Retractable (sliding, sliding) gates are a more technological alternative to swing. Make a gate with a retractable mechanism more difficult than swing, but the convenience of operation and appearance will indicate a modern private house.

Before dealing with how to make a rollback gate from a professional flooring, you need to consider which the types of device are and traced the evolution of their formation.

Types and types of retracting gates

Device and design features of mechanisms and installation methods.By way opening:

- Sliding doors - Consist of two sash, which are departing in opposite sides. Visually similar to the swollen and combine the advantages of swing and sliding gates;

- sliding gates (Self-supporting) - consist of one canvas (rarely two) that are departing in one direction.

Device of sliding and retractable self-supporting gates

The main advantage of the retracting gate - no free space is required for operation. Among the advantages are the ability to connect automation, more modern appearance, sliding ease even if there are snow.

According to the degree of mechanization:

- Hand rolls (Mechanical opening of the gate). Move the sash of the sliding gate is absolutely easy. Going to make a rollback gate with their own hands, many prefer manual rollback of the gate;

- Automatic rollback . When designing and installing the gate, the need to supply electricity and the installation of additional mechanisms is taken into account. Automation for the retractable gate consists of: remote control, electric drive, electric cabinel, photocells, warning lamp.

By type of guide:

- Suspended type . In this case, the guide is installed on top, which limits the height of the gate;

- Console type . For the retractable gate of this type, the installation of the guide frame at the bottom of the structure is characteristic.

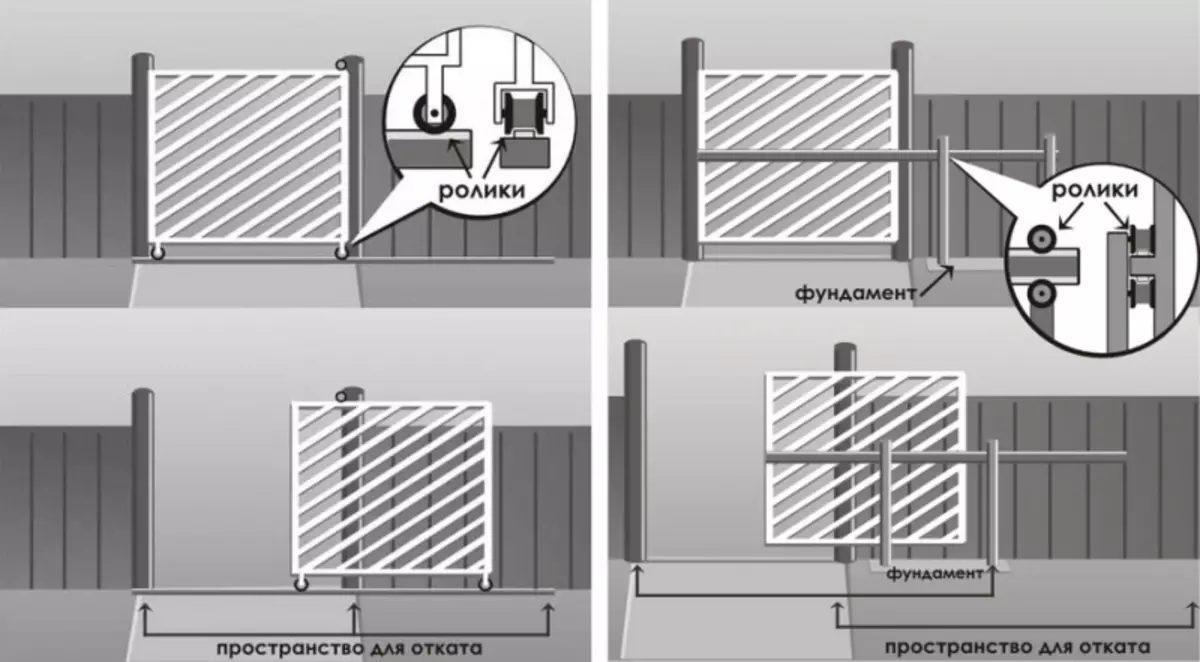

The simplest, it is the gate installed on the rail (Fig. Left). The option is simple, but not very convenient, because Behind the bottom guide requires constant care. Otherwise, the garbage that fell into the sled will lead to scorching of the rollers, and over time to damage the mechanism. A more modern version of the device is a sliding door with a floating rail (Fig. Right).

SCALE GATE OF THE SUSPENDING AND CONSOLE TYPE

It is on how to make a roll-out gate from a professional flooring on floating rails and will be discussed in the article.

