Ngokuya ngokusemakamelweni nasezindlini kwaqala ukufaka amasistimu wephansi afudumele. Amandla wohlelo olunjalo angashintshwa ngesandla, asizakala kakhulu ukusebenza kwawo. Kodwa-ke, ukufaka into yokushisa, udinga ukwazi ukuthi ungayithululela kanjani phansi ngokhonkolo.

Isikimu sokukhuphuka kukagesi.

Izinhlobo zobulili obufudumele

Uhlelo olufakwe kahle lokufudumeza phansi luzogwema umuzwa ongathandeki wamakhaza ebusika. Lapho ama-masces akhulisa amakhaza ehliselwa phansi phansi, kungaholela kumkhuhlane ovame njalo. Kepha nokwazi ukuthi ungayithululela kanjani phansi ngokhonkolo, kufanele uqale uthathe isinqumo ngokubuka kwawo. Kunezinhlobo ezilandelayo zokufudumala:

- amanzi;

- Electric.

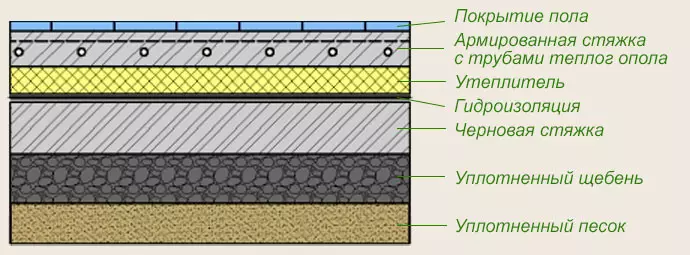

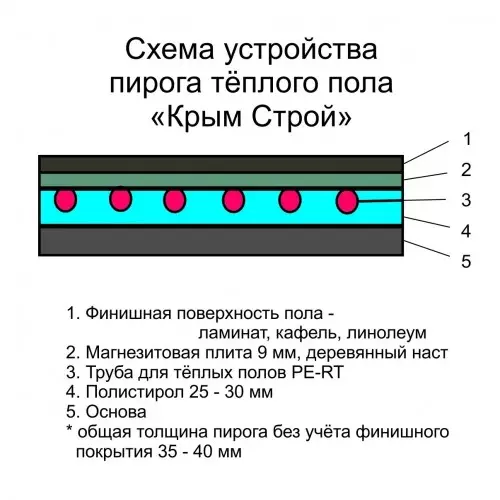

Zombili lezi zinketho ziqongelelwa ngaphansi kokugcwaliswa kokhonkolo. Isitezi samanzi sifakwe ngaphansi kwe-screen sisebenzisa isembozo esiphezulu saphansi. Isitezi esifudumele kagesi sifakwa kusetshenziswa izinto ezikhethiwe ngokuya ngesayithi lokufaka kanye ne-wiring yokuxhumana, isibonelo, amakhebula, amapayipi, i-Upper Flooring, kukhona ingxube ekhethekile engezwe kuyo ukugcwaliswa ukwenza ngcono ukuthuthuka okushisayo kwe-coating.

Isitezi esifudumele samanzi sivame ukufakwa emizini yabantu. Elensia - ezindlini ezinokushisa okuphakathi. Lokhu kungenxa yokuthi kunzima ukuxhuma ekushiseni okuphakathi.

Ukugcwalisa izingubo zangaphansi kwamanzi, kuzodingeka:

Isikimu esifudumele samanzi endlini.

- usimende nesihlabathi sokulungiswa kwengxube;

- isoplen;

- itheyiphu yemali;

- I-Plistic;

- igridi yokuqinisa;

- Isixazululo se-throung seams;

- Ipulangwe elide;

- umthetho;

- I-Concrete Mixer;

- ukupakishwa kodaka;

- I-Level Gauge;

- Ama-spatulas ahlukahlukene.

