Ngaphambi kokubeka i-laminate eduze kweminyango, kudingeka uqiniseke ukuthi yonke imithetho nezidingo zokubeka lesi simbozo saphansi kuyahambisana. Yini okufanele ikufanele ngokukhethekile:

I-Lainate Bearing Diagram eceleni kodonga.

- Hlola ukuphakama kwaphansi nge-substrate ngaphezulu kwezinga eliphansi lephansi. Phakathi kwengxenye engenhla yohlaka lomnyango kanye ne-laminate kufanele kwakhiwe imvume okungenani engu-1 cm;

- Ukubekwa kwe-laminate kufanele kwenziwe kuphela ngesisekelo se-flat, esiqinile futhi esisetshenzisiwe;

- Ekamelweni lapho kufakwa khona phansi okusha kwe-laminate, akufanele kube semoyeni womswakama owedlulele.

Ukulandelana komsebenzi

I-Lainate Bearing Order.

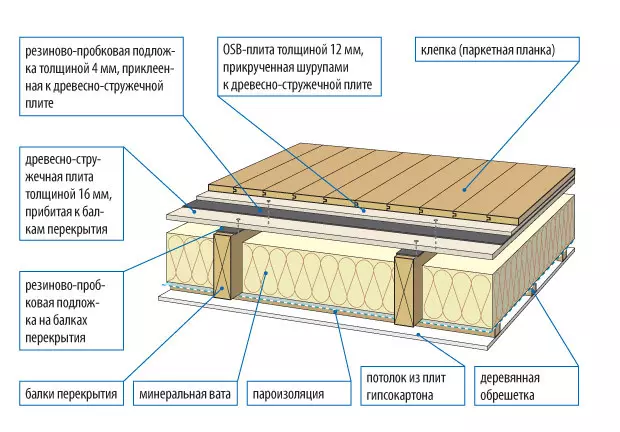

Isenzo sokuqala ekuqaleni komsebenzi ekufakweni noma ekushintsheni kwesembozo saphansi kufanele kube ukuhlolwa kwesimo sesisekelo lapho kuzobekwa khona izidingo zezizathu zezizathu ngesendlalelo se-multilayer.

Ukubekwa kwekhwalithi ephezulu ye-laminate kwenziwa ezisekelweni ezilandelayo:

- i-linoleum;

- tile ye-ceramic;

- ibhodi yocansi enobukhulu obungu-30 mm;

- uthango lodaka lukasimende;

- Amapuleti e-fiberboard;

- Ukhonkolo slab interlap interlap.

Izisekelo ezifakwe kuhlu zinomugqa oqinile, okungomunye wemibandela esemqoka yokuqina kwesembozo esisezingeni eliphansi.

Akunconywa ngokuqinile ukubeka i-laminate ye-spinning kanye nesisekelo esithambile, esingaba yikhaphethi, noma ngokususelwa kokuqukethwe okuphezulu komswakama osele, ngokwesibonelo, impahla ye-xylolite, okuqukethwe okuyisisekelo sazo izithasiselo zamakhemikhali nge sawdust wokhuni oluvuthayo.

Ukulungiselela isisekelo se-laminate

Isikimu sedivayisi ephansi.

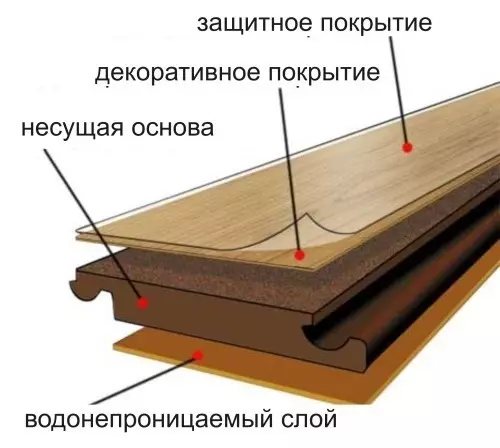

Ngezinga eliphakeme lokuthembela nokusebenza isikhathi eside, faka i-lanemia (igama elithi "ama-laminate" afike kwigama lezokwakha elivela kwisiLatin, lapho umqondo we- "Lamination") kungenzeka kuphela endaweni eyisicaba futhi hhayi engcolisiwe.