Retractable gate from professional flooring with your own hands

Step-by-step instructions for the manufacture of sliding gates for the cottage and private house.

1 Stage - Draft Return Gate from Profile

The design of the retractable gate is complex, and therefore visualization is necessary, i.e. It is necessary to make a sketch or drawing.Sketch of the retractable gate from the professional flooring

Sketch is a picture showing the appearance of the gate, with the designation of the main elements, but without drawing size. From the sketch drawing begins design.

Sketch of the sliding gate

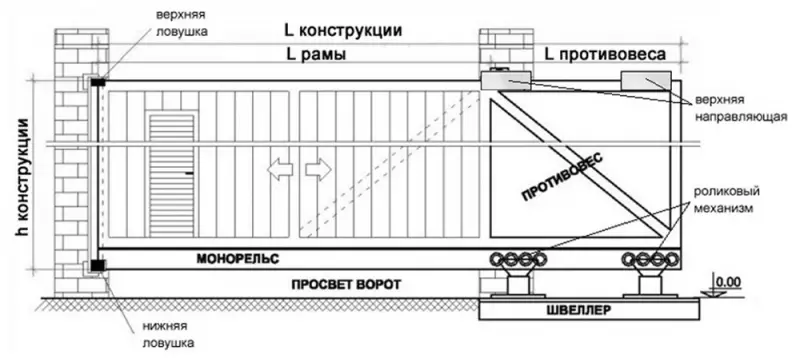

Scheme of a rollback gate from the professional flooring

A schematic drawing is something average between the sketch and the drawing, i.e. The picture that gives an idea of the gate and allows you to apply the sizes. The lack of a scheme is that the proportions are not withstanding. However, for those who do not own the skills of drawing - the scheme of the sliding gate will be a reliable help.

Scheme of sliding gate

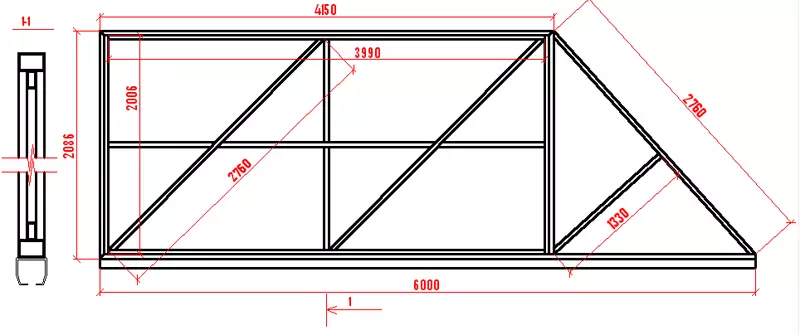

Drawing of the retractable gate from corrugated

The drawing is required to provide construction brigades when ordering services - turnkey installation. The drawing is a document in which the key parameters of the future gate are recorded: the width of the opening, the width of the gate and the counterweight, the size and location of the wicket, the number of sash, the specifics of the opening, additional elements, as well as all sizes.

Article on the topic: How to replace siphon in the kitchen?

Drawing of a rollback gate

Important. The wicket from the professional flooring is mounted in the gate sash, is thought out at the project development phase.

Stage 2 - Calculation of a retractable gate from professional flooring

For the normal functioning of the sliding gate, you need to correctly calculate the parameters of their main elements:Gate weight

The mass of the retractable gate has a direct impact on all carrier elements. The total mass consists of the weight of the frame, the counterweight (shank), the weight of the sheath, the weight of the decorative elements. If it is planned to manufacture a gate of a corrugated floor with an internal gate, the weight of the frame and the material of the wicket is taken into account. The weight of locks and automation is although not so significant, but they also do not need to neglect.

It is possible to reduce the weight of the carrier sash by arranging two sash. Those. Instead of sliding, make a sliding gate.

For example, the weight of the 4-meter gate, coated from the pipe with a cross section of 60x20, was covered with a profile on one side about 200 kg.

Polls for sliding gates

For support pillars, a metal pipe of large sections is suitable.Console length (rail or beam rail)

Length is determined by the width of the opening plus ½ of the length of the counterweight (shank). It is not recommended to reduce this parameter, because Rollback mechanism is rapidly. With the width of the gate of 4,000 mm. Console length will be 6,000 mm. Thus, the side of the fence to which the gate can be logged should be longer than 6,000 mm.

