Garden furniture can become not only an interior decoration, but also a great place to relax. The shop do it yourself - the subject of pride and the back of the future furniture headset.

Make this accessory is not as difficult as it seems. It is important from the very beginning to decide on the material and the appropriate design.

About materials

Plastic details

Such a bench will have a mass gain.

- Affordable price category.

- Light care.

- Mobility.

Pleases a large selection of color design options.

There are plastic furniture and its cons.

- Cheap appearance. Unlike wood.

- Ability to burn out into the sun;

- The surface is quickly deformed.

What about the tree?

Perfect option to make furniture. Gone to any types of processing, has a noble appearance, does not require complex work during installation. Wood variety is allowed to choose any. The main requirement is the absence of defects, high-quality drying.

Stone products

Material of natural origin with an attractive appearance. Let's fit into the interior with any design. The composition will look stylish and unusual, exquisitely. Natural stone has many advantages, but not devoid of flaws. Make this option is also easy.

- It is not always safe to sit on such benches for health, including. There are no such drawbacks.

- It is recommended to purchase pillows and warm spices.

- From place to place such benches do not move, only stationary installation is possible.

How to deal with metal?

Garden benches will be an excellent decoration in any garden, for the manufacture of which the forging, cold or hot method was used.

These are stylish and beautiful designs for which it is better to acquire decorative decorations. Metal will be a good supplement for glass or wood. Make it easy.

Requirements for a bench

- Convenience. The shop must be ergonomic, it is especially important for rest. Comfort and convenience playing a role. A successful option - the presence of a backrest in the product.

- It is important that the bench can withstand even serious loads. Accordingly, the quality of fittings and furniture should be at the height.

- Material must displays any changes to weather conditions without deformations, because it is created for outdoor installation.

Article on the topic: 3 simple ways of making soft headboard bed

Design and its features

1500 millimeters - such a length for the back and seats of the shops are enough so that three people are comfortable. Other dimensions also matter. Seat width reaches 400 mm, the back of the back - 18-20 degrees. The height of the back - 900 millimeters, seats - 450.

From the materials we need to take:

- Varnish, primer;

- Paper with emery effects for wood;

- Screwdriver;

- Electrolake for wood. They will handle chamfer, grind the surface of the boards.

- Coloring boards will be using an electric jig.

- Required number of self-tapping screws.

- The structure of the bench will make it with their own self-draws with sizes 40 by 40 mm.

- For the front legs bench make the blanks. Thickness - 35-40 millimeters, size - 360 per 150.

- Holders for the back and leg benches also require individual billets. Thickness is the same 35-40 millimeters, but size is 900 to 150.

- Do not make it yourself a product without wooden boards. The thickness is the same, and the dimensions are 1500 by 150 mm.

We make a wooden design

- You can immediately purchase boards for the bench, which have the desired size. If there is no suitable option - we use the jigsaw to cut the boards with your own hands. Fantasy saw will also become an indispensable assistant. You can do it quickly.

- Wood must be carefully processed after it was possible to achieve the desired length. Grinding require billets for the seat, backs. Electrolake should handle the ends of the boards. The best option is rounded forms.

- The correct angle of inclination will ask your hands with the long back legs of the bench. They still play the role of the frame of the whole design. We apply markup into two wooden blanks with a length of 900 millimeters. It's not so difficult to do everything.

- 400 millimeters - the height of the bench, they celebrate it with their own hands first. Additional processing in this area of material is not needed. We make a cut at 20 degrees along the entire length of the product, ranging from the segment. This is formed an angle of inclination for the back. The angle of inclination and the height of two legs from the back should be the same.

- The legs benches are going first. 280 mm - the distance between the elements in the front and rear. The entire width of the bench is a rebar, which connects the legs. Its size is 500 mm. Well, if the binding is on top and bottom.

- The sidewalls of the shops are connected with their own hands after the assembly completed. For connection, we use the boards on which it will be necessary to sit. To the top bars, the strapping are screwed them with self-tapping screws. Gaps between wooden blanks should have different sizes. They help to remove moisture, organize circulation.

- Go to the enhancement of the shop with your own hands. Without this action, the product will not be durable and stable. We use brushes in order to make the bottom strapping on the legs. Tighten two blanks with a length of 1500 mm to the front and rear elements. The cross can be alone if the sawn timber is not enough.

- We mount the back in the bench do it yourself. This is one of the last steps. It is recommended to stick to the range of 380 millimeters from the seat for the second board, 200 millimeters from the seat for the first.

- It remains only the finish coating of the shop. Varnish and deep impregnation will always help maximize the external influences. On insect pests, mold and moisture can be forgotten.

Article on the topic: Beautiful folding with illuminated for an apartment

How to work with metal?

Prices are decorated not only with furniture made of wood. Metal can also be an indispensable assistant when creating comfortable places. The technique of hot forging for this is optional.

Cold forging for this is also quite suitable. In a single design, simply weld the frame from metal blanks. Decor elements are degraded by appearance.

detailed instructions

- We start with the development of dimensions and size of the bench. Standard backrest height - 800-900 mm. Width - 400-500 mm. Length 1500 mm. The simplest work is with angular shapes. It is recommended to start working with simpler models.

- Make a skeleton for the seat. Decitation metal pipe. Sizes We need such: 2 fragments of 400 mm and 2 to 1500 mm. Welcome details so that they get a rectangular shape. It is permissible to welcome 2 additional ribs of stiffness to make the design more durable.

