How quickly children grow! You do not have time to look back - and already the baby turned into a teenager, who was small baby cot. There are several options to cope with the problem. The easiest - go to the furniture store and purchase a new bed. But if the children's room has a non-standard layout or dad has certain skills, the bed can be made independently.

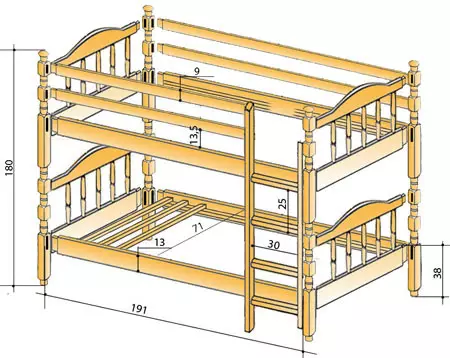

Drawing of a bunk bed.

By the way, to participate in this process you can attract the child himself. In particular, it concerns boys. Especially since today the construction market is ready to offer not only materials for the manufacture of furniture, but also a beautiful and high-quality fittings for her. There you can also cut wood or chipboard on the workpiece, in accordance with the drawings, or do it yourself in the presence of an electrical ruble or jigsaw.

Before proceeding to the manufacture of the bed with your own hands, it is necessary to conduct preparatory work. And you need to do it with great care and attention. After all, the final result will depend on it. Drawing of the bed with your own hands to avoid mistakes, you can do yourself or ask for help to someone who has already had experience in the production of furniture.

After the model is designed, the drawing of the bed is drawn up - you can proceed to the calculation of the required material and related parts and fasteners.

The most rational to perform a bed with drawers downstairs to store sleeping facilities in them. Chipboard sheets should be laminated. Compared to the usual sheets of chipboard, they are capable of not deforming, to withstand loads, ensuring the rigidity and strength of the structure.

Used tool

- Electric jig or disk saw;

- Electric choke;

- screwdriver;

- roulette;

- pencil;

- Rule or square.

Back to the category

Preliminary work

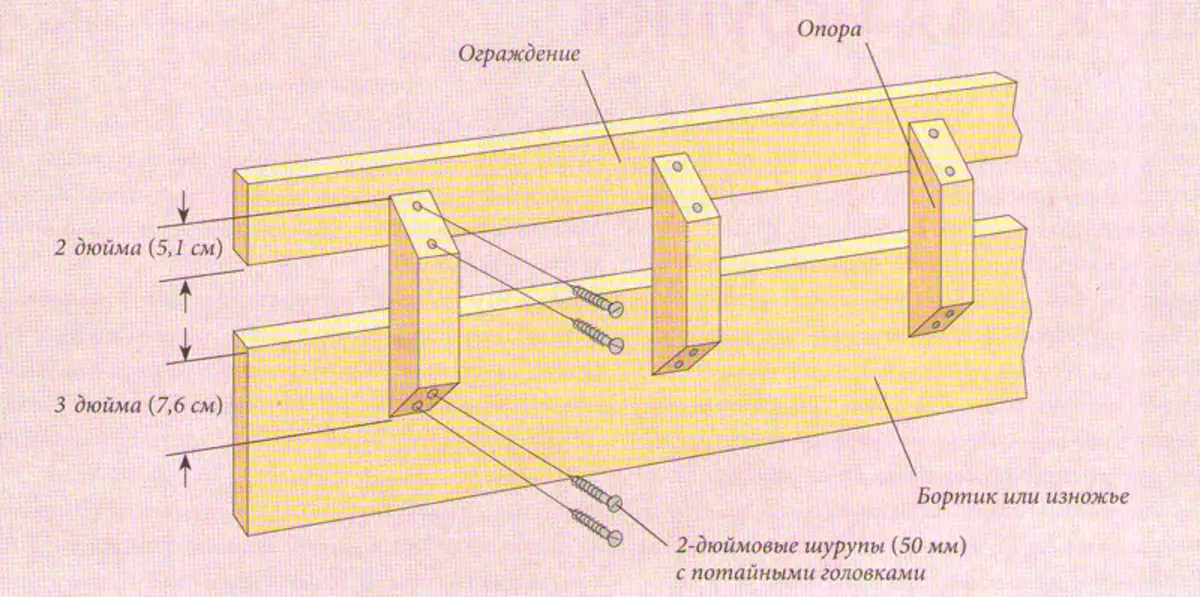

Scheme side of bed.

If you plan to make an additionally bedside table together with the bed, more expedient to immediately buy the material for it, so that you never had to look for exactly the same shade. This saves not only time to search for material, but also money for delivery.

So, sheets are delivered. You can begin to the next step - we will cut the material in accordance with the scheme. This can be done in a specialized workshop or at home - by means of an electric jigsaw or disk saw.

For the finishing of the beds of the bed use self-heartable edge. Despite the fact that this method is not high-quality enough and cannot provide high strength, it is very popular with homemade masters, as it is characterized sufficient simplicity and low cost. The edge gluing technology is as follows: the self-adhesive edge is superimposed on the end of the part and through the sheet of ordinary paper is stroked the hot iron. Thereby gluing her surface. Surplus are trimmed with a sharp knife.