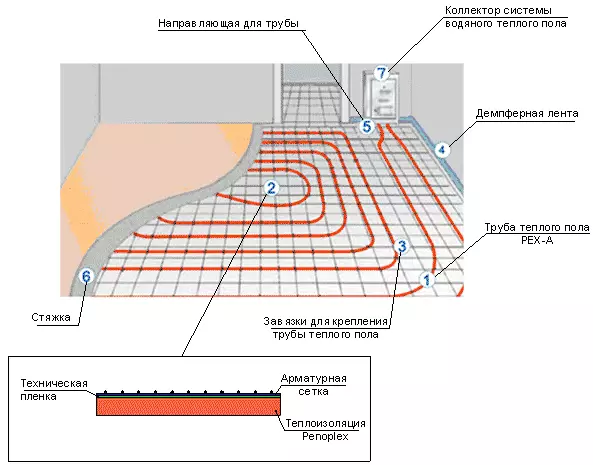

Ngemuva kokuthi isisekelo selilungiselelwe (esifakwe futhi singangeni manzi), sebenza ekubekeni nasekuxhumaniseni amapayipi emthonjeni we-thermal. Ngemuva kokuqeda ukubekwa, amapayipi ahlolwa ngento eshisayo kanye nokwethenjwa kwamakhompiyutha. Uma ukuhambisa kugculisekile, inqubo yokugcwalisa iyaqala. Ukuze uqinise ungqimba lukakhonkolo, igridi yokuqinisa ihlanganiswe ngepayipi ngaphambi kokugcwaliswa. Ngesendlalelo esincanyana, i-polymer fiber iyasetshenziswa.

Isihloko ngesihloko: Ukwenza kanjani ikhalori enhle kusuka ku-orgaza ngokwakho?

Insimu yokugcwaliswa ihlukaniswe izigaba eziningana. Inani lezingxenye lincike endaweni yegumbi likakhonkolo. Lokhu kwenziwa ngenxa yezizathu eziningana:

- Ukuze icesiselo lezikhukhula lilula ukuqasha futhi lingavuki esitezi esiqediwe;

- Iphinde yakha i-zone yezintengiso zokushisa, ezivimbela ukukhuphuka ukhonkolo lapho amazinga okushisa ehla; Kukhona izikhala ezigcwele ingxube ekhethekile phakathi kwezindonga zodonga nokhonkolo.

Izingxube ezingeziwe nezinto zokwakha

Phansi kwamanzi afudumele ngaphandle kwesisu.

Amazinga okushisa aseduze nezindonga agcwele iribhoni elimbi noma isonge, elisetshenziswa esikhundleni sengxube ebanzi. Uma umthungo uthola izingcezu zamapayipi ezidlula kule ndawo, kufanele zisongwe ngengxenye ngezigaba zamapayipi epulasitiki (zensimbi) noma imikhono.

Manje udinga ukukhetha isisombululo esizobe sesishayele phansi efudumele. Ukuze wenze lokhu, ungaya esitolo uthenge ukuxuba ukoma okwenziwe ngomumo lapho. Manje emakethe yokwakha kukhona inani elikhulu lezinhlanganisela zokugcwaliswa.

Kepha uma ukugcwaliswa kwezocansi okufudumele kuzokwenziwa ngesisombululo sikakhonkolo, khona-ke kufanele kwaziwe ukuthi kunokwenziwa okuphansi okushisayo.

Ngalesi sizathu, ukhonkolo omsulwa kungcono ungasebenzisi. Ukuze uthuthukise i-clutch, izinto zokulungiselela ukhonkolo zingcono ukusula futhi ushiye izingxenyana ngosayizi ngo-3 - 7 mm.

Ngaphezu kwalokho, ipulasitiki kufanele ibe isilula esikhokhelwa esikhokhelwa esikhokhelwa, esizokhulisa i-plasticity kanye nokuvuselelwa okushisayo kwesihlahla. Ipulasitiki ithululelwa kwikhambi eliqediwe. Lokhu kuzovimbela ukuqhekeka kwakhe phakathi kwenziwe lukhuni. Isixazululo esinepulasitiki sizodinga okungaphansi kokujwayelekile. Lokhu kuzonciphisa ubukhulu bokuhlanganiswa kusuka ku-7 kuye ku-3 cm.

Umyalo wesinyathelo ngesinyathelo

Lapho uhlelo olufudumele lwaphansi lulungiswa futhi ikhambi lixubene, kungenzeka ukugcwalisa ngokhonkolo walo. Ukuthela ngezandla zakho emazingeni okushisa asuka ku-5 ° C nangaphezulu, uma kungenjalo uhlobo lokhonkolo ngeke luhambisane nalo lwangempela, futhi lungaqala ukudilizwa nganoma yisiphi isikhathi. Into eshisayo kumapayipi kufanele ibe ngaphansi kwengcindezi yokusebenza. Lokhu kuyadingeka ukuze ukhonkolo ungazinikeli amapayipi, futhi amapayipi nawo awazange abhubhise isikrini lapho efudumele.Isihloko ngesihloko: Ungayikhetha kanjani uphawu lokuzinamathela lweminyango?

