I-Laminate ibhekwa njenge-Half-Quality entantayo futhi igqoke ukumelana nezakhiwo ezinhle kakhulu. Kulula ukubekwa, futhi kuqedwe kahle ukubekwa kwe-laminate kuyisihluthulelo sokusebenza isikhathi eside se-coating. Okuqukethwe nokusatshalaliswa kwama-formaldehydes aphansi kakhulu kunemithetho ebekwe yimithetho. Ukubeka ama-laminate ahle phansi kungenzeka ngaphandle kwemikhawulo. Enhliziyweni yayo, ukuhlanganiswa kuqukethe imikhiqizo yokhuni, ngakho-ke izakhiwo zayo zifana kakhulu nezakhiwo zokhuni lwemvelo. Leli qiniso ngeke lincishiswe kwinqubo yokusebenzisa nangokunakekelwa.

I-Lainate Beading Scheme emgodini ofudumele.

Inzuzo:

- Iphansi elihlanjululwe efomini eliqoqekile lifana ne-parquet, yize ngokuya ngezindleko kuphansi kakhulu kunalekugcina. Futhi ukufakwa kwalo kulula kakhulu.

- Ukubekwa kwe-laminate kungenzeka ngokuphelele ezindaweni ezihlukile (zonke izinhlobo ze-linoleum, ithayela, ukhaphethi onesifushane, amabhodi okhuni).

- I-Lamiate ilula kunebhodi elilula, futhi ihlala isikhathi eside.

- Ukunakekelwa okukhethekile ngakho akudingekile: ukuvalwa ngokwanele ngezikhathi ezithile futhi wenze ukuhlanza okumanzi kukho.

- Amandla nokuvinjwa kokugqokwa kwama-coati ahlanzeke kuqinisekiswa ukusetshenziswa okude - uyakwazi ukubona imithwalo emikhulu yeminyaka engu-15 ukuya kweyi-20.

- Kuphephile ngokubuka kwemvelo.

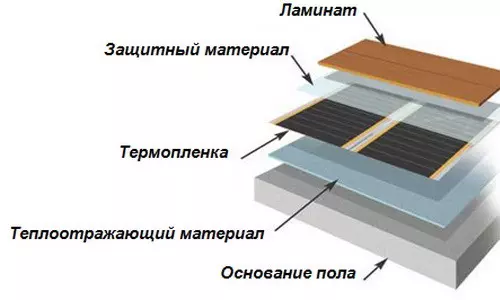

Imfihlo ye-IntracEability kanye nokumelana okushisayo: Isakhiwo sephaneli kusuka phezulu kuya kwesendlalelo esingezansi

Ukumaka ama-laminate.

- Isicelo se-Corrundic (isimo esinamatshe esingu-pofared of Stones) onama-resins ngokungabikho kokungcola okuwungozi kubantu. Ingcindezelo eqondile ye-Lamiate (DPL) - Ubuchwepheshe obukhethekile bokucimanisa ukunamathela ezimotweni ze-laminate floor.

- Ukuzilibazisa kwetshe lemvelo noma okokuhlobisa izinkuni okuphathwa ngama-resins.

- I-coating ehambisanayo (imikhiqizo elula ayenzeki) - isebenza ukuthuthukisa ukungasebenzi kokuhlanganiswa komhlaba kanye nokuphikiswa kwayo kokugqoka.

- I-sawdust ecindezelwe (HDF) - ungamukeli umswakama.

- Ohlangothini oluphambene nokutholwa okuvela ku-resin, ukuvimba ukugcwala nokuvumela ifomu ukuthi ligcinwe.

Amaphethini angaphezu kwama-20 afaka iphalethi lemibala yamaphaneli we-tramided amaphaneli ochungechunge oluhlukile - kusuka ku-cherry blossom kuya kuma-maple. I-Lanemia Coating inikeza amandla okuhlola nombala kanye nefomu layo. Lapho usebenzisa imicu ehlukahlukene yombala ebeka i-laminate kungenzeka. Ungabeka ukuhlela okuhlobisa. Kubukeka kungajwayelekile kakhulu futhi kubeka ngokungafani ne-laminate nge-angle yama-degree angama-45, kodwa futhi nomsebenzi omningi kanzima. Yize umphumela unxephezela yonke imizamo esetshenzisiwe.

Isihloko ngesihloko: isikhunta ngaphansi kwesithombe sangemuva sibonisa ngokwaso ezindongeni zezindawo ezimnyama

Amathuluzi

Ukubeka i-laminate kuzodinga ukuba khona: amadivaysi okulula (ama-30 cm), ama-wedges, isando, umugqa, ukuncibilika, ukumelana nomswakama (ukusetshenziswa - 0,5 l ngo-12 m).Izici zokukhuphuka i-laminate

Ubuchwepheshe abuhlinzeki ngokusetshenziswa kokumbozwa ngaphandle noma endlini ngomswakama ophezulu. Kepha i-laminate iguqulwe kahle ngokubeka ngaphakathi endlini enezitezi ezifudumele. Kuzoqinisekisa ukusatshalaliswa kwamazinga okushisa okufanayo phansi komhlaba.

