Since the weight of the plasterboard used for the ceiling finishes is almost 30 kg, difficulties may occur with the installation of such a heavy material. In order not to redo the hands and do not contact the help of acquaintances, unprofessional repairmen it is recommended to use a lift for drywall. Such a lift can be bought and rented. However, if on the purchase, the device's doodlement is not highlighted in the budget, make a lift for drywall do it yourself. In this article we will look at what the design of such a mechanism and how to do it at home.

Description of the mechanism

The lift for mounting drywall is a design that represents a reduced semblance of a building crane with a flat top. Unlike an ordinary cargo crane, where the cargo is suspended, the load is placed on top of the drywall. It should be remembered that the weight of one GLC rarely exceeds 40 kg, therefore should not be loaded its lifting lifter, weighing more than 45 kg.

The plasterboard lift consists of several main parts:

- base. The base is, as a rule, a tripod on wheels, which are necessary for convenient movement of the design indoors;

- tripod, the device allows you to change the height of the lift;

- Lifting winch. This element is the driving force of the entire design;

- The site for cargo is part of the lift where the GLC is stacked. The platform is a metal frame of rectangular shape with a crossbar in the middle. If desired, this frame is likely to complicate, adding the change in the width change. Often these frames are made with the option of changing the angle of inclination, so that the laying of the GLC on the lift becomes simple and safe.

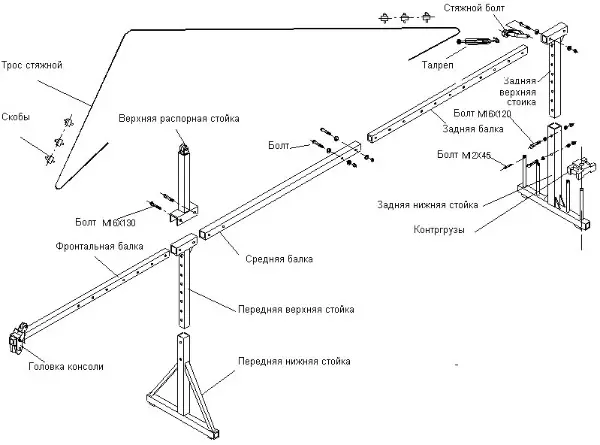

Drawing of the components of the lifting device for GLK

In addition to the above mandatory parts, the lift can be equipped with an electric drive and a special platform for work. In principle, your fantasy to upgrade the device is not limited. The main thing is that such a device will qualitatively performed the lifting of the drywall and its retention.

Article on the topic: Freezer on the balcony in winter - can I put

Design device

When the Glkl lift device, you can go in two ways - make a device for a specific room or make a more mobile version, thanks to its compactness and modifier, it will be possible to use indoors with different ceiling heights and different types of drywall.

Definitely, experts recommend to make a second version of the device, for which it is necessary to make a design with removable items. It is desirable that the tripod disconnected and folded, the tripod was a pull-out, and the cargo frame could be folded into a more compact appearance.

All these parts will not reduce the functionality of the device, and its mobile design will allow the lift to use the lift on different objects.

Making your own hands

In order to make a device that increases the drywall, it is necessary to stock up with metal parts in the form of wheels, pipes, corners and frames. From the tools you will need a welding machine, Bulgarian, hardware and winch.

Starting with the manufacture of tripods. In the base of the tripod should be a tripod, therefore it is necessary to manufacture the base based on the pipe width data used under the main axis. Three "legs" reinforced by Ramami are welded to the base, to the ends of which are attached wheels on hinges. Hinges must rotate 360 degrees.

Next, a telescopic tripod is installed, which is used as a round or square tube, the width of which should not be less than 8 cm. The tripod should be needed durable and strong. It must be remembered because the tripod should be folded, which means to the upper part the diameter of the pipe will decrease, as a result of which the stability of the design that holds the drywall sheet will decrease.

The trotting mechanism is installed on top of the tripod, thanks to which the carriage platform will change the degree of inclination.

After completing the second stage, you can start the installation of the load. The playground is made either as a full-fledged rectangular frame, or in the form of the letter "H". In any case, the design design should be as follows: on both ends of the horizontal beam parallel to each other two other beams are the same length. By the middle of these beams perpendicular to them (but in the same plane), the backups are welded in the form of the letter "T". As a result, you should get a similarity of two cooked crosses that have short overlaps at the top ends.

Article on the topic: Tailoring curtains for the kitchen with your own hands: options with patterns

If you decide to make a platform for GLK in the view of the frame, the welded rectangle details should cross the beam, which makes the design more stable.

Lastly, the lifting mechanism is manufactured. It can be in the form of a wheel with a winch or lever. The convenience of the first mechanism is that the effort is applied less, however, work with such a device takes more time. The design on the lever helps to save time, but requires an employee of a non-lawyer physical effort.

The lever is attached directly to the tripod, and the winch is on the removal beam.

As already mentioned, simple mechanisms in the form of winch and the lever are likely to replace the electric drive, which will make it easier to work with the lift.

Which to choose

The lifts are ceiling "disposable", ceiling mobile and universal."Disposable" devices, of course, really use not once. However, they are distinguished by the fact that the design is made under the specific height of the ceiling, which greatly reduces the possibilities of both the repairman and the lift itself.

Ceiling mobile lifters fit any ceiling height and GLC width. Such a device will serve its host in many objects, and the cost of its production will quickly pay off.

Universal lifts, thanks to the mechanism for changing the degree of inclination, can be used when installing plasterboard sheets not only on the ceiling, but also on the walls. Such a lift is an excellent assistant in the work of a good builder.

In any case, remember: the cost of making the device must justify your goals and construction skills.

Video "Lifting device for plasterboard"

A lifting device for plasterboard sheets can raise more than a person, and eliminates the need to attract assistant to work. How to make such a mechanism yourself, will tell this video.