If the fence is shorter, you should make two shutters of the gate with two counterweights and automation sets. This increases the cost of the retractable gate, but will allow "fit" into the specified dimensions (the length of the fence next to the gate). Otherwise, you need to install the swollen gate from the professional flooring.

The counterweights in ¼ from the width of the gate is possible only when using roller console roller guide.

Council. If the entrance to the yard is located on a narrow street, it is advisable to make an opening and gate wider to provide a free place for maneuver.

The effect of the weight of the retractable gate on the parameters of the rail rail (console)

| Mass of the goal sash, kg. | Section of guide rails, mm. | Steel thickness, mm. |

|---|---|---|

| Up to 300. | 60x70. | 3.5 |

| 300-700 | 85x95. | five |

| 800 or more | 170x180 | 12 |

Section of beams (rails) for sliding gates

Furnitura

The harder the gate - the stronger it is necessary to acquire accessories. This will avoid its deformation and skew of the gate during operation.Automation

The more massive leaf of the sash, the more powerful you need to take automation. In turn, the automation for the retractable gate is selected taking into account the reserve in power. Therefore, buying must be added to the weight of the gate of 100 kg.

The effect of the weight of the retracting gate on the parameters of the electric drive (power)

| Mass of the goal sash, kg. | Power of electric drive, watt |

|---|---|

| Up to 300. | 250. |

| 300-700 | 350. |

| 800 or more | 500. |

3 Stage - Materials and Tools

We give data on the number of building material, for the manufacture of a rollback gate from the professionalist of 4,000 x 2,000 mm.Estimation on the consumption of materials and funds on the sliding gate device

| Material | number | Cost |

|---|---|---|

| Professional flooring * | 4 sheet 2 m.p. about 10 m.kv. | 150-350 rubles. Behind M.KV |

| Pipe 100x100, 4 mm thick. | 2. | 560 rub / mp. |

| Pipe 60x30, 2 mm thick. | 2 m.p. - 2 pcs. 3.5 ppm - 1 PC. 4 mp - 1 PC. 6 mp - 1 PC. | 153 rub / mp. |

| Pipe 60x20, 2 mm thick. | Depending on the location of reinforcing jumpers | 147 rub / mp. |

| Metal sheet, 2 mm. To enhance the frame. Installed in case of strong wind load. | Kosinki - 4 pcs.150 | 764.80 rub / m.kv. |

| For the arrangement of the nickname 150x150 | 2 pcs. | |

| Schweller, a length of 2-3 m.p. For installation on the foundation for the shank | 1 PC. | 300 rub / mp. |

| Selfless / rivets | 80 pcs / 130 pcs. | 1,25 rub. / PC. 0.3 rubles / pcs. |

| Paint for professional flooring | 1 PC. | 240 rubles per 1 kg. |

| Anticormer primer: GF-021 Lacra Phosphogrun Zinconal. | 1 PC. | 140 rubles / kg. 257 rub. / Kg. 463 rubles / kg. |

| Paint for carcass | 1 PC. | |

| Cement M 400. | 1 PC. | 200 rubles per 50 kg. |

| Sand | 85 rub. / 50 kg. | |

| Armature, Ø 12 | 20 mp | 41 rubles / mp. |

| Pens | Need if the drive is not used | |

| Hidden loops | ||

| Locks | ||

| The mechanism of the sliding gate | 1 PC. for rollback 2 pcs. For sliding gates | |

| Rollatk micro | Width opening 3 000 Sash weight up to 350 kg. | 7530 rub. |

| Alutech | Width open 4,000 The weight of the flap is up to 450 kg. | 150. |

| Came. | Width opening 4,500 Sash weight up to 700 kg. | 29330 rub. |

| Came. | Width opening 4,500 Sash weight up to 800 kg. | 33980 rub. |

| Automation AlUCh. | 1 PC. for rollback 2 pcs. For sliding | 25000 rub. |

Article on the topic: Little Kitchen Design

* Professor. The height is equal to the height of the flap, the width depends on the type. For the wall corrugated, the working width is from 1000 to 1190 mm. For the gate of 4 m wide. It will take 4 sheets with a height of 2 m. It is preferable to take a painted professionalist. The service life is much longer, and the look is more beautiful.

Complete gate components

Separately, let's focus on what elements includes the mechanism of the sliding gate. In general, it is accessories and automation.

Accessories for a rollback gate is a set (set) of elements that ensure the functioning of the door sash.