Ukulula kwe-Lamiate Bearing ngalo mzuzu njengokuntuleka kwesidingo sokususa i-coating yangaphambili kusuka phansi.

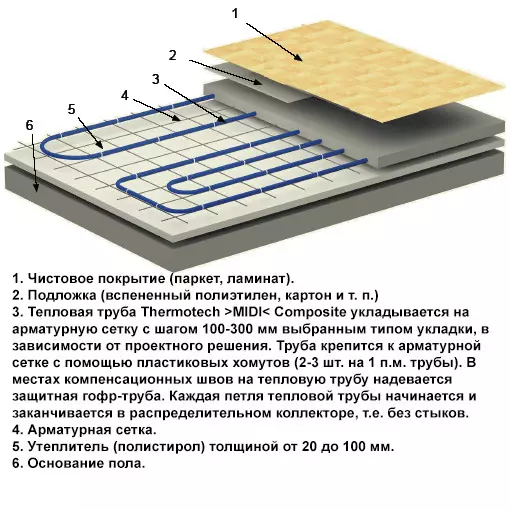

I-Lainate Bearing Diagram yamanzi afudumele wamanzi asuselwa ku-conkcrete screed.

I-Laminami dice ingafakwa esisekelweni: i-fiberboard noma i-chipboard, kuthayela, esitezi sokhuni, esitezi sokhuni, i-linoleum, ngisho nokufakwa kwe-laminate kuthayi.

Umhlangano wamabhodi ama-lamonated ngesikhathi umfushane. Ubuchwepheshe butholakala kalula kunoma ngubani owaziyo ukubhekana nesando. Ngokwemvelo, udinga ukulandela ukulandelana okucacile komsebenzi.

Ukulandelana kwesenzo lapho kuhlangana ama-laminate

- Amaphaneli angukukhipha, awahlole ngobuqotho nekhwalithi. Shiya amahora angama-48 endlini engaphakathi lapho kuzokwenziwa khona umhlangano wawo. Ukushisa kwamanani - ama-degree ayi-18, umswakama ohlobene - 75%. Ukudlulisa inqubo ye-acclimatization, i-laminate izothatha ubukhulu obudingekayo ngokuya ngezimo zasekamu.

- Ukunciphisa ukubonakala kwamalunga phakathi kwamaphaneli, kuyadingeka ukuhamba kuyo yonke imiphetho ukuze uhambe ngephepha lokugaya 320, uzicindezele kalula.

- Lungiselela isisekelo sokubekwa kudingeka kusengaphambili. Ingaphezulu kuze kube sekupheleni komsebenzi kufanele lome, lihlanziwe, libe mnene futhi bushelelezi.

I-Linoleum, i-polyvinyl chloride nanoma yikuphi okunye okuqukethwe okuqinile kungasala, kepha ukuhlanganiswa kwe-fibrous kuyadingeka ukudilika. Flooring nge zoboya emfushane kanye ne-linoleum ethambile kuvunyelwe ukufaka isicelo ngaphansi kwesisekelo esitezi se-limate.

I-Lainate Bearing Scheme emsureni.

Beka i-laminate kuthayela kusuka kuthayela, ibhodi yezinkuni kungaba ku-linoleum ebibiwe, udinga ukunakekela ungqimba owengeziwe (okungenani 2 mm) kusuka ezintweni ezithambile. Okunjalo kungaba yigwebu noma i-substrate ekhethekile evela ku-polyethylene. Kumele ibekwe ngokunembile futhi igcotshwe. Okwe-Gluing, ungasebenzisa ifilimu elinamathela (4-5 cm ububanzi).

Isihloko ngesihloko: Izicucu ezenziwe ekhaya ezenziwe ekhaya nezicathulo ze-moose zomzingeli

Ukuqeda ukungena komswakama ngaphansi kwesitezi, kuyadingeka ukubhema ama-engeli egumbi kanye nezindonga eziphakeme cishe ezingaba ngu-2-3 cm. Ngokuzayo, i-plinth izovala zonke izinto ezingadingekile.

Kuso usimende noma phansi kwethayela, udinga ukubeka ifilimu le-polyethylene ngendlela yokuthi ihlolwe kakhulu engxenyeni yodonga. Izosebenza njengesendlalelo sokufaka i-vaporizolation.

Okungahambi kahle kwephansi lomthungo kufanele kuqondaniswe negrout ye-spacion kwenzelwe phansi phansi.

- Nquma ekuqondisweni kokubeka futhi unikeze ama-deformation seams amakamelo amakhulu. Emnyango wegumbi okudingeka unikeze indawo, ulibambezele ukungcola nomswakama.

Ngaphambi kokuthi uqale ukubekezelela i-Parquet, udinga ukulinganisa ukuthi kuzokwazi yini ukusebenzisa ngokukhululeka umnyango ongaphakathi uma i-Parquet izobekwa ngaphansi kwayo. Kuyadingeka ukususa amapulangwe avela emnyango uJamebs kanye ne-plinth yangaphambili.

