Polyfoam (expanded polystyrene) - the most common

insulation, which is used everywhere in both the insulation of the walls and for

insulation pipelines. Most often foam is used to perform

Work on the insulation of the facade of the house. There are several reasons for this, this is low cost,

Excellent thermal insulation characteristics and simple installation.

Technology of insulation of the facade of foam (expanded polystyrene)

Advantages of foam for insulation:

- zero hygroscopicity (no need to use

vapor barrier films);

- durability (with good finishes);

- resistance to biological activity;

- Stability of geometry under the influence of external conditions.

Among the disadvantages: flammable, toxicity when burning.

In general, many have an idea of how

The wall is insulated outside the hard insulation, but on how to insulate the facade

Polyfoam correctly, you need to stop more. Knowledge of features

Installation of heat-insulating material will help to perform work with your own hands and

Check the hired specialists.

Facade of Foam Foam Facade Technology

Main steps:

- selection and calculation of the material;

- Preparation of the wall surface;

- installation of the base profile;

- Installation of foam (slope and wall);

- seaming seams;

- reinforcement and plaster facade;

- Finishing work.

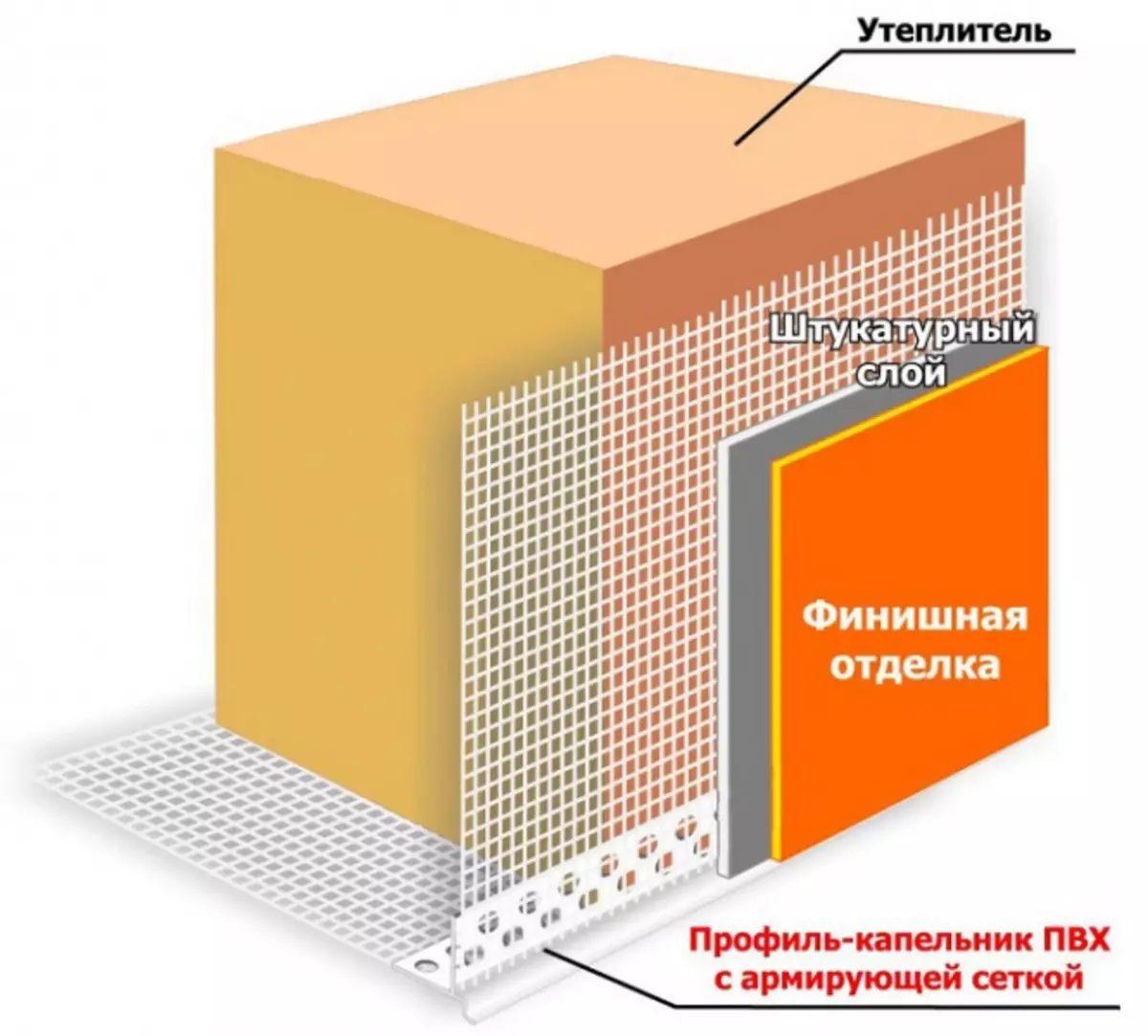

The order (diagram) of the insulation of the facade is shown in the photo.

