The main operation in the woodworking industry is the sawing. And one of the best tools for performing such a task is a disk saw. If you are using an electrolovka, then, like many other homemade masters, you can mistakenly assume that it is more versatile and easy to work. This, of course, is so, but it is still better to create direct propils, a circular saw is suitable. And that work was the most secure, productive and high-quality, you need to know about the features of the design of this tool and the rules of its use.

Circular saw is used to create direct propilis of various materials.

What you need to know about the design of the circular saw

The design of all amateur and semi-professional level models is almost the same. Dear professional aggregates are equipped with additional elements and functions, but if you do not plan to open your sawmill, you will not need such a tool.

Circular saw design.

One of the main structural elements is the reference plate. It is attached directly to the tool. Despite the external simplicity, this element is very important. The reference plate can be made of aluminum alloy and stamping.

Stamping is cheaper. Such a stove is quite durable, but any more or less strong mechanical exposure, even the usual fall, lead to the deformation of the product. And it is impossible to get high-quality cutting from the saw with a deformed support plate. Yes, and it is unlikely to straighten it yourself. Stamping smaller rigidity than their cast analogues. Therefore, if you have a sufficient budget, it is better to buy a slab with cast support. The only disadvantage of such products is that when falling, they can split. However, it all depends on caution and user responsibility.

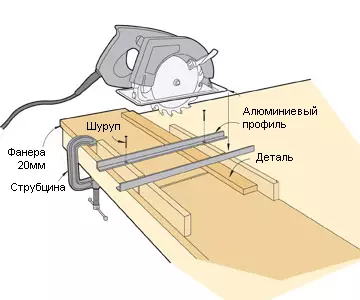

The support plates of virtually all saws are equipped with an attachment for stop. Thanks to this element, it is possible to obtain relatively precise parallel propuls. Almost all modern models are completed with parallel focus. Such an emphasis is fastened in front, but there are also such models that allow you to fix it and behind, and in front.

If you have to cut very delicate materials, it is necessary to wear a special nozzle on the sole of the reference plate. Usually such nozzles are included with the manufacturer in the kit. Professional models have support plates equipped with a special groove that allows you to work with a guide bus. With this element, you can achieve the highest accuracy of work. However, the guides are usually not included, they have to be bought separately.

Article on the topic: Calculation of consumption of materials when installing drywall

Appointment and use of tool items

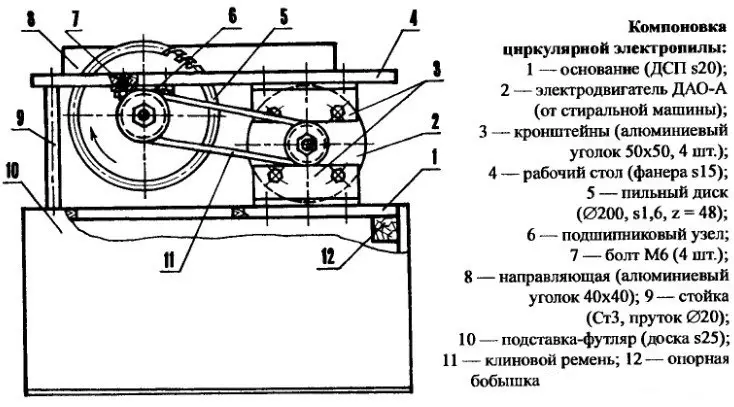

Table for circular saw.

Circular saws are equipped with a variety of different elements and additional functions. For example, quite often there is an additional handle on the tools. It makes sense to talk about her appointment - she makes work with a tool more convenient. The only thing to note is this element is 2 species. The most convenient, according to user reviews, is the handle installed on the saw platform. Most often, the tools are completed with an additional handle in the form of fungus.

The disk saw is necessarily equipped with a protective casing. This element consists of two parts. The lower is movable, the upper is fixed. In the upper part there is a special hole through which sawdust is removed during operation. The hole may have a different form. If you do not connect a vacuum cleaner to your saw, then you can not pay attention to the hole. If the vacuum cleaner is connected, it is better to select a round hole tool, otherwise you will have to additionally search for a special adapter.

Disk saws are necessarily equipped with a split knife. It is intended for the disk not climbing in the process. This element of the bolt pair is attached. To make it more convenient to install and clean it, there is a special hole in the upper casing of saws. But there are models without such a hole. In a similar situation, to gain access to fasteners, the saw should be installed in such a position that corresponds to zero propyl. Disassemble the knife is quite rare. Usually the need for this occurs when the workpiece has to be cut from the middle, and not from the edge.