Ukunganaka kufika ku-3 mm ubukhulu, okunganxeshezelwa ungqimba lwe-substrate. Konke ukuqina kanye nama-bulges adlula lokhu kuphakama kufanele kususwe ngokusebenzisa ingxubevange ye-spacion noma ukugaya.

Isihloko ngesihloko: Amakhethini alula enza ngokwakho: Ukukhiqiza Ubuchwepheshe

Izitezi ezindala zokhuni zithola amabhodi noma imigoqo yamabhodi e-convex zingaphansi kokuqondanisa nokugaya. Amapuleti ama-Laminate kulezi zindawo ezinjalo kufanele abekwe ohlangothini njenge-coating yakudala.

Ukunakwa ikakhulukazi kufanele kukhokhwe esimweni sesisekelo esiseduze komnyango. Le ngxenye eduzane nomnyango wokungena ingaphezu kwezinye izingxenye zaphansi zizobe zisetshenziswa njalo.

Isicelo Substrate: Ama-Nuances

Kukuliphi amacala adingekayo ukubekwa kwe-laminate ye-substrate:

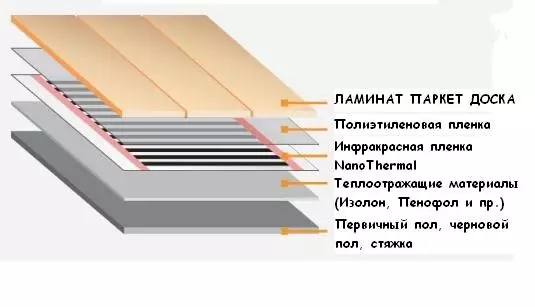

- Ngokwesisekelo sezinto zamaminerali ukuvikela umswakama nangomphunga wamanzi;

- Lapho isisekelo uhlelo "olufudumele lwaphansi";

- ngendawo esondelene nesendlalelo somhlaba;

- Esimweni lapho kunoshintsho oluvame kakhulu futhi olubukhali ekushiseni kwezinto ezisekelwayo;

- Emakamelweni anesisekelo.

Ngokwenziwa kwe-Thermal Insurturess Substrate Faka isicelo se-polyethylene.

Isakhiwo se-laminate.

Into efanayo inezimpawu ezinhle zokuthola umsindo, igcizelela ukuthi i-rug yekhadibhodi enomswakama - ilawule.

Ukubeka i-laminate eduze komnyango kufanele kubhekwe esinye isici salesi simbozo saphansi. Kwenziwa ngokusetshenziswa kwezinto ezibonakalayo zemvelo - isihlahla, esingashintsha ivolumu yayo yoqobo lapho izinguquko zokushisa zingashintsha, noma, njengabasebenzi zokwakha, "uphefumula". Ngakho-ke, eduze nezindonga neminyango kuyadingeka ukubeka ama-laminate ngezikhala ezisukela ku-10 kuye ku-15 mm.

Emakamelweni anendawo enkulu kanye neminyango eminingana, ukubekwa kwe-laminate kwenziwa nokwakheka kokunxephezelwa kwesinxephezelo ngesilinganiso se-1.5 mm seam ku-1 p. Ukugqokwa. Kulokhu, uhlelo lwe- "Flouting Floor" lusetshenziswa lapho isembozo saphansi singabi nokusobholisa ngesisekelo, futhi i-plinth inamathiselwe kuphela ezindongeni.

Izici ze- "Floating Floor"

Ngokubekwa kabi okungenacala, i-laminate eyenziwe ngobuchwepheshe be-HDF iyasetshenziswa, okuhlinzeka ngokumelana okuphezulu kulayishi kanye nokuphikiswa komswakama okwengeziwe ngaphandle kokumiswa.

