During the execution of repair work, a circular saw may be needed, which will help to produce high-quality sawing the necessary surface. This tool is required infrequently, and it is not suiced. In order to save your own savings, you can collect a drink yourself. Circular saw with their own hands made, it will be easy to solve all questions arising from construction / repair.

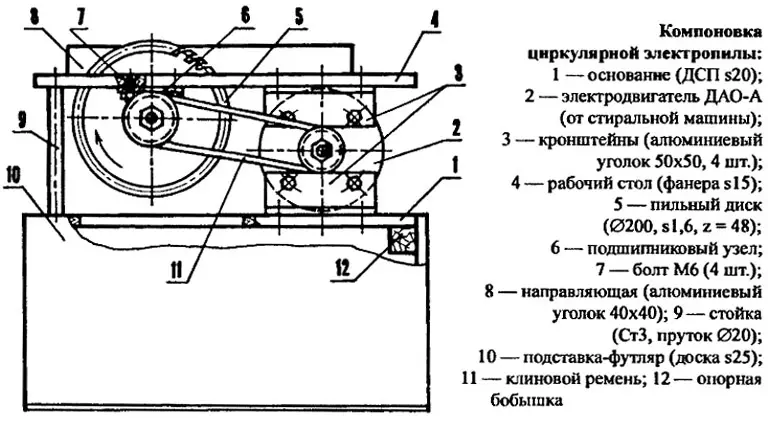

Design of homemade circular saw.

We collect a drink with your own hands

Circular saws is designed for sawing logs or various wood products. From the power of its electric drive will depend on the thickness of the material being cut, i.e. What it is higher, the more thick product can be shed. Increase sawing, you can not only with a powerful engine, but also by installing the camshaft.

Any circular saw consists of 2 parts - upper and lower. At the top there is a desktop, saw blade and shaft with pulley. At the bottom of the device, the entire electrical equipment is installed. This equipment includes:

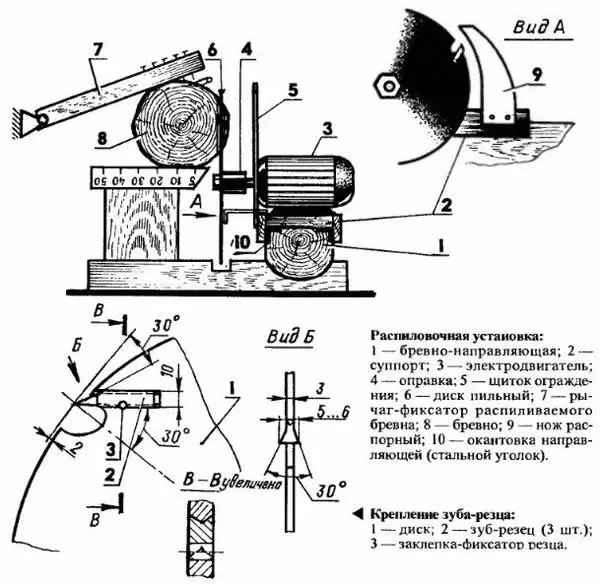

Drawing homemade disk sawmill.

- electric motor;

- transformer;

- Current starter.

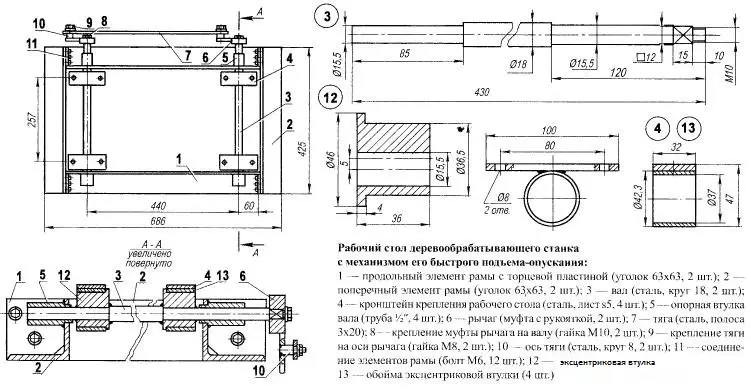

The frame of the cutting mechanism is better made from metal corners of 25x25 mm or 30x30 mm. The size of the desktop should be 650x450 mm, in the corners of which you need to weld the pipe with a diameter of 18-20 mm.