Foaming facade insulation diagram (polystyrene foam)

Installation technology will be identical for foamflast,

polystyrene foam and inferno.

1 - Calculation of thermal insulation material

What you need to prepare for the insulation of the facade:- Polyfoam (2560-3200 rubles / cube) or polystyrene foam (Penoplex)

(3500-5000 rubles / cube). According to its properties, these are almost identical materials,

But the polystyrene foam is more convenient in operation at the expense of the junction of the "groove comb". For

It is much more expensive;

- Decorative elements made of foam for finishing facade;

- primer. It is better to buy not universal, and primer

deep penetration, for example, ceresite st-17 (555 rubles / 10 l);

- Adhesive for foam (dry mix). For example, Kosbud (Poland,

390 rubles / 25 kg), Ceresit Art 34 (315 rubles / 25 kg), Ceresit Art 83 (410 rubles / 25 kg);

Note. Cook glue can be prepared for this

PVC adhesive (1 l per bucket of the mixture) is added to the classic cement solution.

This technique does not greatly reduce costs, but it increases the labor intensity.

process and its duration (sifting, maintenance of proportions, kneading and

etc.).

Master notes that more convenient tool is

Glue-foam. For example, AKFIX (Turkey, 390 rubles / ball.) Or Tytan (Poland, 410

rub / ball.). Foam is more convenient in work, due to the lack of wet works and losses

time to extract the solution, and it also has much less consumption.

- Social profile. Performs the function of the reference edge of the system

insulation and ensures the evenness of laying sheets, without offset horizontally.

The profile has a different width, for convenient mounting of the insulation. For example, the price of Baukom profile (Germany) is a standard length of 2,500 mm.

| Width of the working shelf, mm | Price per M.P. rub. | Price per pc. rub. |

| 40. | 78,72. | 196.80 |

| fifty | 112.92 | 282.30 |

| 60. | 124,54. | 311.35 |

| 80. | 140.54. | 351.35 |

| 100 | 145.00. | 365.70 |

| 120. | 109.24. | 523.10 |

| 150. | 326.00. | 815,00 |

| Connector socket profiles | For 100 pcs. | 221.40 |

| Compensator for base profiles | For 100 pcs. | 226.94 |

Material prepared for site www.moydomik.net

- Mounting foam (Pensil 65 L 800 ml foam, 348 rubles);

- window profile;

- Facade reinforced grid (cell 22x35 - 54.9 rubles / mp, cell

12x14 - 65 rubles / mp);

- Reinforced plastic corner or perforated

Aluminum corner.

- Putty. There are ready-made mixes, such as VGT,

Russia, 287.25 rubles / 3.6 kg. Buying dry putty, will cost cheaper. TO

Example, TM "Students" Finishna, Russia - 405 rubles / 20 kg. Basic gray - 225

rubles / 20 kg;

- Dowel Tarled (2.39 - 9.99 per pcs. Depending on

Length).

Article on the topic: Moldings in the interior of the living room: design and decoration of walls with a TV

From the tool you will need: spatula (smooth and gear),

Hammer, perforator, grater for grouting, stationery knife.

Calculation of foam for insulation facade

Quality insulation of the facade of the house foam is possible

only with a competent calculation of the number and the main thickness of the material with regard to

its density and thermal conductivity of the wall (brick, foam block, gasoblock).

Calculate the number is simple - enough to calculate the area

walls and add 3% on trimming (5% with a complex wall configuration).

Note. When insulating the walls of the facade of the house should think

On the insulation of the base, basement and even the foundation right up to the level of freezing.

Only such insulation can be considered effective.

It is more difficult to choose the optimal density of foam - it

Varium ranging from 15 to 35 kg / m.Kub. Note that the lower the density,

The higher the thermal insulation properties, however, the material will be the fragile.

