Since the facade of the house is the facial part of the structure, they are striving to decorate. But the facade facing is performed not only in order to give the walls aesthetic appearance. The main task of the finish is to protect the facade from the destruction caused by the factors of the external environment and guarantee the most long-term lifespan.

This requirement in combination with the development of the industry led to the modernization of the existing and emergence of new facing materials and technologies of the facade finish. One of these new products is a system of ventilated facades (Ventfasad).

What is a ventilated facade of the house?

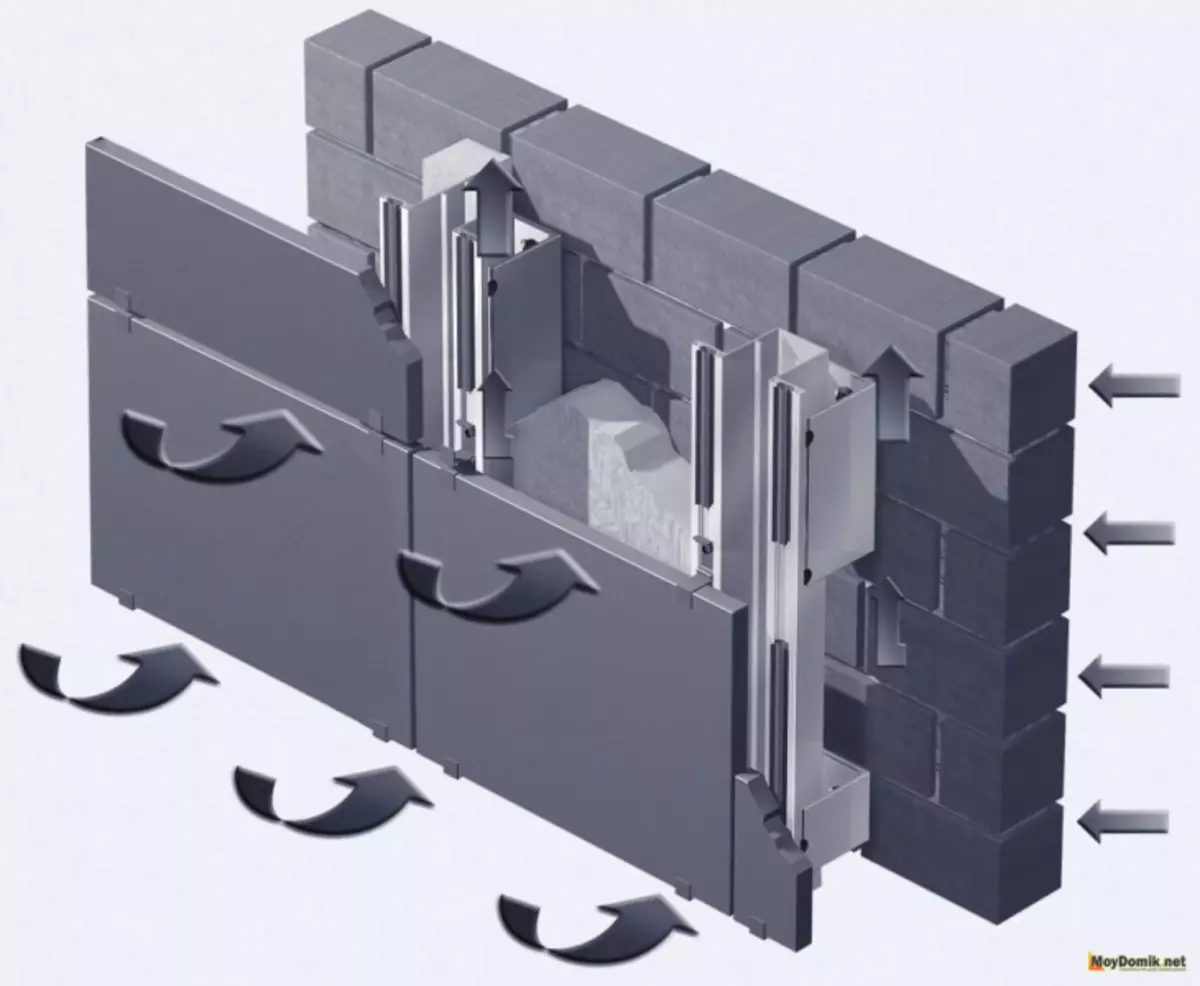

Why is needed, which is, features, characteristics, properties, types, types and device diagrams.The mounted facade is a facade system, made according to a special technology, which is to fasten the facing material on the wall by means of a frame (subsystem). As a result, a gap (up to 100 mm) remains between the wall (facade of the house) and the facing, which circulates the air. Thus, moisture is given to the design, condensate and the heat transfer is reduced at home.

The name itself reveals the essence of the system of attached ventilated facades.

- Hinged facade - the finishing material is mounted on the frame (hanging on the wall) with a given retreat from its plane;