Kodwa-ke, ngokufakwa kwezandla, ukuhlanganiswa okunjalo akufanelekile, ngoba ubukhulu obufanele bokugcina ababuqiniselu. Izibopho ezikhethekile zisetshenziselwa ukudonswa kabusha, kanye nokulungiswa kokhiye obekwe ngqo kumaphaneli. Ukusetshenziswa kwama-Locks kukuvumela ukuthi ugweme "ukuvuvukala" noma ukungafani kwesembozo saphansi.

Isihloko ngesihloko: Ungahlanganisa kanjani i-linoleum online online ekhaya: ukuvunyelwa ukuvunyelwa, ukunamathela kumalunga nokuhlanza

Ukuhlanganiswa kwangaphandle emnyango

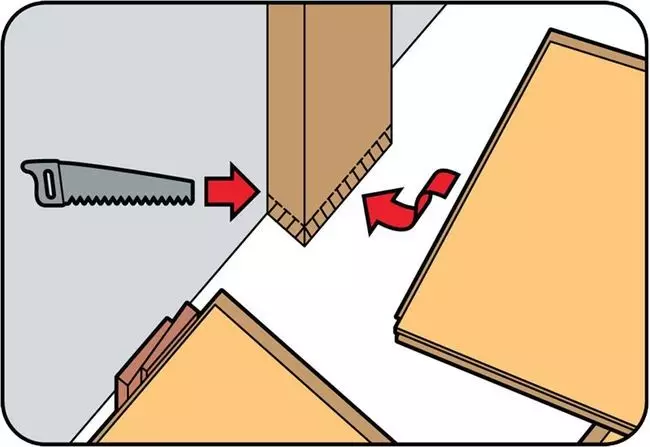

Ukubekwa kwe-laminate ngaphansi kohlaka lomnyango.

Ngokusho kwabakhi - ukuqeda, ukubeka phansi kwesembozo esiphansi, ikakhulukazi njenge-lansinate noma i-parquet, emnyango futhi eduze kwazo kungenye yezigaba ezinzima kakhulu zomsebenzi ophela phansi.

Ukubeka i-laminate ezungeze umnyango kwenziwa ngezindlela ezi-2. Ngokusho kwenye indlela, kufanelekile (ukunquma) kwento yama-laminate ye-laminate kwenziwa, futhi kwenye indlela, kudakiwe emnyango wesitshalo ngaphansi kwephepha le-lime.

Indlela yesibili inguchwepheshe ngokwengeziwe, ngoba ayishiyi ama-seams angadingekile. Kepha unaye amaminithi akhe. Ama-minus abaluleke kakhulu alele eqinisweni lokuthi lapho efaka isembozo esiphansi emgodini omncane, okwenza ibhokisi lepayipi ngaphansi kwe-laminate enobude obungu-8 mm, i-slot izosala, okuzodinga uphawu lwe-curly. Umbuzo kanye nohlangothi lwezezimali luvukile. Uma uhlaka lomnyango lusho isigaba sentengo ye-VIP-Class Class, khona-ke akufanele usheshe umnyango wenhlaka yomnyango.

Ukufaneleka kwe-laminate ngaphansi kokulungiswa kohlaka lomnyango wale mizuzu engenhla akunawo, kodwa lapho kwenziwa, kwakhiwa izikhala ezindaweni zokuhlangana kwesembozo esiphansi kanye nohlaka lomnyango. Kufanele bashumeke, bathathe ama-sealant anemibala.

Ngokunciphisa uhlaka lomnyango, wabona ngamazinyo amancane. Ukunquma ukuphakama kokuphakama, kuyadingeka ukusebenzisa isampula lokuhlanganisa kanye ne-substrate efakiwe. Ukufakwa okungaphezulu kuka-3 mm akufanele kunikezwe. Amashubhu ngaphambi kokuba ama-shear angcono adilizwa kangcono.

Lapho-ke isilinganiso sesihlalo sokuhlala nokusika amabhodi we-laminate kwenziwa. Ibhodi elitshalwe kahle kufanele lihambe ngaphansi kwebhokisi le-5-10 mm, kepha ngasikhathi sinye akufanele likhawulelwe odongeni lukakhonkolo lokuhlukaniswa.