Masters note that for the insulation of the wall of a residential building you need to use

Polyfoam density 25 kg / m.Kub. (Mark PSB-C-25) and 40-50 mm thick.

Note. General recommendation to reduce the number of bridges

cold - put sheets in two layers. Therefore, it is advisable to purchase not one

The sheet whose thickness is 100 mm, and two are 50 mm.

What foam flame is better to choose for insulation at home?

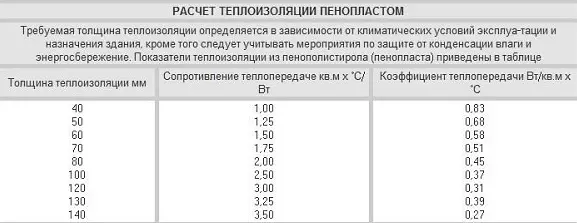

The data for selection is provided in the table (for foam

PSB-C-25 brands)

It is worth noting, to redevelop the basement in a residential premises

It is necessary not only to insulate the foundation, but also the base, floors on the soil.

Requirements for foam:

- geometry. The sheet should be perfectly smooth, permissibleDeviation in length and width - 10 mm., By plane - 2 mm.;

- color. High-quality material is white. Yellowness

Indicates non-compliance with storage conditions;

- List integrity. For insulation, unfolded and

Deformed sheets.

2 Stage - Preparation of the facade to insulation

The surface of the wall to which foam will be glued,

Must be clean, without protruding elements. Permissible height difference - 10-15

mm. All that is higher (protrusions, hillocks) - gets off, all that is significantly lower

(recesses, potholes, cracks), it is desirable to be sealing with a solution.

How to prepare walls for insulation foam:

- Painted walls - paint is removed (only if it is withzero vapor permeability);

- Chalk trail - primer used;

- Splashing walls - stripping with a metal brush.

A primer is applied to the prepared wall. It will increase

The adhesion of the surface and will avoid the appearance of fungus.

3 Stage - Installation of the base profile under insulation

Purpose of the ground profile for facades insulation systems -

Simplify the installation of the first row of foam sheets, and minimize the deviation

row horizontal. In addition, according to the masters - it is a profile

It is a good profile protection from rodents. The profile of dowels and

Mandatory verification level.

Installation of the base profile under the insulation of the facade of foam

In order to ensure the correctness of the installation of sheets and

Vertical It is recommended to install suspensions (piping cords with nut for

Weighing). Step of their installation 600-800 mm.

4 Stage - Installation of foam on the facade (slope and wall)

How to start the insulation of the facade?Masters pay attention to the fact that users-beginners

Incorrectly choose a place to start work on the insulation of the facade. Usually they

taken over the wall, the virtue of the simplicity of work, toli due to its scale,

Then how work should be started with the arrangement of the slope.

For insulation of slopes, you can use a thinner sheet

Polyfoam. When installing, he must play the wall on the thickness of the insulation plus

15-20 mm depending on the surface of the wall surface. Excess material later

Cropped.

To provide a beautiful and tight fit of the end

Foam plastic for the window frame is recommended to use the window profile or

Profile for plasterboard (plastic angle).

Article on the topic: how to equip a cottage

Often, the slopes are not distinguished by a smooth surface, so

The resulting cavity should be filled with a solution, and large pieces

Polyfoam. It is possible to additionally isolate cavities and

Conducts the beginning of work with slopes.

Council. Takeaway insulation under a drop of 30-40 mm will allow

Reduce the noise of rain metal lowbow.

Installation of foam on the wall plane begins with the bottom

An angle and is performed with a displacement of half a sheet, i.e. Sheets are stacked by B.

chess order. Thus, cold bridges are excluded.

Before starting fastening the foam to the wall, sheets are preferably

Prepare. Namely, spend on the surface of a sheet with a gear roller or

grater. This will increase its roughness and improve adhesion with glue.

How to glue foam on the facade?

The method of applying glue depends on the smoothness of the wall:

- With drops of no more than 10 mm. glue applied to the surface

Sheet using a toothed spatula;

- With differentials over 10 mm. The glue is applied small

"Blots" because, the adhesive need more, and the smeared sheet will be harder. For

Stacking sheet presses against a wall with minor displacements. So glue

Fills hollow space under the sheet. The remnants of the adhesive are removed by the spatula.

