Water floors are intended for a uniform distribution of heat in the room due to the circulation of hot water through the pipes installed inside the tie of the floor.

Warm flooring of metal-plastic pipes is a common and cost-effective option for heating apartments, private houses and public premises. For the pipeline device, it is important to choose high-quality material at an affordable price, as well as pay attention to the durability of the system elements.

Types of pipes for warm floors

Water Gender is most often used as an independent heating system. It is rarely mounted as an additional heating element.

Structure of metal-plastic pipe

Consider the types of pipes used in the installation of warm floors, their advantages and disadvantages:

| Types of pipes | Dignity | disadvantages |

|---|---|---|

| Metal plastic | • resistance to corrosion and influence of chemicals; • Low expansion coefficient; • The smooth surface provides good pressure; • service life of 40-50 years; • withstand water temperature up to 95 degrees; • Anti-oxygen defense guarantees from disconnecting elements from a compound with metal parts; • Pipes are easily bent, put them in the form of a snake will not be difficult. | • due to the difference in the expansion of aluminum and polyethylene, the pipe of low quality may be stuffed; • Fittings with thread can form screens; • With a strong fitting clamp, the pipe can burst. |

| Copper | • the highest thermal conductivity; • durability up to 50 years; • withstand water temperature up to 300 degrees, pressure up to 400 atm; • not afraid of rodents; • Not subject to corrosion. | • Complex installation, special equipment is required for connecting elements and work experience; • Connecting elements should only be from brass. |

| From stitched polyethylene | • Practically not deformed under the influence of high temperatures; • resistant to mechanical effects, abrasion, shrinkage; • service life of more than 50 years; • flexibility, freezing / defrost resistance; • Easily restore the form; • Do not crack under the action of internal pressure. | • The pipe does not have a frame, it is quite difficult to give it a shape, laying the snake; • In case of non-compliance with the laying technology, it is possible to damage the anti-infusual protection on top of the pipe. |

Metal-plastic pipelines for a warm floor are used more often than the optimal ratio for the price and quality.

All about metal-plastic pipes

Metal-plastic pipes are easy and do not waste the carrying construction

The structure of the metal-plastic pipe includes 5 layers:

- The inner layer is performed from stitched polyethylene. It ensures the preservation of the working form of the pipe when exposed to high pressure and temperature.

- The next layer is applied with a glue composition, which is fixed by aluminum interlayer to internal polyethylene.

- The aluminum layer is made of foil with a thickness of 0.2-2.5 mm, which is welded into the shape of a jack or brass tube. The thickness of the layer depends on the diameter of the product.

- Adhesive composition.

- Protective outer layer of sewn or conventional high density polyethylene.

Article Artificial Flowers in the Interior

Warm floor from metal plastic has a small weight. Pipes at the expense of their structure have good flexibility, which greatly simplifies their styling in the shape of a snake or spiral.

The durability of the adhesion depends on the quality of the adhesive, if the glue composition loses its elasticity, the product is smelted, and the leaks on the joints begin.

To check the quality of metal plastic, you need to heat it up to a temperature of 100 degrees. If the layers are viewed during heating, it means that low quality pipe.

