo olungasebenzi kahle olufudumele. Izintambo kufanele zifakwe esitsheni se-sand-cement, zimboze i-substrate, bese zibeka i-laminate. Okusho ukuthi, kuzofanela zifudumale zonke izingqimba zangaphakathi kuqala, ukuze zinikeze ukushisa phansi. Lokhu kuzothatha isikhathi esithile nogesi. Ungaqala ukusebenzisa uhlelo ngemuva kwezinsuku ezingama-28 - ngemuva kweqhwa eligcwele le-screed.

Amathiphu amaningana abalulekile

Isitezi esifudumele akufanele sibekwe ngaphansi kwefenisha kanye nemishini yasendlini, ngaphandle kwalokho kuzoba nokugcwala ngokweqile kulezi zindawo, okuzoholela ekusetshenzisweni kwalezi zindawo, kuzokonakalisa izinto ze-laminate, zizokonakalisa izinto eziphezulu.

Ngazo zonke izindonga zekamelo, kuyadingeka ukubeka impahla yokufakelwa okushisayo ngobukhulu okungenani be-1 cm ukuze isikhala sokwanda kwe-liquite sihlala, futhi akukho okunye ukuqhekeka nezinye iziphambeko phansi.

Ngaphambi kokuqala ukubeka i-substrate nephansi, kuyadingeka ukufaka uhlelo oluhlangene izinsuku ezimbili ukubheka ukusebenza kwalo nokushisa ingaphezulu. I-Laminate ngalesi sikhathi kufanele kube ngaphakathi endlini. Usuku ngalunye, khulisa amazinga okushisa angu-5 ° C aze afike ku-15 ° C.

Izinga lokushisa eliphakeme ebusweni be-laminate ngesikhathi sokusebenza kwaphansi okufudumele kungu-27-28 ° C.

Lapho ukhetha ukufakwa, kubalulekile ukubheka hhayi kuphela ukuphakama kophahla, kodwa futhi nezinga lomswakama egumbini. Abanye ukufakwa akunakusetshenziswa endaweni emanzi, kuzodingeka ukuhlomisa ukunika abanye amanzi. Ukufakwa okukhethwe kahle nokufakwa kwawo okufanele kuzonikeza impilo ende ye-laminate.