During the construction of any building it is worth remembering that its foundation is susceptible to serious loads during operation. In addition to physical exertion, it is constantly affected by various environmental factors, which are by no means continue its operational period. Warming and decoration of the base is the ability to make the house with warm, durable, attractive externally and unique.

The base of the house is a very important part of the structure, so it needs to pay no less attention than the roof or walls.

Causes that encourage the insulation of the base

If you leave the base without insulation, the dampness and cold from the ground will penetrate into the house.

The foundation of the building is deepened in the freezle earth, in turn, concrete slabs do not prevent the cold hodge. In winter, concrete freezes, and in the summer - it is rare. Systematic temperature drops lead to rapid destruction of the structure. In addition, the lower part of the residential building constantly penetrates the coolness.

In the rooms of the house, the air is heated with a stove or heaters, warm air masses become easier, warm, rising up, penetrates freely through the rods and ceiling floors, in case they are not insulated. In the absence of insulation and cladding the base, the cool air will penetrate the house and displace warm.

In the meeting place of two air flows will certainly be condensed by moisture. As a result, water droplets will appear on the floor, in the basement of the house. As is known, excessive humidity is the reason for the spread of fungal organisms and mold.

Insulation for the base and requirements for them

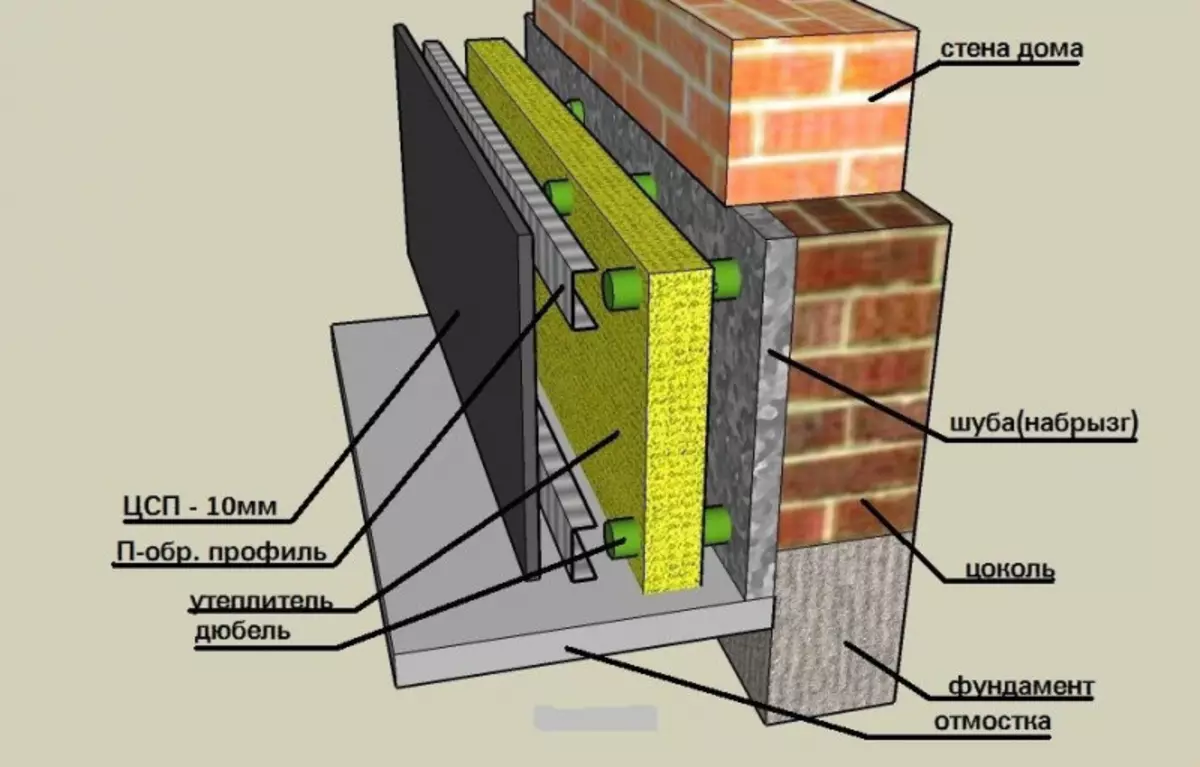

Circulation insulation scheme.

Choosing a heater for the base, it is worth a preference to the material with strength, resistance to mechanical loads, the minimum ability to hold and absorb moisture. Not the last place in the choice occupies an indicator of frost-resistant and security for a person.