Calculation of material

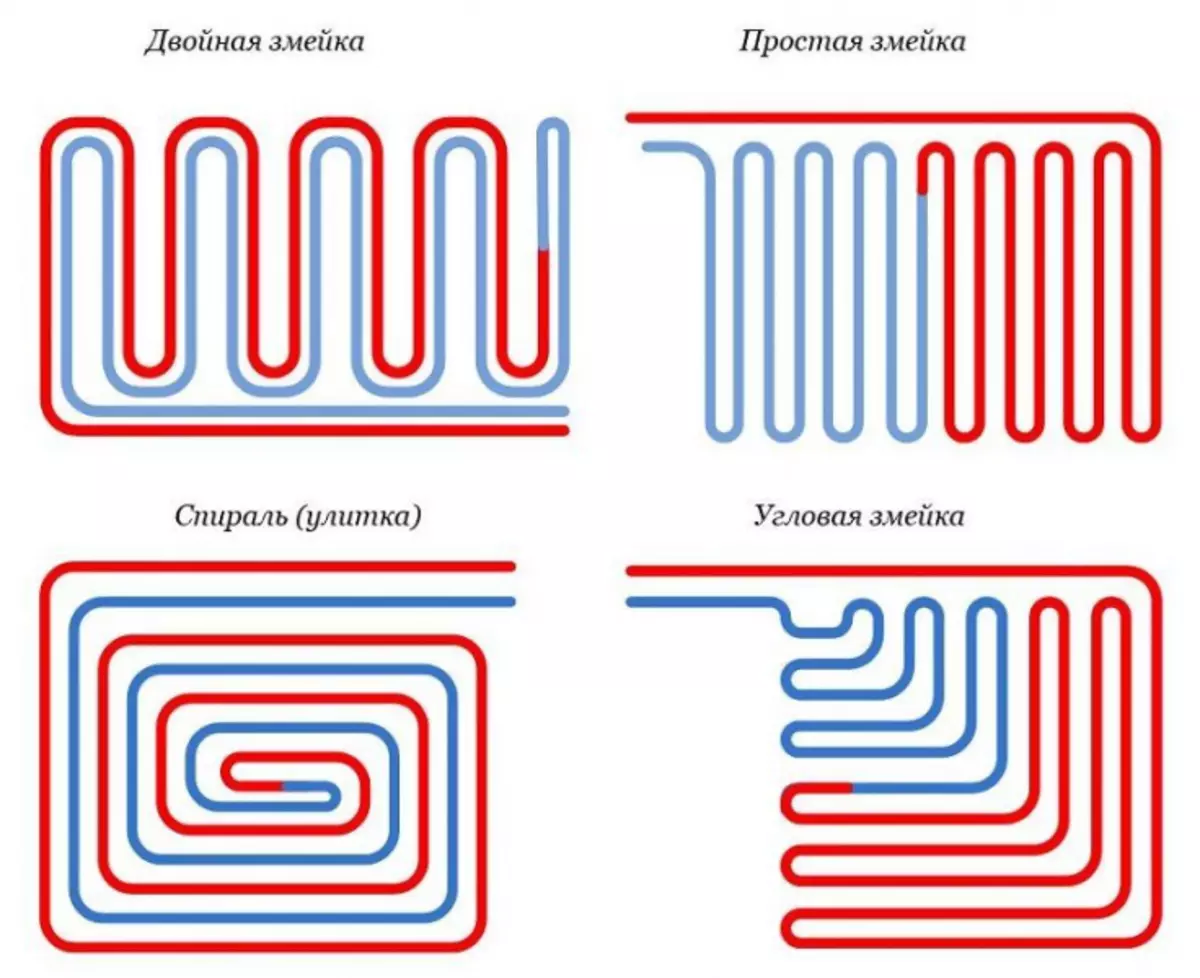

Before proceeding to the purchase of material, you need to correctly calculate the flow of the pipe, which will go to the warm floor. Metalplastic can be laid:

- spiral;

- snake;

- Double spiral.

Installation Snake is easier, but has a significant drawback. Hot water enters the pipeline on one side of the room, when driving on a snake to another part of the room, it gradually cools. As a result, one side will always be warmer than the other.

The contour stacked by a spiral warms the floor evenly

The installation of the helix contributes to a uniform heating of the floor, because The pipe from the insert goes to the middle of the room, then the spiral heads to the collector. There are fewer curves in this system, so you can use a pipe for a warm floor with a smaller bend radius.

Large rooms need to be broken into several sectors. For effective heating the length of the pipeline laid with a spiral should not exceed 60 m in each circuit.

Installation schemes:

When designing a warm flooring system, you need to think over the location of the pipe and select the most appropriate laying scheme.

Under the furniture and household appliances, the pipe is better not to lay.

The distance between the turns must be at least 30 cm

To calculate the desired amount, the diagrams of the pipeline location on paper. The optimal distance between the turns of 30 cm, if it is reduced, the floor surface will overheat, if you increase, the floor between the pipes may well heal. From the walls to the metal-plastic pipe, 150-200 mm retreat.

