Huge popularity conquer the heated floors. In private housekeeping with central gas supply, heating of pipes with hot water is particularly often suited.

The gas boiler supplies a liquid coolant into a system of pipelines built into the floor structure. Pipes for such systems are manufactured from several types of materials. Among them is drawn to the stitched polyethylene for heated floors. What is attractive for a warm floor of stitched polyethylene? This will be discussed in this article.

Types of pipelines warm water floors

Copper pipes the best thermal conductivity

Assembling equipment for warm water floors is a rather difficult job that requires the involvement of qualified labor. The heating contours are mounted from pipes made from various materials:

- stitched polyethylene pipes;

- metal-plastic pipelines;

- polypropylene systems;

- Pipes made of copper.

Each heating system has its advantages and disadvantages. Compare the crosslinked polymer with other materials for pipes in the table:

| № | Name of material | Dignity | disadvantages |

|---|---|---|---|

| one | Stitched polymer | Durable and durable material | Pipes are susceptible to destroying ultraviolet |

| 2. | Metalplastic | High flexibility | High price |

| 3. | Polypropylene | Low price | Pipes bend under heating |

| four | Copper trumpet | Universality, high thermal conductivity | The most expensive pipes |

What is stitched polyethylene

The shape of the pipes during bending is preserved due to the foil layerIn an inexperienced reader, the phrase "stitched polyethylene" causes an association with a sewing needle with a thread. In fact, this means processing polyethylene structure at the molecular level.

The polymer under high pressure "bombard" electrons. Freed molecules form links that flash the entire structure of polyethylene.

Article on the topic: Repair of the mixer for the bathroom: Causes of breakage and repair methods

Stitched Polyethylene Pipes

Thanks to polyethylene tubes withstand high temperature loads

For a heating device from a cross-linked polymer for warm floors, tubes of three-layer material are used:

- The outer surface consists of a monolithic polymer, which performs the functions of the frame;

- The middle layer is a laying of aluminum foil; Foil does not let oxygen and retains the shape of the pipe when it is bending;

- The most important inner layer consists of stitched polyethylene for a warm floor; It is due to him that the pipes withstand the heating temperature of more than 100 degrees and the internal pressure of up to 10 bar.

Advantages and disadvantages of stitched polyethylene pipes

Environmentally friendly material is not dangerous to health

Consider what advantages and disadvantages have pipes of cross-linked polyethylene for a warm floor:

Benefits

- High heat resistance. The polymer withstands the heating up to 100 degrees and more, keeping its properties.

- The polymer has the quality of the reverse shrinkage. Stitched polymer pipes rapidly restore its shape after exposure to deformation loads.

- Due to its elasticity, a pipe for a warm floor can be bent at any angle, while maintaining its integrity.

- The material is environmentally absolutely safe. Even with a strong heating, the polymer is not capable of harming the environment.

- Firms Manufacturers provide a guarantee for impeccable pipes from stitched polyethylene for more than 20 years.

UFO disadvantaged for such pipes

disadvantages

- The polymer "does not tolerate" ultraviolet radiation, so pipes are stored in conditions of complete darkness.

- Pipes are connected by complex fitting designs. The use of special fixtures will significantly facilitate the installation of warm floors from stitched polyethylene.

- The outer surface of the pipelines "very gentle" and "afraid" even light mechanical impacts.

Based on perennial tests concluded that the optimal size of the passing hole for the cross-linked polyethylene pipe is 16 mm.

Assembling warm floors from stitched polyethylene

A closed ring of pipelines for a warm floor is called a circuit. The length of one ring should not be more than 120 m.

Article on the topic: How to glue phlizelin wallpapers: Casting Corners, facing drawing

The optimal length of the contour was determined on the basis of thermal calculations.

In case of exceeding this length, the contour will not be able to provide sufficient heating of the floor.

For heating large areas, warm floors are arranged from several contours.

In the presence of experience in the work on the installation of sanitary equipment, arrange water warm floors from stitched polyethylene is quite possible with their own hands. See this video for details:

The device for warm floors from stitched polyethylene consists of several stages:

- Install a gas boiler. The unit is connected to the central gas pipeline and to the water supply.

- Install the collector distribution node.

- On the finished base of the floor, steel vapor barrier from the polyethylene film. The film is raised on the walls around the perimeter of the room at a level of more than the height of the future floor.

