Modern methods for processing plywood and wood allow you to create exclusive structures affecting your beauty and originality. Laser cutting plywood opened the possibility of making very complex designer products. These can be various lattices for decorating window openings, doors, inserts in furniture facades, elements of suspended ceilings, internal partitions. Such plywood products will harmonize both at home and in the interior of hotels, restaurants, bars, shops, clubs.

Laser cutting of plywood of different wood breeds differs among themselves at the temperature of the beam and the degree of pond.

Features of Laser Plywood Treatment

Cutting plywood with a laser refers to the most advanced methods for processing sheet materials. Unlike traditional cutting with manual or electric jigsaw, the laser cutting of plywood allows you to achieve a minimal consumption of material, perform the most complex forms and patterns, jewelry detail. This became possible due to the very small thickness of the laser beam, which is a lobe of a millimeter, as well as using machine tools with computer software control.

Advantages of plywood processing with a laser:

Advantages of plywood treatment with laser: the edges of the cut are obtained very neat and smooth, no need to make special physical efforts.

- The high-energy ray is pointing to the surface, carrying out contactless processing. Because of the powerful increase in the temperature at the point of contact of the wood and the beam, the material evaporates, as a result of which the seam is 0.01 mm width.

- The edges of the cut is very neat, which is very important for cutting openwork small details and engraving. Through the high-temperature exposure to the edge of the cuts, it turns a little darker.

- In order to cut the faeer, it is not necessary to make physical efforts.

- You can perform absolutely any drawing or engraving - for this it is enough to have a digital image sketch.

- The quality of the laser cutting depends on which wood is made of plywood. As a rule, the desalted material from coniferous wood is best cut.

Article on the topic: Installation of glass in the interroom do it yourself

With the help of laser cutting, you can perform:

- cutting down all sorts of blanks of different sizes from sheet material;

- souvenir and gifts;

- elements of decoration of facades and interiors;

- presentation and promotional materials;

- Different patterns and patterns.

Equipment for plywood treatment with laser

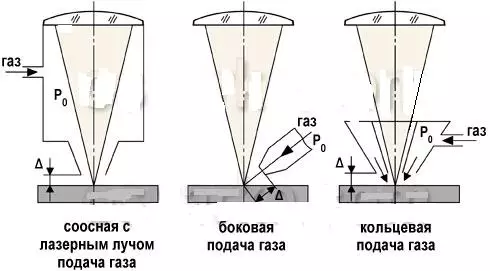

Laser cutting is performed using special machine control machines, in the design of which gas lasers are used.

Schemes for feeding auxiliary gas to the laser cutting area.

The person does not actually participate in processing - it is fully automated. All you need to do is copy the selected pattern to the memory card, install it in the machine control unit and wait until the machine cuts the specified contours. This procedure is performed very quickly and is non-frequensed.

To improve the quality of wood sheets, except machines, chillers and blowing systems can be used. Chillers are used to further cool the flasks with gas. They consist of a water pump and refrigerant (freon), which does not allow to heat the water circulating in the chiller. Pulling and blowing systems will help remove combustion products and subsequent cooling from blanks. This reduces the degree of charging (darkening) of the edge of the cut.

Homemade machines, with which the laser cutting of plywood can be performed, are ineffective. Made in handicrafts, they cannot provide the required laser power, high-quality cooling and power, ideal mechanical fitting of all the machine elements.

Laser cutting plywood provides maximum precision of the initial pattern. Elegant parts from plywood are able to decorate even a very simple interior, giving it a shade of romanticity and sophistication. If necessary, they can be used to hide defects, heating radiators or other engineering communications. Depending on the cutting pattern, such lattices can be almost opaque, which does not interfere with high-quality heating and ventilation of the premises.

Article on the topic: Tips for choosing heat-resistant glue for facing the fireplace