Thip the number of turns and multiply the resulting number on 2 (pipeline with cold and hot water).

Article on the topic: Cross embroidery scheme for free: download without registration, good quality Create, new schemes, photo fantasy

Then calculate the length of the pipe in the twist and add 10-15% about the reserve (for marriage and waste).

If you cannot calculate the length independently, you can use the ONLINE-miscalculator. For the program to give the correct result, you need to know such a pipe parameters:

- diameter;

- material;

- The thickness of the screed and finishing flooring.

The length of the pipeline in one contour should not exceed 120 m, the difference between the contours should not be more than 15 m. Also in the calculation the power of the pump is taken.

Materials for installation system

Thermal insulation will not give heat to dissipate down

In addition to metal plastic for a warm floor, you will need:

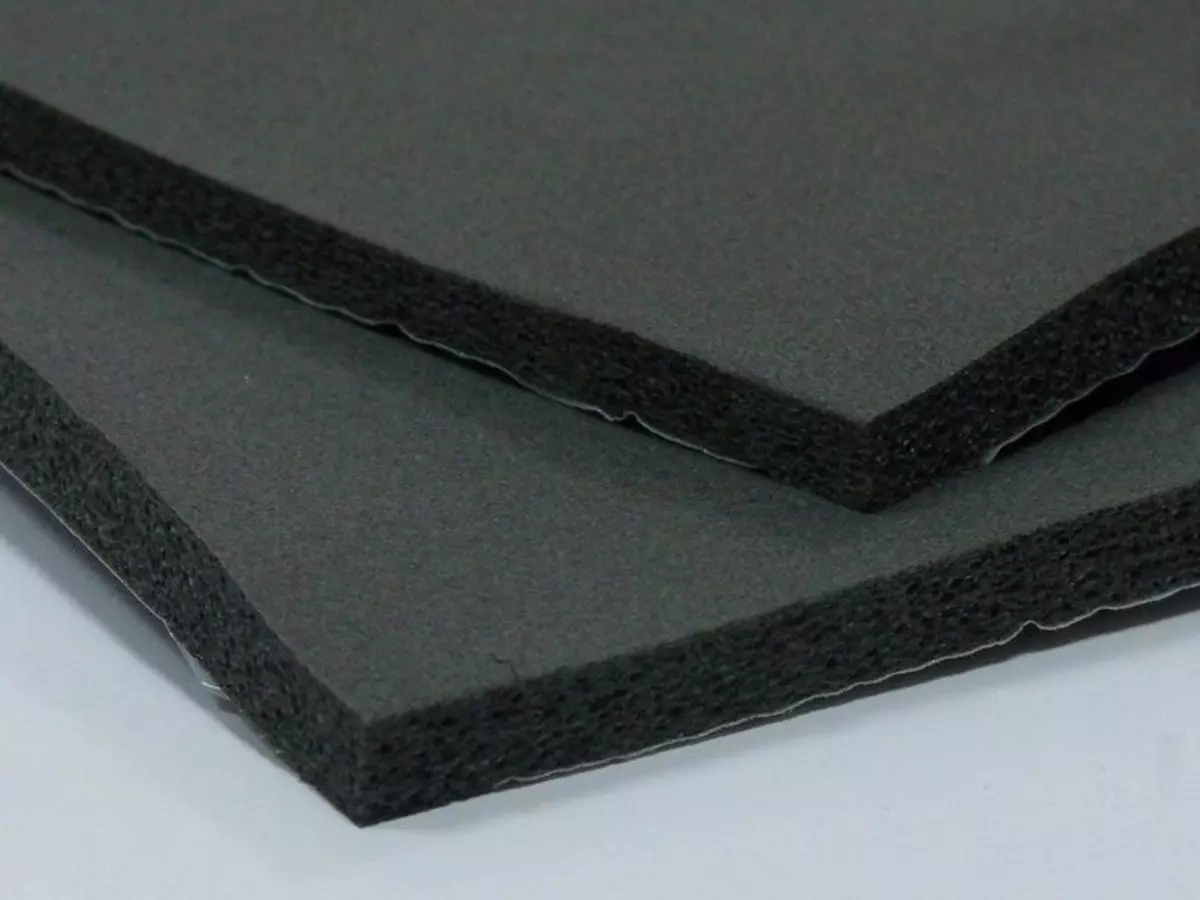

- Hydro and thermal insulation material will help maintain heat in the room, and not to give up the neighbors from the bottom. As a heat insulator, we purchase polystyrene foam, foam. Polyethylene film is most often used as protection of coating and moisture materials.