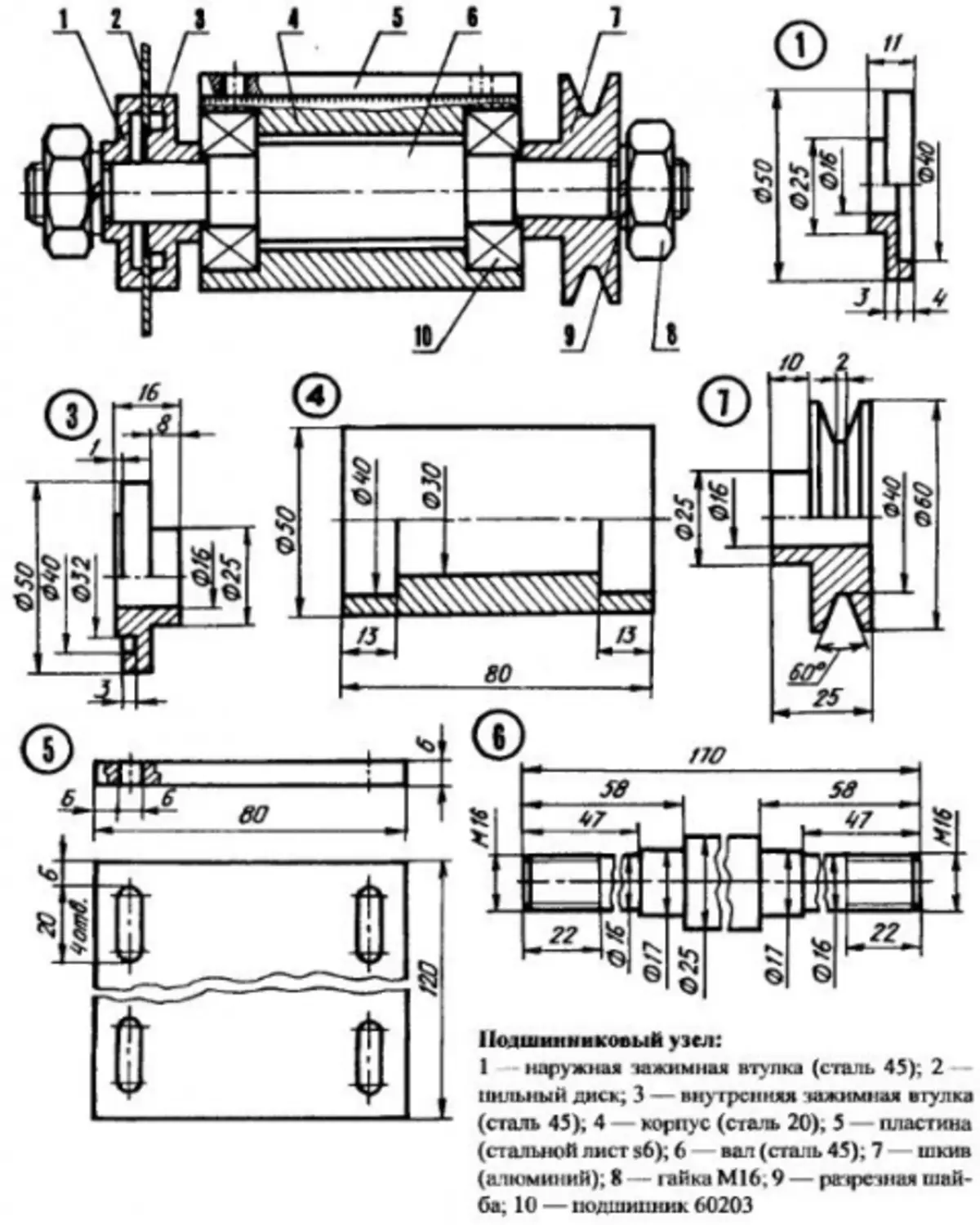

On the prepared frame of the mechanism, 2 small corners should be fixed, the length of which should be 20-30 mm, and the distance between them will be determined by the sizes of the shaft. These corners will help to fix the bearings, for the attachment of which you need to use clamps.

To increase the smoothness of the soda of the saw and improve the quality of work, it is necessary to use closed bearings. It will not allow you to score the bearing clip with chips and sawmills.

Lower saw

The lower part of the saw mechanism must be made massive, it will increase its stability and reduce the vibrations that occur during operation. For these purposes, it is best to suit the corner, the cross section of which is 40x40 mm or 50x50 mm. To mount the electric motor, you must install 2 transverse corners.

Article on the topic: Replacing doors in the bathroom and toilet do it yourself

Table circuit for circular saw with lifting-lowering mechanism.

The engine itself is better to use three-phase asynchronous, the power of which will be 1.5-2 kW, and the maximum number of revolutions - 2000 rpm. The engine should be put on the motor pulley, the stream of which is 80-100 mm, it will allow you to use a wide and reliable belt.

On the vertical rack of the bed should be a short steel plate. It will be attached to the launcher. Its wires need to be laid carefully so that they do not engage for the electric motor shaft.