- ventilated facade - Between the facing material and the wall surface (not closed or insulated), air flows are freely moved, i.e. There is a natural air convection. This ensures the implementation of the main feature of the ventilated facades - elimination of condensate, which traditionally accumulates between the wall and finish. Such an approach to insulation and / or facing makes it possible to provide a favorable microclimate in the premises of the house.

In general, the ventilated facade is a complex finish technology of the facade, which allows it to ensure reliable protection against the destructive action of various factors.

It is if briefly, for a complete understanding, which represents the ventfassada system, it is necessary to consider its component elements. Note that each of them is universal, which allows the finishing of complex architectural forms in different styles.

Hinged ventilated facades - Characteristics

What is the ventilated facade?

1. Subsystem for ventilated facades

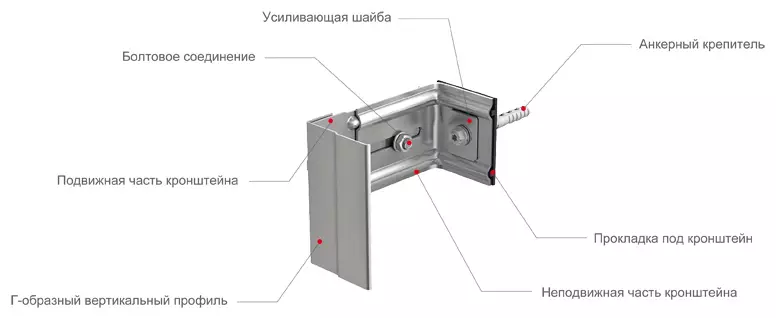

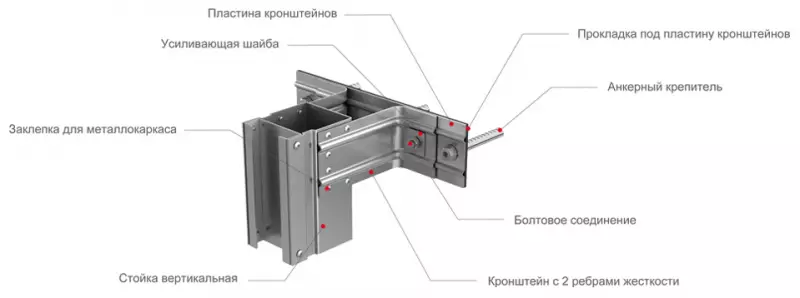

The system of fasteners includes carrier profiles, brackets, anteric elements (dowels and screws), special fasteners. The use of brackets for ventfassada makes it possible to adjust the distance between the frame and the wall, so that there is no need to align the surface of the walls;Article on the topic: Nutrition curtains in the interior - advantage and photos

Despite the fact that the fasteners system is not visible, this is not a reason to save on its components. The composite elements account for the main load: on the weight of the facing material, from the strength of the wind and the movement of the air flow. Therefore, all materials used must comply with the quality of standards.