The peculiarity of this method of installation is that the level must be checked

Sets each sheet.

The second row of foam sheets is placed with displacement

relative to the previous one. When laying sheets in two layers, you must wait until

The previous layer will completely get dry.

Note. The finish finish of the foam of foam makes it possible

Perform decorative design of window or doorways.

Warming of the facade of foam - finishing of window slopes

Some disagreements between masters causes

Use dowels-umbrellas, disc dowels or dowels with a wide hat

(fungi). Fastening the foam to the wall of the dowels prevents offset and

The disappearance of the sheet. Part of the specialists claims that glue is enough

a strong retainer, and therefore the use of umbrellas is an extra spending

resources and time. Their opponents argue that this stage is neglected not

worth it because The umbrella will provide more reliable fixation.

Fasteners of plate dowels are possible only after full

Frozen glue. Usually it takes 1-2 days depending on the weather.

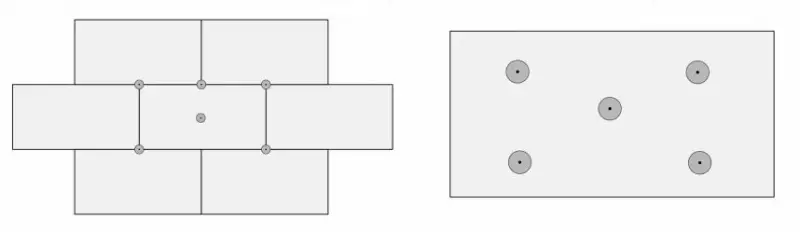

There are two ways of fastening foam:

- Fastening in the middle and in the corners . In this case, used

5 dowels umbrellas for each sheet. And their total consumption is calculated taking into account

Numbers. At the same time, parts of the sheets are also attached at least three umbrellas;

- Fastening in the middle and adjacent edges or corners . This

The method saves, reducing the number of umbrellas. The method is more

Preferably, since several sheets are fixed simultaneously. But this

The method is suitable only for perfectly laid foam sheets that no

The need to be adjusted in height after installation on the wall.

Scheme of fastening places of foaming dowels

Council. Dowel is clogged into the foam immediately after it

glue (before drying the glue) in the event that work is performed on

Foundation and to avoid the destructive action of ultraviolet.

One of the ways of fastening foam umbrellas is

Cleaning a dowel into the material and the subsequent seal of the installation site

foam plug. Due to the complexity, this method is rarely used.

How to fix foam on the wall using a dowel-umbrella with a hidden method

Note. After the foam plastic is fixed with dowels,

Crop the protruding parts of the slopes.

5 Stage - sealing seams between foam

Do not forget that the geometry of the foam sheetsometimes leaves much to be desired, and it inevitably leads to the appearance of slots

Between sheets. Even small gaps are substantial heat loss. therefore

After laying foam sheets, it is necessary to ensure sealing (smeared

seams).

How and how to close the seams between the foam?

The procedure for performing work differs depending on the thickness of the seam:

- To fill large seams, it is advisable to use

Trimming foam plane that are placed in the gap. Note, large seams

Do not fill in solution, because His thermal conductivity is much higher than

Polyfoam. As a result, through the seam will still be quite a lot

heat;

- Mounting foam applies to fill thin seams,

Which is blown in the seam, and its surplus is trimmed after frozen. Eventually

It turns out the so-called "warm seam".

Article on the topic: Dermantine Door Upholstery With Your Hands: Wooden Sheathing, Metal Door

How and what to close the seams between the foam

Note. The protruding parts of the foam is erased by a rigid grater.

6 Stage - reinforcement of foam mesh and finishing plaster

In principle, facing the facade of foam at this stageEnds. But unprotected insulation, not long to perform functions

Thermal insulator effectively. The fact is that the foam is destroyed under

exposure to ultraviolet and not very resistant to mechanical damage, and

So, he needs to protect.