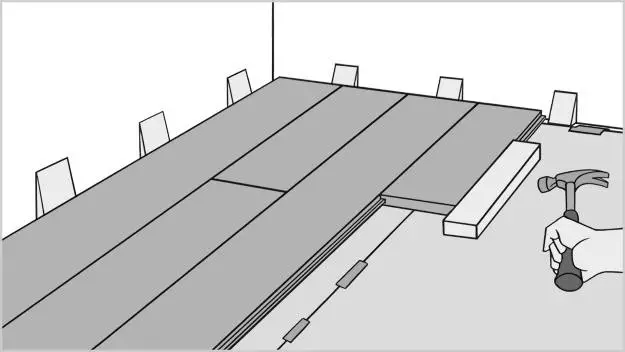

Ibhodi lama-Liminate elinokuhlelwa okuholela lihlelwe okokuqala eduze kokhiye omude (uhlangothi olude), bese kuthi ngosizo lwesando senjoloba kanye nebha yokhuni, shayela ngobumnene kube izingidi eziguqukayo. Ngobude obuphezulu bebhodi, ukulawula okungapheli kokuntuleka kwe-longitudinal skew, okungalimaza izingidi.

Isihloko ngesihloko: Amakhethini anemibala emibili ekwakhiweni kwanamuhla kwezangaphakathi

Lapho ushayela umnyango, kufanele uqale wenze ithempulethi. Isifanekiso senziwe ngekhadibhodi eliminyene futhi kuphela ngemuva kokuthi i-Fit yayo idluliselwe esisembozweni saphansi. Imvume eduzane nebhokisi lomnyango iyadingeka, ukuze igweme amaphuzu we-voltage. Kamuva, kufanelekile ngezindlela zokuhlobisa.

Ukubekwa kwe-Laminate: Ukukhetha kanye nezimpawu zamathuluzi

Ngomsebenzi othelayo futhi osezingeni eliphakeme, ukukhethwa ngokucophelela nokulungiswa kwawo wonke amathuluzi adingekayo adingekayo. Ngaphandle kwalokho, isikhathi sesithathu esichithwa ekwenzeni noma yimuphi umsebenzi uzonikezwa ukusesha idivaysi noma ithuluzi oyifunayo.

Uma ukulandelana kwemisebenzi ngokubeka i-coating ye-lamined kuyaziwa, ngaleso sikhathi ngokulandelana kwalokhu kulandelana futhi kuyadingeka ukukhetha ithuluzi nemishini yokusiza noma amadivayisi.

- Iphuzu lokuqala kunoma yiliphi iqoqo lamathuluzi omakhi, kungakhathalekile ukuthi ngabe ungumsebenzi osolwa ngokusobala, uyi-roulette.

- Bese kuba nepensela, mhlawumbe ukwakhiwa, kepha ukungabikho kwalo kufanelekile futhi kulula. Kepha ngobunzima obungaphezulu kakhulu kune- "TM", nokuthi kuzoba njani, kube lula ukwenzela ukumakwa. Uma kwenzeka, ungangeza umaki omnyama kwipensela.

- Okokumaka amaphaneli, uzodinga isikwele, mhlawumbe ngokhuni ukugwema ukuklwenzeka okungenzeka ngokunganaki.

- Amaphaneli wokusika azosheshisa ukuba khona kwebhayisekili kagesi noma i-saw eyindilinga embhedeni omkhulu. Kubona okungcono kakhulu, ikakhulukazi ngamanani amakhulu okusika ngaphakathi endlini eyinkimbinkimbi.

- I-Wood-hacksaw izoba wusizo ekulaleni okuncane.

- Isando senjoloba samaphaneli afanele;

- Sliding lump.

- Ukushayela ngesethi "yezimpaphe" izinhlobo ze-nozzles nge-5-6 mm ukudala izimbobo ngepayipi.

- I-Metal Hacksaw.

- Ubakaki ngokuqinisa amashidi e-laminate kukhiye.

- Imishado yi-spacer ukulawula igebe phakathi kwezindonga nomphetho wesembozo saphansi.

Akukho okubizayo noma okugadiwe ekusebenziseni amathuluzi.