Framework for ventilated facades

Several species of frameworks are distinguished:

a) depending on the material:

- metal carcass . It consists of elements made of metal. Almedy aluminum, galvanized and steel subsystems. At the same time, the horizontal elements on which the main load accounts, have a thickness of 1.5-2 mm, and the vertical is 0.5-1 mm. This reduces the load on the facade of the building, while maintaining the carrier properties of the carcass itself. Metal frame is required when using severe facing materials, such as stone (ventfassad of porcelain stoneware);

- Wooden frame . It is a system of timber 50x60 mm and rail 20x40 mm. Applicable for light facing materials, but needs protection and requires additional processing that prevents wheels from rotting;

- Combined carcass . Combines the advantages of both systems. In this case, the main system is metallic, and the counterclate is wooden.

b) depending on the configuration of the profile

Subsystem for ventilated facades:

- L-shaped subsystem . Different with the fastening of two ribs of stiffness on the bolted joint. The bracket allows you to align the surface of any curvature. The maximum possible distance from the wall is 380 mm. The only drawback is a high price;

L-shaped profile for the subsystem of the ventilated facade

- U-shaped subsystem . It is characterized by a profile with four rigid ribs - it is also reliable, but more complicated in the installation. In favor of this system, its cost says.

U-shaped profile for the subsystem of the ventilated facade

The Ventfasada subsystem must meet such requirements:

- corrosion resistance;

- High bearing capacity;

- ability to withstand static and dynamic loads;

- The possibility of levetling the curvature of the surface of the facade;

- Easy and higher, compared to other ways to cladding, mounting speed.

2. Insulation for ventilated facade

The thermal insulation material is not a mandatory part of the ventilated facade. If the task of additional insulation is not set, but only the protection of the front surface of the outer walls, then the insulation does not apply. But it is rather an exception than the rule.In the overwhelming majority in the arrangement of the system of the ventilated facade, thermal insulation material is established.

Theoretically, any insulation can be installed under the ventilated facade. But, the main requirement that is put forward to the insulator is that it can provide passage from the room. Traditional tough insulation, such as foam or polystyrene foaming, do not meet this requirement (especially in the case of fire, they distinguish the harmful substance - styrene). Therefore, preference is usually given to soft insulation - basalt car, less often glass.

Note. An excellent solution for use in the ventfassad system is the installation of mineral wool with a double density. Such material on the one hand has sufficient parpropuscular ability, and on the other, the required stiffness reserve.

As an example, Rockwool products can be brought (Russia, Poland or Denmark). The plates from the stone wool VATTS D BATTS D (two-layer insulation) have a density of 90/45 kg / m. Cube (90 for the upper layer, 45 for the lower), and the facade of Batts D optima - 180/94. The cost of Valtts d (100 mm) comes from 2,283 rubles / m.Kub, the cost of the facade of Batts D Optima from 2 205 rubles / m.Kub.

Basalt wool can be attributed to the number of basalt wool: the ingredibility, the stability of the shape, ease of installation, resistance to the wind, immunity to biological factors.

3. Film for ventilated facades

The use of steam, hydro and windproof films allows you to additionally protect the insulation from the exposure of moisture, which is contained in moving between the facing material and the air wall, as well as from the wind pressure. The wind film is rarely applied today, because To change, she came new progressive materials - superdiffusion membrane and geotextile.

The membrane refers to synthetic semipermeable films that are able to regulate the properties of diffusion.

Geotextile (construction) is a synthetic polypropylene web (less often polyester), which reliably protects the insulation from destruction. In addition, it is resistant to high and low temperatures, the influence of chemicals, is durable and is a serious barrier for different animals and bacteria.

A distinctive feature of these materials is one-sided vapor permeability. On the one hand, they effectively dismiss the pairs, which comes out of the room through the insulation, while allowing it to exclude its wetting. On the other hand, they are protected from moisture from the outside (atmospheric precipitation).