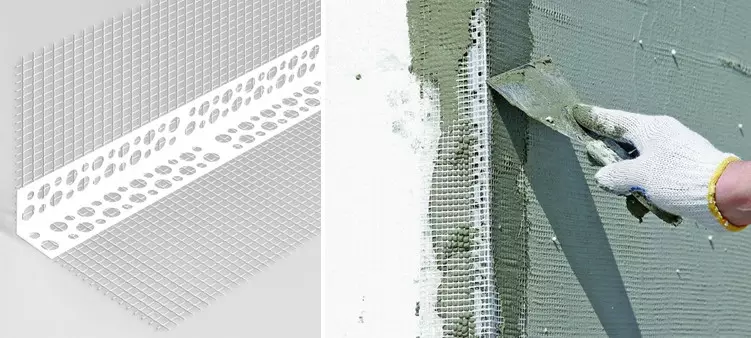

The protective material is plaster. So that she went well and kept on a smooth sheet surface, a reinforced grid is used. It is not necessary to save on it, because the insulation technology of the facade of foam plastic provides for the mandatory use of the reinforcing grid.

Reinforcement foam mesh - video

How to reinforce the foam?

- Neighboring mesh web mesh mounted in 70-100 mm.;

- The grid should be fixed so as to avoid the appearance of folds

(lines the net with hands);

- Mesh is literally interpreted into the solution;

Council. If work is performed at hot season,

Moisturizing the adhesive layer from the spray gun is allowed.

- Installation of the grid is performed quickly, because Glue quickly freezes

and fastens the grid to the foam;

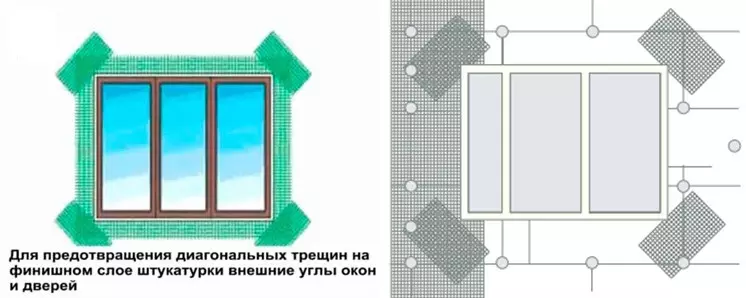

- Mounting place near window and doorways

Additionally reinforced pieces of grid. Slices are mounted at the corners of the openings,

slopes and prevent the appearance of cracks;

Reinforcement of foams around windows and doors

- Corners of the house and window openings are separated by special

Plastic corner with a grid. The grid is placed on the adjacent web.

Alternative can serve perforated aluminum corner, but it is bad

copes with its function protection of the corner from deformation and is more complicated in

Installation. Aligns the corner with the rule or corner spatula.

How to reinforce the foam around window and doorways

7 Stage - Painting of the facade of the house after insulation of foam

After mounting on the polymer mesh foam still appliedOne layer of adhesive mixture. The optimal thickness of the glue is 3 mm., And

Purpose - Hide the irregularities and give the surface to a smooth view by preparing it

Thus, to staining.

If the second decorative layer was not very smooth, his

You can align the grater. The process is time consuming, but allows you to get beautiful

Smooth surface.

Painting the facade after insulation foam is aimed at

Giving a grayish building more aesthetic species.

For staining the facade, any paint is suitable, which

Designed to perform external work. Paint is applied with a spray gun

or a soft foam roller.

It is worth noting that painting with special facade paints

Creates a film on the surface of plaster, and ensures the achievement of "effect

Thermosa ", making the house more sealed and, accordingly, warmer.

Often users refuse to staining and instead

The second layer of adhesive solution is applied to the facade of decorative stucco

Coroede or lamb.

Technology of application of the plaster "Coroed" - video

Application of decorative plaster "lameas" - video

How to insulate the facade of foam with their own hands - video

The cost of insulation of the facade of foam (polystyrene foam)

As an additional incentive to perform the facade

insulation of foam independently we give rates for work on

Thermal insulation for 1 m2.

| Type of work | Price for work, rub / m.kv |

| Primer | 150. |

| Insulation walls of the facade of foam | 450. |

| Dowling | 300. |

| Reinforcement of foam (including angles) | 375. |

| Foam finish finish (stucco + staining) | 375. |

| Finish finish (decorative apparatus plaster) | 375. |

| Foam finish (staining) | 200. |

| Finishing (brickwork technique) | 800. |

The estimated cost of works depends on the type of material, volume

works, surface quality and complexity of wall configuration, execution speed

works, work time (season of the year).

Can and easier to calculate how much the insulation of the meter

Square. How to celebrate users, the price of materials is approximately equal

The cost of work performed. This season (2019) insulation of foam under

The key goes around in 2000-2500 rubles. Behind M.KV