Back to the category

Design elements of bed and strengthening its design

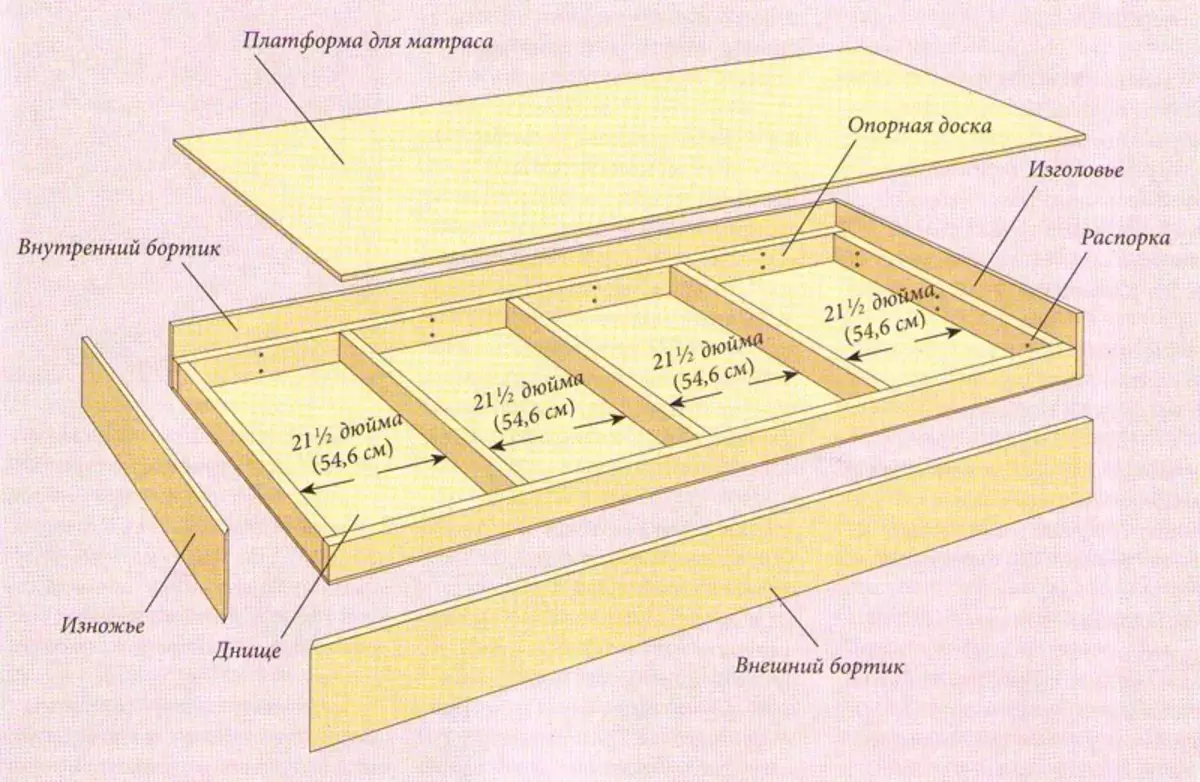

Bed pallet diagram.

For the design of the full bed, which is located at the head of the head of, use another method. After all, it must have an attractive appearance. It is discharged by a P-shaped profile made from PVC, which is glued with "liquid nails".

Of course, chipboard sheets are excellent material for the manufacture of furniture. If you walk on furniture stores, it can be noted that this is the main material from which the furniture today is produced. But as for the bed with their own hands, its design requires strengthening. It is produced by means of a frame made of wooden bars around the perimeter of the bed. In the middle perform the ribbiness.

If the teenage bed is manufactured for the girl, then it is not necessary to strengthen it with the crate. To do this, use the usual chipboard, carved around the perimeter.

Article on the topic: Surface pump for dirty water: centrifugal, self-priming unit, species, price