What is the membrane for Ventfasada better?

Among the recommended by professional assembly companies, membranes can be allocated:- Izospan, Russia (density 64-139 GR / M.KV., Price - 1,500-4 500 rubles / steering wheel. 50 mp);

- Juta (Utah), Czech Republic (density 110-200 gr / m.kv., Price - 1 359-6 999 rub / Rul. 50 mp);

Also positive geotextile reviews

- Duke, Russia (Density of 80-230 gr / m.kv., Price 1 580-2 598 rubles / steering wheel. 50 mp).

Maximum vapor permeability rate for membrane> 1200 gr / m.kv / 24 h.

4. Air gap in ventilated facades

The air layer reports the ventilation properties of the thermos and protects the house from significant temperature fluctuations. Thanks to the air, the building cools slower in winter and heated in summer.

Council. For the effective and durable functioning of the ventfassada, it is necessary to provide conditions - air moving in the mounted facade system must overcome some resistance that create metal casing or plates.

Air direction under the ventilated facade

What is the clearance of the ventilated facade should be?

As a rule, the size of the gap is 40-60 mm, up to 100 mm, but the minimum maximum size is calculated for each case individually.If it is too small gap - it is possible to destroy the heat insulating layer (when the insulation is adjacent to the facing). As a result, the wall surface will worsch and collapse.

If it is too big a gap - the appearance of a hum (noise) is possible with a strong direction of the wind. This happens if the length of the brackets is incorrectly, as well as when using low rigidity wool as insulation.

5. Facing material for ventilated facade

The decorative layer of facing is the visible part of Ventfasada. Today there are more than two dozen species of finishing materials for the facing of the ventilated facade, which can be combined into six groups:

Materials under the stone:

- a natural stone;

- fake diamond;

- Porcelain stoneware.

Brick materials:

- pillage concrete under the brick;

- clinker tile;

- Full facing brick;

- Fibro cement panels.

Metal materials:

- Metal siding (metal);

- Metal cassettes and panels;

- composite cassettes and panels;

- Aluminum panels;

Plastic materials:

- Linear panels. Made from polyester. Act as finishing and insulation;

- Vinyl siding. The easiest installation material that has low weight, which allows you to install it on a wooden frame.

Tree materials:

- thermalvice;

- block house;

- Planken (wooden facade board);

- Porcelain stonework.

Glass materials:

- Glinders - made of shockproof glass. Allowed to provide a high level of natural lighting indoors and give the building a stylish look. But differ in high cost and complexity in the installation;

- Solar panels - a separate type of facing of a ventilated facade. It is a complex and expensive electronic system, so it is not enough in private construction.

Due to the variety of facing materials, the customer has the opportunity to implement any designer solution.

Device and principle of operation of hinged ventilated facades - video

Advantages and disadvantages of ventilated facades

Comparison of advantages and disadvantages for a number of parameters.Pros of Ventfasadov:

- elimination of condensate and dampness;

- Reducing the number of building material that reduces the cost of the house;

- performing effective building insulation;

- expanding the possibilities for decoration of the building;

- reduction of premises heating costs;

- improving the operational characteristics of the facade, its sustainability to external factors;

- Implementation of lightning protection function;

- Exception of overheating of the building in the summer;

- High mounting speed and maintainability.

Cons Ventfasadov:

- The need to conduct a survey of the technical condition of the supporting structures, in the case of installation of the ventilated facade to the operating building (during repair or restoration, reconstruction);

- strict requirements for the quality of installation and qualifications of specialists performing work;

- lack of standards for work on the installation of Ventfasada;

- The presence of weak places in the design of the "Cake", which leads to a violation of fire safety requirements.

Due to its advantages and contrary to disadvantages, the ventilated facades gradually displacing traditional ways to finish buildings.

Article on the topic: Autumn Cart: Several ideas for crafts from natural materials