Complete gate components

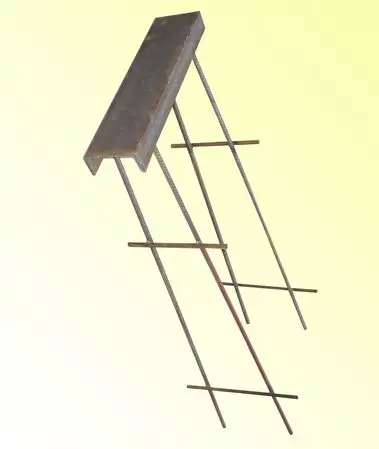

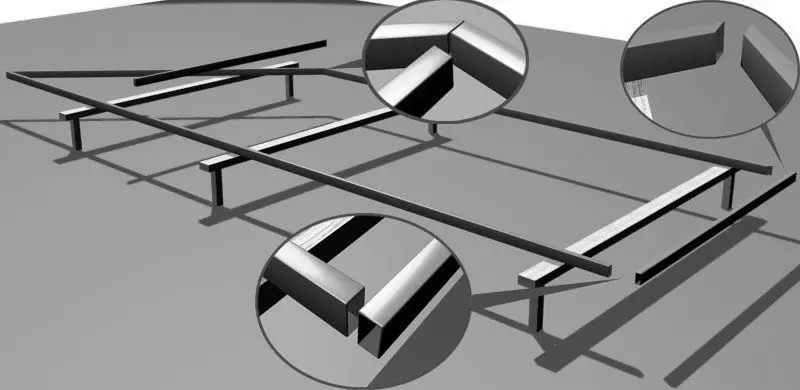

Tight gate beam (console or guide rail)

Sold in the amount of 6, 7, 8 m.p. The guide beam is welded to the carcass pipe from below. Inside the console are placed guide rollers that are responsible for the movement of the gate sash.Council. Buying a console, check about the warranty and pay attention to the quality of the metal, its thickness, geometry. Otherwise, the rail will join, and the goal sash community. The masters warned if in the cross section of the console beam for a sliding gate the square is a fake. The factory console is characterized by a complex geometric shape.

Rollers for sliding gates (roller carriages)

Mounted on top and bottom of the frame. The top roller holds the sash in the horizontal position, and prevents the rumble of the web. The lower support is mounted in the end of the console (beams). Support rollers are responsible for holding the sash in the closed position. And also, for preventing its savory and spontaneous discovery. Rollers are hardly fixed on the foundation.

Council. Rollers with a plastic envelope of good quality are more durable. In addition, they are devoured by rocks when moving the gate, and protect the base of the roller from damage.

High-quality material for the rollers is considered intrestable plastic or chromovanadium steel. But most of the quality affects the manufacturer.

Catching machine for a rollback gate (Upper and bottom catcher)

The catchers take the gate frame when closing. Also are designed to hold the sash from sagging.Plugs for guide beam

Plastic plugs are installed at opposite ends of the console.

Automation for sliding gate

Selected on the basis of the technical characteristics that the manufacturer indicates. Includes a drive that can be several types:- belt drive - relatively cheap, but the belt is quickly wearing, it can burst from the temperature drop;

- Chain drive - just more expensive, but the chain is prone to sagging and requires care;

- toothed - the most reliable. The gear rail ensures that the gate will not open from outside, but at the same time, they will not open if the electricity is turned off. Automation with gear drive can be installed on the gate with a gate from the professional flooring.

Council. Masters recommend buying a gate mechanism in a set. It is easier to choose a complete set and take into account his carrying ability. Good reviews about such manufacturers: CAME (Italy), Rolling-Center (Italy), Doorhan (Russia), Roletek (Russia).

4 Stage - Installation of a rollback gate from professional flooring

Installation of the gate of the retractable (sliding) type with your own hands without automation

Foundation for gate

The foundation is poured under the shank.