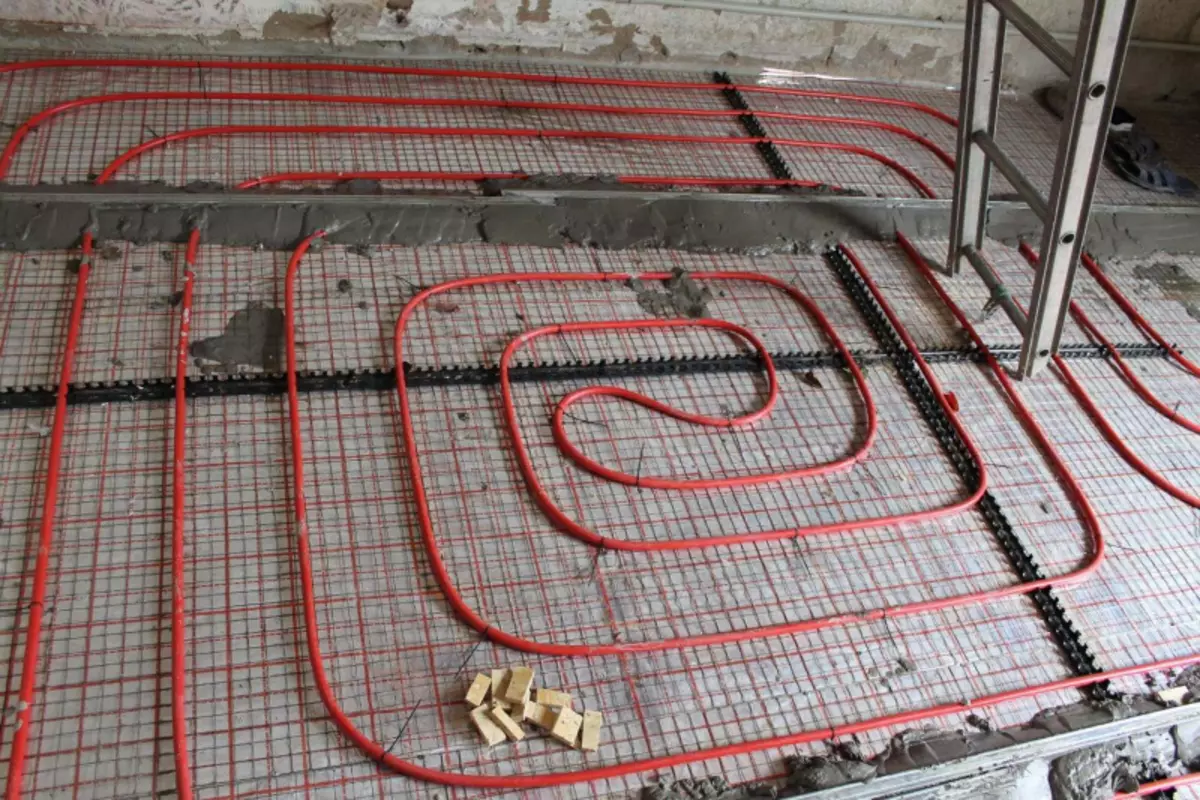

The hose is placed on the reinforcing grid

- Plates from the insulation (polyurethane, foam or other similar material) are placed on vaporizolation.