- To strengthen the concrete screed, the reinforcement grid will need.

- The damper tape passes around the perimeter of the walls, serves as a compensation seam when expanding the screed under the influence of heat. Protects the base of the floor from deformation and cracking.

- Clamps in the form of anchor for fastening pipes.

- If not in all rooms in the house, a warm floor system is installed, you need to buy a mixing node.

- The collector distributes the arrival of hot water into various circuits of the system. Water circuit installation secrets from metal plastic See in this video:

If the contours in a system of different lengths, the collector should be installed the coolant flow regulator. At the same time, we take into account that the long circuit is heated longer than the short, so you need to adjust the pressure and the degree of heating.

Installation of heating

Before laying a water heating circuit, you need to prepare the surface. All cracks and chips on the plate close in cement mortar. If the difference in the height of more than 5 mm is required to level the base. If you put the pipeline to the surface with a slope, an air stopper may form in the pipes. All stages of laying floor from screed to contour See this video:

For better grasp with concrete, we wat the surface with water. Then, to increase the strength, it is necessary to project the base in two layers.

Under water contour there must be metallic or metal-plastic fittings

System mounting sequence Heat floor:

- After surface preparation and removal from it, the dust along the perimeter of the walls glue the damper tape for the entire height of the screed.

- We are placing thermal insulation. If the material with a foil surface is placed in foil up.

- Estimate waterproofing material. When using a roll material, the bands are stacked by 15-20 cm, the joints fix the scotch.

- Mount the reinforcement grid, we will attach pipes to it.

- We carry out the installation of the cabinet for the collector and the distributor itself. In the closet, we bring the feed and return pipes to which the valves are installed. Connect the collector to the valve, we mount the drain crane on one side, on the other - the air shutter system.

- Connect the end of the pipe to the collector and put metal-plastic pipes for a warm floor, according to the scheme provided. The pipe clamps attach to the reinforcement grid. Fasteners have 1 m away from each other.

- Upon completion of the laying of the entire contour, we connect the second end to the collector.

- We carry out the system test, supply water pressure, 1.5 times higher than working pressure.

- If the system works correctly, the rusks and leaks did not occur, you can start the installation of the screed.

The warm floor is poured with a screed thickness 3 - 5 cm

- We mix the components according to the instructions until the homogeneous mass of the cream-like consistency. Pour the resulting solution with a screed on a thickness of 30-50 mm.

- We cover the concrete base with polyethylene, 1 times a day we watter from the pulverizer to avoid cracking.

- One month after complete drying, the screed can be commissioned a water warm floor system.

We carry out the screed using:

- cement-sandy solution in proportion 1: 3 with the addition of plasticizer;

- Mixtures for bulk sex.

The second option is easier mounted, has increased strength, but it is much more expensive than cement.

The pipe with a diameter of 16 mm is capable of drying around an area of 10-15 cm wide width.

The advantages of water floors

Two layers of screed will significantly raise the floor level

Like all other systems, water floors have drawbacks:

- Mounting complexity;

- A water pump is required to increase water pressure in horizontally located pipes;

- decrease in the height of the room due to several layers required for the installation of such a system;

- Not suitable for use in apartments, since due to such a system, water pressure drops in risers. For more information about the advantages and disadvantages of this design, see this video:

Most often, the water floor is used for the heating of private houses, in this case it fully justifies itself on durability and economic benefits.

It is best to attract specialists who will fulfill all the work, strictly adhering to the installation technology. They will help correctly calculate the consumption of materials and the step of laying pipes.

Article on the topic: Tips for finishing 6 m Loggia and balcony