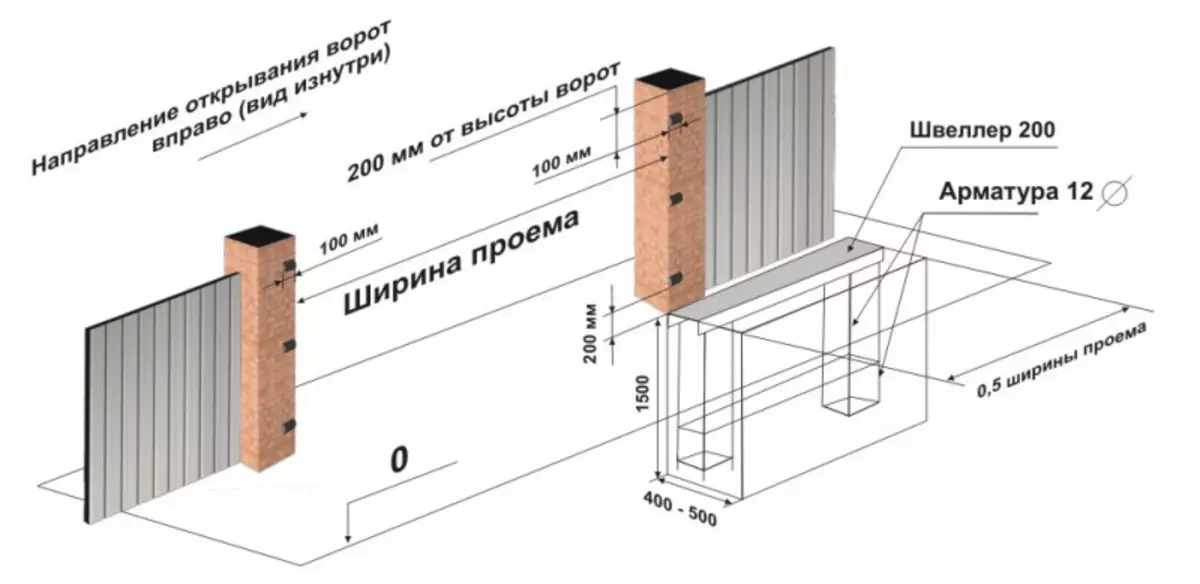

Scheme of concrete gate concreting

The channel of 200 mm is stacked close to the post, and the channel 160 mm is laid with an indent of 50 mm from the support pillar.

Installation of mortgages in the posts is performed "flush" with brick masonry (facing of support pillars).

How to make a foundation for a sliding gate

To correctly fuel the basis, you need to perform a number of actions:

- Prepare the soil (remove the top layer of soil);

- Drop the trench. The depth and width is 500 mm, the deepening length is ½ width of the gateway. For a sash width of 4 m.p. Need a trench 2 meters long;

- Drive two holes that are designed to install support pillars. The drilling depth is 1/3 from the length of the pipe, usually it is 1300-500 mm. The width of the well depends on the reinforcement. It is recommended that the diameter of the well 2.5 times exceeds the diameter / section of the pipe. The result of earthworks will be the P-shaped deepening;

- Make a sandwicted pillow in recesses (at the bottom of the pillars). Failure height 50-100 mm.;

- pour concrete solution;

- Upon the bottom of the trench (between the support pillars) to equip a sand-chick pillow;

- associate and lay the reinforcement;

- concrete.

Article on the topic: How to sew pipes in the toilet plasterboard do-it-yourself

Mortgage foundation from a chapellery for roll back tangle the second option of the foundation device for a sliding gate - using a chapellery. This is the so-called mortgage foundation.

The method also involves taking the trench and vertical well. But in this case, in addition to the reference pillars, the reinforcement is stacked in the wells, welded with a channel that will perform the function of the foundation, and on top of the construction concrete.

Council.

The fill level of concrete should be the coincidence with the slave level. Otherwise, water will accumulate in this place. Materials prepared for the site www.moydomik.net

While the concrete will be bought, you can proceed to the manufacture of the frame.

Installation of a rollback gate - frame (frame frame)