Then the lower and top of the saws must be combined with each other, it can be done using the cuts of the pipe of the corresponding diameter. They need to drill holes in 2 sides in advance. Bolts are inserted into these holes that will allow you to pull the entire mechanism of the circular saw.

After both parts are connected, you need to pull the belt. Its stretch should not be very strong, otherwise it will lead to its rapid rupture. The starting mechanism needs to be provided with condensers that will help smooth down increased starting currents. To increase the torque and output currents, you can use a 500-600 W transformer.

Other types of circular saws

Circular saw bearing assembly circuit.

You can make a circular saw of pendulum type. This type of saws is intended for the sawing of thick wood. In the pendulum devices, electric motors with increased power are used, the torque of which enters the saw shaft through the belt gear system.

The bed of the circular pendulum saw should be very powerful and is made of thick steel challers. It is determined by the fact that it will have all the cutting and rotating load of the mechanism. Moreover, such a model can be equipped with a saw disk lifting device.

But it does not always require large and serious sawmills. In this case, a good solution will be the use of a mini-circular saw. The mini circular saw allows you to work at the place, while it is possible to perform cut at different angles.

Article on the topic: Curtains on a window with a balcony door: Rules for selecting the optimal design

The presence of such a saw mechanism will save the used area in the premises of the workshop. In this case, it is easily possible to move it throughout the free space of the room. The presence of such a device will help simplify all repair and construction work. And the quality of the separated cutting will be quite high.

Mini-device assembly

Circular saw application scheme.

Before you start doing a mini-saw, you need to perform sex preparation in the workshop. The floor in the room should be even so that the saw during operation did not swing, because It does not have heavy races. The swinging of the mechanism will not only interfere with the workflow, but can also lead to the emergence of various kinds of injuries.

As a bed of a mini-device, you can use any old table and metal goats. These elements must be combined with each other with a thick board (40-50 mm).

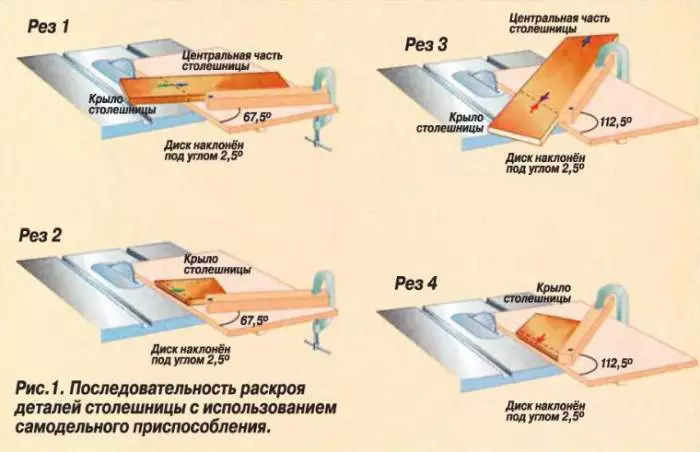

Also, the tabletop can be made of 2 steel plates, the thickness of which is 4-5 mm. Well for this is suitable and thick bars, which need to be connected to a plywood jumper with a thickness of 25 mm. Between the sheets / bars should leave the gap of 10-15 mm, it will be needed for the passage of the saw disk.

Performing these works should be obtained to obtain a flat surface and parallelism between the inner edges of the plates. The fastening of the mechanism should be done in such a way that the circular saw is in the middle of the prepared gap.

To mount the sawing item to the table, you must drill on its surface of the hole. With the help of bolts, it is necessary to produce its reliable fastening.

Engine installation and completion of work

To mount the manual saw motor, you should provide a device transmitting torque. In some cases, disk saws can be installed directly to the motor shaft, but this will reduce the power of the entire device.

As such a mechanism transmitting rotation, a spindle from the bicycle carriage mechanism can be used. It must be cut with a metal hacksaw. An asterisk will also need further work.

Article on the topic: 3 Apartments in Bohemian Style: Phototour and Interior Review (20 photos)

The spindle is required to equip the transition sleeve, which will allow the cutting disk to firmly on it. The sleeve must be attached in several places, it is possible to do this with welding. A metallic plate, having a thickness of 5-6 mm, is attached to the resulting spindle node. It is required to install an asterisk on the disk shaft, the size of which will be 2 times less than the spindle on the spindle. Then these stars are connected by chain. To do this, you can use the usual bicycle chain. Now the mini-circular saw can be finished and started to use it.

The disk saw made in this way with their own hands will be very convenient and useful.

In order to make a mini-circular saw, you need to show a little imagination and smelting.

All assembly works will not take a long time. The mechanism obtained as a result will accelerate repair work and save money.