Circular saw device.

It is important to be able to work with the start button. Disc sawing it is not quite simple. This button is associated with a protective mechanism that eliminates the risk of random switching on the saw. That is, you will not be able to click on this button until you click on the unlock button. Thanks to this solution, the disk saw becomes the most conveniently use. The button may have different size. It is more convenient if it is big.

Another important element of the design is the spindle lock mechanism. It makes the process of installing the disk easier. It is found in most cases exclusively in expensive models of imported production.

Article on the topic: Mastery crafts for the garden and giving do it yourself

It is important to be able to handle with a network cord. First, it seems very simple, but if the saw will be used outdoors in cold weather, it is better that the power cord is in rubber insulation. This option is preferable than plastic, because Rubber is more flexible and its elasticity is not reduced at low temperatures.

Quite often, modern models of disk saws are equipped with different electronics. It facilitates the operation of the instrument and makes it more comfortable. Most often there are features such as a smooth start, overload protection, revolutions adjustment, maintaining a constant level of revolutions.

What you need to know about saw blades?

Circular saw discs are used different for different materials.

One of the most important elements of any disk saw is a saw blade. You need to know that each tool can work with discs of a certain size. It is important to pay attention to such moments as the seating and the disk diameter. Safety equipment prohibits the use of larger or smaller diameter discs than the design of a specific tool requires. This can be done only subject to the use of special adapters.

The canvases are 6 main types:

- Type A. These are saw blades with a large number of teeth variables. Used for sawing plastic products, chipboard and aluminum alloys.

- Type B - Universal discs. You can cut a variety of wood and materials based on it. Provide high quality propyl.

- Type S. Disks of this type have less teeth compared to previous web. Used when working with chipboard and wood soft and solid rocks.

- Type D. Such canvas have a small amount of flat teeth. The cut is quite rude. Apply mainly for quick cutting.

- Type E. Disks have many teeth. Their main purpose is the subtle cutting of soft wood.

- Type R - the canvas have a small number of teeth. Created for coarse saws of soft wood.

Safety when working with disk saw

It is important to take into account that the disk saw, like almost any other power tool, is unsafe. Therefore, when working with it, you need to adhere to certain security measures, which will help to avoid shock, fire, and receiving other damage. When working with such a tool, manufacturers recommend complying with the following rules:

When working with a disk saw and eyes should be protected.

Use the saw only in a set with the shavings removal system.

- Be sure to wear a respirator and safety glasses during operation.

- Clean the workpiece and the tool itself only with a special brush.

- Control the ratio of the height of the proppant knife and saw blades. The first must be more than a second at least 5 mm.

- Before changing the saw blade, be sure to make sure that the tool is turned off.

- Regularly remove the workplace.

- Do not wear too loose clothes. It is impossible to allow it to fall into a moving mechanism.

- Do not use the saw to perform tasks that exceed its capabilities. For example, saw a thick solid log in a cheap amateur saw is categorically not recommended.

- The workplace must be well lit.

- During the work, the operator can not be distracted anything. He must save the point of the support.

- If possible, the product being processed must be fixed in vice. It is much safer and more correct than keeping the workpiece in your hands.

- It is necessary to ensure that the power cord is located as far as possible from the saw blade.

Before getting to work, be sure to make sure that the extension cord and the integrity of the saw cord. The disk saw itself should be dry and clean. Check the health of the protective casing.

There are a number of moments that are not allowed when working with a disk saw. It is forbidden to do the following:

- Work with damaged and deformed pylines.

- Install on the tool discs of inappropriate diameter. To compensate for the internal diameter, you can use an adapter, but the outer diameter must fully comply with the capabilities of the tool used.

- Working with material containing nails, brackets and other metal products. Before starting, they should be removed.

- Install a badly compatible disk.

- Use a saw without protective casing.

- Start work in poor well-being.

- Use the tool with an incorrect disk (to the side or up).

- Use a tool with a faulty pad.

- Stop disk by side pressure.

For repair it is recommended to apply only to certified centers. Subject to these simple rules and recommendations, work with a circular saw will be the most secure and efficient as possible. Good job!

Article on the topic: How to replace the reinforcement of a drain tank