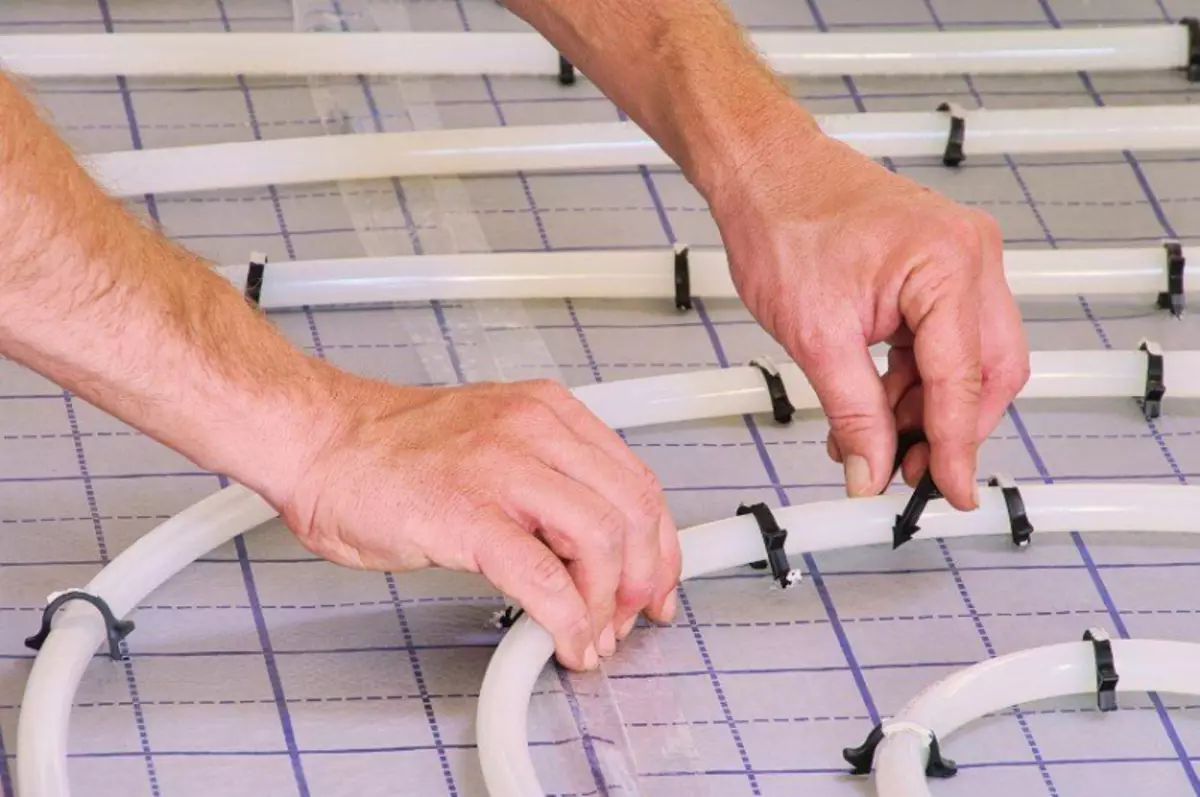

- Place a reinforced mesh made of metal or plastic wire.

- Enclosed hose from stitched polyethylene. Fasten it to the grid by plastic clamps.

- The contour is arranged from a solid cut pipe.

- At the ends of the pipe install fittings and connect them.

- Install the thermal sensor, connect it to the instrument of temperature adjustment.

- Compare pipelines. Feed water with a pressure of 1.5 times higher than the regulatory.

- If disruption is manifested, they are eliminated. Then the tests renew.

- After that, it is suitable for a concrete tie or fill the space with a dry fringe of a clay crumb.

Filling the space of floors with a labeling heated system of stitched polyethylene

Filling the base of the warm floor is performed in two ways:- concrete screed;

- Dry floors.

Concrete screed

Enough screed in 50 mm

The minimum screed thickness should be 50 mm. The minimum height of concrete above pipes in 30 mm will provide the maximum degree of heating of the floor.

In order for the floor quickly heated, and also cooled effectively, the screed thickness should not exceed 70 mm.

It is necessary to take into account the fact that the unlimited thickness of the screed can cause a threatening load on the design of the overlap.

1 m 2 ties with a thickness of the coating of 50 mm weighs 125 kg.

Device of stitched polyethylene pipes

Another important part of the installation of warm water floors is that in front of the device of the screed around the perimeter of the room on the walls are glued with damper tape. A strip thick of 6 to 30 mm provides a dense filling of the gap between the walls and the screed.

The adhesive tape in its size should exceed the height of the screed layer. The damper layer compensates for the increase in the area of heated concrete. For details on the floor of the floor, see this video:

If the floor area exceeds 30 m2, then the concrete base is separated into several sections, separated by deformation seams with a width of 10 mm.

Dry floors

The device of dry filling of warm floors from stitched polyethylene in the event of an emergency leakage of pipelines will avoid laborious work on sex disassembly.

Ceramzite sand can be easily removed. After repairing the pipes, the dried ceramic crumbs return to its place, so it is best to do your warm floor from dry fridge.

If you do not have experience in self-installation of warm water floor, it is recommended to provide this work to those skilled in the art.

Article on the topic: Storage boxes do it yourself