Article on the topic: Restoration of the enamel of pig-iron bath do it yourself

Extruded polystyrene foam, rigid polyurethane foam, liquid bitumen tires, polyurea, is responded to all of the above qualities.

The insulation of the base performs the function of the heat accumulator and guarantees comfortable accommodation at any time of the year, allows you to preserve the temperature in the range from +5 to + 10 ° C without additional heating of the structure.

The thermal insulation increases the wear resistance of waterproofing, prevents mechanical damage, protects it from aging and deformation when the soil is freezing.

Installation of insulation on the external perimeter of the base

To carry out the insulation, the base of the house will need:- set of spatulas;

- toothed spatula;

- Construction rule and marker;

- brush for painting or roller;

- a hammer.

Before insulating the base, it is important to clean the surface from impurities and dust, to be primed up with a deep penetration with a composition. Waterproofing is carried out after complete dying of the primer, this time is indicated in the instructions for the compositions. In order for the insulation of the surface to take place as quickly as possible, perform in advance by cutting the foam.

The point of installation involves the application of special glue on the layer of plates of extruded polystyrene foam from above the insulating membrane of the base. A profiled membrane is placed on them, whose task is to protect thermal insulation and perform drainage functions for removal of groundwater from the walls. For the base of the house, experts are recommended to sweeping the soil necessarily to cover the filtering layer of geotextiles. In order to minimize the loads that are associated with the fruit of the soil, insulate the concrete breakdown and the horizontal plate of the foundation around the perimeter of the house.

A protective geotextile is laid on the prepared sandy pillow, the gravel layer is laid and arrange concrete preparation of skinny concrete. The waterproofing membrane (bitumen-polymer) is placed on the plates, and the seams are welded.

In order to warm the base of the house with high quality, several layers of plates of extruded polystyrene foam plates are placed on top. Sheets are tightly pressed to the surface of the base, and the formed joints are scrupped with adhesive composition. The appears of the gaps are eliminated by the mounting foam. After installing several sheets, they are strengthened by a dowel. After completing the installation of all the plates, set the slope. The technology of its attachment allows the use of the same glue as for foam.

Article on the topic: How to put a linoleum on parquet or on an uneven surface?

To protect the insulation slabs from the penetration of cement milk, which prevents the adhesion of concrete and has a negative effect on strength, in the fields of joints over thermal insulation, a polyethylene film is necessary. A reinforced screed is satisfied on top of it.

Subtleties of insulation base

Proper waterproofing of the base must be carried out in compliance with a number of mandatory requirements.

- Warming should be carried out at a temperature of at least + 5 ° C, so that frost appears on the surface of the glue for foam or plaster, which significantly affects the quality of insulation.

- The technology using polystyrene and mineral plates involves mandatory preparatory work on equalizing and eliminating cracks and surface defects.

- Material for insulation should rise above the level of the house of the house approximately 10-20 cm.

- If the design of the base is provided by the presence of beads, it is necessary and in the insulation to make holes for them.

Selection of finishing material for socle

Having completed insulation, you can move to the trim of the base of the house. The modern building market offers various natural and artificial materials for cladding.

The base, decorated with natural stone, not only harmoniously look, but also protects the building from getting cold.

Facing can be carried out by sea or river natural stone (large pebbles). Natural stone is inherent in good waterproofing and high strength that have become the result of constant interaction with sea or river water. Waterproofing makes it difficult to transmit melt and rainwater stones. This finish has a rather attractive and interesting texture, gives a wide scope for fantasy.

The category of natural materials also includes finishing with dolomite and granite. They combine texture and color with other facing materials: decorative plasters and facing bricks.

A good and inexpensive finish option will be rectangular or broken sandstone blocks. An additional benefits of material include an extensive selection of color shades. It is worth considering that the cladding of the base of sandstone (as well as other limestone rocks) is not as strong as dolomite or granite. If you still decided to bind the base of sandstone, take care of the use of special water-repellent impregnations.

Article on the topic: Self-elected bulk sex with your own hands: Preparation and fill of the solution

If the chapter is worth the issue of savings, you can pay attention to siding and tile from porcelain stoneware. Plastic siding for the base has the maximum external similarity with natural finishing materials. Facing is carried out due to the iron frame, and in an empty space between the basement and siding, a heater is placed or a waterproofing coating. Plastic siding decoration does not require additional care, which is another advantage.

The base of the house can be protected not only by synthetic and natural solid-state products, but also liquid paint-based compositions based on acrylic resins. They are able to protect against external influences of atmospheric phenomena and have excellent waterproofing properties.