Ukubekwa kwe-laminate kwenziwa ngendlela yemisebe yokukhanya. Ekamelweni eliphakeme, i-laminate kumele ibekwe ngaphandle kokuqondiswa kokukhanyisa i-perpendicular edongeni olude. Ukungena ngaphakathi kwegumbi inqubo yokulala akufanele kube.

- Ukubekwa kwephaneli le-liminate kuhlale kwenziwa ngenketho entantayo ngaphandle kokusebenzisa i-gluing noma enye i-clutch enobuso obuphansi. Amafa awathathwa phansi phansi kanye nezipikili azilungisiwe. Ephrintiwe kuma-semigris ami kanye nama-spikes. I-Glue Glue kuphela phakathi kwawo. Imishwana kufanele ibe ngu-0.1-0.2 mm. Ngesimo sezulu esomile egumbini okudingeka ulinikeze esikhathini esizayo ngokwanda kwezikhala.

Ungakhohlwa ukuthi isisekelo semikhiqizo isihlahla sinempahla "yokuphefumula". Ngokuhambisana nonyaka, umswakama egumbini ungahluka. Ngakho-ke, ngoba phansi kufanele kunikezwe ukuthi kungenzeka kuvuse futhi kunciphise izinkomba ezi-4. Enqubweni yokubeka, kuyadingeka ukushiya izikhala ezingama-8-10 mm endaweni yonke yaphansi. Izikhala ezinjalo zidinga ukushiywa eduze kwamapayipi okushisa futhi eduze komkhawulo. Ekupheleni kokubeka i-laminate, zonke izikhawu zizovala i-plinth, ezingafakwanga phansi. Yekani ukuqala nge-angle yegumbi.

Isihloko ngesihloko: Imibono emisha yokuhlobisa umgwaqo ophethini

Ukubeka ama-laminate kuhlelo olufudumele lwaphansi

Ngabe ifudumele lihlangene kanjani ne-laminate lihlanganisa? I-liquite coating ihlanganiswe ngokuphelele ngohlelo lwezinqwaba, ukwethula ukwethenjwa nokuphepha kokushisa komhlaba phansi. Inzuzo yalokhu kuxhumana ukuthi i-screed in inqubo yokusebenza kwe-fur floor ifudumele ngokulinganayo, yandisa ukusetshenziswa kwe-laminate.

Awukwazi ukufaka amalebula ukunamathela okumisiwe esitezi esifudumele, ngeke uthande, kepha ngemvume ekhona evela kumenzi.

Umswakama osele wedayisi kufanele uhlolwe ngaphezu kwalokho. Isixazululo sokonga esilungiselelwe phansi ukuze sibeke ngokulinganayo.

Umsebenzi wokulungiselela wokubeka ama-laminate afudumele esitezi esifudumele ngokulandelayo.

I-screed ngensimu efudumele ebekiwe kufanele ifinyelele isilinganiso esithile somswakama esinikezwe ukomisa. Ukufeza leli zinga, okuphansi kubangelwa ukusebenza (ngemuva kwamaviki ama-2-3 ngemuva kokomisa ukhonkolo), kancane kancane kwandise izinga lokushisa kwalo. Amaviki ama-3 kufanele abe ku-Off State. Futhi cabanga ukuthi yini efakiwe hhayi ngokushesha ngokugcwele, kepha ngokukhulisa izikhathi ngama-5 degrees. Le nqubo yenziwa kungakhathalekile isikhathi sonyaka, okungukuthi, ehlobo.

Lapho izinga lokushisa eliphakeme lifinyelelwa, udinga ukufudumeza phansi amahora angama-72, ukuba sohlelweni olunjalo lwamandla.

Izinsuku ezi-1-2 ngaphambi kokubeka i-laminate, uhlelo lokushisa oluphansi luvaliwe futhi luvumele indawo yokushisa yegumbi.

Ingaphezulu le-screed kufanele limunwe ngesisekelo sezidingo zabakhiqizi be-laminate. Futhi izinga lokomiswa lihlolwe ngaphambi kokulala kwalami.

Ingaphezulu laphansi ngesikhathi sokuhlangana kwe-laminate kufanele lifudumalo (18 noma ama-20 degrees).

Ukuze ugweme ukungena komswakama phansi, ifilimu ye-polyethylene, egcotshwa nge-scotch. Emva kwalokho, faka i-substrate (ungasebenzisa ikhwalithi yayo ye-polyethylene enobukhulu be-2 mm). I-substrate iboshwe ngokuhlekisa kuyo yonke indawo yegumbi. Ngemuva kwalokho, i-rack laminaminate.

Inqubo yokubeka i-laminate efudumele esitezi esifudumele ayinawo umehluko ezindleleni ezijwayelekile zokubeka. Kubalulekile ukulandela imiyalo eyenziwe ngumenzi.

Ngosuku ngemuva kokufakwa kuqediwe, kungenzeka ukuvula phansi okufudumele, izinga lokushisa laso akufanele libe ngaphezulu kuka-26 ° C.