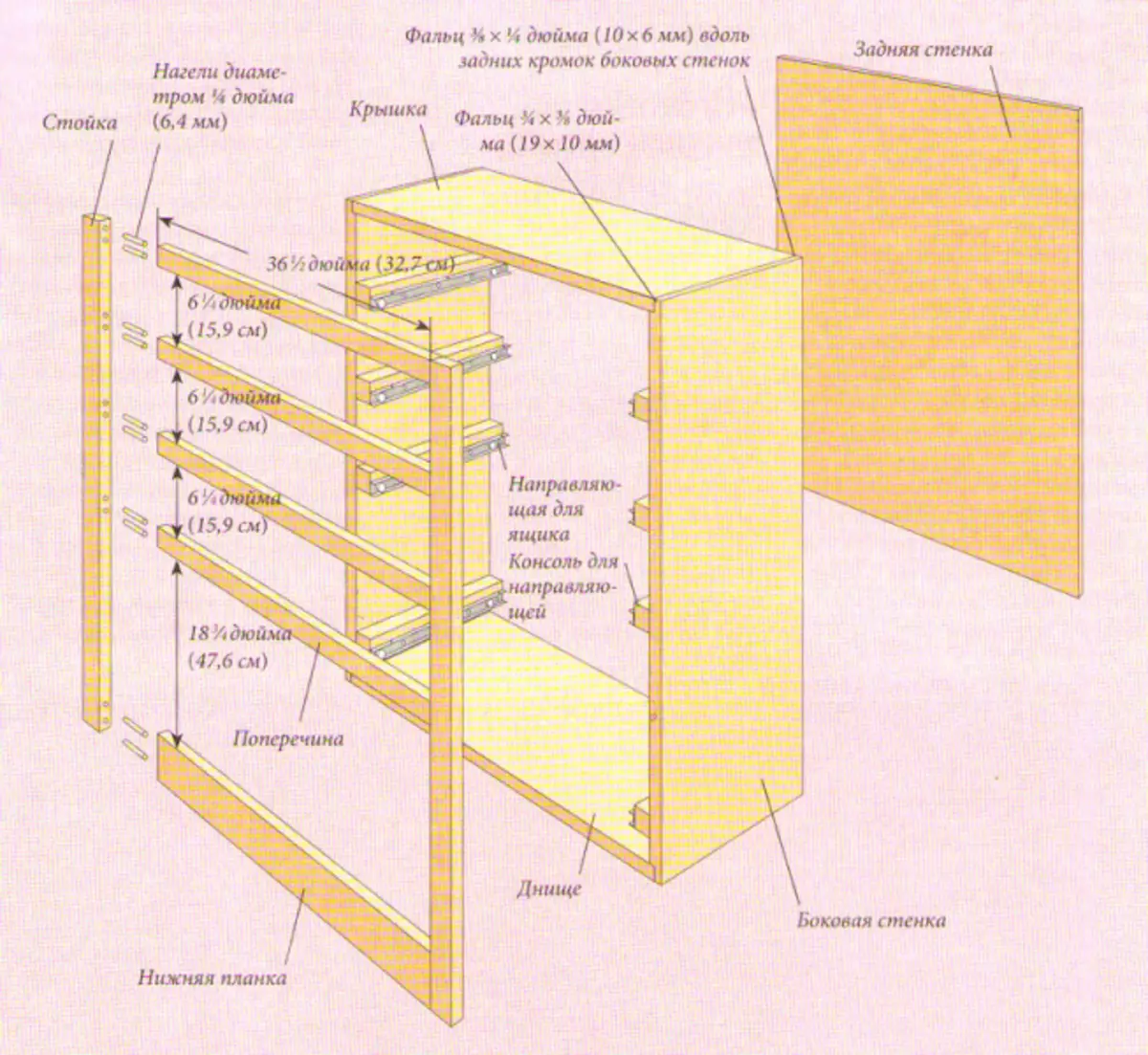

Bed frame circuit.

Frame and bedside bed is made according to the drawing. The DSP slabs are attached to the frame, equipped with spyers that play the role of legs. The fastening takes place with the help of euro-shop or ebolovints, which are used as a single element screed for chipboard sheets.

Similarly attach to the fireworks of the aircraft and facing material. They are also playing the role of a bed for bed. Bylts, the bottom of which is at the level of the legs, take part of the load.

At the bottom of the beds make retractable boxes, so the facing of this part is narrow. In the boxes you can store bed linen or personal teen things. They make them from the same material as the bed itself - from the laminated sheets of chipboard. For convenience, roller guides are used for convenience of drawers. So that the dust does not get into the box, its upper part is placed below the facing level.

So, the bed is practically made. It remains only to insert boxes and put the mattress!

Back to the category

Bunk Bed Design for Teens

Bunk wall diagram.

Very often a teenage bed is performed by a bunk design. The principle of its manufacture is similar to the first option. However, there are some features. First of all, it concerns where the bed will be located. It depends on which side it will have a ladder to the second floor. From this side you will have to add about 45-50 cm to the dimensions of the structure.

Much attention should be paid to the bed height. It all depends on the height of the ceiling and the distance between the first and second tier. It is necessary to take into account the height of the lower tier, as it should be convenient to sit, and under its bottom so that you could put something.

If the bed is made from the boards, it is necessary to purchase a material of different sizes, for example, from a whiteboard size of 18x140 mm2, you can make a crate on which the mattress will be located. Of the same material, a bed is made for the second tier.

Article on the topic: Creep the floors: what to do, without disassembling, expert advice

A 30x30 mm2 bar is enough to arrange lying on it.

The ladder and sterns for a mattress can be made of 40x80 mm2 size. Lower side can be made removable.

And finally, the most massive detail of the design. Its size is 40x140 mm2. With it, the entire design is connected around the perimeter.

The technological process of manufacturing a bunk bed is similar to the manufacture of a regular bed.