- Next, we need legs. Metal pipe Crow on 4 parts, 460 mm. Billets are then connected to the corners of the shop. Additional ribs of stiffness between the front and rear legs will not be superfluous.

- We make a back. It welds one billet with a length of 1500 mm to another, by 440 mm. The design then weld to a part of the bench, which is ready. 15-20 degrees - the optimal angle of inclination for the back. Then the rest will be comfortable.

- Ribrami rigid can also be strengthened.

- At the final stage, all seams are cleaned. The frame is covered with primer.

Bar and board: the simplest forms

Options for execution and designs There are a large number. There are the simplest, some prefer wood threads. They become real works of art.

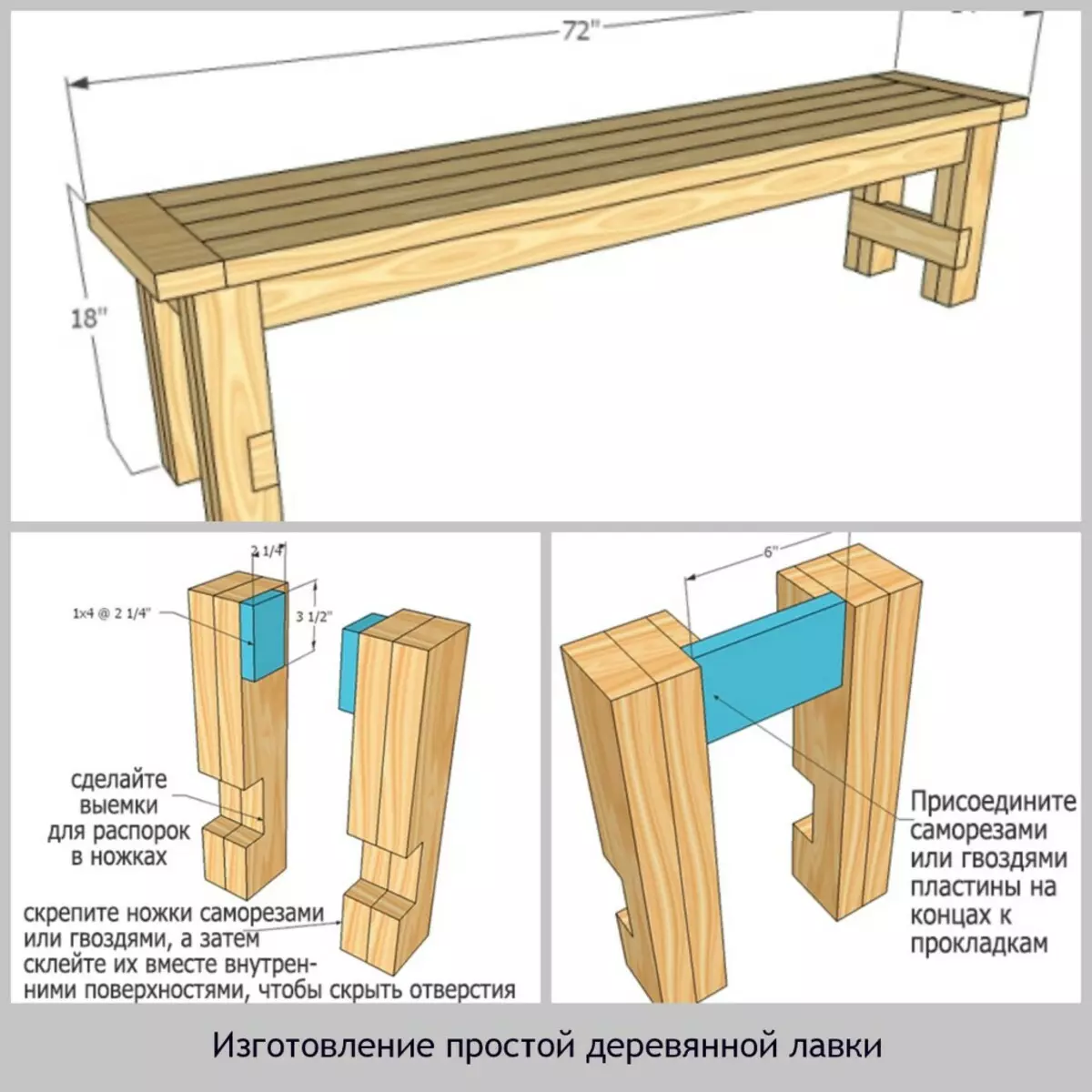

Wooden shop without back - the simplest solution. It is allowed to use a board with a thickness of up to 75 mm. For two parts consists of each element.

Of the two boards we collect the seat, the ends are bevelled. It is better to provide a gap between the elements if it is planned to place the design on an open area where there is no heating. The gaps compensate for the swelling of the tree, allow you to get rid of moisture in large quantities.

Article on the topic: how easy it is to make a tumbon for the balcony yourself

Of the two glued elements, every leg consists. The pin or the wanks will make the connection more reliable. Two short beams should be fixed on each of the legs. This will consolidate the seat itself. Saws and glue, grooves - indispensable assistants to consolidate. Beams and legs are attached to each board in the last stages of work.

Several additional tips

Radius cuts and curly elements are a little complicated, but if desired, this task can be solved without problems. For example, choose a rectangle shape.

Drawings are not dogma, they can be changed at their discretion.

The beam is downstairs, if the bench is not very long. The beam itself becomes an edge of rigidity in such a situation. The wanking involves the use of both closed and open installation, the last option is very unusual. Forms of material can be any. Even the use of options with which wooden houses are built.

Video Gallery

Photo Gallery