Ngemuva kokugcwalisa phansi okufudumele, kusele nesixazululo sezinsuku ezingama-21-2 28. Ngalesi sikhathi, ukhonkolo uzothatha izinkomba zawo eziphambili zokusebenza. Lapho isixazululo sikakhonkolo siba siqine, kuphathwe amandla ohlelo lokushisa. Ngaphezu kwalokho, izinga lokushisa likhuliswa kancane kancane isikhashana kuze kufinyelele ukusebenza. Uma uhlelo lokushisa, olufakwe phansi komsebenzi, lunedrasi, luvulwa ezinsukwini eziyi-10 ngemuva kokugcwaliswa. Uhlelo olufudumele lwaphansi lukhulisa izinga lokushisa nsuku zonke ukuthola ama-degree abili, kungashintshwa futhi ngemodi yezandla.

Okokuqala, kuyadingeka ukubheka ukugcwaliswa komhlaba wokushisa kwamanzi, ngoba uhlelo lukagesi lubekwe cishe kuhlelo olufanayo, kodwa ngokuhluka okuthile. Isibonelo, igridi yokuqinisa ifakwa ngaphansi kokushisa ama-elektrode. Ngaphansi kwezintambo ezinikeza amandla kagesi ku-heater zifakwa kumashidi we-foil roll.

Lapho ufaka phansi okufudumele, udinga ukukhetha amapayipi, ngoba kungenye yezinto ezibaluleke kakhulu ekubekeni phansi. Umsebenzi wohlelo lonke lokushisa uncike kwikhwalithi yamapayipi. Izinto eziphelele zamapayipi yithusi, njengoba inokuphakelayo okuphezulu okushisayo, futhi impahla ngokwayo ayigwiki futhi ayigugi. Kodwa-ke, ithusi liyinsimbi ethandekayo, namapayipi ukuze enze phansi okufudumele, kuzothatha okuningi. Okuningi ukufaka amapayipi ethusi kuzodinga ukufudumala okukhethekile.

Kulokhu, kungcono ukusebenzisa amapayipi kusuka ku-Metalplastic. Ipulasitiki yensimbi ishibhile futhi ilula lapho ifaka, kanye nokuzithoba ekusebenzeni. Kuyipulasitiki, okungukuthi, kungagobeka, kunezici eziphakeme zokushisa futhi akuveli ngesikhathi. Okwensimbi yensimbi, ukufudumeza ngeke kudingeke, njengoba kulula ukuyifaka ngesandla.

Lapho ubeka ungqimba oluphansi lwaphansi, kubalulekile ukuhlela amapayipi ukuze uqinisekise ukufudumala okufanayo kwendawo yonke engaphezulu, okungukuthi, kuyadingeka ukudala ukuvumelanisa okufanayo kwezindawo zonke. Lapho ufaka amapayipi, kubalulekile ukuthi isinyathelo sesiphawuliwe, ububanzi bepayipi ngokwabo busondela kulo. Izibalo zikhombisa ukuthi ngesinyathelo 300 mm, ububanzi beshubhu kumele bube ngu-20 mm. Lokhu kungenye inzuzo yamapayipi epulasitiki wensimbi: abekadambisa isinyathelo esijwayelekile.

Isihloko ngesihloko: Ungasihlanza kanjani isihlungi emshinini wokuwasha?

Izinketho zamapayipi

Kunezinhlobo ezintathu zokufakwa kwamapayipi phansi okufudumele: Kuvunguza, inyoka noma ukushaya, ngokuvunguza okubili. Lapho kufakwa amapayipi, ukushisa kusatshalaliswa ngokufana, ngoba ipayipi liqondiswe maphakathi negumbi. Ngakho-ke, ukushisa okuvela emthonjeni ugeleza uye enkabeni, futhi kusuka enkabeni kuthunyelwa kumqokeleli. Isitayela se-Spiral asinakho ukugoba okubukhali, kepha kukhona izingxenye ezimbalwa eziqondile. Yize okunamathiselwe kuvame ukusetshenziswa kulokhu kufakwa. Lapho ebeka inyoka, ukushisa kuzofaneleka ngakolunye uhlangothi, nokuphuma kolunye. Njengoba amanzi esusa kupholile, futhi lokhu kuzoholela eqinisweni lokuthi ingxenye yepayipi ende yepayipi izofudumeza ngaphezu kwalokho okusondele kakhulu. Ngakho-ke, ubude bamapayipi obusetshenziswe ohlelweni olunjalo akufanele ludlule ku-70 m.