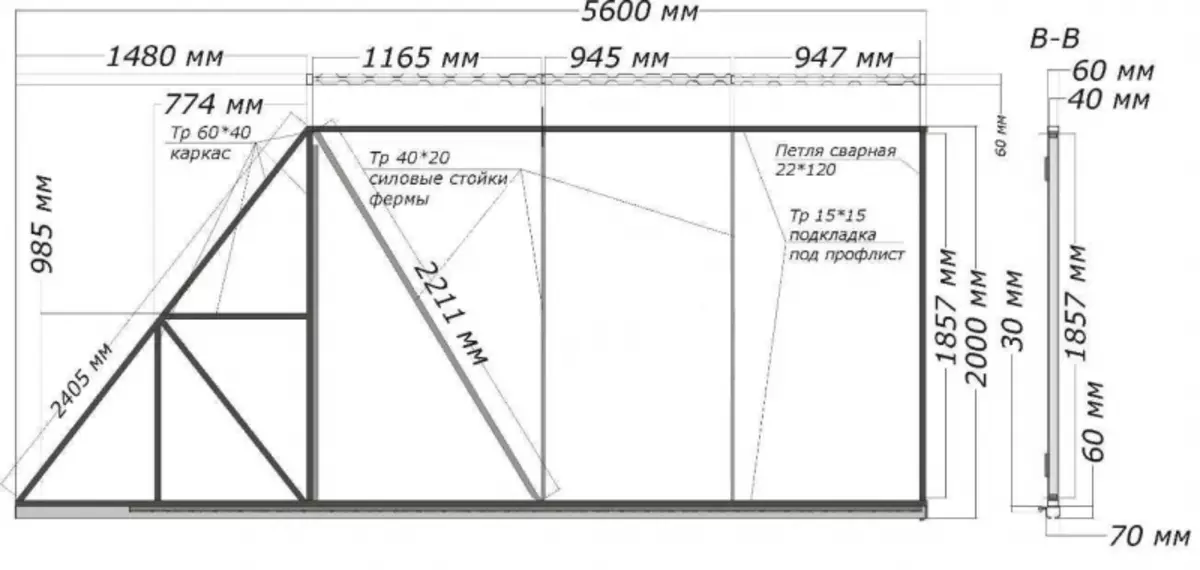

By configuration, the frame is one-sided trapezium.

At how the corner is connected to the profile of the rolling gate

Welding the corners of the frame for a rollback gate

How to cook frame (frame) for a sliding gate

- Cut metal blanks to weld the rolling gate frame. Note that the blanks forming a straight angle are welded at an angle of 45 °. Perpendicular - at an angle of 90 °. It means that they need to cut them accordingly.

Council. Newcomers who do not have greater experience in welding work, the masters advise to chop at an angle only those billets that will be located on top of the framework. So the water access will be excluded in the frame frame. Lower, you can weld at right angles.

- Clean iron blanks from rust, dirt, etc.;

- Cut together all elements according to the drawing. At the same time, it is necessary to ensure that the welding will be conducted by the "tiles", and not used the solid welds (it can be a story). In addition, with a point welding method, it is easier to dismantle the framework for repair or reconstruction ("points" are cut by a grinder).

Only after there is no doubt in the accuracy of the size and geometry of the structure, you can perform the final welding of a solid seam;

- Billets and welding places are grouped;

- Processing of primer against corrosion.

Making a frame for a rollback gate

Power Frame for Return Gate

If necessary, the framework additionally (at the welding stage) is enhanced by the longitudinal / perpendicular crossing or sheep - a steel sheet welded in the corners of the structure.

Power Frame for Return Gate

Council. The enhancement of the triangle that is formed on one side of the frame (shank) occurs by installing the rigid rib in such a way that the straight angle is divided by half.

Installation of beams for sliding gate

Console (guide) beam is welded to the bottom of the frame. Rubber plugs are installed on its edges. Without plugs in the console, the garbage will fall, which makes it difficult to move the movement of the sash on the guide rollers.Installation of fittings for a sliding gate

- A nachetner is mounted on the support post - a corner of 150x150 mm or a chamber;

- Slippers (upper and lower) are fixed to the nachel.

- On the mortgage foundation (installed channel) mounted rollers (retaining carriages). Mounted rollers as far apart from each other;

- A console is put on the carriage;

- pollizers are finally adjusted;

- Installation of accessories and / or automation (drive) is carried out.

Installation of professional flooring

The objects of the gate by the straight line is carried out in accordance with the installation technology.We recommend material on the topic:

- Features of the installation of professional flooring do it yourself

- Professional flooring and gate

- How to fix the fence

Installation of electric drive

Independent installation of automation for retractable gate is problematic, because Relevant skills are required. To ensure reliable operation of expensive automation at this stage, it is better to attract a specialist.

Gate

There are no difficulties in leaving the gate of the gate of the netting type. After all, rollers do not need lubrication, the console is protected from dirt sticking. And the slotted gate is good that they do not need snow cleaning for opening.

In conclusion, we note that the complexity and high cost of the project with interest pays off when the skipping gates made by their own hands are opening without effort and invite to enter the courtyard of the private house or cottage. In addition, the sliding gate eliminate the likelihood of slamming or disclosure of the wind at the wind (as it happens with swing), respectively, the sash will not remember the machine, and do not deform the fence.